Adjustable conical bearing outer ring turnover device

A tapered bearing and adjustable technology, used in transportation and packaging, conveyor objects, etc., can solve the problems of high machine maintenance cost, high cost, complex machine structure, etc., to achieve normal operation and eliminate the effect of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

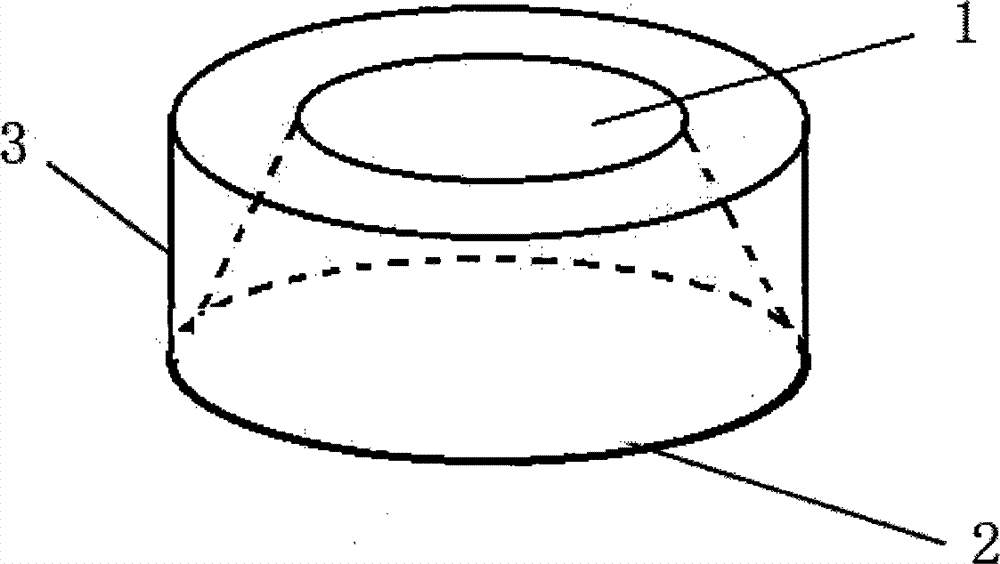

[0046] Taking the domestic new model 30244 tapered bearing as an example, the inner diameter (1) of the outer ring of the tapered bearing is 220mm, the outer diameter (2) of the outer ring of the tapered bearing is 400mm, and the thickness (3) of the outer ring of the tapered bearing is 73mm.

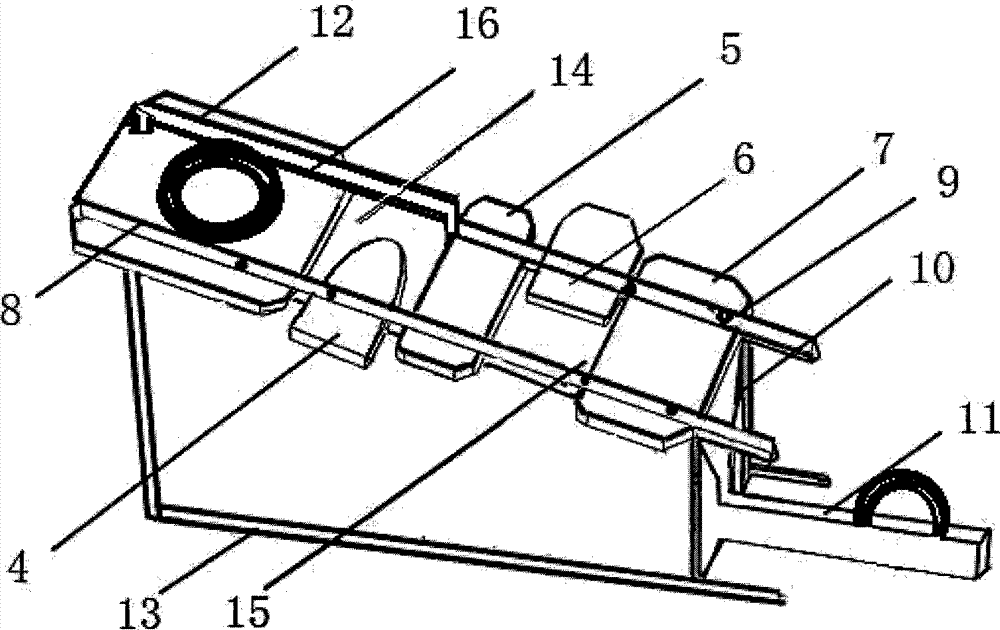

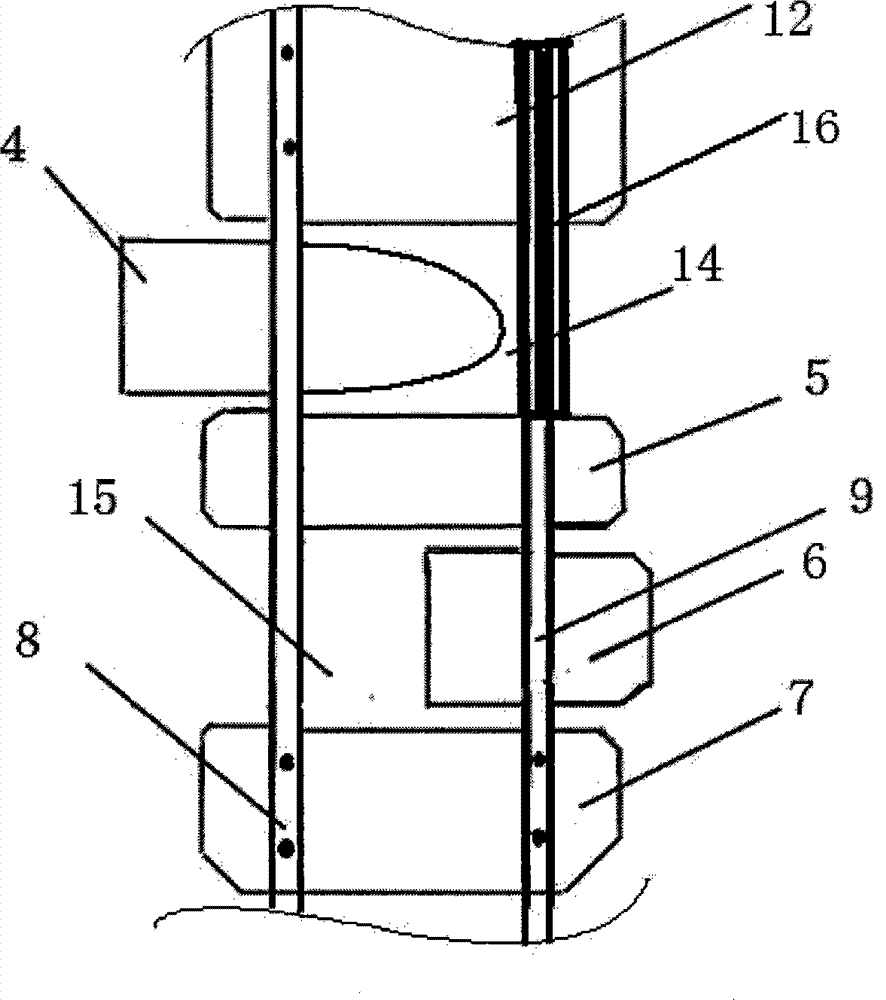

[0047] Such as figure 1 and figure 2 As shown, the front screening port (14) and the rear screening port (15) are arranged on the same plane of the feeding plate (12), and there is a Y-shaped concave hole directly below the front screening port (14) and the rear screening port (15). Groove (10), Y type groove (10) is connected on the chassis (13), is characterized in that:

[0048] A. On the front screening port (14), adjust the horizontal distance between the left adjusting splint (8) and the right lifting steel plate (16) to be M, and the distance between the feeding plate (12) and the middle moving plate (5) to be M , on the rear screening port (15), adjust the distance between th...

Embodiment 2

[0061] The structure of the device in embodiment 2 is basically the same as that in embodiment 1, and will not be described in detail here.

[0062] Taking the domestic new model 32303 tapered bearing as an example, the inner diameter (1) of the outer ring of the tapered bearing is 17mm, the outer diameter (2) of the outer ring of the tapered bearing is 47mm, and the thickness (3) of the outer ring of the tapered bearing is 19mm.

[0063] Adjust the horizontal distance between the left adjusting splint (8) and the right lifting steel plate (16) to be M, the distance between the feeding plate (12) and the middle moving plate (5) is M, and on the rear screening port (15), adjust The distance between the left adjustment splint (8) and the right adjustment splint (9) is M, and the distance between the middle moving plate (5) and the rear moving plate (7) is M. Substituting into formula 1, after calculation, M=50.70mm, The value is 51mm. The outer ring of the tapered bearing meets...

Embodiment 3

[0067] The structure of the device in embodiment 3 is basically the same as that in embodiment 1, and will not be described in detail here.

[0068] Taking the domestic old model 7304E tapered bearing as an example, the inner diameter (1) of the outer ring of the tapered bearing is 20mm, the outer diameter (2) of the outer ring of the tapered bearing is 52mm, and the thickness (3) of the outer ring of the tapered bearing is 15mm.

[0069] Adjust the horizontal distance between the left adjusting splint (8) and the right lifting steel plate (16) to be M, the distance between the feeding plate (12) and the middle moving plate (5) is M, and on the rear screening port (15), adjust The distance between the left adjustment splint (8) and the right adjustment splint (9) is M, and the distance between the middle moving plate (5) and the rear moving plate (7) is M. Substituting into formula 1, after calculation, M=54.12mm, The value is 55mm. The outer ring of the tapered bearing meets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com