Molten copper slag dilution-side top composite blowing reduction integrated method

A molten copper and depletion technology, applied in the field of comprehensive utilization of copper slag, can solve the problems of inability to achieve slag-free and clean treatment, low energy utilization rate, and unusable sensible heat, etc., to achieve slag-free resource utilization , high-efficiency and low-energy heating smelting treatment, and the effect of reducing reduction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

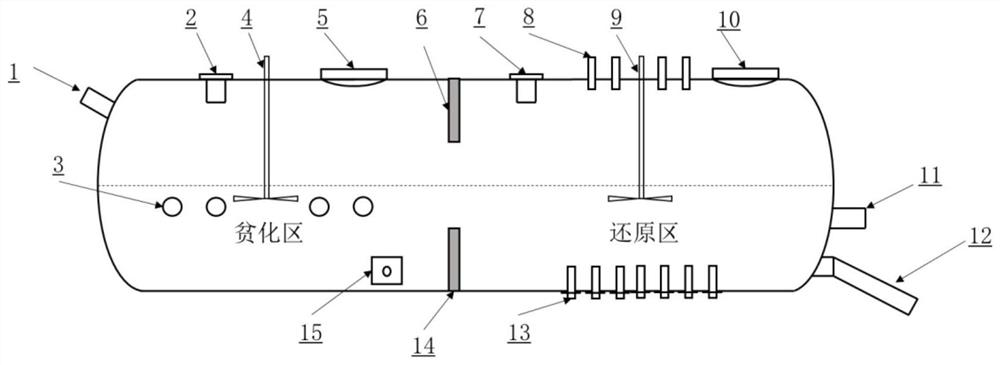

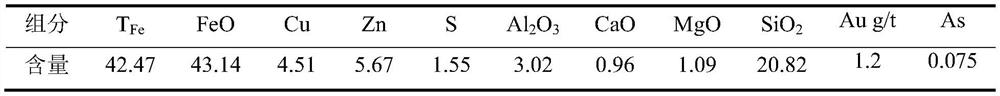

[0041] (1) The molten copper slag is added to the depleted zone by the molten copper slag feeding port 1, and the oxygen-enriched fuel composed of pulverized coal and oxygen with an oxygen content greater than 30% is blown through the fuel spray gun 3 at the side of the depleted zone, and the The molten copper slag is heated to 1300°C to form a molten pool in the depleted area and maintain the temperature of the molten pool in the depleted area;

[0042](2) The depleting agent is added from the depleting agent feed port 2 to the molten pool in the depleted area for eddy current depletion, the mechanical stirring paddle 4 in the depleted area rotates at 100 rpm, and the depletion time is 30 minutes; depletion produces matte and copper content of 0.48% Depleted slag and matte are discharged and recovered from copper matte outlet 15;

[0043] (3) The lean slag overflows to the reduction zone, and the oxygen-enriched fuel is sprayed into the reduction molten pool through the top-b...

Embodiment 2

[0046] (1) The molten copper slag is added to the depleted zone by the molten copper slag feeding port 1, and the oxygen-enriched fuel composed of pulverized coal and oxygen with an oxygen content greater than 50% is blown sideways by the fuel spray gun 3 at the side of the depleted zone, and the The molten copper slag is heated to 1350°C to form a molten pool in the depleted area and maintain the temperature of the molten pool in the depleted area;

[0047] (2) The depleting agent is poured into the molten pool of the depleted area from the depleting agent feed port 2 to perform vortex depletion, the mechanical stirring paddle 4 in the depleted area rotates at 80 rpm, and the depletion time is 30 minutes. Depletion generates matte and copper-containing 0.39% depleted slag, and matte is discharged and recovered by copper matte outlet 15;

[0048] (3) The depleted slag overflows to the reduction zone, and the oxygen-enriched fuel is sprayed into the reduction molten pool throug...

Embodiment 3

[0051] (1) The molten copper slag is added to the depleted zone by the molten copper slag feeding port 1, and the oxygen-enriched fuel composed of coal gas and oxygen with 60% oxygen content is blown sideways by the fuel spray gun 3 at the side of the depleted zone, and the molten copper The slag is heated to 1250°C to form a molten pool in the depleted zone and maintain the temperature of the molten pool in the depleted zone;

[0052] (2) The depleting agent is poured into the molten pool in the depleted area from the depleting agent feeding port 2 to perform vortex depletion, the mechanical stirring blade 4 in the depleted area rotates at 20 rpm, and the depletion time is 40 minutes. Depletion generates matte and copper-containing 0.42% depleted slag, and matte is discharged and recovered by copper matte outlet 15;

[0053] (3) The depleted slag overflows to the reduction zone, and the oxygen-enriched fuel is sprayed into the reduction molten pool through the top blowing lan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com