A method for processing zirconium alloys recovered by smelting and recycling electron beam cooling hearth furnace

An electron beam cooling bed furnace and processing method technology, applied in the field of titanium alloys, can solve the problems of difficult control of zirconium smelting process parameters, and achieve the effects of short recovery and remelting process, good surface quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

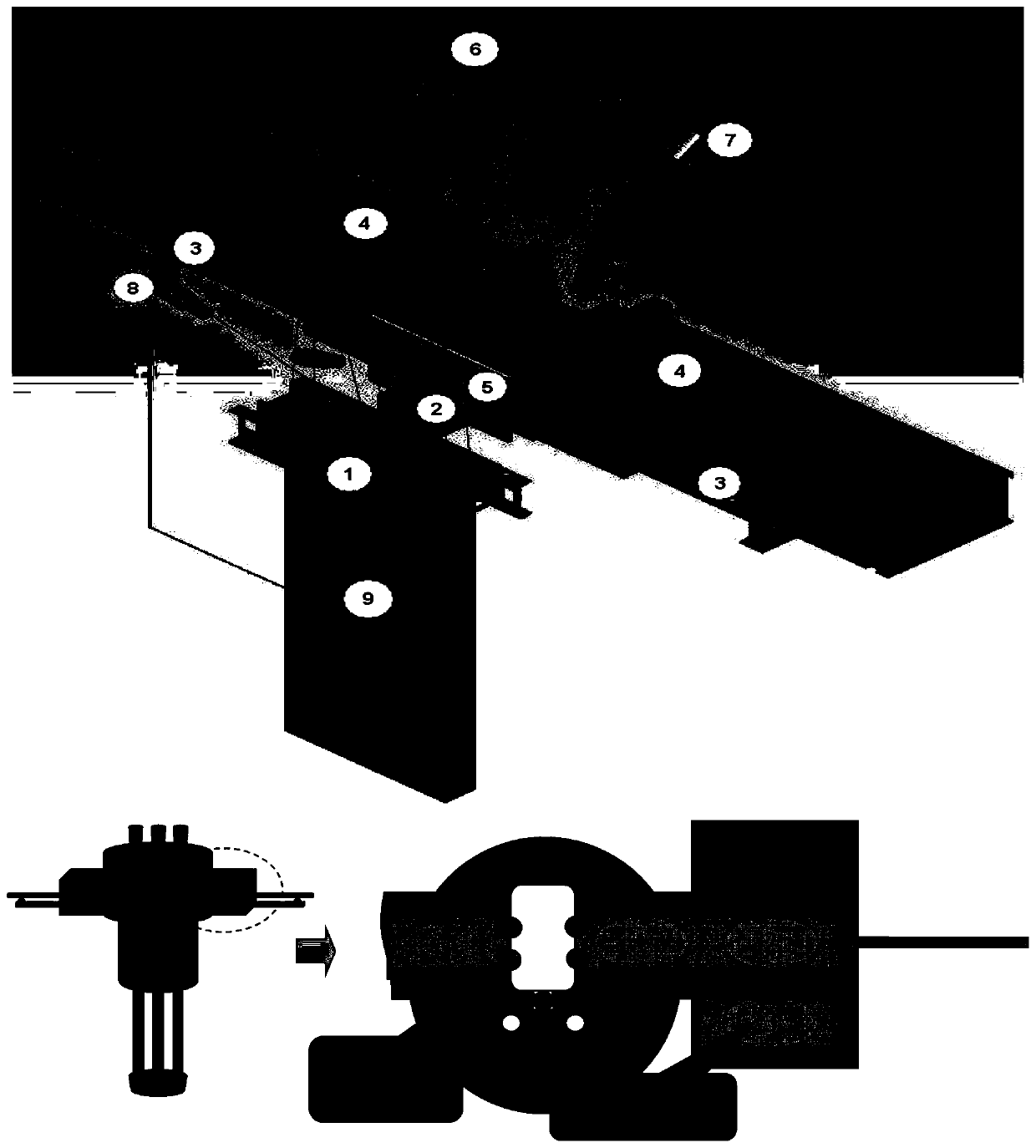

[0030] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

[0031] The difficulty of smelting zirconium metal is that zirconium metal has a high melting point of 1855°C and has high chemical properties. Zirconium can strongly absorb nitrogen, hydrogen, oxygen and other gases. When the temperature exceeds 900 degrees Celsius, zirconium can absorb nitrogen violently; under the condition of 2000 degrees Celsius, 100 grams of metal zirconium can absorb 817 liters of hydrogen, equivalent to more than 800,000 times that of iron. This characteristic of zirconium has caused great trouble to the smelting process.

[0032] Key details of casting control of zirconium metal in EB furnace include:

[0033] (1) Reasonable ingredients and placement are the prerequisites for successful casting;

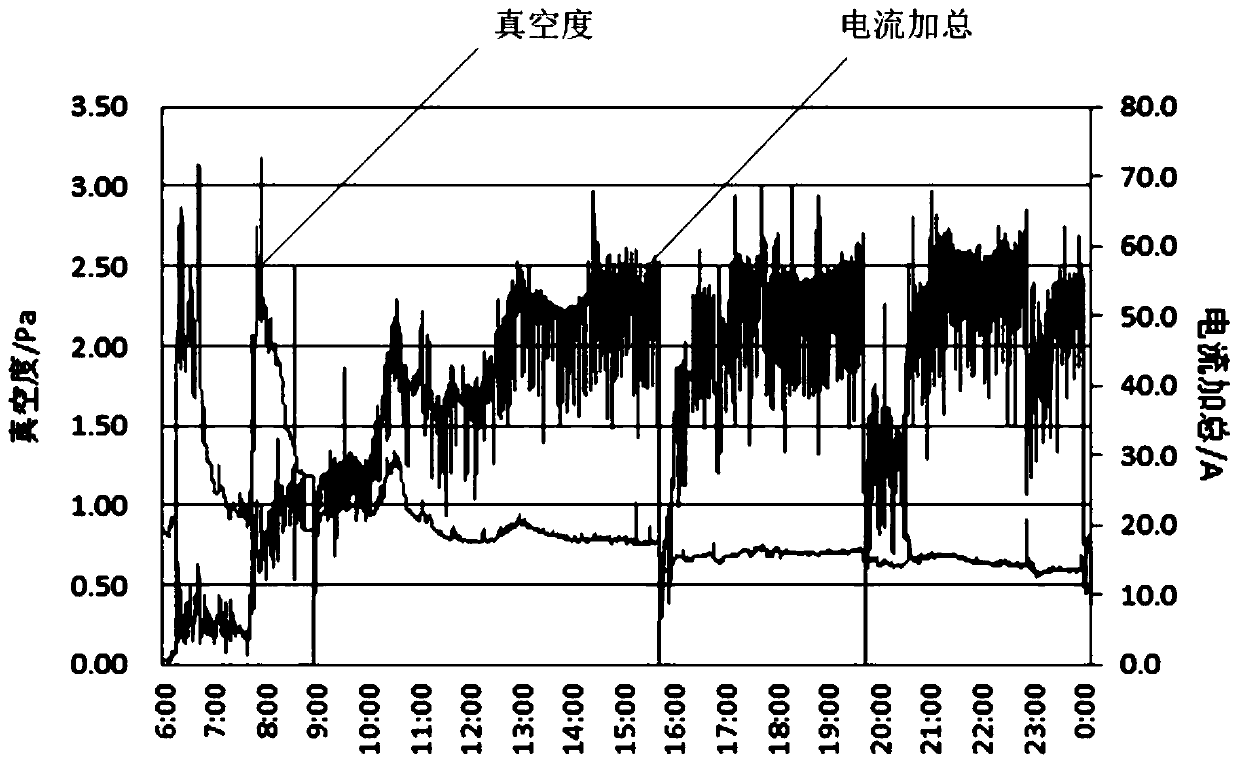

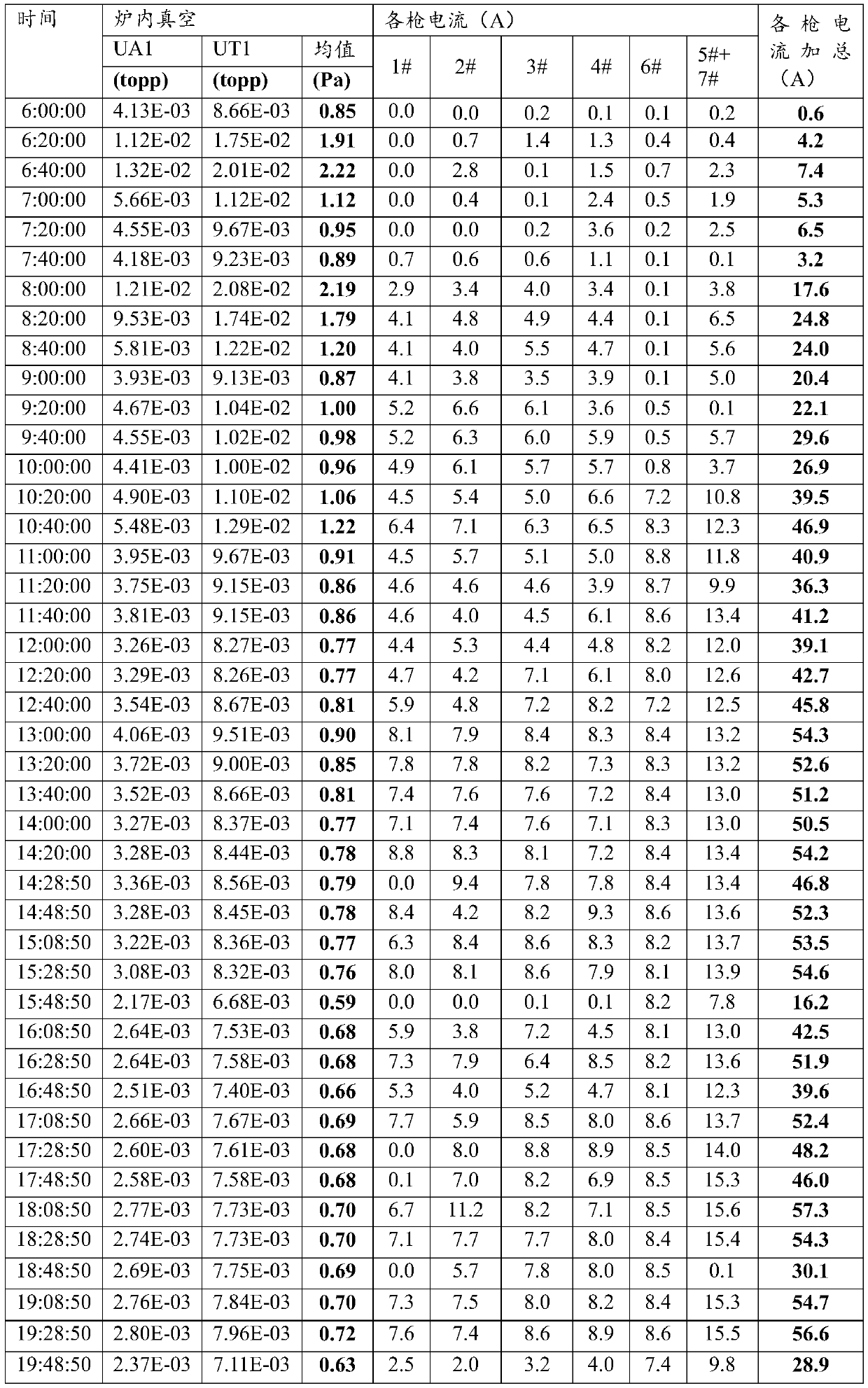

[0034] (2) Ensuring a good vacuum environment throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com