Portable underwater dry-type welding device

A welding device and portable technology, applied in welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of low welding efficiency, unstable arc, small miniature cover, etc., achieve fast welding speed, high welding quality, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

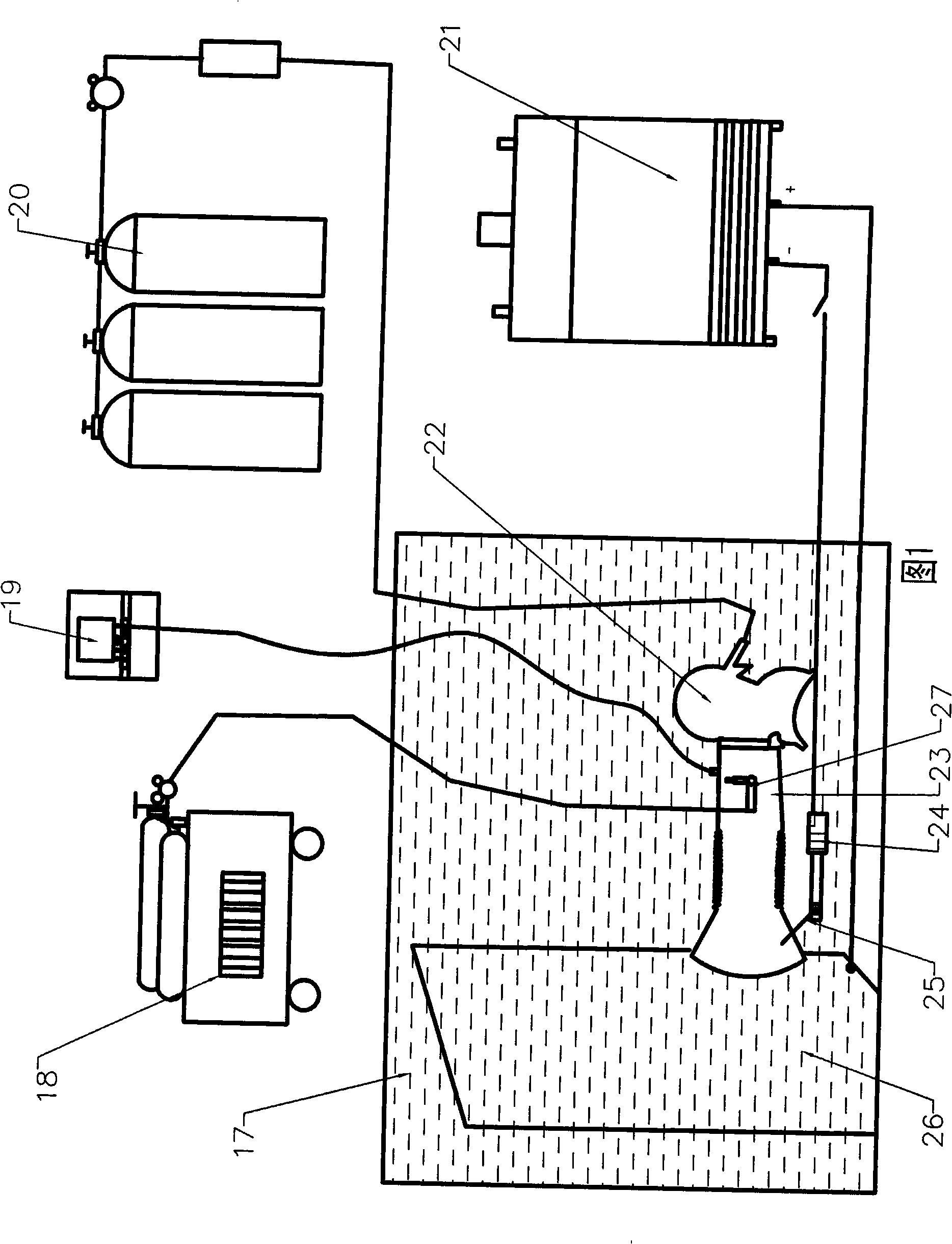

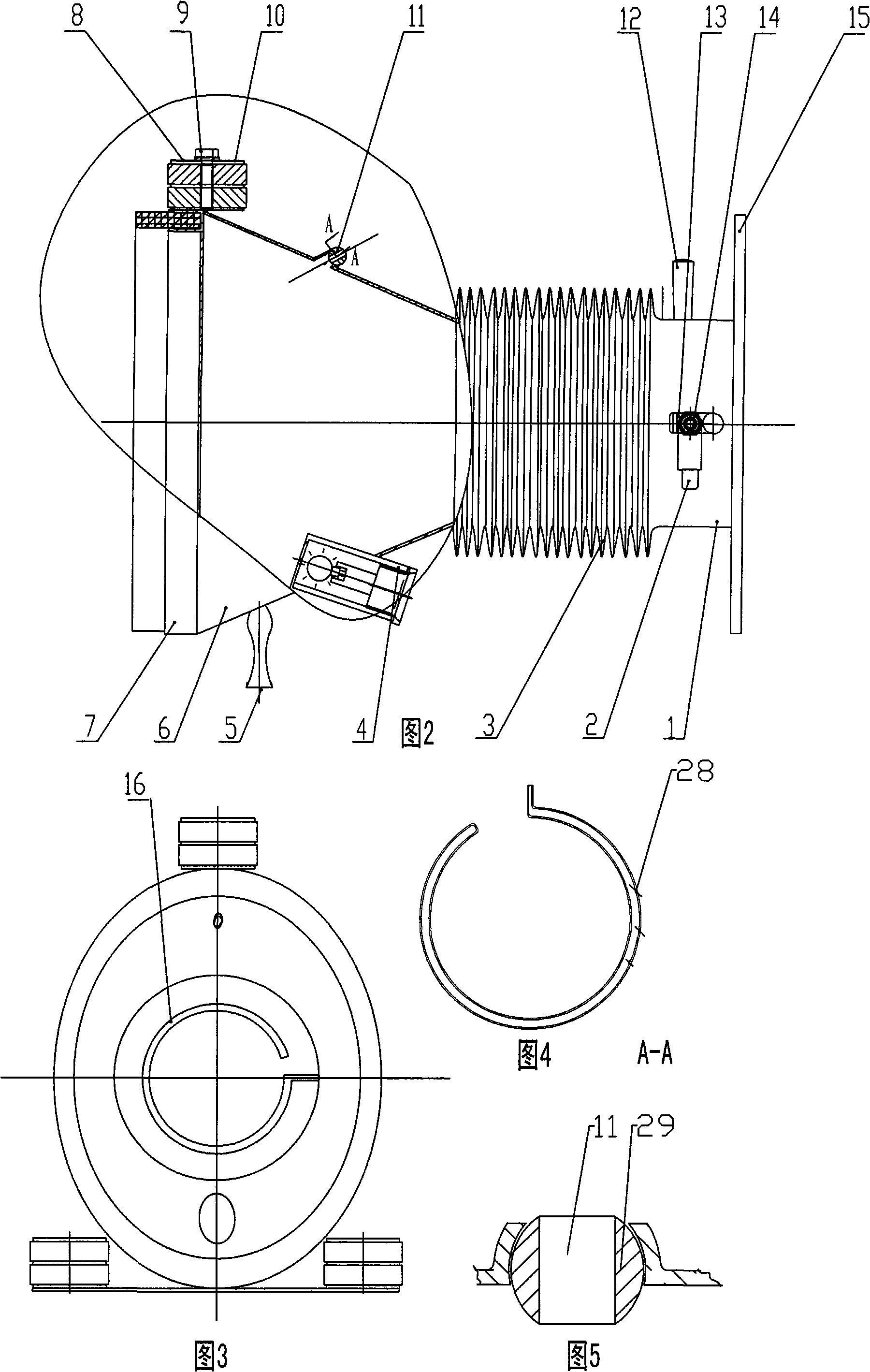

[0024] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0025] As shown in Figures 1-5, the numbers 1-29 represent: connecting pipe 1, intake valve wrench 2, bellows 3, lighting assembly 4, handle 5, welding cover 6, gasket 7, magnetic steel 8 , bolt 9, magnetic steel frame 10, electrode inlet 11, goggles pull rod 12, nut 13, nut 14, adapter plate 15, air intake pipe 16, underwater area 17, air compressor 18, display and video camera 19, Diver's air supply system 20, DC welding machine 21, diver's helmet 22, welding cover 23, welding handle 24, welding rod 25, workpiece 26, camera assembly 27, air inlet 28, hinge ball 29.

[0026] The present embodiment comprises DC welding machine 21, air compressor 18, diver's gas supply system 20, display and video camera 19, underwater welding handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com