Wet-clutch friction plate's wear extent testing method and testing stand

A technology of wet clutch and testing method, which is applied in the direction of testing wear resistance, instruments, measuring devices, etc. It can solve the problems of unable to monitor the clutch in real time, easily cause damage to the equipment, and destroy the matching relationship, so as to ensure the reliability of the test and prevent friction. The effect of damage and not easy to accumulate

Active Publication Date: 2015-11-04

BEIJING INFORMATION SCI & TECH UNIV

View PDF14 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The wear degree of the friction plate will directly affect the reliability and performance of the integrated transmission. Clutch wear is the process of continuous damage to the surface material of the clutch friction pair. The conventional measurement method for the wear amount of the clutch friction plate is to directly weigh or measure the thickness after disassembly and inspection. Accurate, but it often destroys the original matching relationship, and it is time-consuming and labor-intensive. Some scholars have studied the calculation method of clutch wear. Zhang Xueyong expressed the amount of wear as a linear function of positive pressure, and calculated the change of wear amount of the friction plate over time by using theoretical analysis and computer simulation methods, and carried out wear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

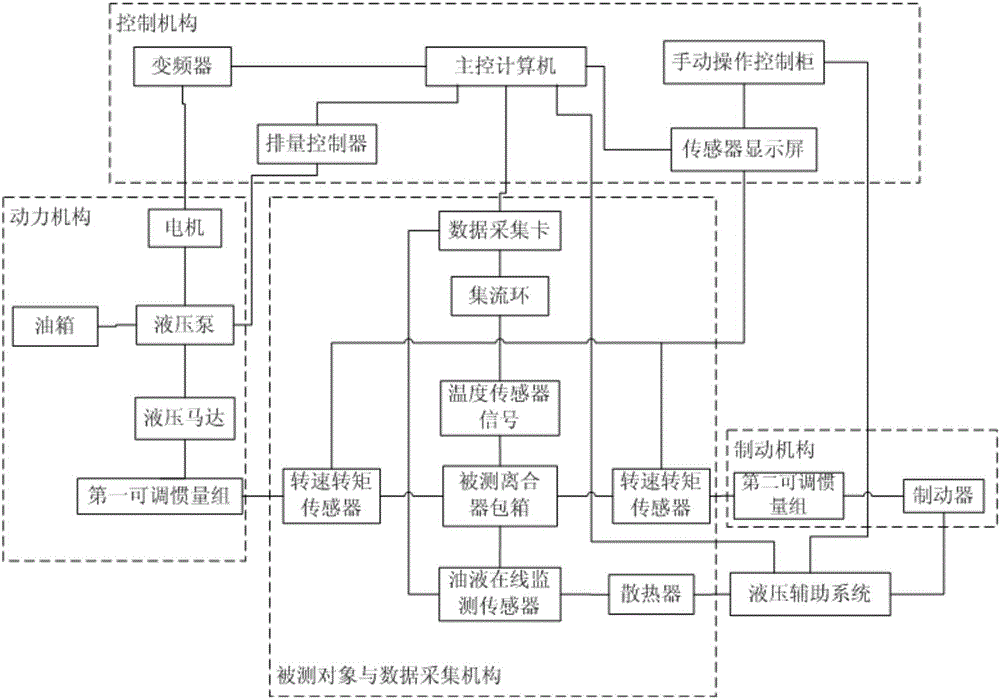

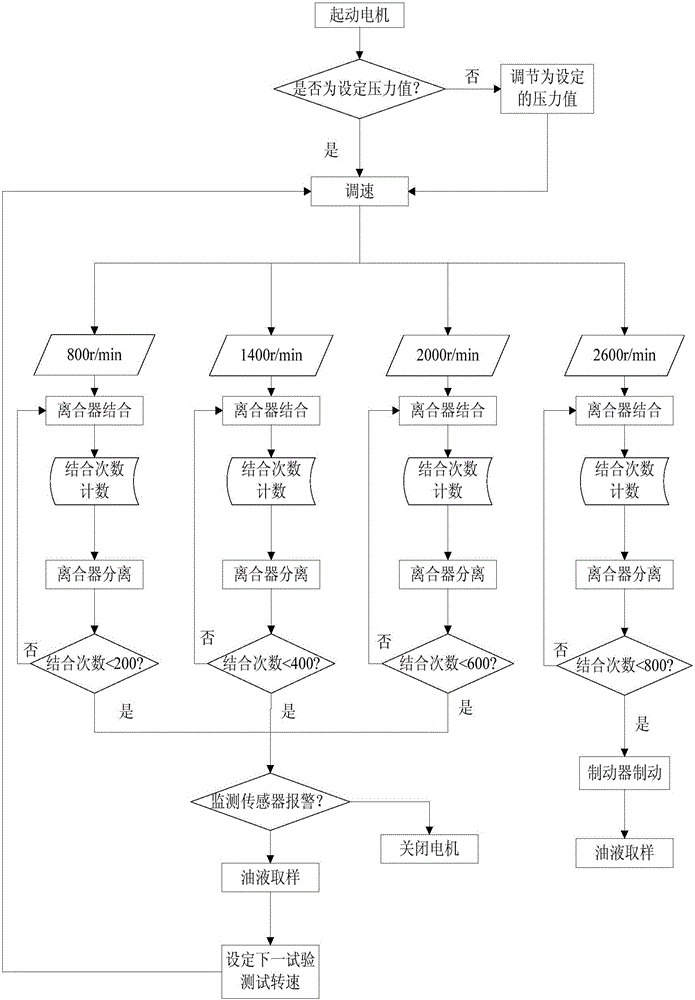

The invention relates to a wet-clutch friction plate's wear extent testing method and a testing stand. The testing stand comprises a control mechanism, a power mechanism, a measured object and data acquisition mechanism, a brake mechanism and a hydraulic booster system. The measured object and data acquisition mechanism transmits acquired measured object status data, power mechanism status data and hydraulic booster system data to the control mechanism and the brake mechanism, and the control mechanism controls operations of the power mechanism and the hydraulic booster system. The testing method based on the testing stand comprises steps of testing static friction torque and static friction coefficient of friction plates, testing dynamic friction torque and dynamic friction coefficient of the friction plates and testing wear extent of the wet-clutch friction plates. According to the invention, wear extent and lifetime of wet-clutch friction plates can be tested, test results are accurate and measurement is convenient. Friction damage of clutch friction parts due to many times of combinations is prevented, and clutch testing reliability is guaranteed.

Description

technical field [0001] The invention relates to a method and a test system for testing the wear amount of a clutch friction plate, in particular to a test method and a test bench for the wear amount of a wet clutch friction plate. Background technique [0002] With the development direction of high performance, high power density, high reliability and long life of vehicle transmission, wet clutch is one of the core components of automatic transmission system and integrated transmission, in order to meet the high speed and heavy load of vehicle transmission High, high power density, high reliability transmission system needs to achieve high efficiency, high stability, safety and reliability, and long life, and can better detect and study the characteristics of dynamic combination of wet clutches. The friction and wear characteristics of the friction plate were studied. [0003] The friction pair of the integrated transmission wet shift clutch is composed of the internal toot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/56G01N19/02

Inventor 王立勇李乐李浩

Owner BEIJING INFORMATION SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com