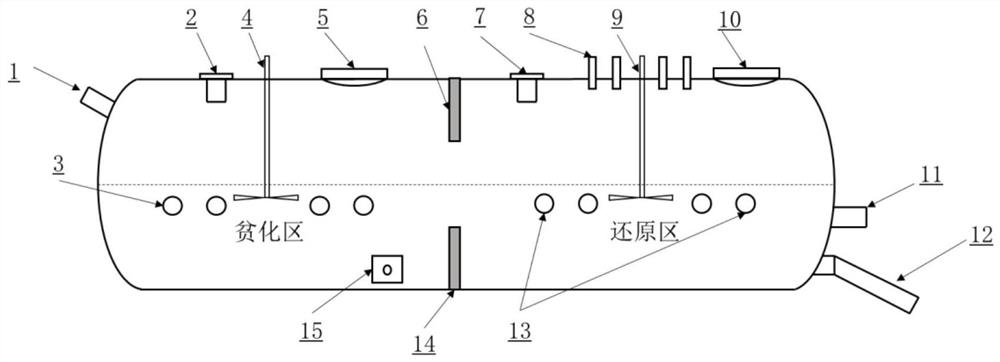

Copper slag dilution-side top combined blowing reduction integrated furnace

A lean and side-top technology, applied to furnaces, furnace components, waste heat treatment, etc., can solve the problems of long treatment process and low heat utilization rate, reduce reduction energy consumption, reduce equipment investment, and strengthen high-efficiency dispersion distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Using the above copper slag, in which FeS 2 The amount added is 8% of the copper slag mass. The constant temperature depletion time is 35min, wherein the rotational speed of the mechanical stirring paddle 4 in the depletion zone is controlled at 110rpm; an excessive 50% of coke and calcium oxide are added in the reduction zone, the stirring speed in the reduction zone is 100rpm, the reduction time is 45min, and the copper content obtained by the reduction is 0.86% of molten iron.

Embodiment 2

[0048] Using the above copper slag, in which FeS 2 The amount added is 8% of the copper slag mass. The constant temperature depletion time is 35min, and the speed of the mechanical stirrer in the depletion zone is controlled at 90rpm; an excess of 40% of coke and calcium oxide is added to the reduction zone, the stirring speed in the reduction zone is 90rpm, and the reduction time is 30min. molten iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com