Laser welding method for thin stainless steel composite plate

A technology of laser welding and laser welding machine, applied in the direction of laser welding equipment, welding medium, welding equipment, etc., to achieve the effect of advanced technology, high welding quality and high weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

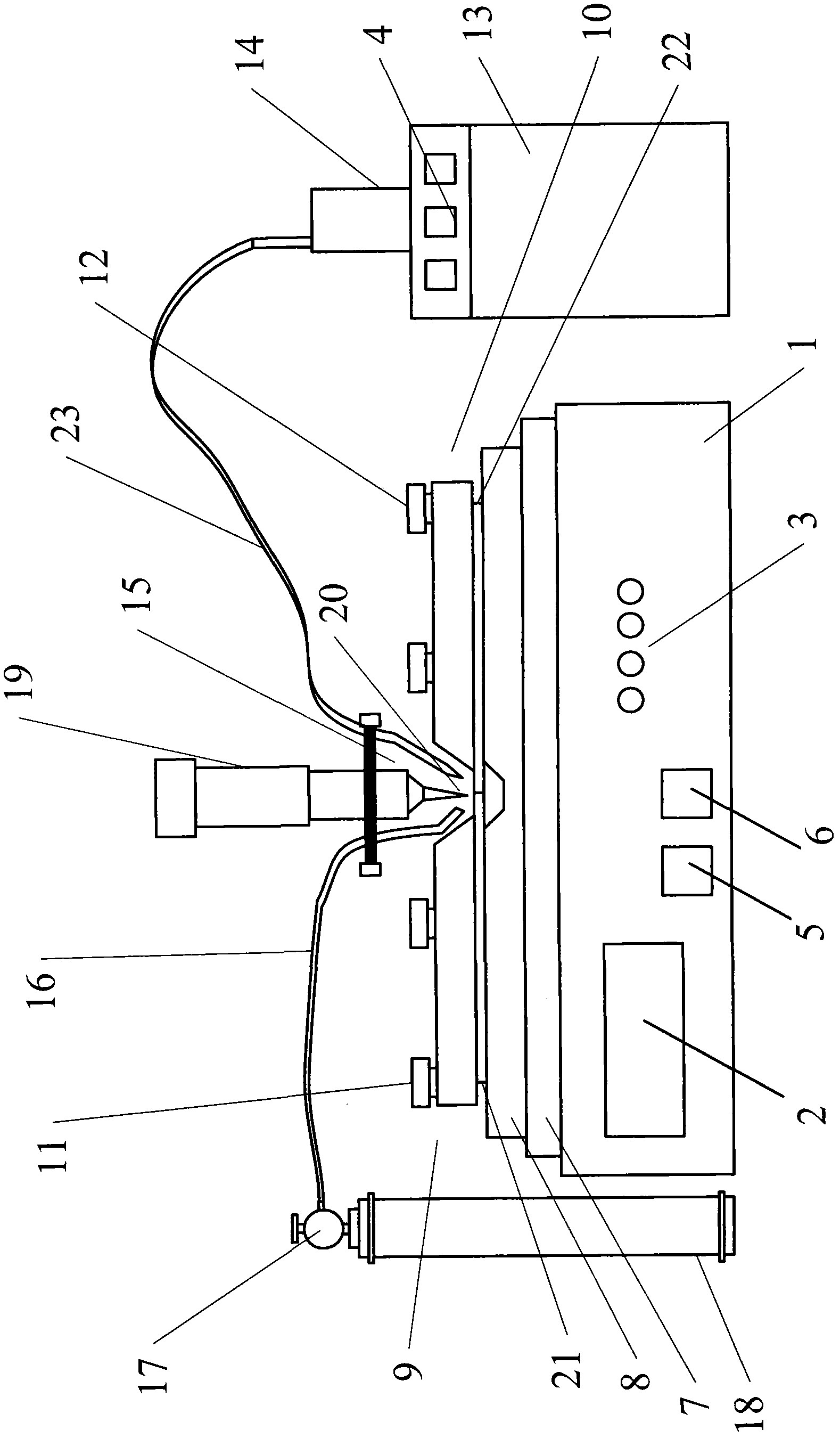

[0080] The present invention will be further described below in conjunction with accompanying drawing:

[0081] figure 1 As shown, it is the laser butt welding state diagram of thin stainless steel composite plate. The position and connection relationship of each part must be correct, and the welding powder should be transported according to the amount, and the argon gas should be supplied in sequence.

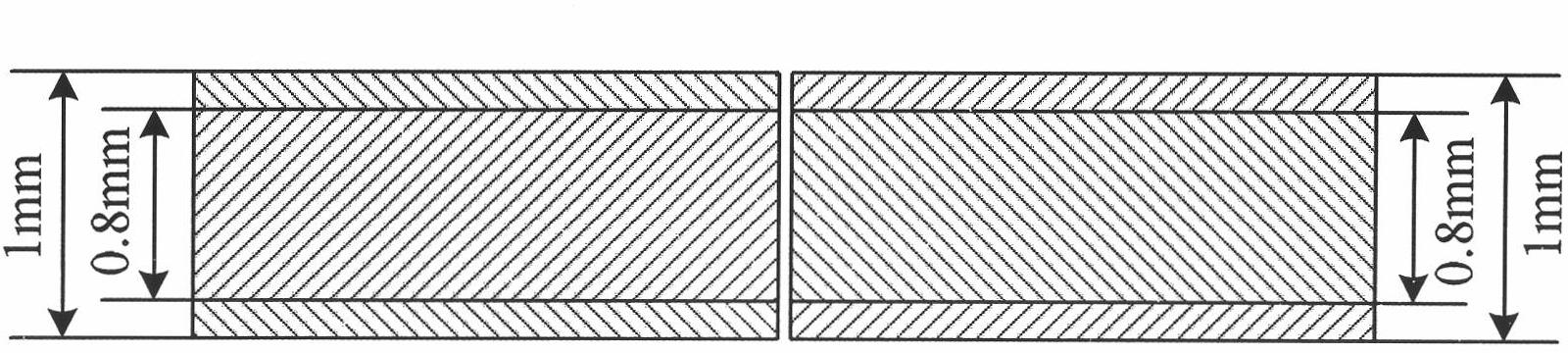

[0082] The amount of chemical substances used in welding is determined according to the preset range, in mm, g, ml, cm 3 is the unit of measurement.

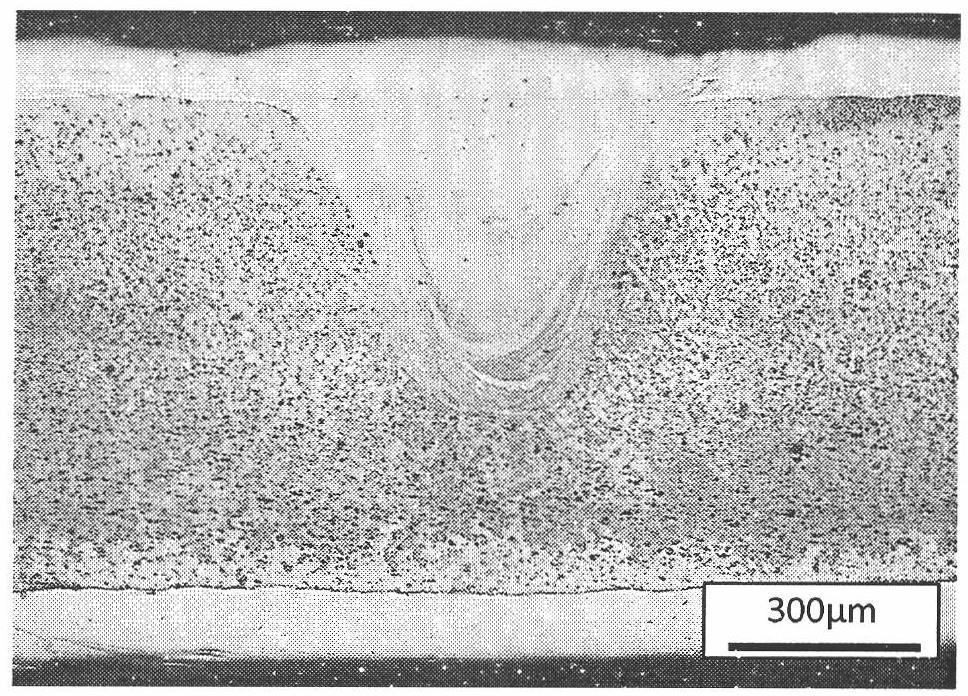

[0083] The butt welding of thin stainless steel composite plates is carried out on a laser welding machine, which is completed under laser beam irradiation, powder feeding by a powder feeder, and argon protection. The laser beam irradiation power, powder feeding rate, and welding speed are all controlled by a computer program. The control is completed; the laser welding machine 1 is horizontal, the upper part of the laser weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com