Polyamide resin composition and molded body molded with the same

A technology of polyamide resin and composition, which is applied in the field of polyamide resin composition, can solve the problems of poor productivity and high cost, and achieve the effects of excellent brightness and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

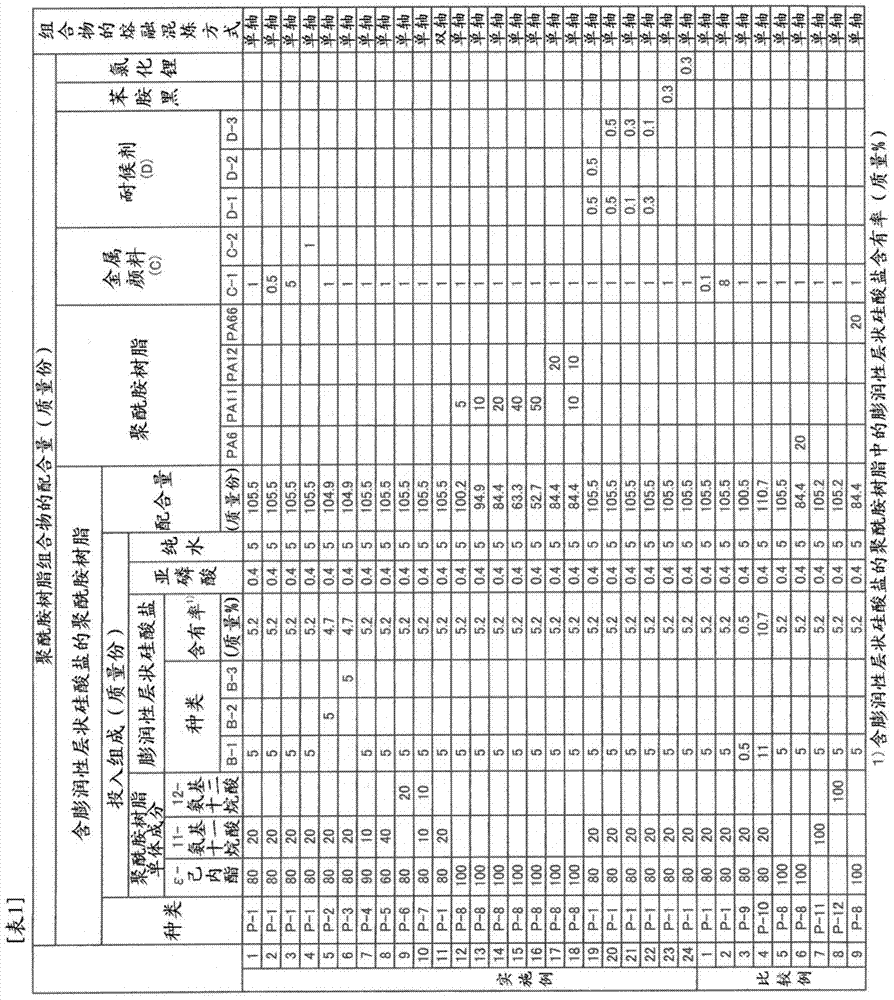

[0169] To 80 parts by mass of ε-caprolactone and 20 parts by mass of 11-aminoundecanoic acid, add 0.4 parts by mass of phosphorous acid, 5 parts by mass of swelling phyllosilicate (B-1), and 5 parts by mass of water , after stirring at 80°C for 1 hour, stirring at 260°C and 0.7MPa for 1 hour, and then stirring at 260°C and normal pressure for 1 hour to polymerize and obtain a swellable phyllosilicate containing 5.2% by mass ( B-1) Polyamide resin (P-1).

[0170] Mix the obtained polyamide resin (P-1) containing swellable phyllosilicate with metallic pigment (C-1) according to the compounding amount shown in Table 1, and put it into the main hopper of the single-screw extruder , melt-kneaded, extruded from a die in the shape of a strand, cooled, and pelletized to obtain polyamide resin composition pellets. Melt-kneading was performed at a resin temperature of 260° C., a screw rotation of 200 rpm, and a discharge rate of 30 kg / h.

[0171] Using the obtained polyamide resin com...

Embodiment 2~24、 comparative example 1~9

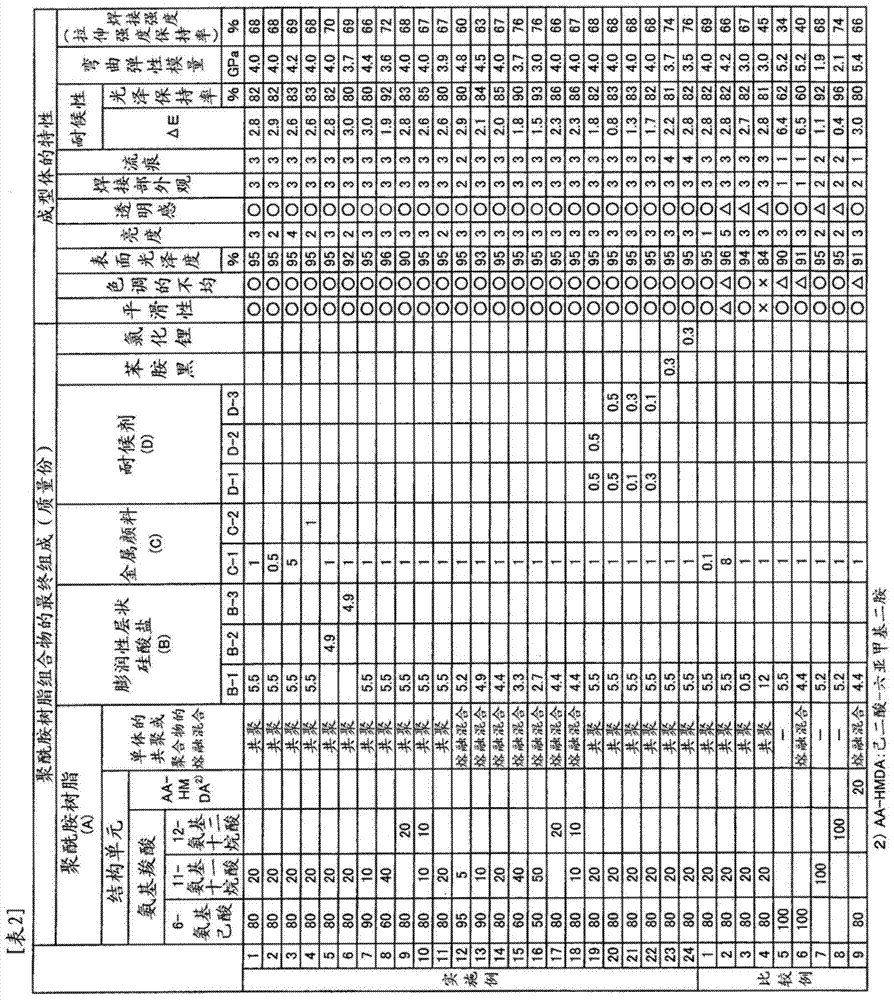

[0177] Except having followed the charged composition described in Table 1, swelling phyllosilicate-containing polyamide resins (P-2) to (P-12) were obtained in the same manner as in Example 1. Next, the polyamide resin composition pellets were obtained in the same manner as in Example 1 except that the respective components were compounded in the compounding amounts described in Table 1, and injection molding was further performed. Various evaluations were performed using the obtained plate-shaped molded body. The results are shown in Table 2. However, in Example 11, polyamide resin composition pellets were produced using a twin-screw extruder instead of a single-screw extruder.

[0178]In Examples 1 to 24, each component constituting the resin composition was within the range prescribed by the present invention, so the obtained molded body was excellent in welding strength and brightness. In the example where the copolymer was used as the polyamide resin (A), the welding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com