Drum material-fetching machine moving avertence detection device and working method thereof

A detection device and reclaimer technology, applied in the direction of measuring devices, conveyor control devices, conveyor objects, etc., can solve the lag and error of the detection value of the pull rope position detection switch, do not meet the requirements of automatic operation, and the reliability of the detection device is poor and other problems to achieve the effect of eliminating jamming, saving manpower, and compensating for high and low position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

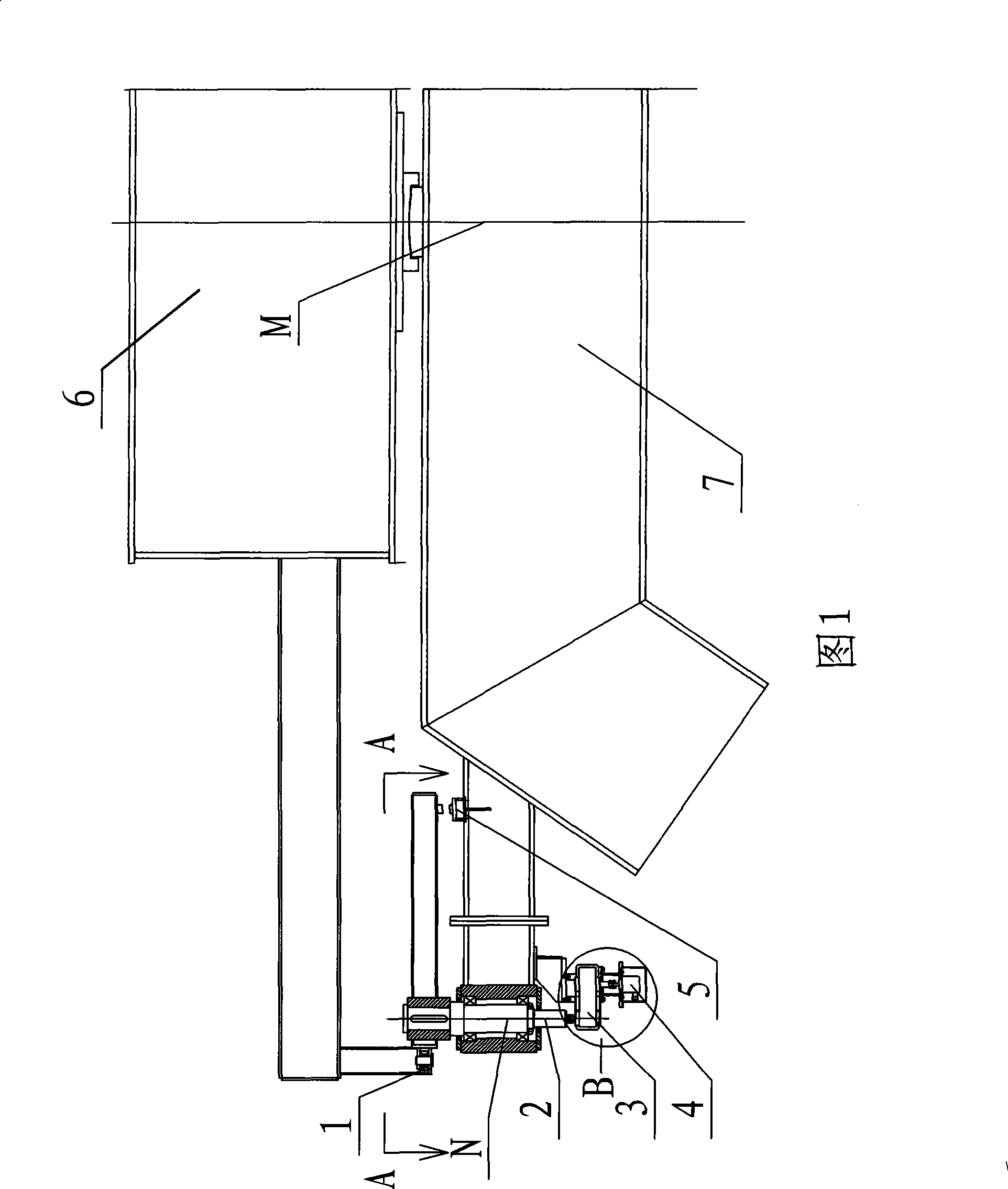

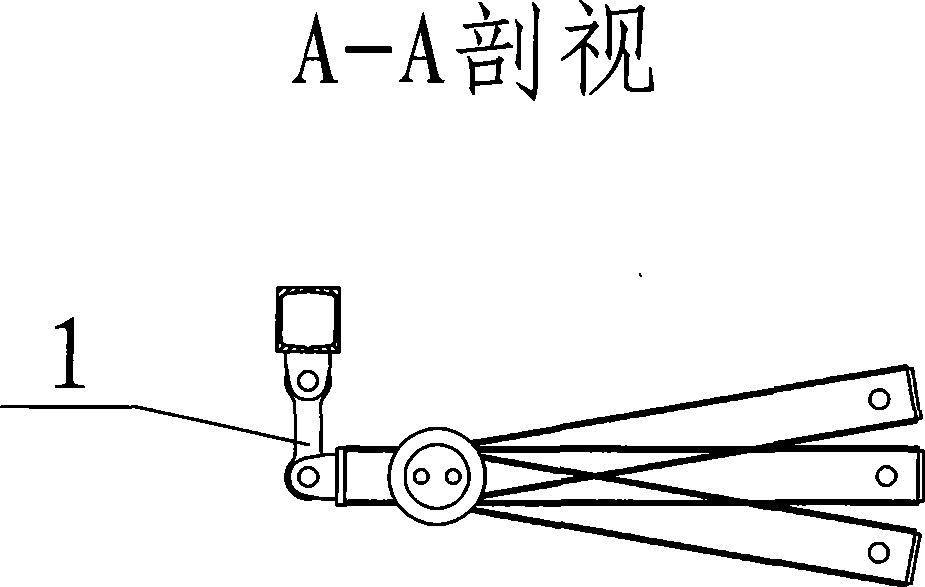

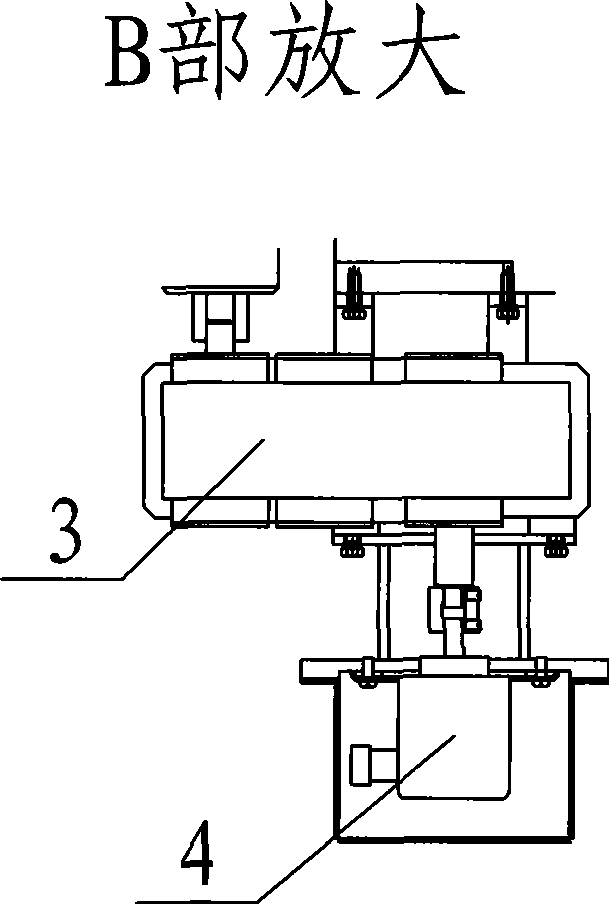

[0025] The present invention will be further described below in conjunction with accompanying drawing. As shown in Figure 1-3, a walking deflection detection device for a drum reclaimer includes a connecting rod amplification system 1, a rotating shaft device 2, a speed increaser 3, an encoder 4, and a protection device 5. The connecting rod amplification system The system 1 is welded on the bridge frame 6, and the rotating shaft device 2 is welded on the door leg 7. The rotating shaft device 2 has a shaft extension on the upper and lower sides, and one shaft extension is located at the same level as the connecting rod of the connecting rod amplification system 1. The rod amplification system 1 is fixedly connected, and the other shaft extension is connected with the low-speed shaft of the speed increaser 3 through a coupling, and the high-speed shaft of the speed increaser 3 is connected with the shaft extension of the encoder 4 through a coupling. The protection device 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com