Manufacturing method of copper composite niobium-titanium multi-core superconducting enameled wire

A manufacturing method and enameled wire technology, applied in the usage of superconductor elements, cable/conductor manufacturing, superconducting devices, etc., can solve superconducting wire surface defects, paint quality defects, insurmountable surface defects and paint defects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

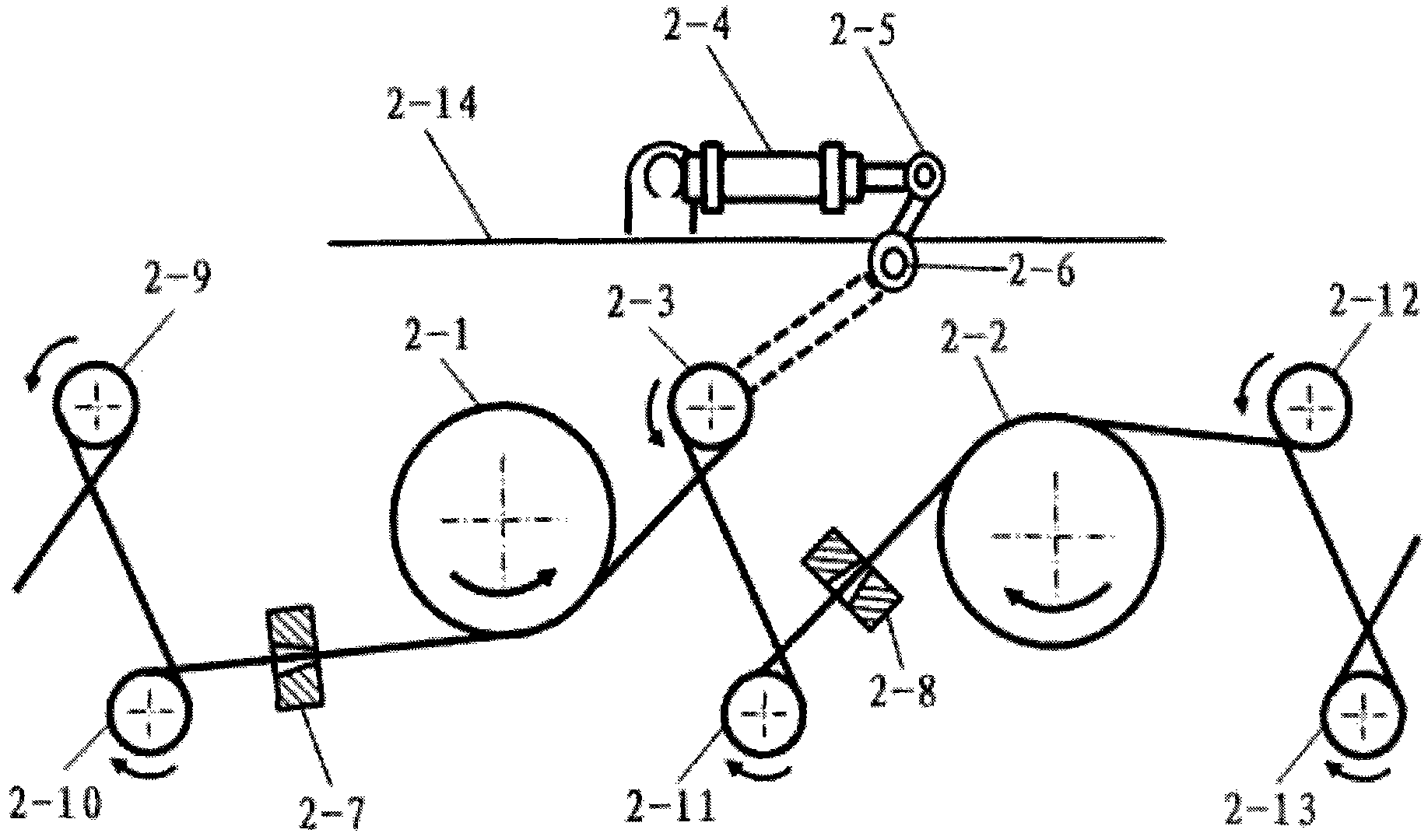

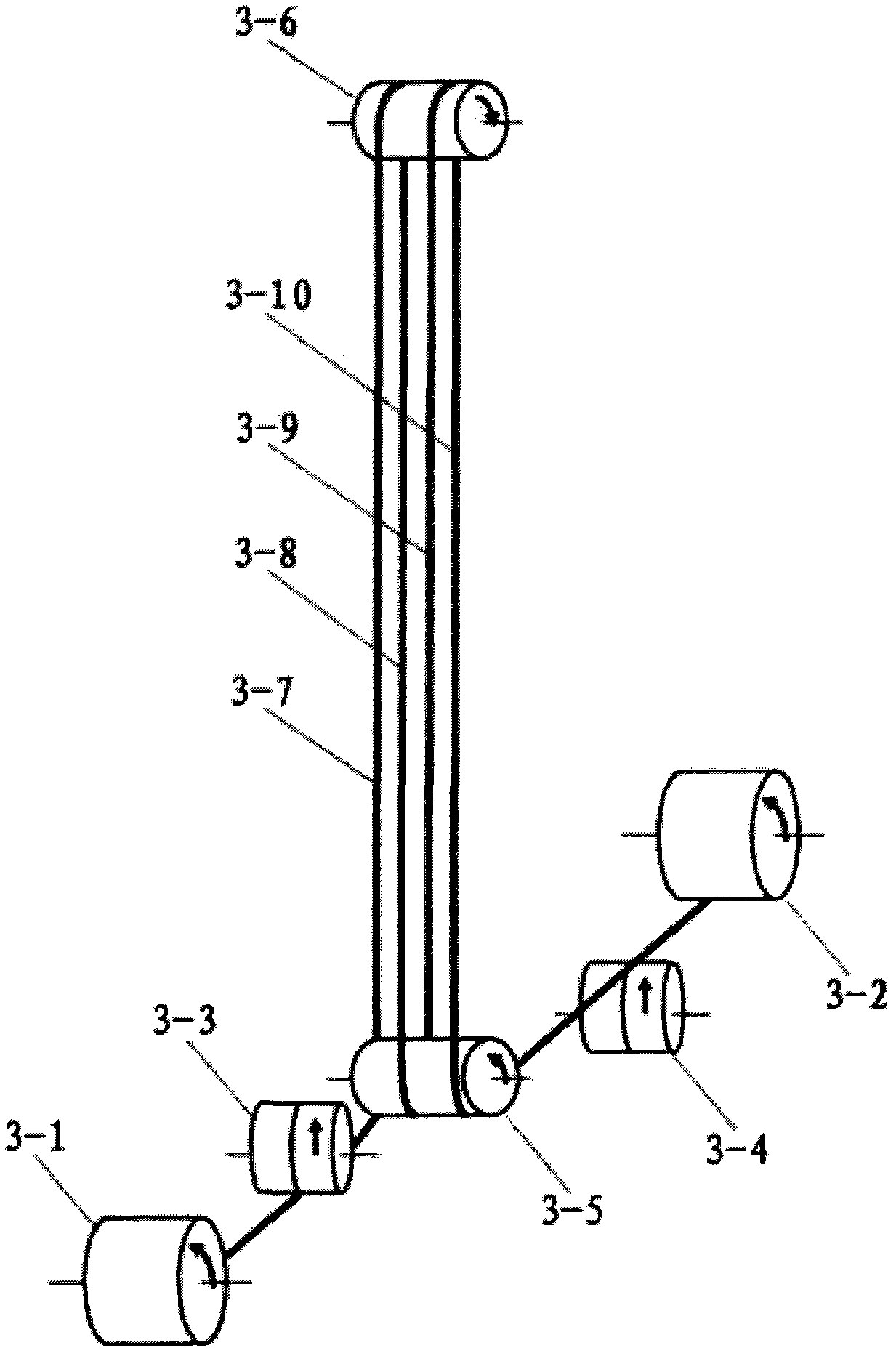

[0020] The invention provides a method for manufacturing a copper-composite niobium-titanium multi-core superconducting enameled wire, which includes a drawing process and a painting process. , take-up reel and drawing die to process the wire; in the process of drawing and painting, the winding direction of the wire between the adjacent pay-off reel, winch, guide reel, straightening reel and take-up reel is staggered and changed , to realize the staggered cross winding of the wire, and the friction force surface acts alternately on the inner and outer sides of the bent wire, so that the compression deformation of the inner surface of the wire and the tensile deformation of the outer surface of the wire are balanced.

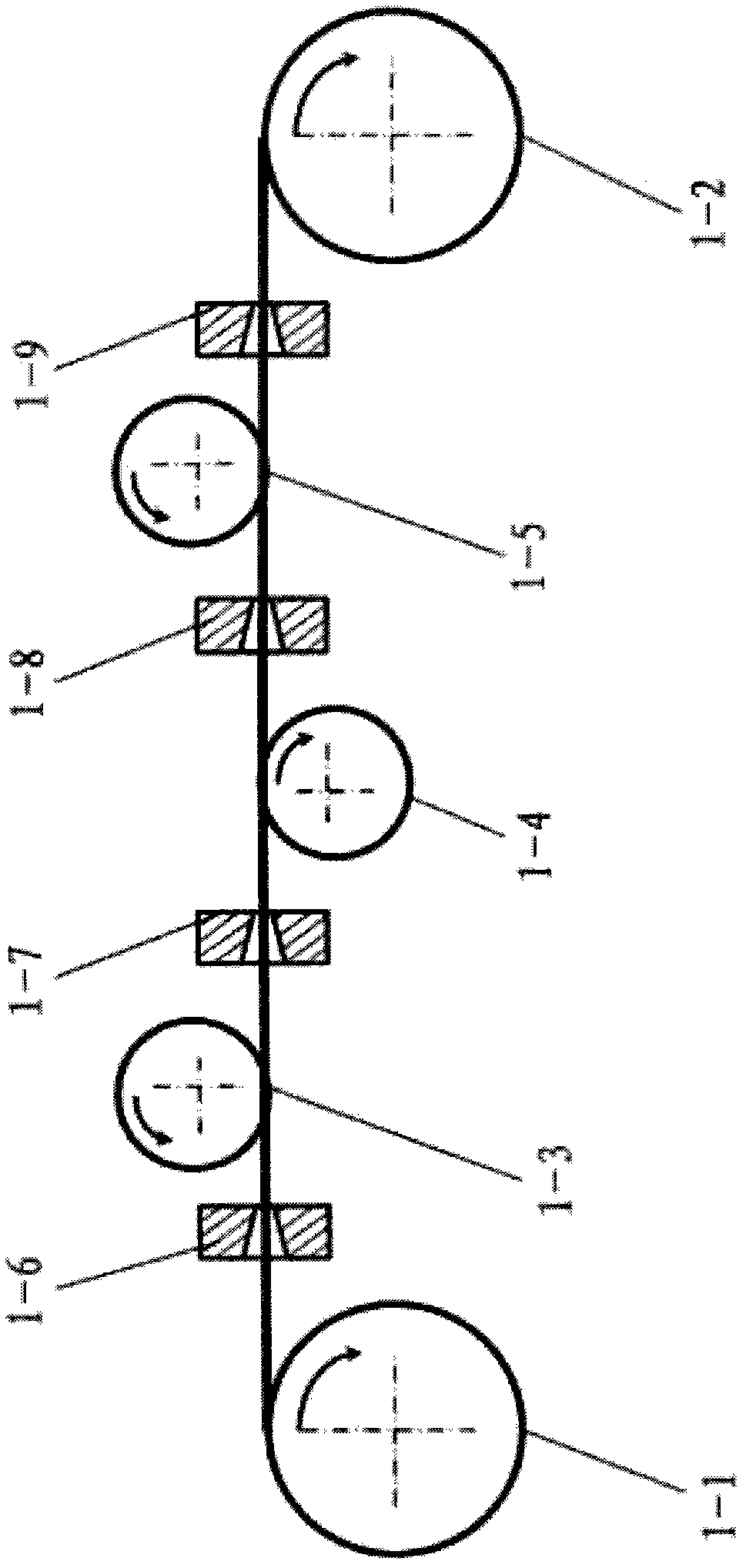

[0021] Such as figure 1 As shown, in the production of superconducting wire rods, the drawing process is multi-mode continuous drawing, including drawing and paying off reels 1-1 and drawing and taking up reels 1-2. Three capstans 1-3, 1-4, 1-5 are arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com