Copper slag dilution-reduction integrated furnace

A depletion and integrated technology, applied in the field of copper slag depletion-reduction integrated furnace, to achieve the effect of promoting reduction, strengthening dispersion distribution, and reducing copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

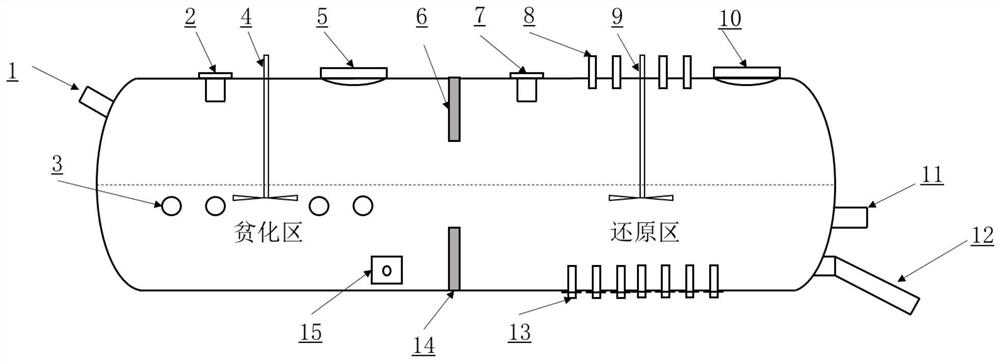

[0035] A copper slag depletion-reduction integrated furnace, the schematic diagram of which is shown in figure 1 ; Including the dilution system and the reduction system, the dilution system and the reduction system are connected in series and separated by a retaining wall, the retaining wall is an upper retaining wall and a lower retaining wall; the upper retaining wall is connected to the top of the copper slag depletion-reduction integrated furnace , the lower retaining wall is connected to the bottom of the copper slag depletion-reduction integrated furnace, and the channel between the upper retaining wall and the lower retaining wall is the depleted slag inlet of the reduction system; the retaining wall separates the copper slag depletion-reduction integrated furnace into The depleted area and the reduced area, the depleted slag generated in the depleted area flows into the reduced area by way of overflow after passing through the retaining wall.

[0036] The depletion sy...

Embodiment 2

[0047] A kind of copper slag depletion-reduction integrated furnace, same as embodiment 1;

[0048] Its operation includes the following steps:

[0049] Using molten copper slag, in which FeS 2 The amount added is 8% of the copper slag mass. The constant temperature depletion time is 35min, and the speed of the mechanical stirrer in the depletion zone is controlled at 110rpm; an excess of 50% of coke and calcium oxide is added to the reduction zone, the stirring speed in the reduction zone is 100rpm, and the reduction time is 45min. molten iron.

Embodiment 3

[0051] A kind of copper slag depletion-reduction integrated furnace, same as embodiment 1;

[0052] Its operation includes the following steps:

[0053] Using the above copper slag, in which FeS 2 The amount added is 8% of the copper slag mass. The constant temperature depletion time is 35min, and the speed of the mechanical stirrer in the depletion zone is controlled at 90rpm; an excess of 40% of coke and calcium oxide is added to the reduction zone, the stirring speed in the reduction zone is 90rpm, and the reduction time is 30min. molten iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com