Automobile shock absorber support projection welding floating tool

A technology of automobile shock absorber and shock absorber, which is applied in the direction of manufacturing tools, welding equipment, resistance welding equipment, etc., can solve the problems of severe shunt, unstable quality state, and large loss in the welding process, so as to reduce the cost of tooling and energy consumption, stable welding process quality, and stable welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

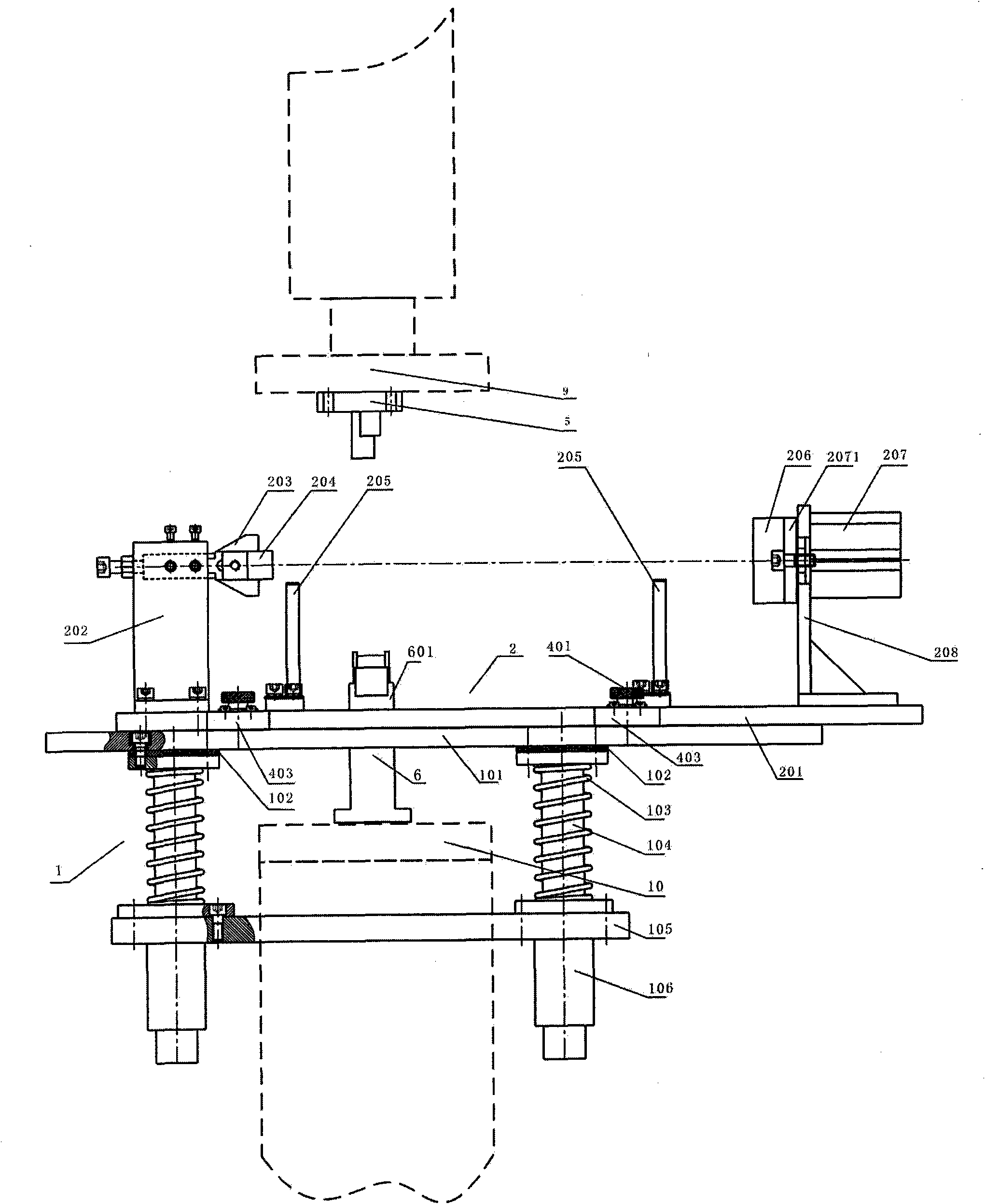

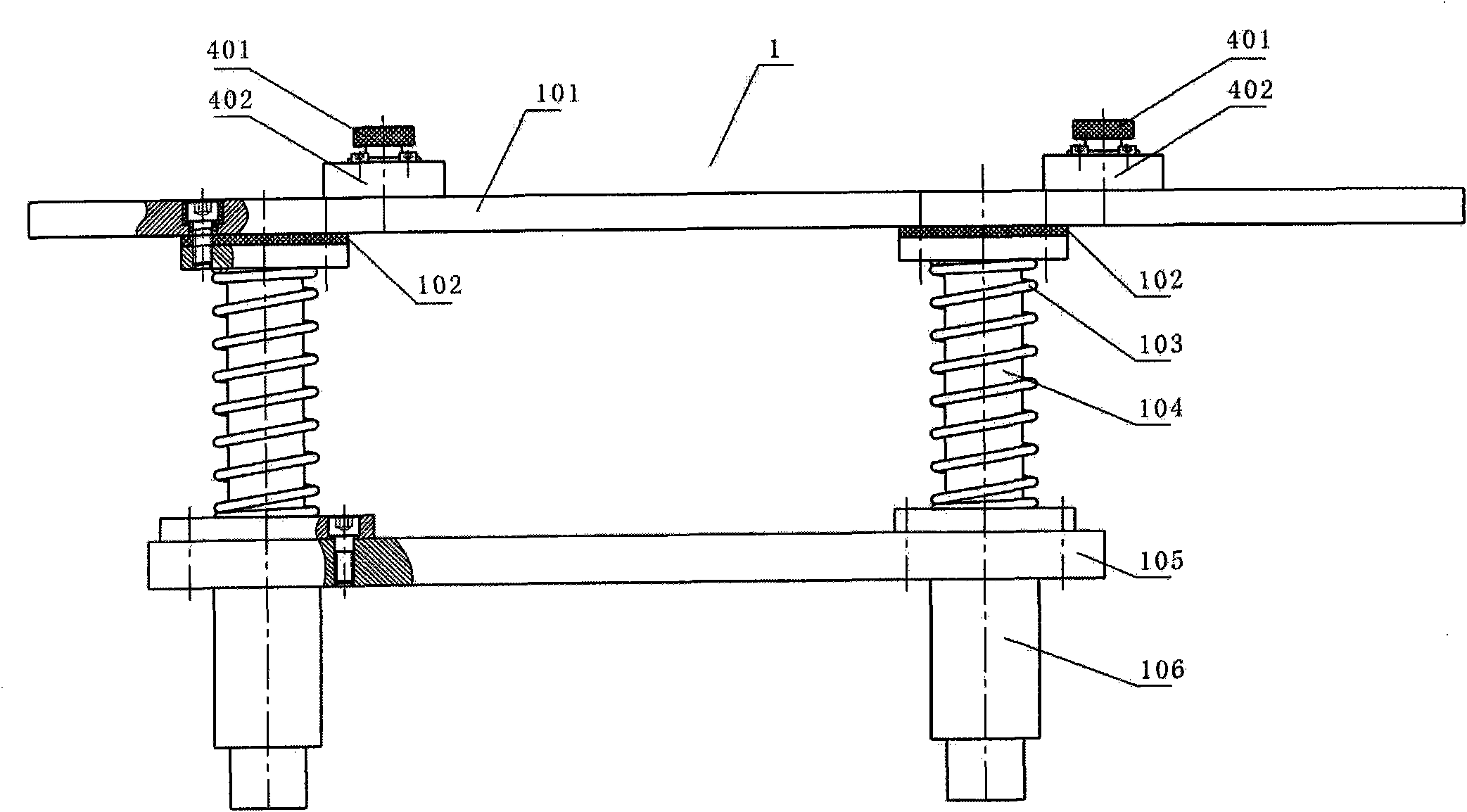

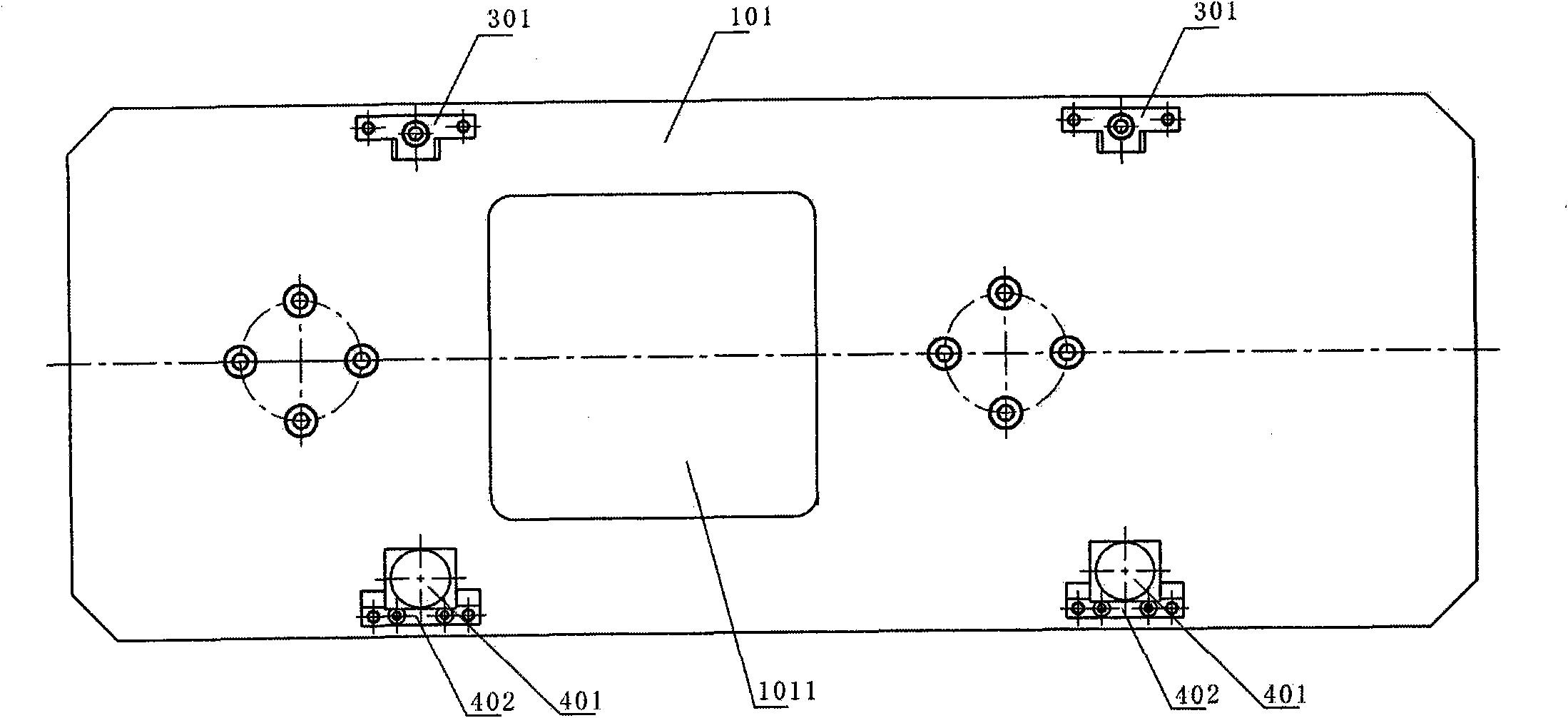

[0062] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0063] The automobile shock absorber support projection welding floating tool provided by the invention is specially used for the projection welding of the automobile shock absorber support. It is composed of projection welding floating general base 1, replaceable automobile shock absorber bracket positioning frame 2, replaceable positioning frame positioning mechanism 3, wedge-shaped pressing mechanism 4, upper electrode seat 5 and lower electrode seat 6;

[0064] The replaceable car shock absorber bracket positioning frame 2 is installed on the projection welding floating universal base 1 through the replaceable positioning frame positioning mechanism 3 and the wedge-shaped pressing mechanism 4, and two symmetrically welded on the projection welding machine shell on both sides of the lower electrode plate 10. The supporting plate, the floating general base 1 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com