Small-torque electric ball valve

An electric ball valve, small torque technology, applied in valve details, valve devices, engine components, etc., can solve problems such as slow response and execution of electric ball valves, damage to the electric driver of electric ball valves, and increased starting torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

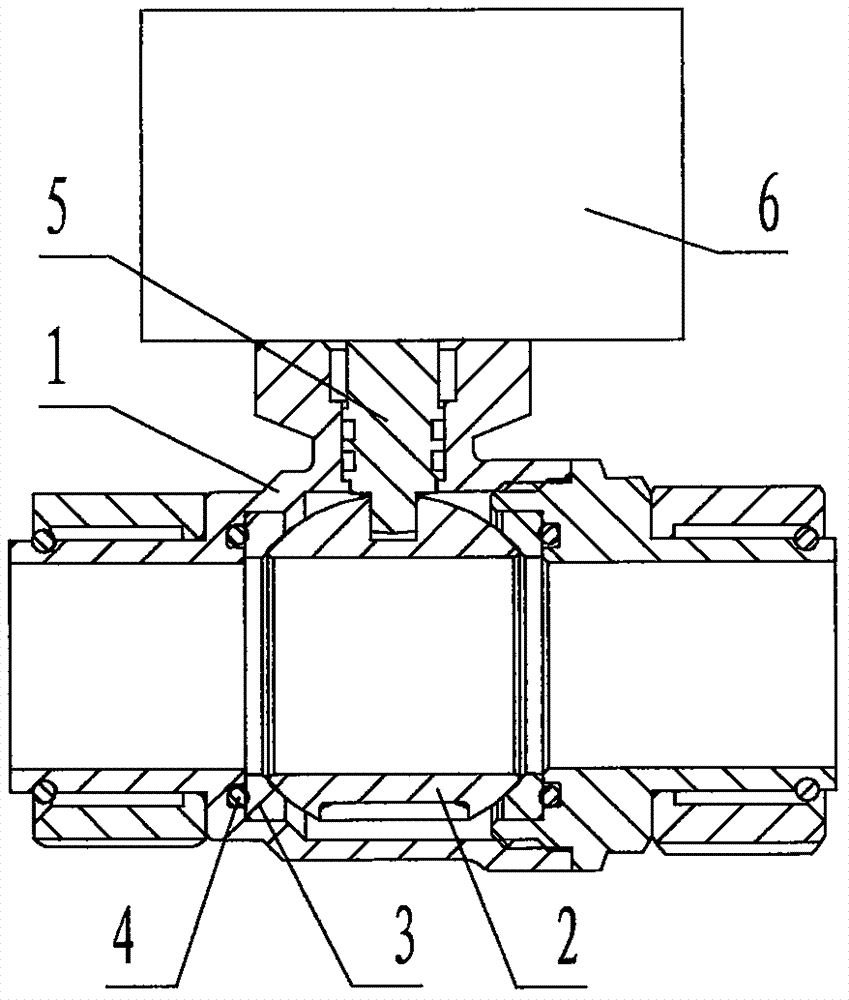

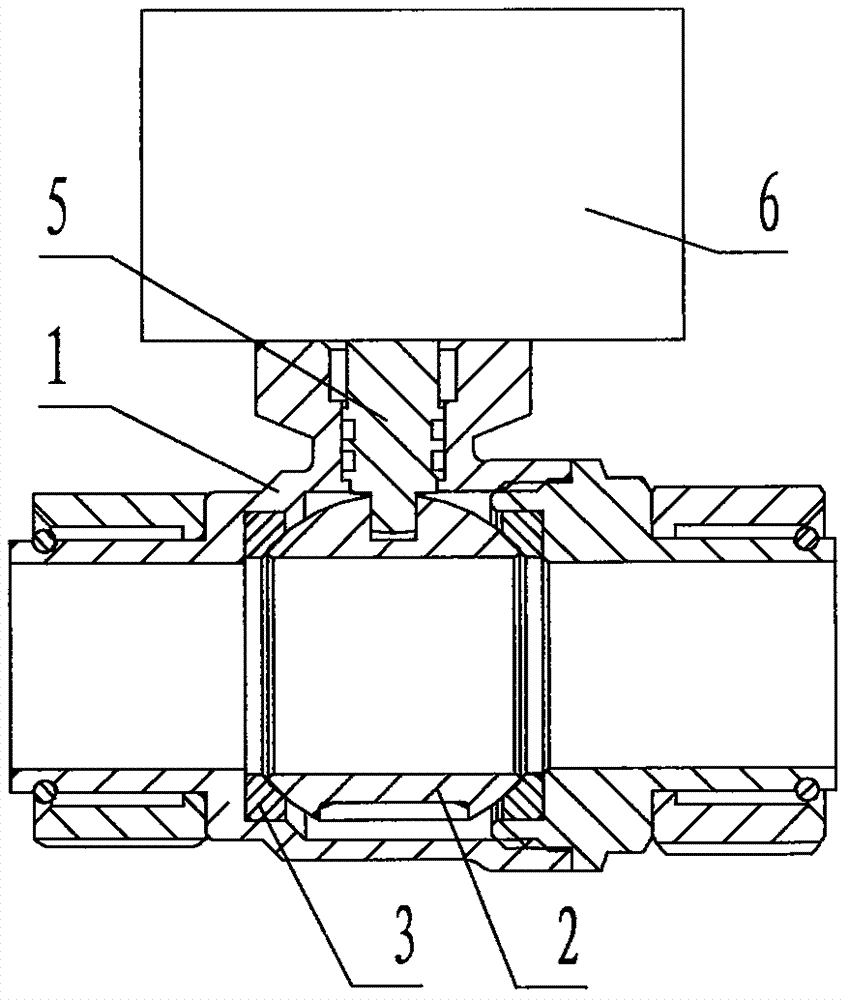

[0019] refer to figure 1 , a small torque electric ball valve of the present invention, including a valve body 1, a ball valve core 2, a sealing ring 3, an O-ring 4, a valve stem 5, and an electric driver 6, wherein: the valve body 1 is centered with a hollow The inner channel of the inner channel, the circular tubular copper shell with two ends open, the upper part of the valve body 1 is provided with a valve stem seat that protrudes upwards and is provided with a central through hole communicating with the inner channel; the left and right sides of the inner channel The annular steps for placing the sealing ring 3 on both sides are called the ring groove, and the bottom of the ring groove is provided with an annular groove for placing the O-ring 4 called the ring groove;

[0020] The O-ring 4 is a silicone rubber elastic member with a circular cross section and a circular appearance. The hardness of the O-ring 4 is 60-70 Shore hardness; the width of the ring groove is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com