Surface ornamentation technique of composite material

A composite material and surface decoration technology, which is applied in the field of composite material surface decoration, can solve the problems of reducing product output, reducing product qualification rate, occupational injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

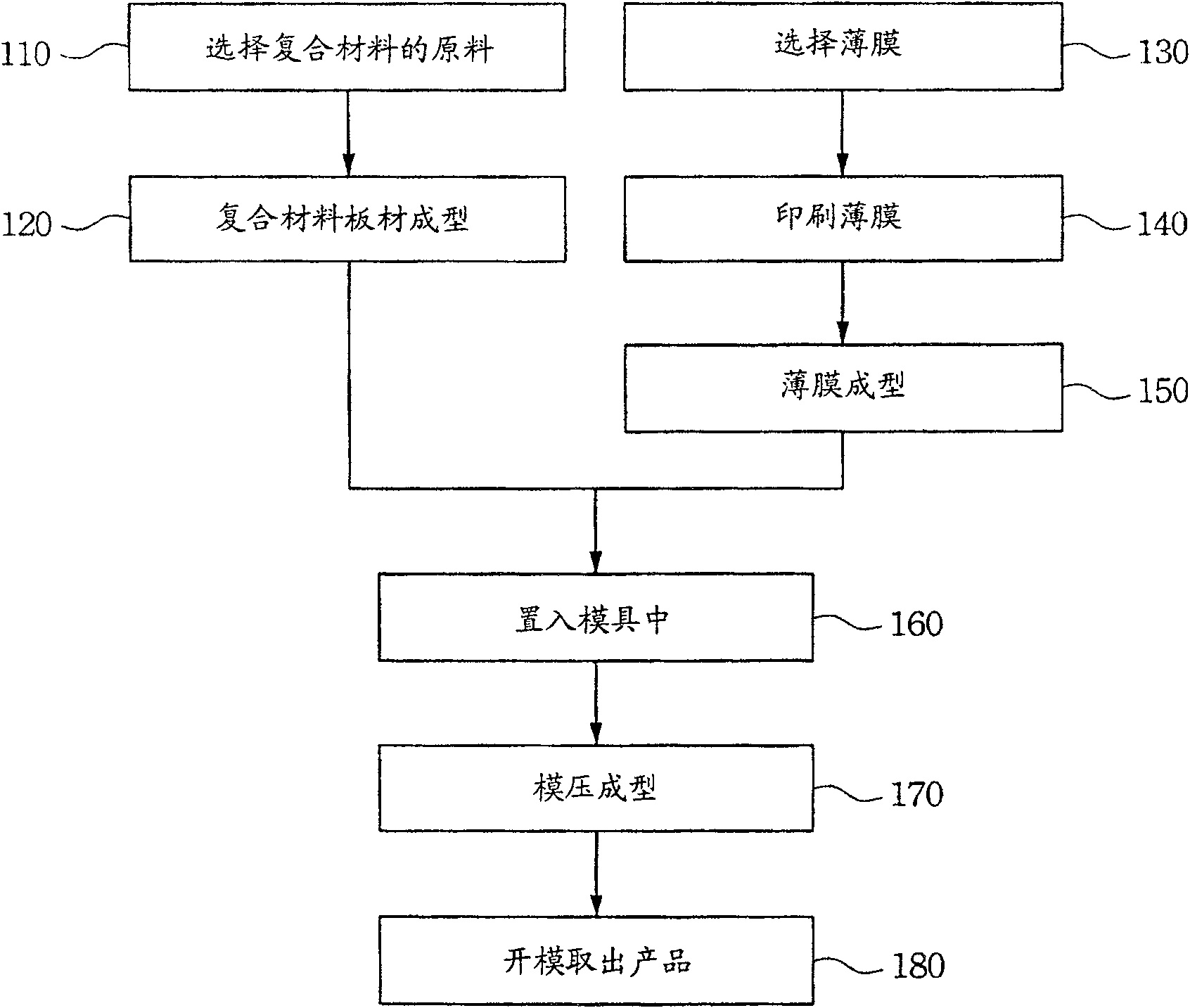

[0012] As mentioned above, the present invention provides a surface decoration technology for composite materials, which can effectively solve the problem of surface defects of composite materials without the problems of the prior art. The following will describe in detail with preferred embodiments.

[0013] In-mold decoration (IMD) is a way of using color printing to do color printing on a transparent film. After that, let the color-printed film undergo steps such as thermoforming and die-cutting. Finally, put it into the mold and carry out the step of plastic injection molding, so that the color film and plastic can be combined and formed to produce plastic products with beautiful and colorful appearance. Many plastic products that cannot be processed by printing and painting often use the technology of in-mold decoration to decorate their appearance.

[0014] The present invention applies the above-mentioned in-mold decoration technology to the surface decoration technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com