A kind of pull-tab outer cover material for infusion bottle or bag and preparation method thereof

An infusion bottle and pull-ring type technology is applied in the field of modified polypropylene pull-ring type outer cover material for infusion bottles or bags and its preparation field, which can solve the problem of poor welding performance between bottle caps and polypropylene bottle bodies, and the size of the outer cover. Poor stability, the outer cover is not resistant to radiation, etc., to achieve good toughening effect, improve processing fluidity, and easy to open.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

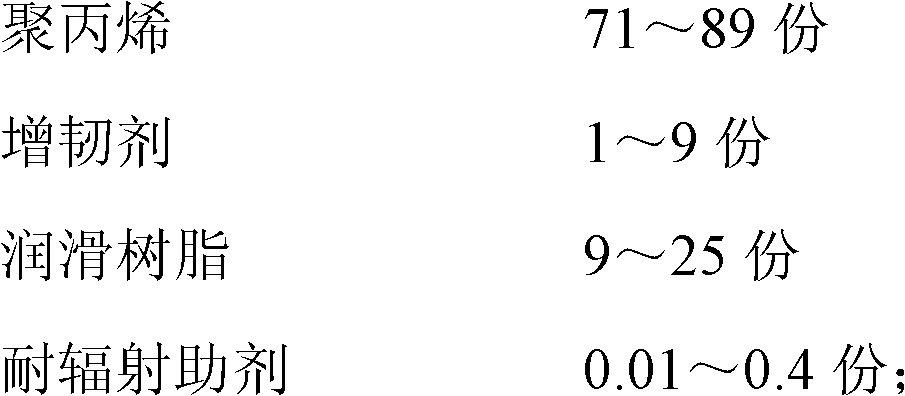

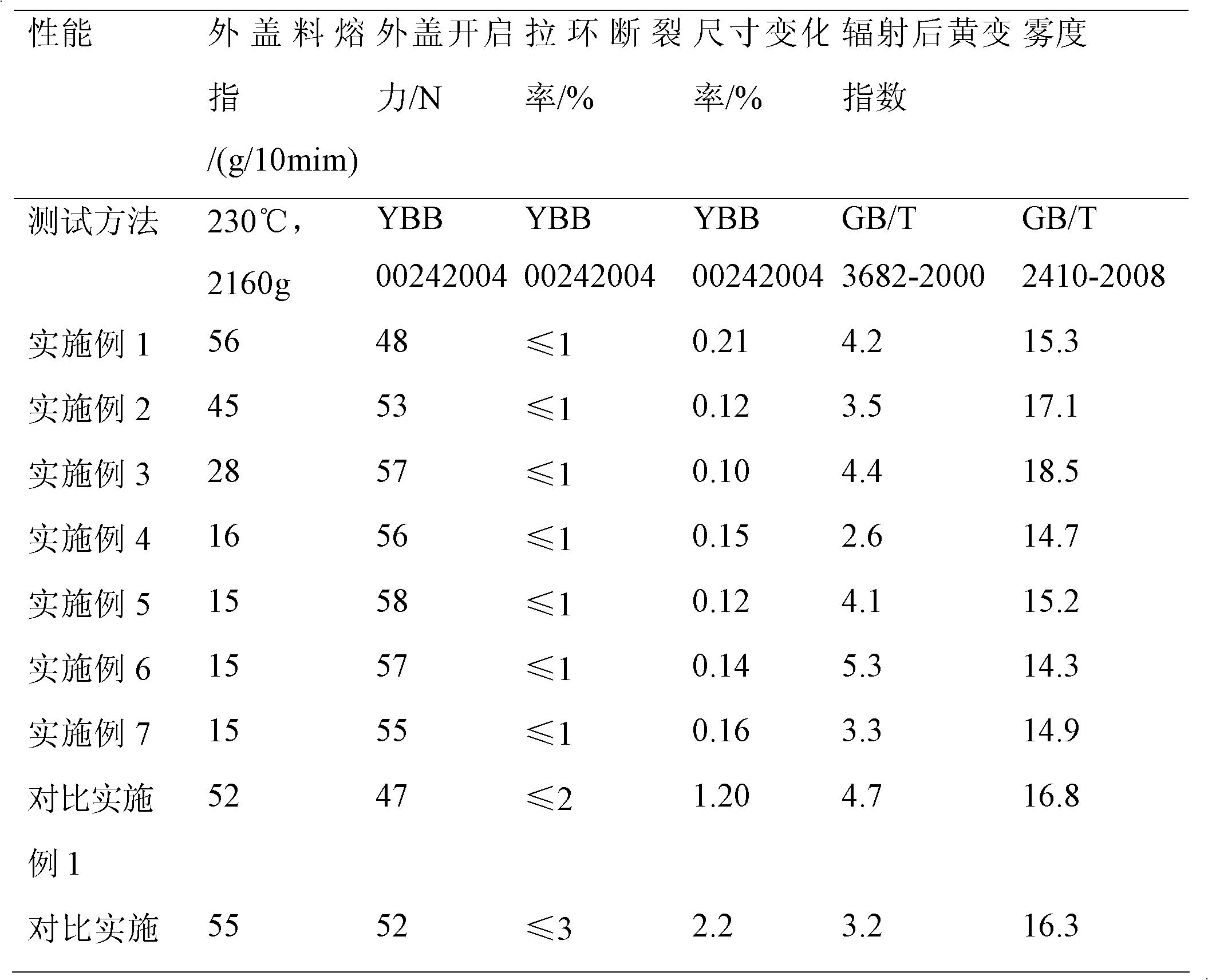

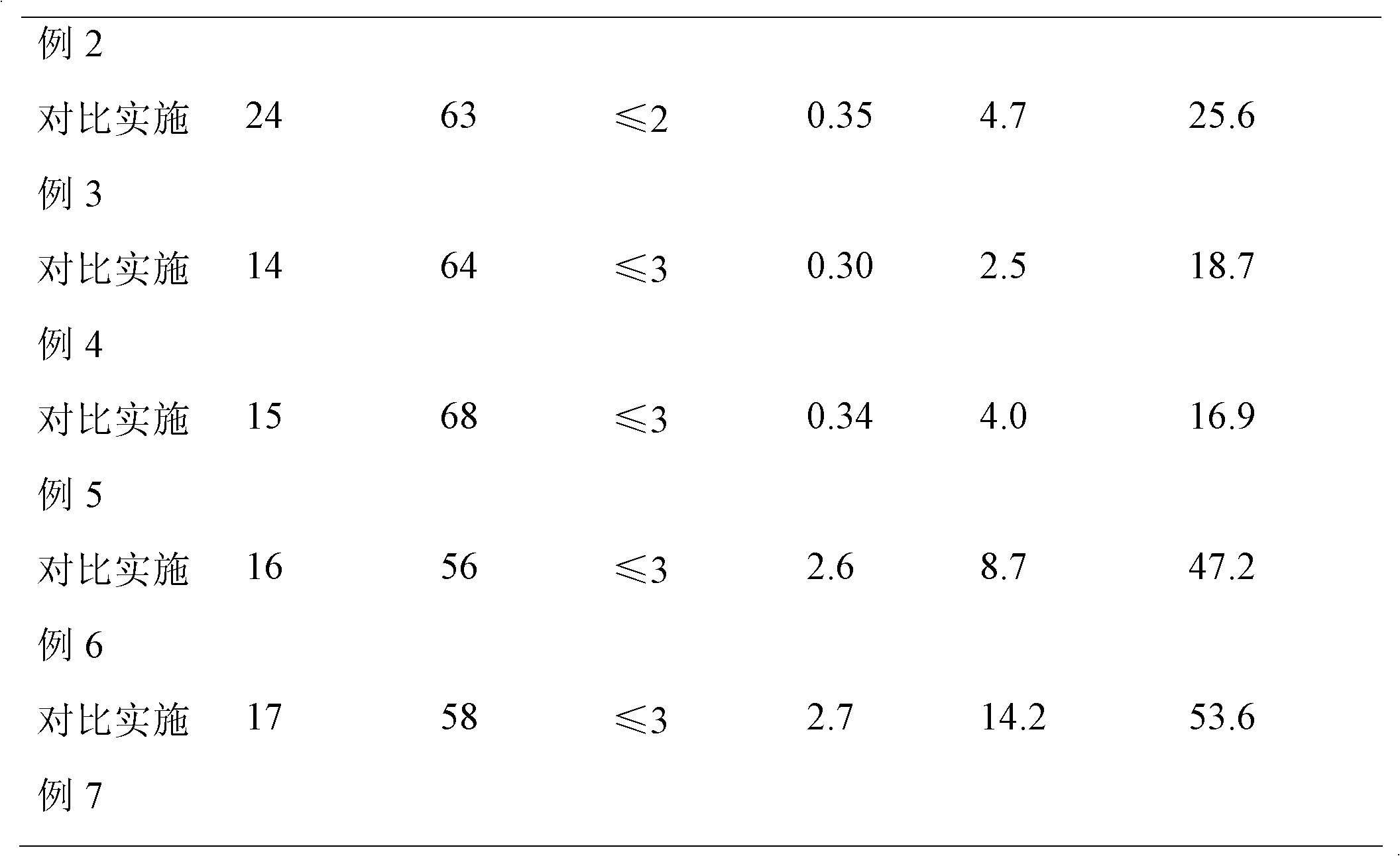

[0044] 71 parts by mass of polypropylene (ethylene content is 9% by mass, MI is 5g / 10min at 230°C and 2160g) and radiation resistance additives (7-methoxyrosmanol and tetrakis[methyl -β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is formed by mixing 0.05 parts by mass in a mass ratio of 70:30, and mix well, then add styrene-butadiene- Styrene copolymer (density 0.88g / cm 3 , MI is 6g / 10min at 230°C and 2160g) 9 parts by mass and lubricating resin (by 7 parts by mass of silicone masterbatch (10% by mass percentage of silicone powder and 90% by mass of poly Propylene blending) mixed with 12.95 parts by mass of polytetrafluoroethylene (particle size 400nm)) 19.95 parts by mass, mixed uniformly, then added to the extruder at a speed of 60 rpm at 150 ° C, and extruded at a speed of 300 rpm , water-cooled, granulated, and dried to obtain a pull-tab outer cover material for infusion bottles or bags. The melt index of the pull-tab outer cover material for th...

Embodiment 2

[0046] 75 parts by mass of polypropylene (the ethylene content is 4% by mass, MI is 30g / 10min at 230°C and 2160g) and radiation-resistant additives (7-methoxyrosmanol and β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate is formed by mixing 90:10 by mass ratio) 0.2 parts by mass are uniformly mixed, and then successively add 50% benzene by mass percentage Ethylene-butadiene-styrene copolymer (density 0.86g / cm 3 , MI at 230°C and 2160g is 5g / 10min) and ethylene butene copolymer (density 0.89g / cm 3 , MI is 18g / 10min under the condition of 230 ℃ and 2160g) total 8 mass parts, and lubricating resin (made of 6 mass parts silicone masterbatch (silicone powder with mass percentage content 10% and mass percentage content 90% Polypropylene blending) mixed with 10.8 parts by mass of polytetrafluoroethylene (particle size 500nm)) 16.8 parts by mass, after mixing uniformly, then added to the extruder at a speed of 60 rpm at 180 ° C, and at a speed of 400 rpm Extruded, water...

Embodiment 3

[0048] 80 parts by mass of polypropylene (ethylene content is 8% by mass, MI is 8g / 10min at 230°C and 2160g) and radiation resistance additives (7-methoxyrosmanol and 3,9- Bis[1,1-dimethyl-2-[(3-tert-butyl-4-hydroxy-5-methylphenyl)propionyloxy]ethyl]-2,4,8,10-tetraoxo Heterospiro[5.5]undecane is formed by mixing 0.3 parts by mass at a mass ratio of 80:20) and mixes uniformly, and then successively add styrene-butadiene-styrene copolymers (density of 0.89 g / cm 3 , at 230°C and 2160g, MI is 8g / 10min) and styrene-ethylene-butylene-styrene copolymer (density 0.87g / cm 3 , MI is 20g / 10min under 230 ℃ and 2160g condition) totally 6 mass parts, and lubricating resin (made of 4 mass parts silicone masterbatch (silicone powder with mass percentage content 10% and mass percentage content 90% Polypropylene blending) mixed with 9.7 parts by mass of polytetrafluoroethylene (particle size 600nm)) 13.7 parts by mass, after mixing uniformly, then added to the extruder at a speed of 80 rpm at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com