Seamless explosive core aluminium welding wire and manufacturing method thereof

A flux-cored aluminum welding wire, seamless technology, used in manufacturing tools, welding media, welding equipment, etc., can solve the problems of scattered active substances in the core, easy moisture absorption in gaps, inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

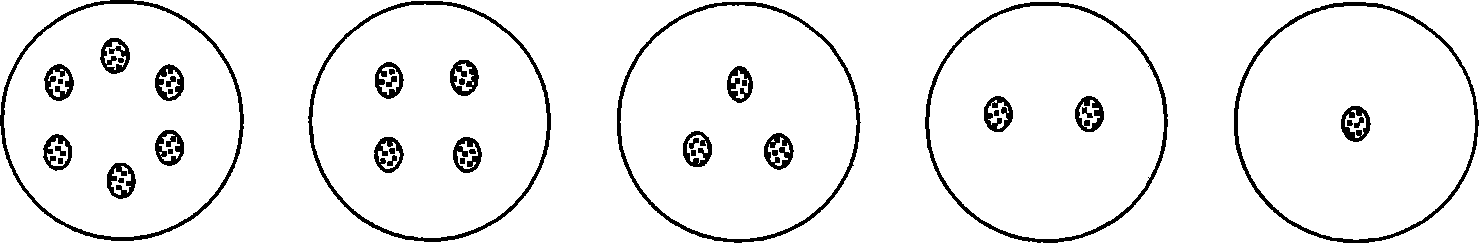

Image

Examples

example 1

[0013] Example 1, the weight percentage of aluminum on the outer skin contains 100%; the various halides in the core contain by weight percentage: aluminum fluoride 25%; potassium fluoride 30%; cesium fluoride 5%; J201 40%.

Embodiment 2

[0014] Example 2, the outer skin aluminum alloy contains 30% by weight of aluminum; 10% of silicon; 60% of zinc; the core contains various halides by weight: 25% of aluminum fluoride; %; J201 15%.

Embodiment 3

[0015] Embodiment 3, the outer skin aluminum alloy contains 68.7% of aluminum, 11% of silicon, 20% of zinc and 0.3% of titanium by weight percentage. The various halides in the core include by weight percentage: 25% of aluminum fluoride; 40% of cesium fluoride; 35% of J201.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com