Patents

Literature

69results about How to "Reduce rotational torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

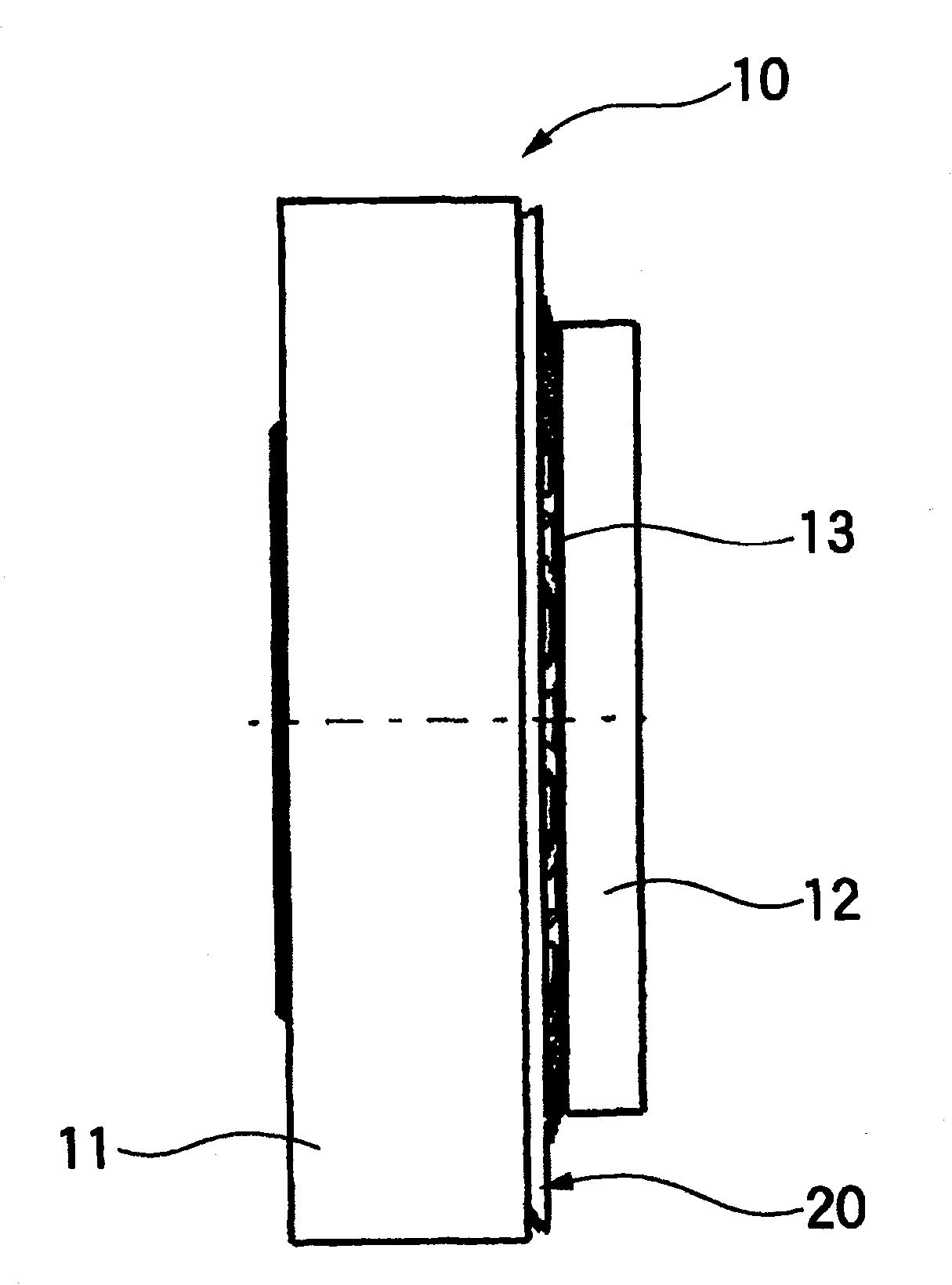

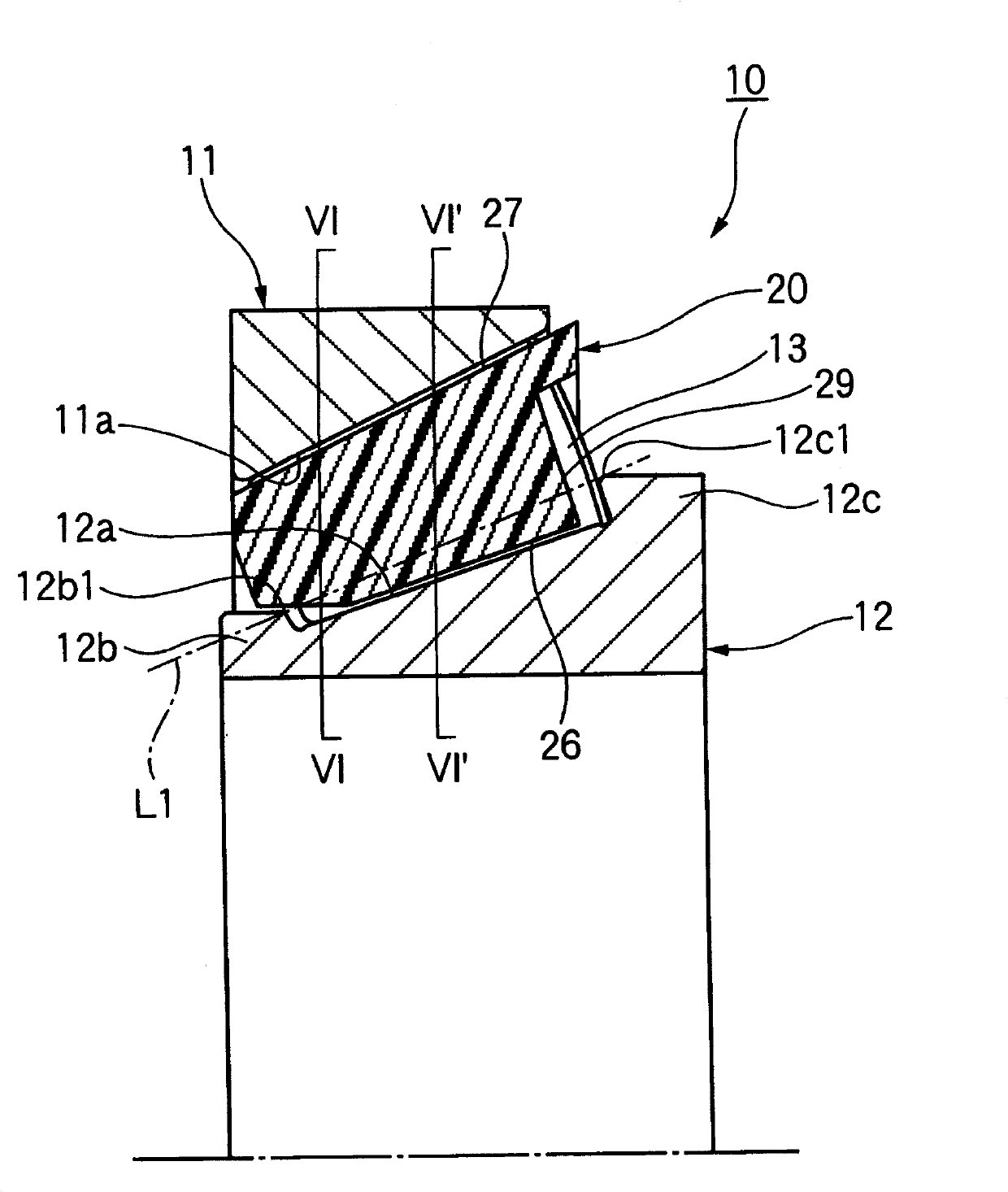

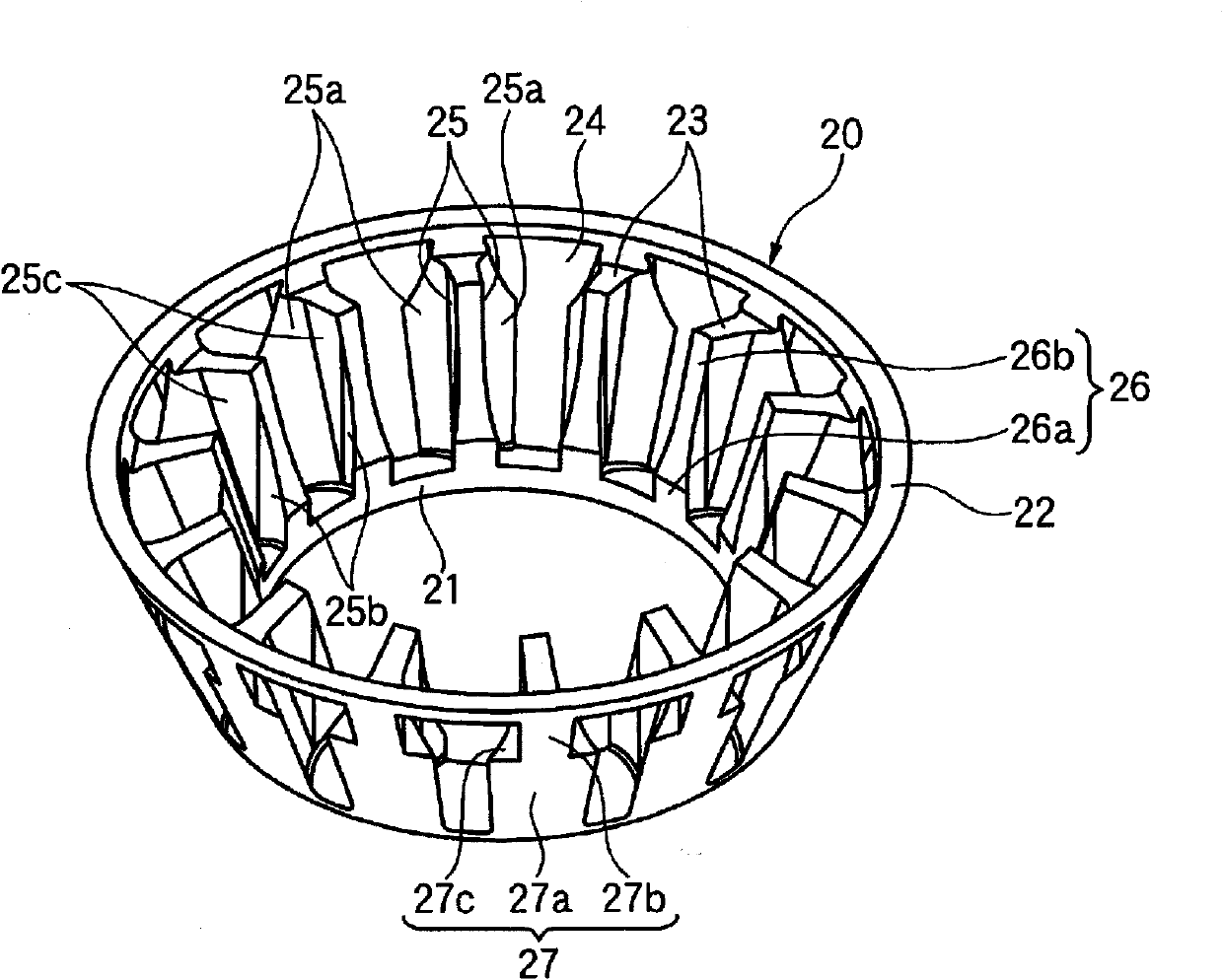

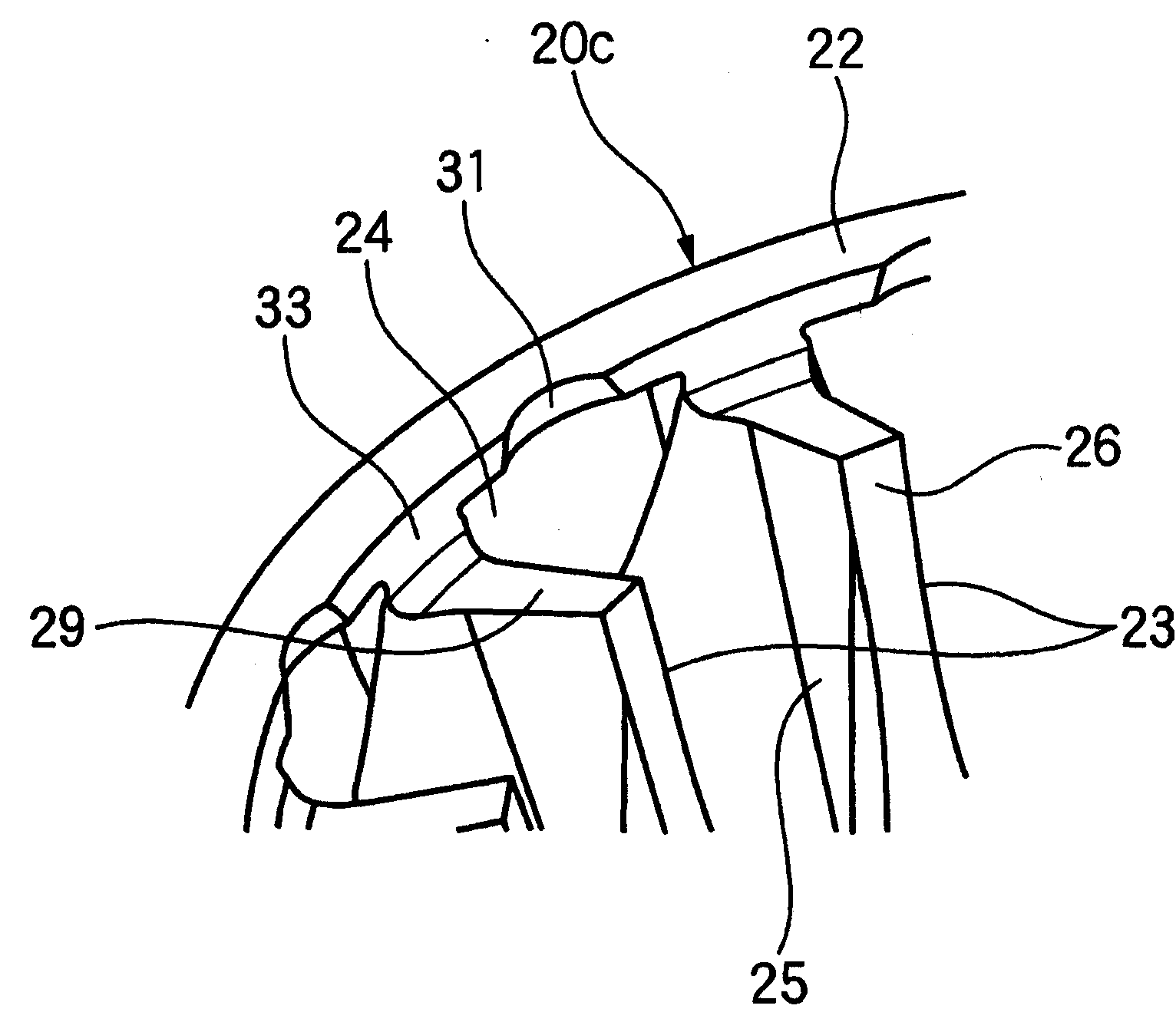

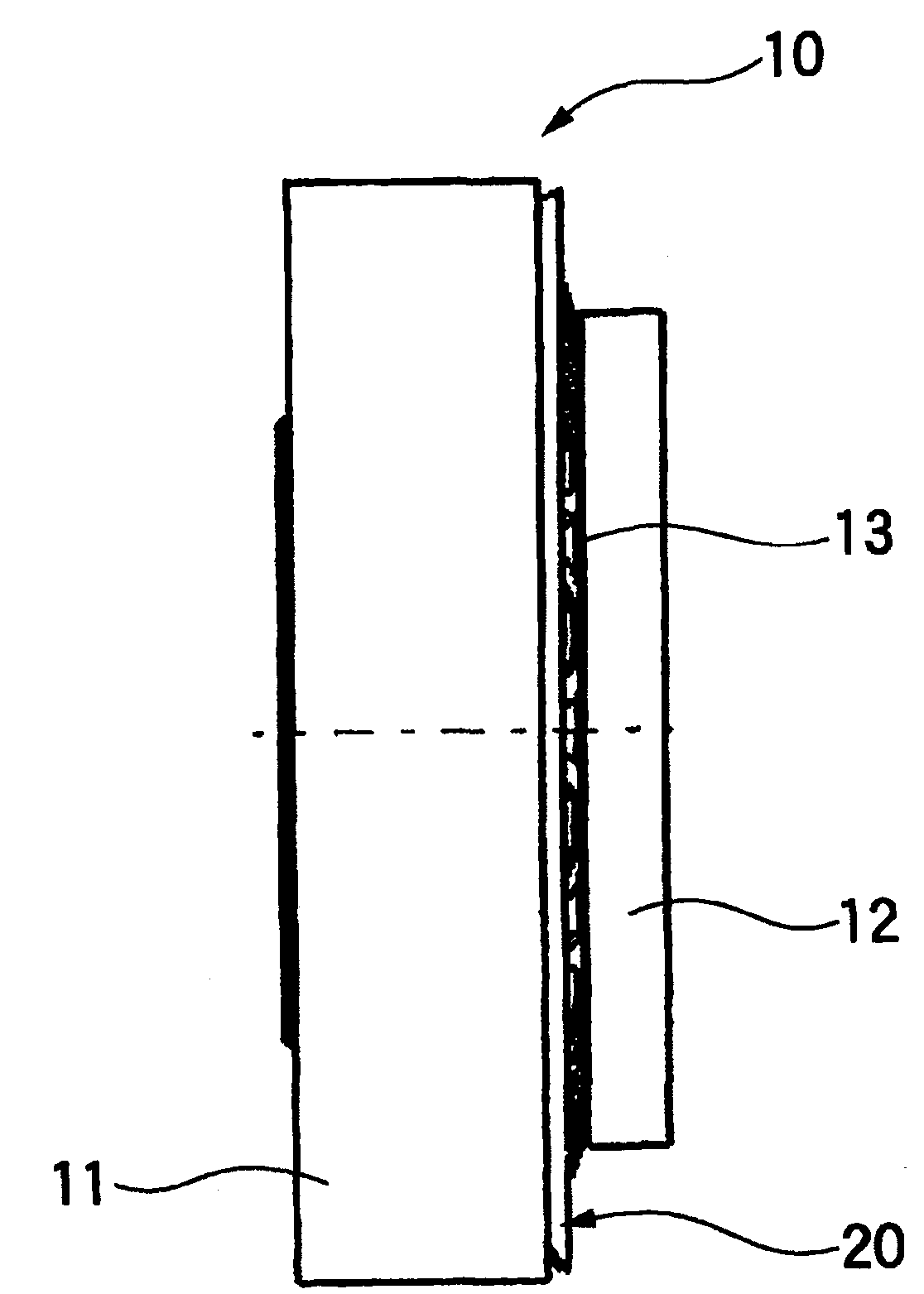

Resin retainer for tapered roller bearing, and tapered roller bearing

ActiveCN102089541AReduce stirring resistanceImproves ease of installationRoller bearingsShaftsEngineeringMechanical engineering

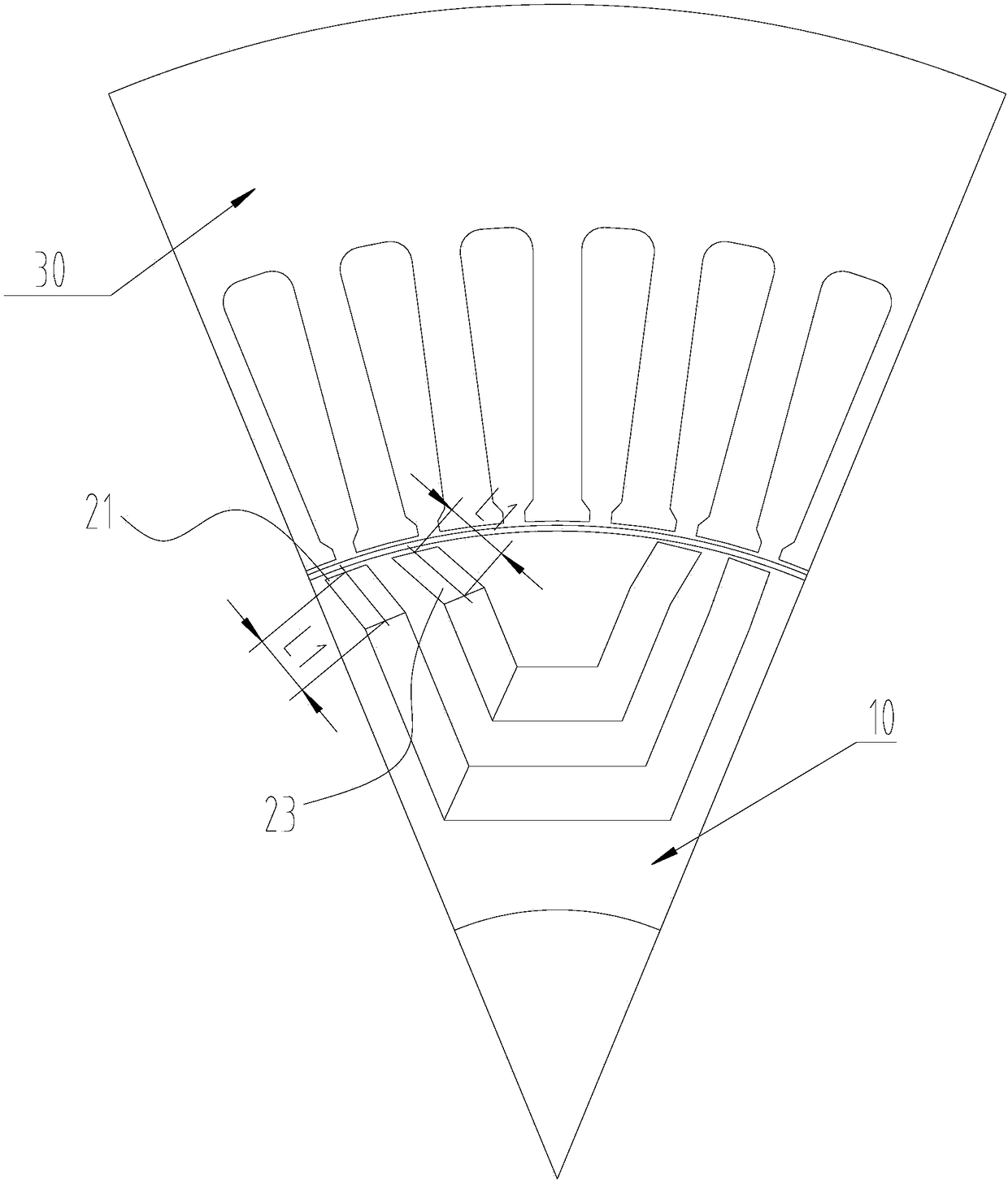

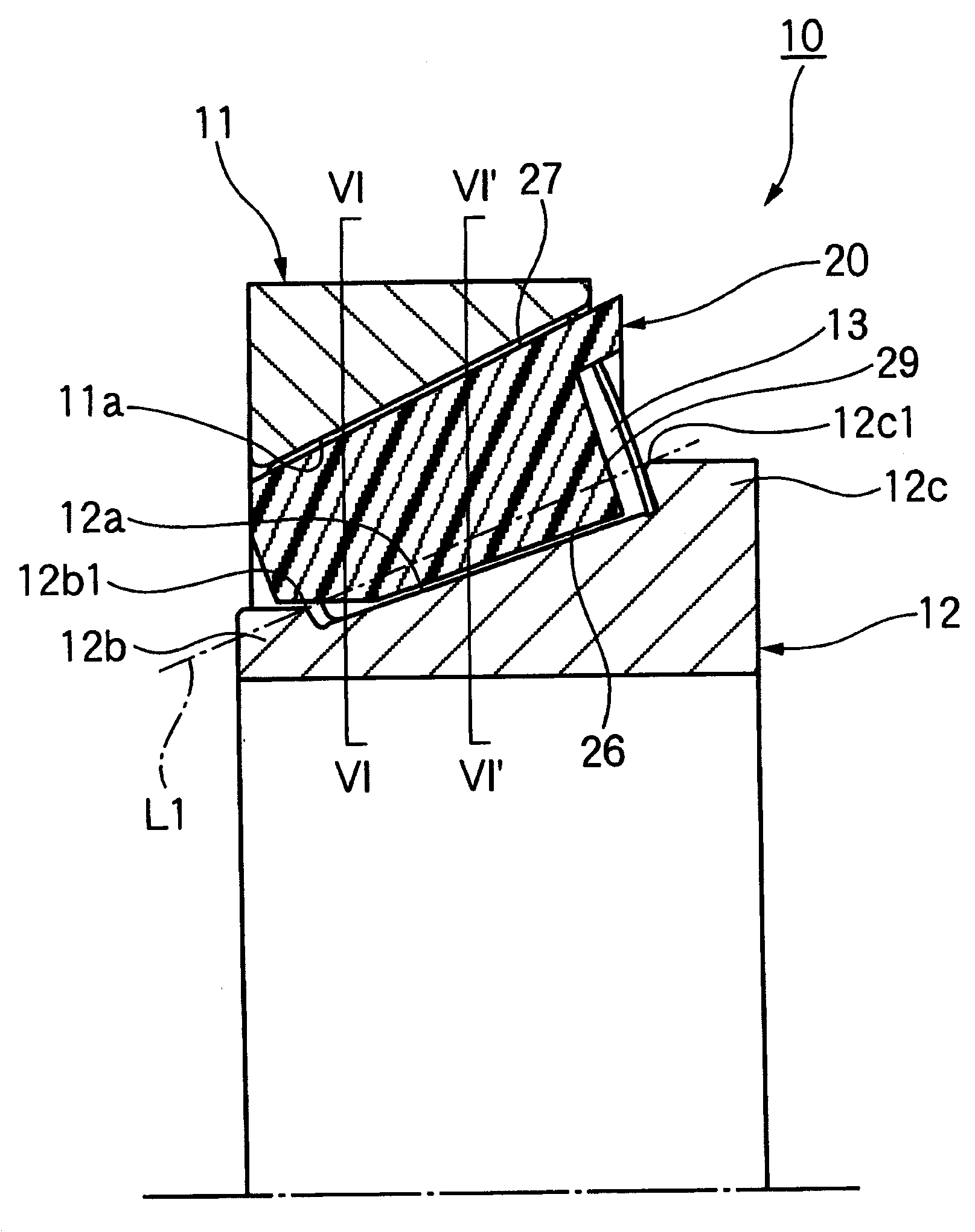

A resin retainer for a tapered roller bearing and the tapered roller bearing which are configured such that a space in the tapered roller bearing is reduced, stir resistance of lubricating oil contained in the bearing is reduced, and easiness of mounting of tapered rollers into the bearing is enhanced. A resin retainer (20) for a tapered roller bearing is provided with a small-diameter annular section (21), a large-diameter annular section (22), and struts (23) for interconnecting both the annular sections (21, 22). The struts (23) are each provided with a pair of circumferential side surfaces (25) respectively having roller guide surfaces (27), and also each provided with an inner peripheral surface (26) having a circumferential width smaller on the large-diameter annular section (22) side than on the small-diameter annular section (21) side. Between adjacent struts (23) is provided a retaining region (Ar) having, between the opposed circumferential side surfaces (25) of the adjacent struts (23), an outer-diameter-side pocket width (W1) and an inner-diameter-side pocket width (W2) which are set less than a diameter (D) of the tapered rollers.

Owner:NSK LTD

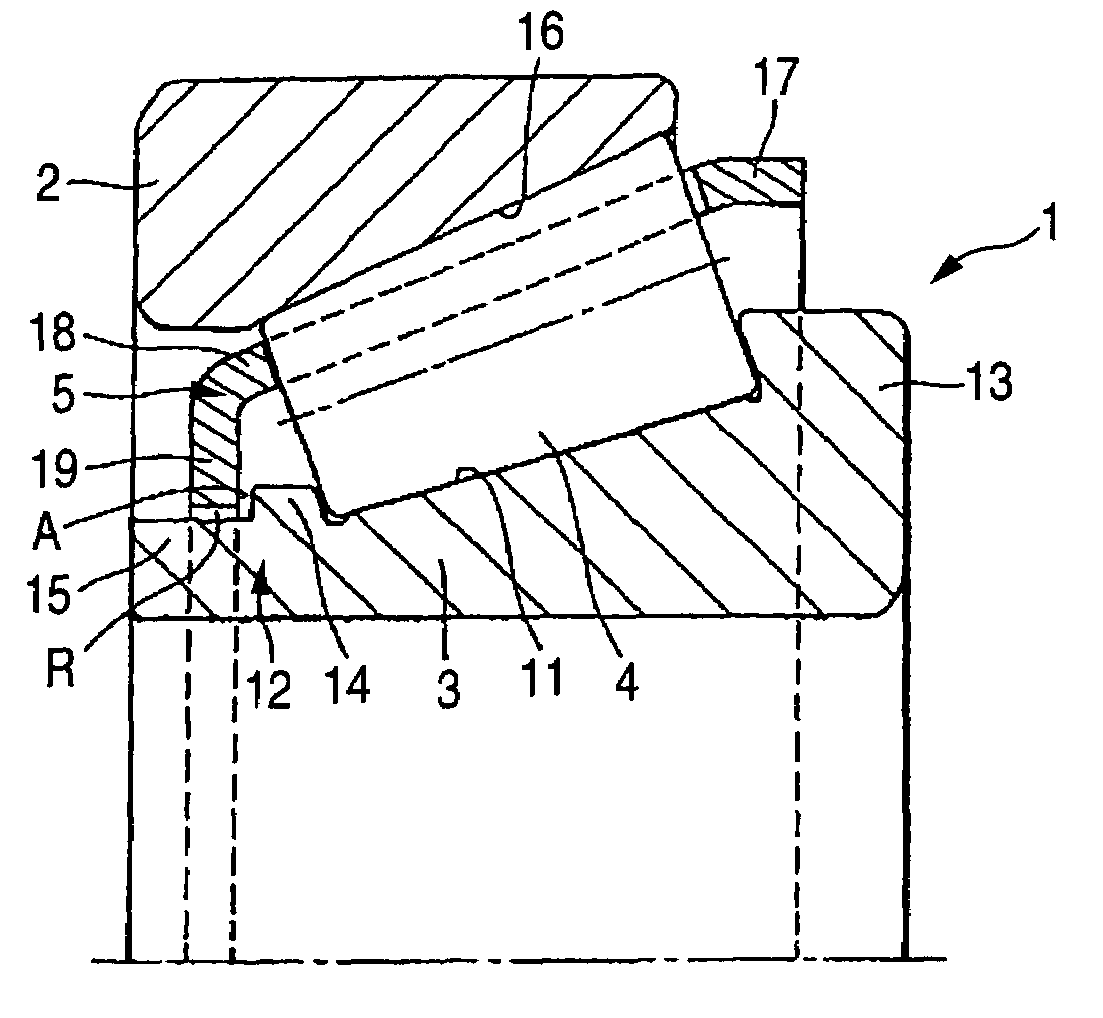

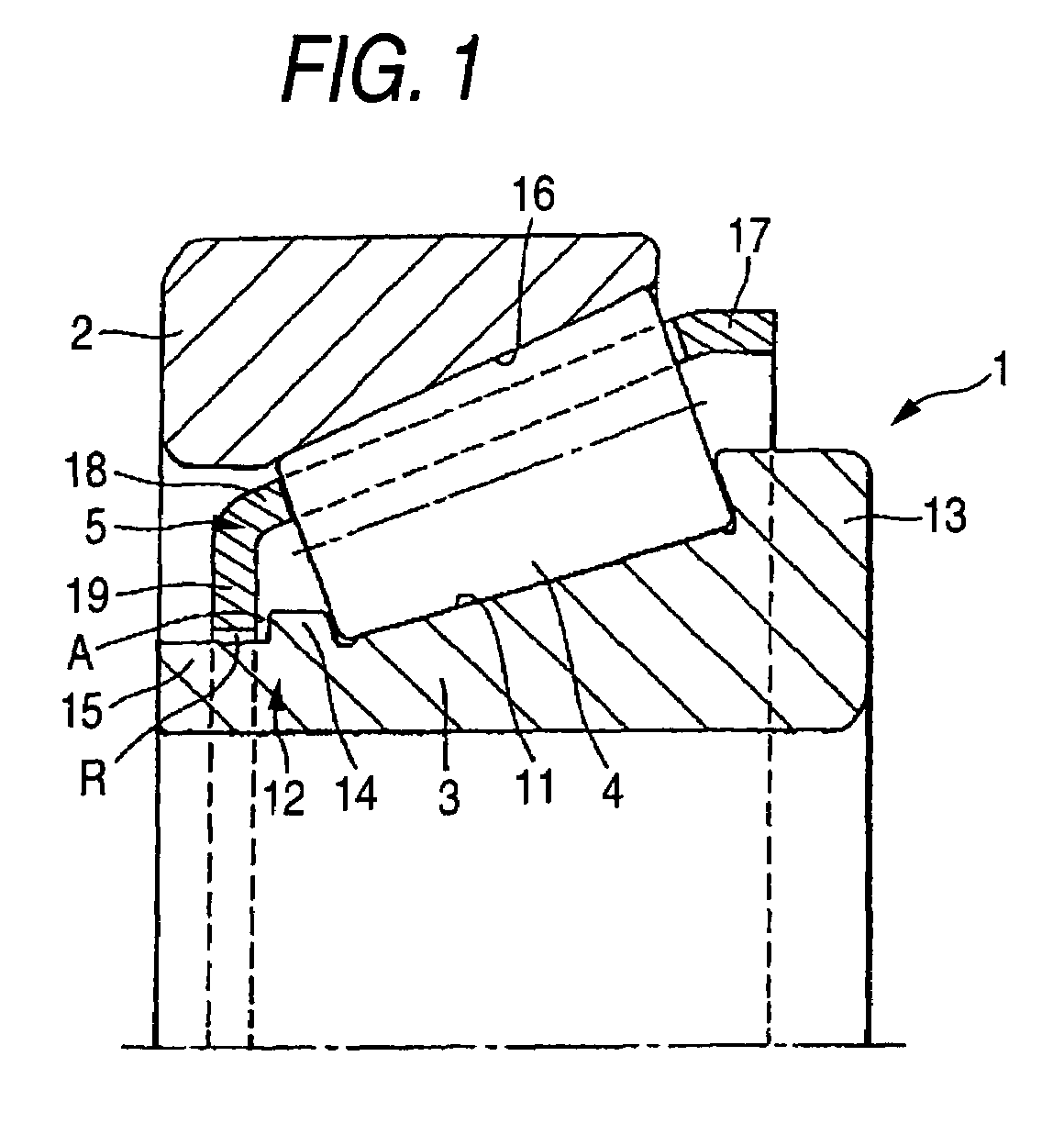

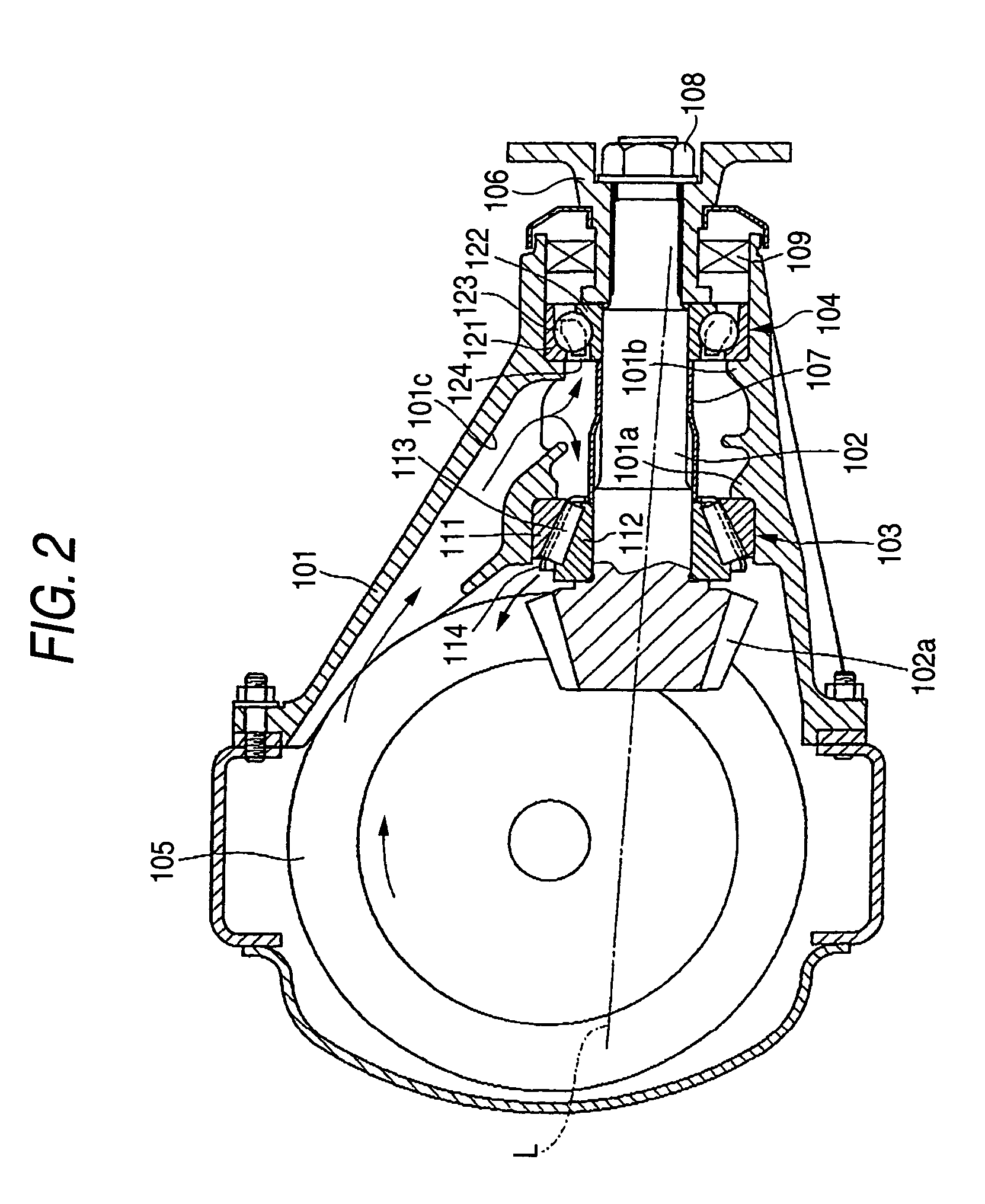

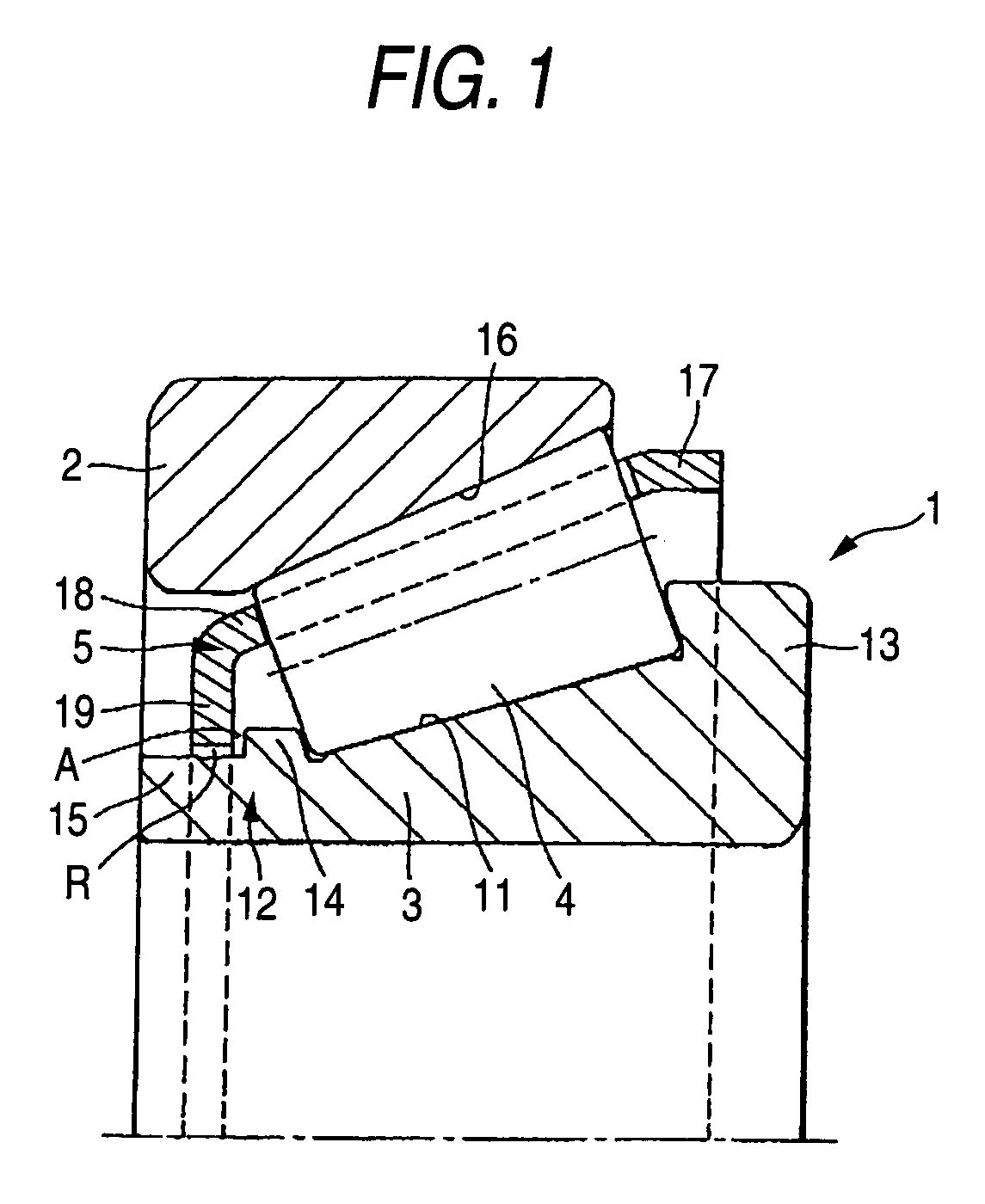

Tapered roller bearing

A tapered roller bearing comprises an outer race, an inner race, a plurality of tapered rollers, and a cage. A small-diameter end portion of the inner race is formed with a small flange portion for limiting axial movement of the tapered rollers and a cylindrical portion which has a less diameter than the small flange portion and is connected to an axial outer end of the small flange portion. The cage is formed at a small-diameter end portion thereof with a bent portion which is bent inward in a radial direction. A small-diameter end portion of the cage has a bent portion which is faced to an outer surface of the cylindrical portion of the inner race with a predetermined clearance therefrom such that a labyrinth is created between the cage and the inner race.

Owner:JTEKT CORP

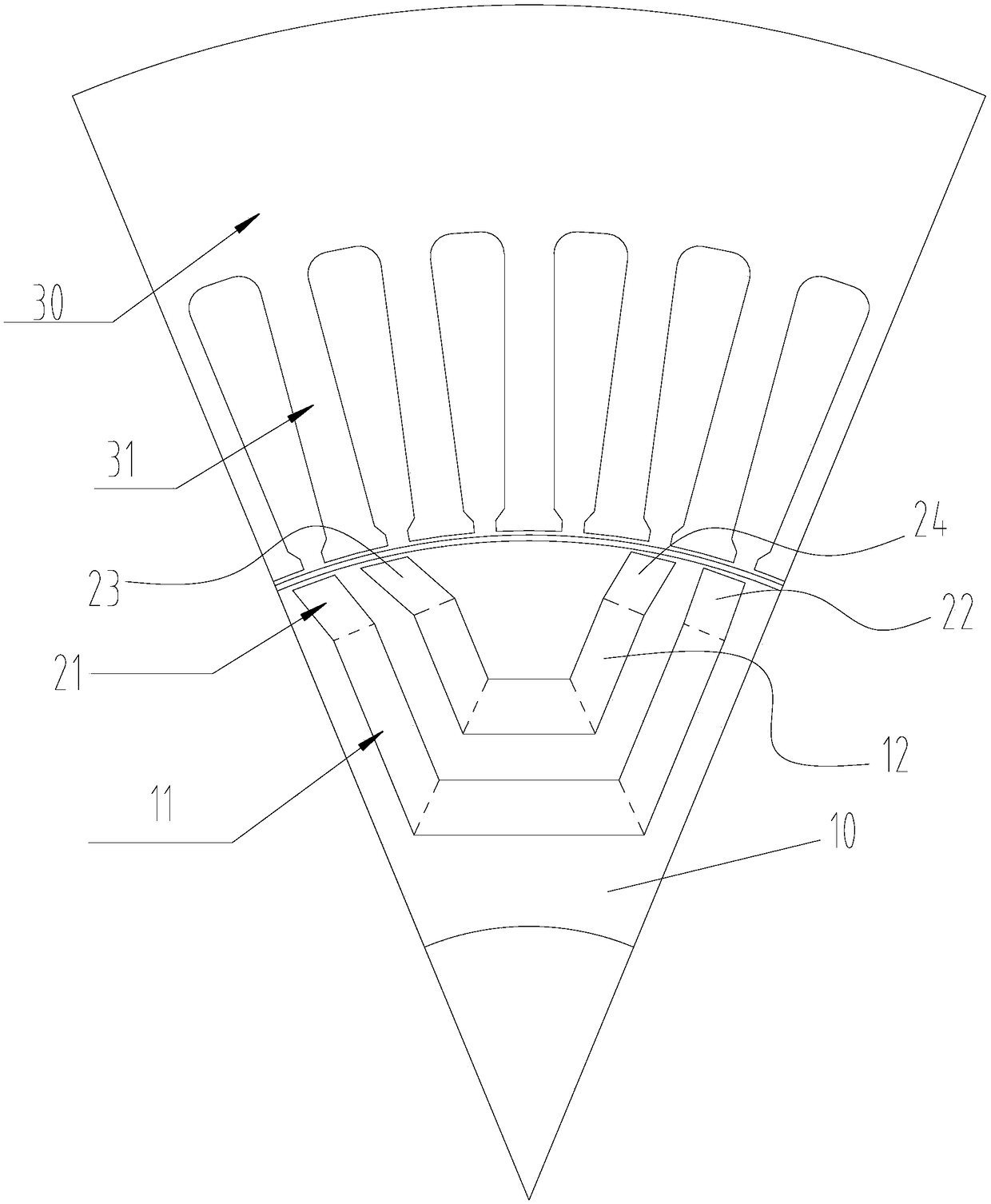

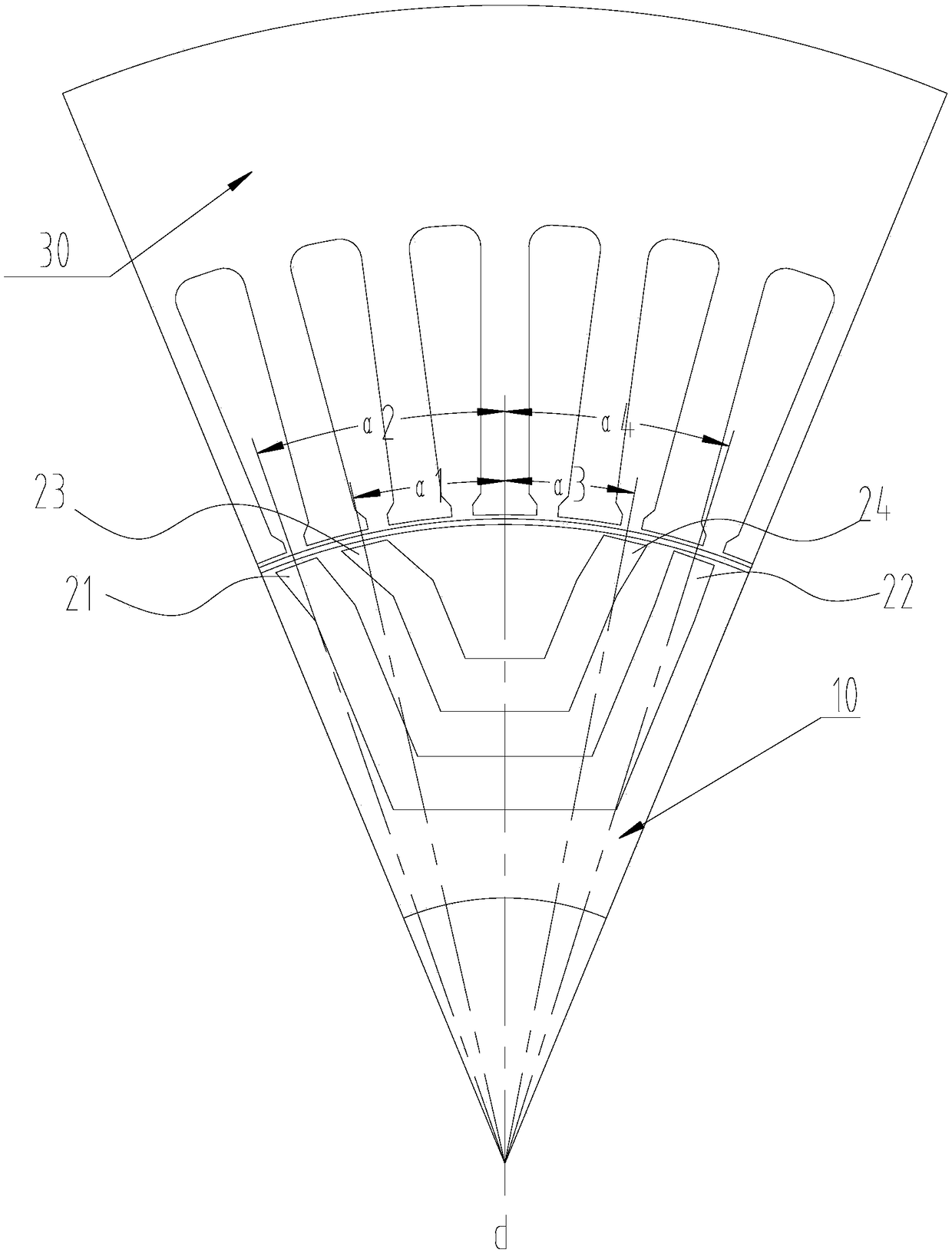

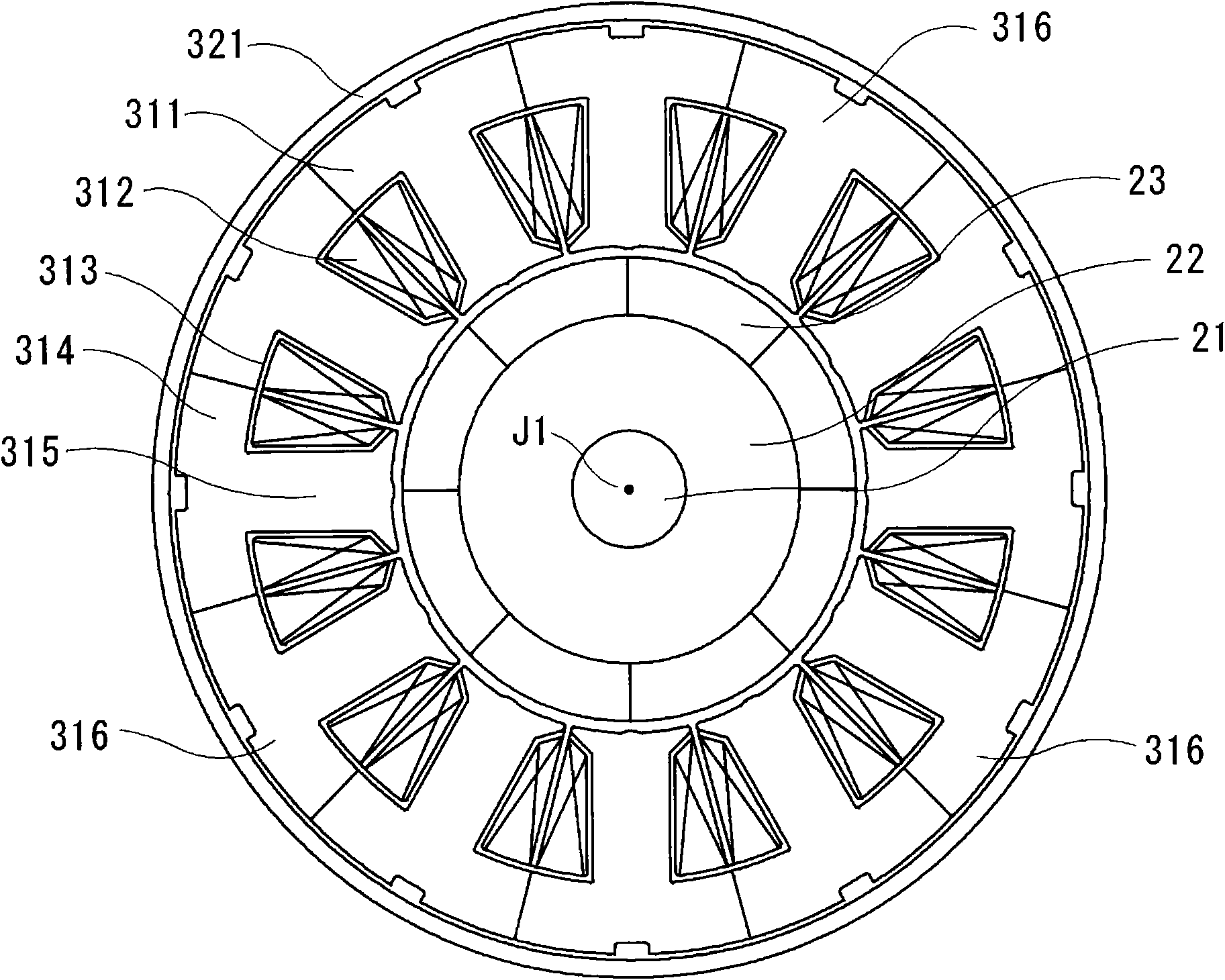

Rotor structure, permanent magnetism auxiliary synchronization magnetic resistance motor and electric vehicle

ActiveCN108321953AOptimized magnetic circuitHigh torqueMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric machinery

The invention provides a rotor structure, a permanent magnetism auxiliary synchronization magnetic resistance motor and an electric vehicle; the rotor structure comprises a rotor body having a magnetic steel slot set; the magnetic steel slot set comprises inner magnetic steel slots; the rotor body is also provided with a first fold slot and a second fold slot; the first fold slot is connected witha first end of the inner magnetic steel slot; the geometric center line of the first fold slot in the length direction and that of the first end of the inner magnetic steel slot in the length direction form a first inclined angle; the second fold slot is connected with a second end of the inner magnetic steel slot; the geometric center line of the second fold slot in the length direction and thatof the second end of the inner magnetic steel slot in the length direction form a second inclined angle; the first and second inclined angles are different. The first and second inclined angles are set to be different, thus optimizing the rotor structure magnetic path, increasing the rotor structure torque, reducing rotation pulse torque, improving the motor anti-demagnetism capability, and improving the motor efficiency.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

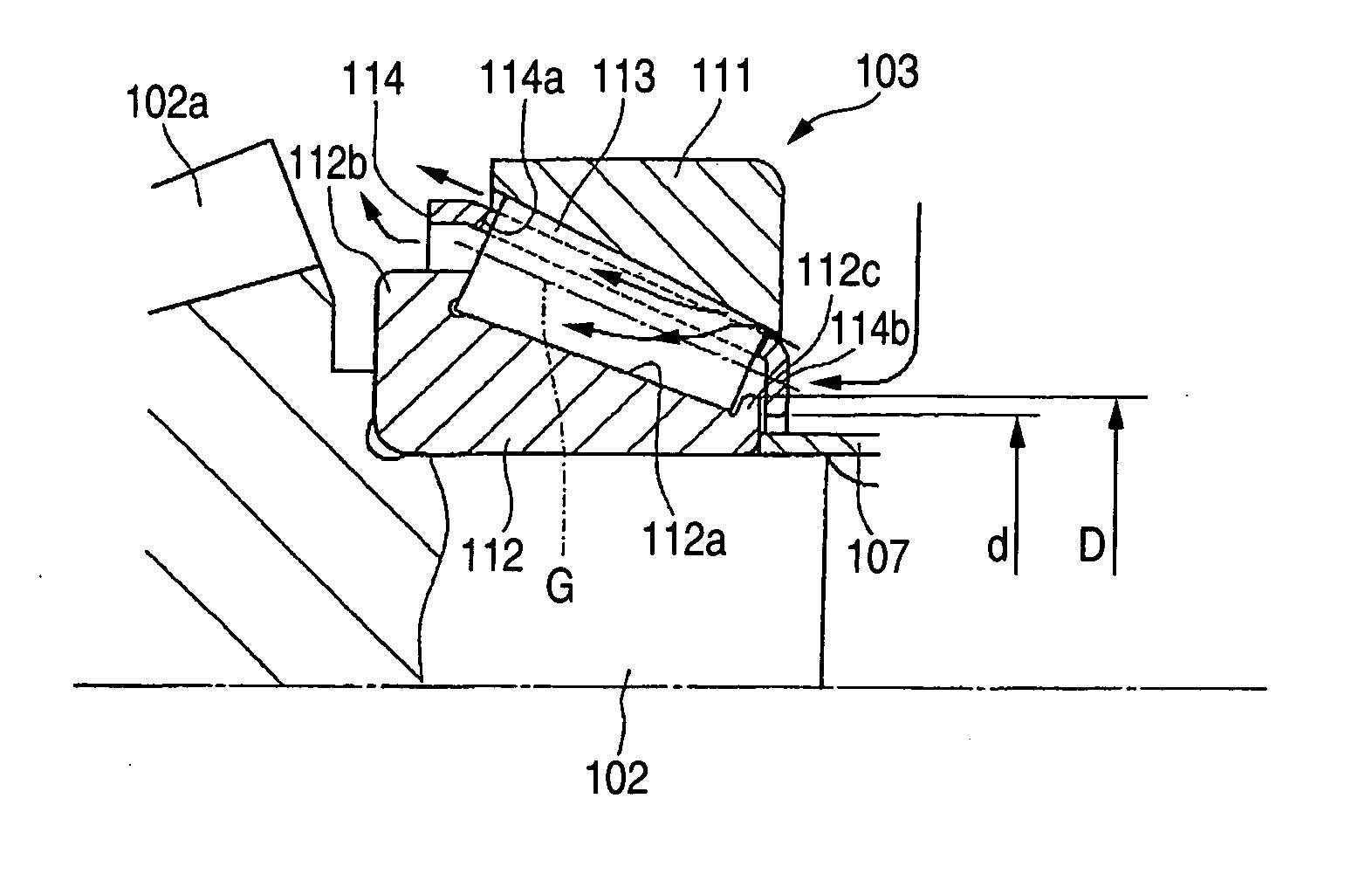

Tapered roller bearing

A tapered roller bearing comprises an outer race, an inner race, a plurality of tapered rollers, and a cage. A small-diameter end portion of the inner race is formed with a small flange portion for limiting axial movement of the tapered rollers and a cylindrical portion which has a less diameter than the small flange portion and is connected to an axial outer end of the small flange portion. The cage is formed at a small-diameter end portion thereof with a bent portion which is bent inward in a radial direction. A small-diameter end portion of the cage has a bent portion which is faced to an outer surface of the cylindrical portion of the inner race with a predetermined clearance therefrom such that a labyrinth is created between the cage and the inner race.

Owner:JTEKT CORP

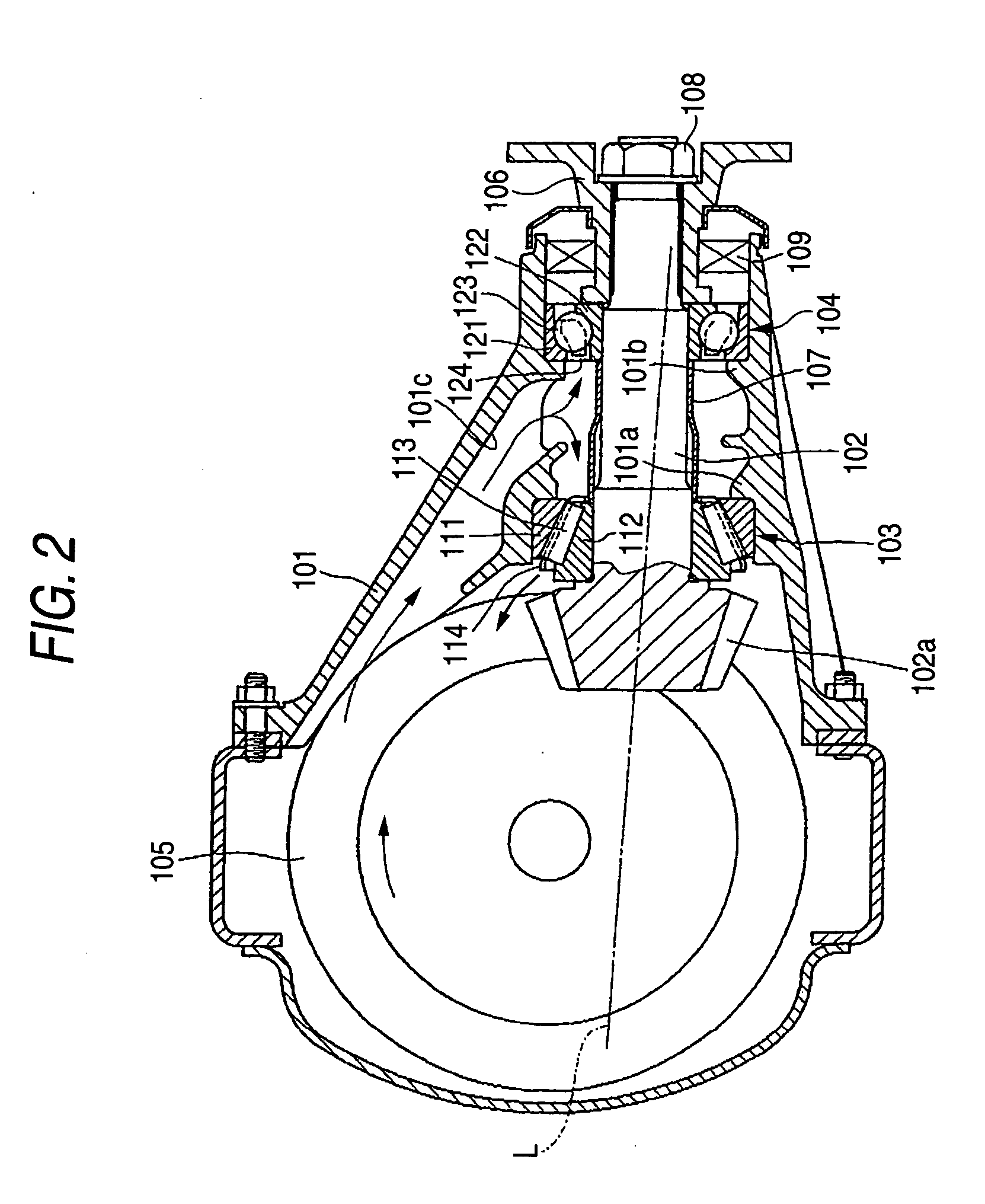

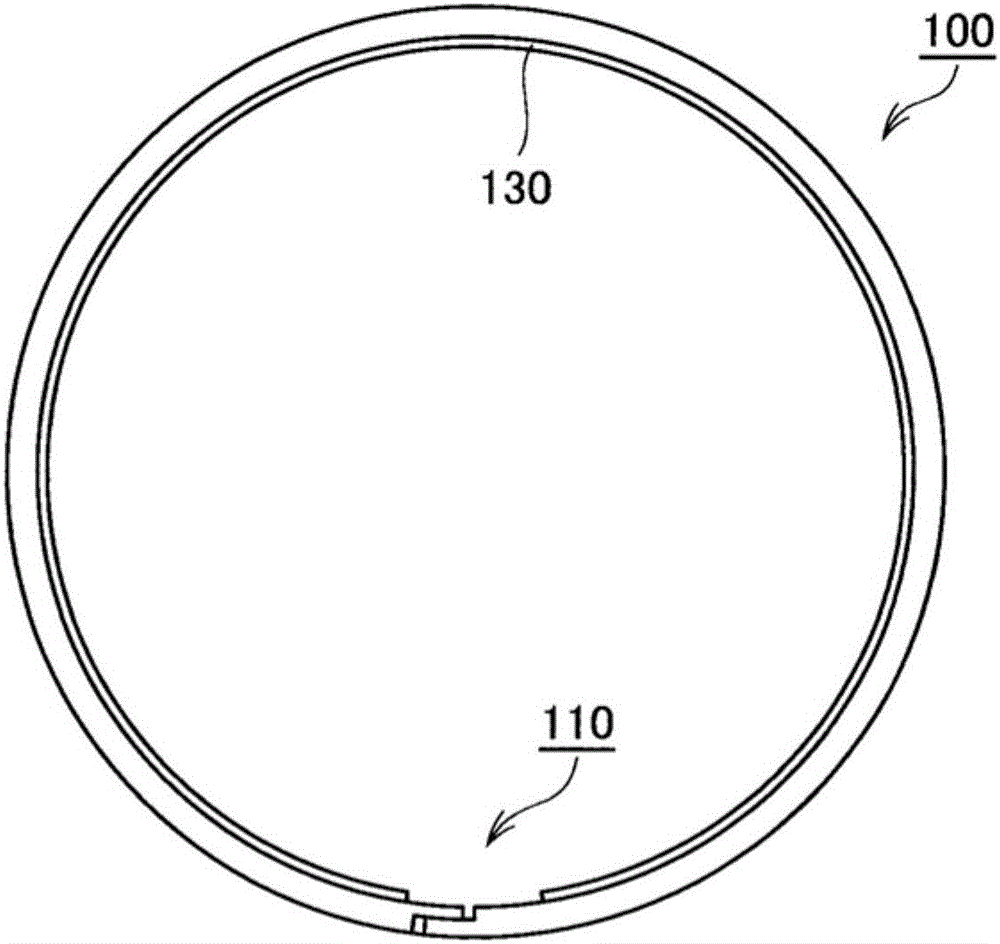

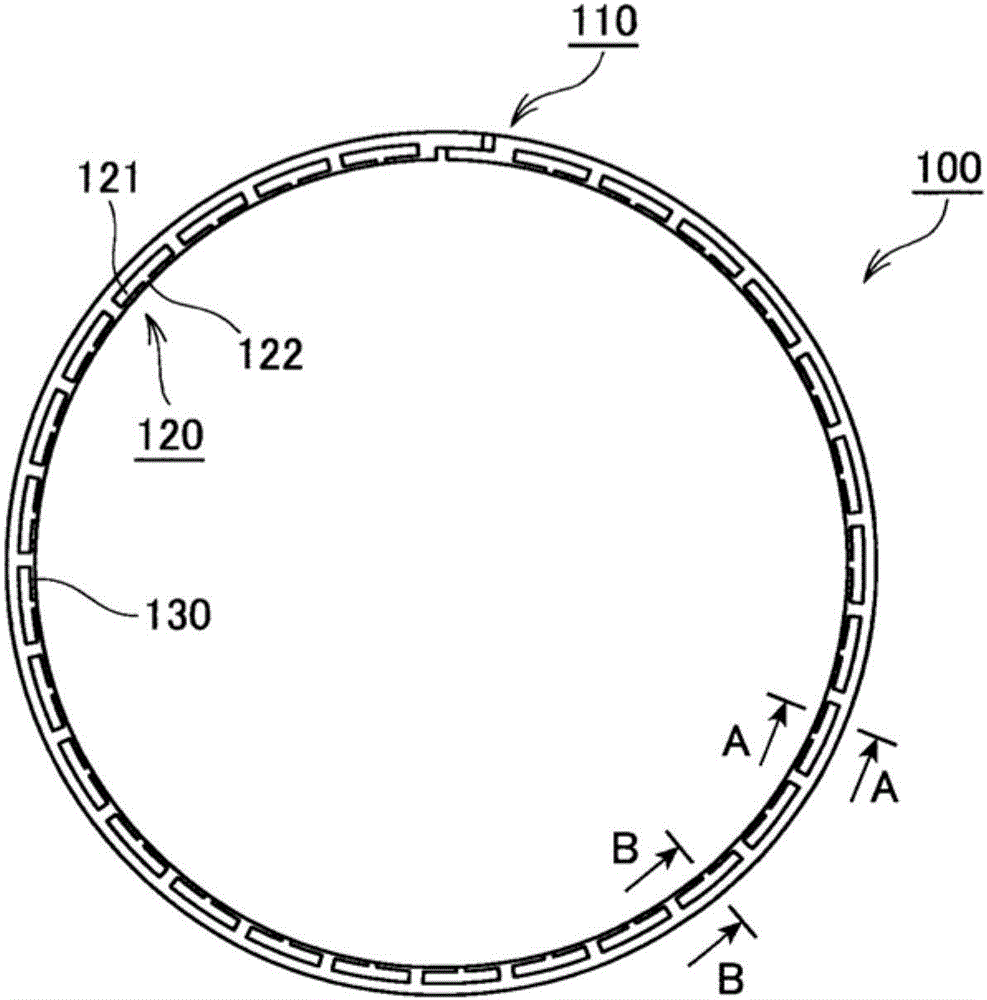

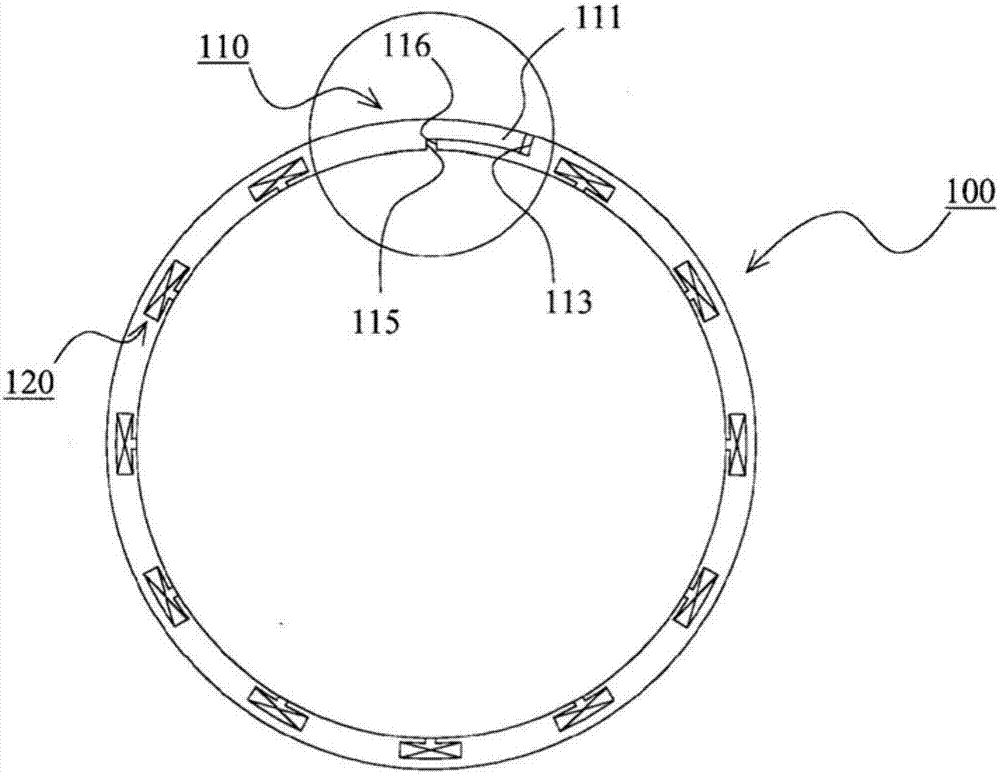

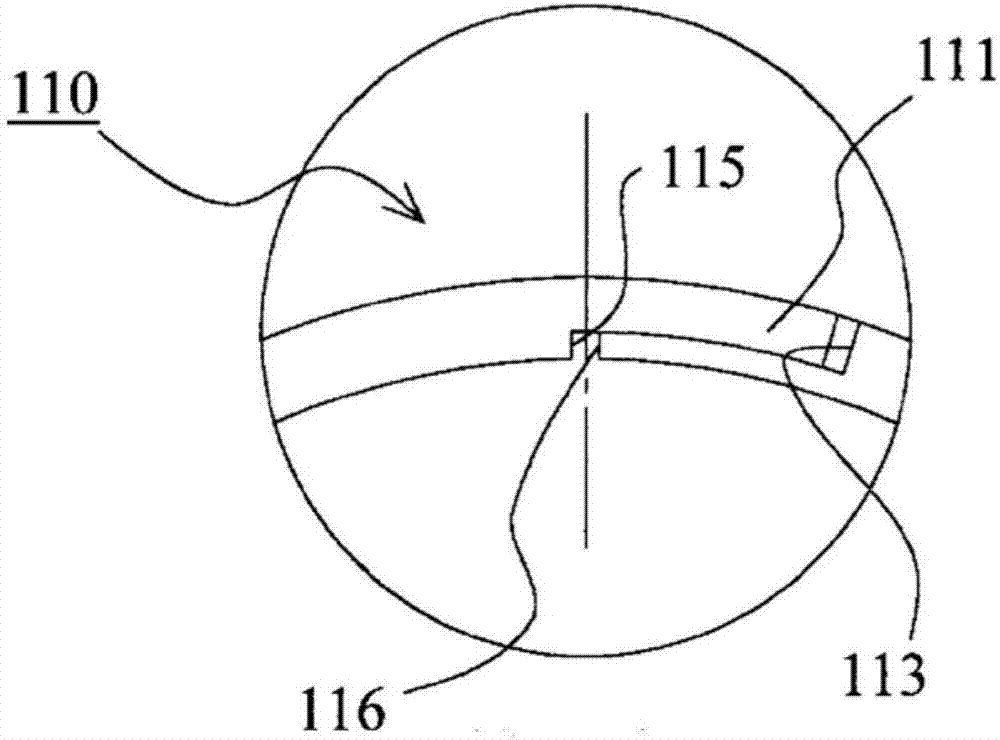

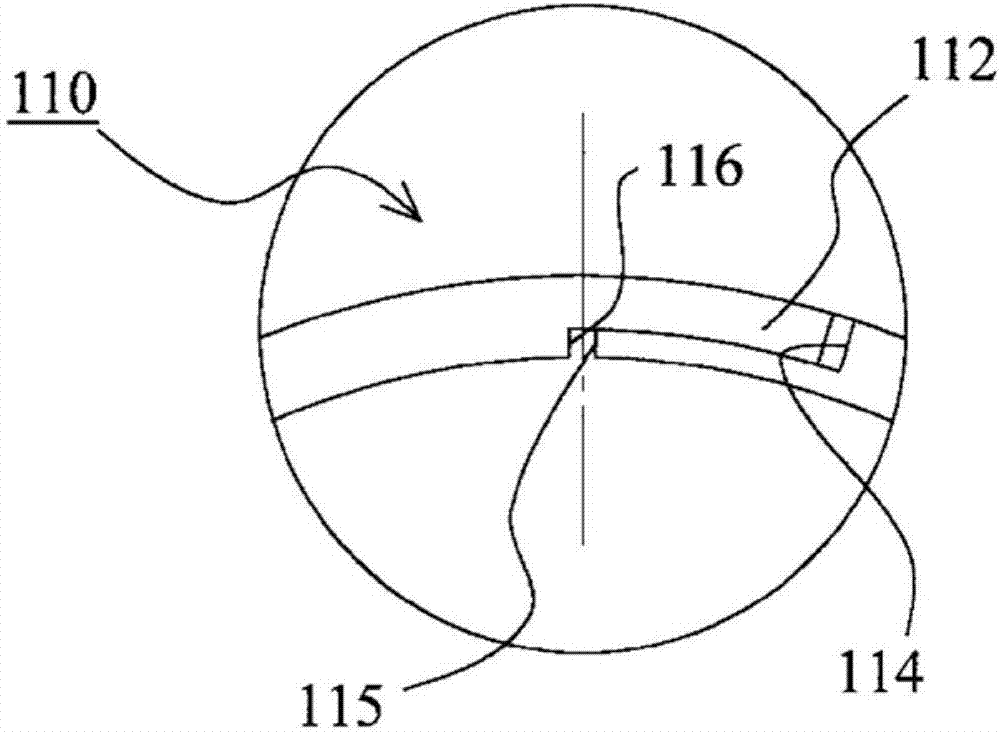

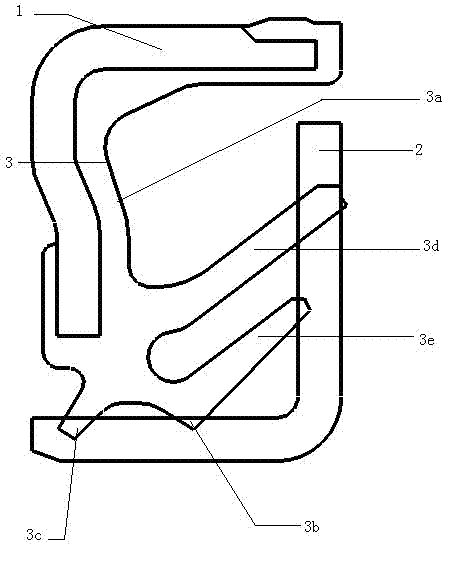

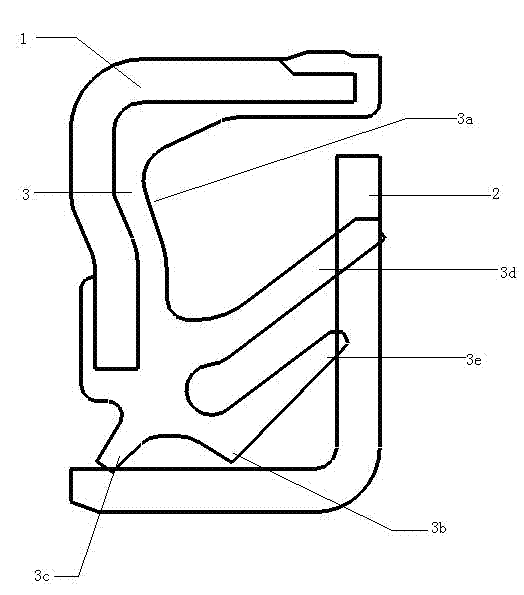

Seal ring

InactiveCN105917151AContainment leakReduce rotational torqueEngine sealsSealingEngineeringBiomedical engineering

Provided is a sealing device configured so that, irrespective of a rotational direction, rotational torque can be reduced and the leakage of sealed fluid can be prevented. The seal ring is characterized in that in the seal ring (100) sliding relative to the low pressure-side sidewall surface of an annular groove, a dynamic pressure generation groove (120) is formed in the slide surface which slides relative to the sidewall surface, the dynamic pressure generation groove (120) comprises a first groove (121) circumferentially extending with a constant radial width and a second groove (122) extending from the circumferential center of the first groove (121) up to the inner peripheral surface thereof and conducting sealed fluid into the first groove (121), and the first groove (121) is provided at a position within a slide region sliding relative to the sidewall surface.

Owner:NOK CORP +1

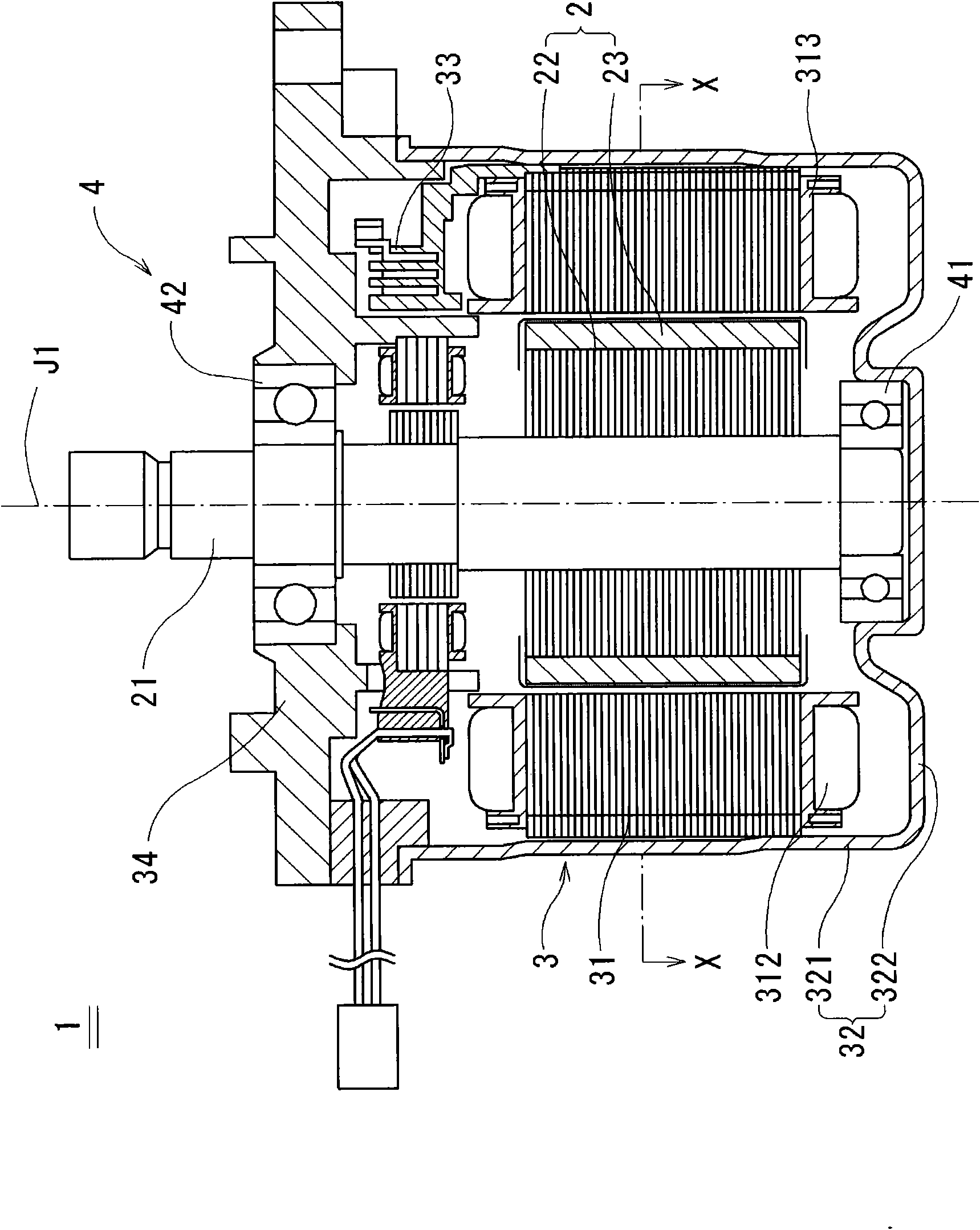

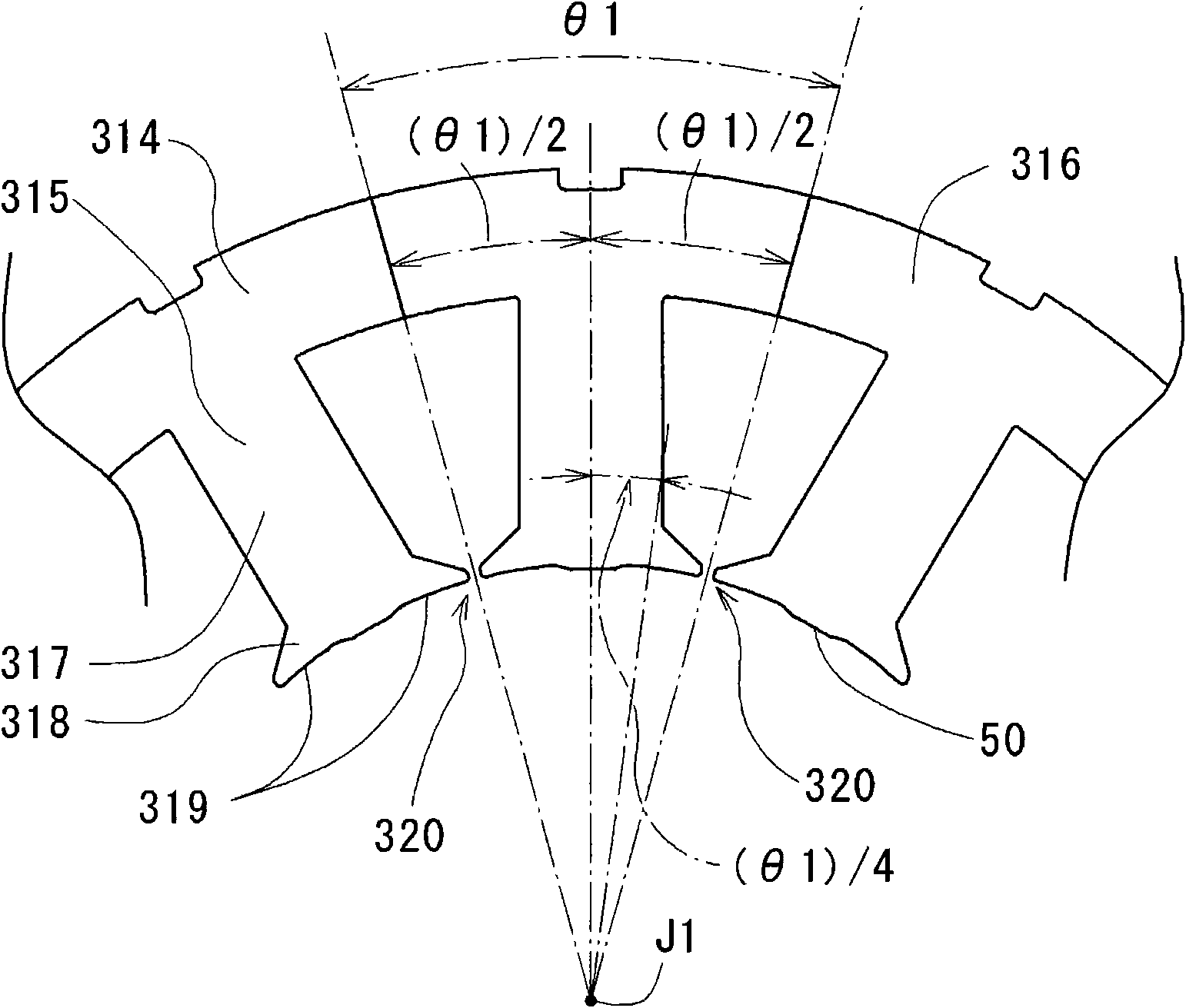

Motor

InactiveCN101978574AReduce rotational torqueReduce cogging torqueMagnetic circuit rotating partsMagnetic circuit stationary partsRotor magnetsEngineering

A protrusion (50) is arranged on an opposing surface (319) of a teeth portion (315) to protrude toward a rotor magnet (23). The protrusion (50) is arranged substantially at the center of the opposing surface (319) in the circumferential direction. Thus, the fundamental wave of the waveform of a cogging torque generated by the slot opening (320) has a phase inverse to the phase of the waveform of a cogging torque generated by the protrusion (50). Thus, the cogging torque generated by the slot opening (320) is reduced by the cogging torque generated by the protrusion (50).

Owner:NIDEC CORP

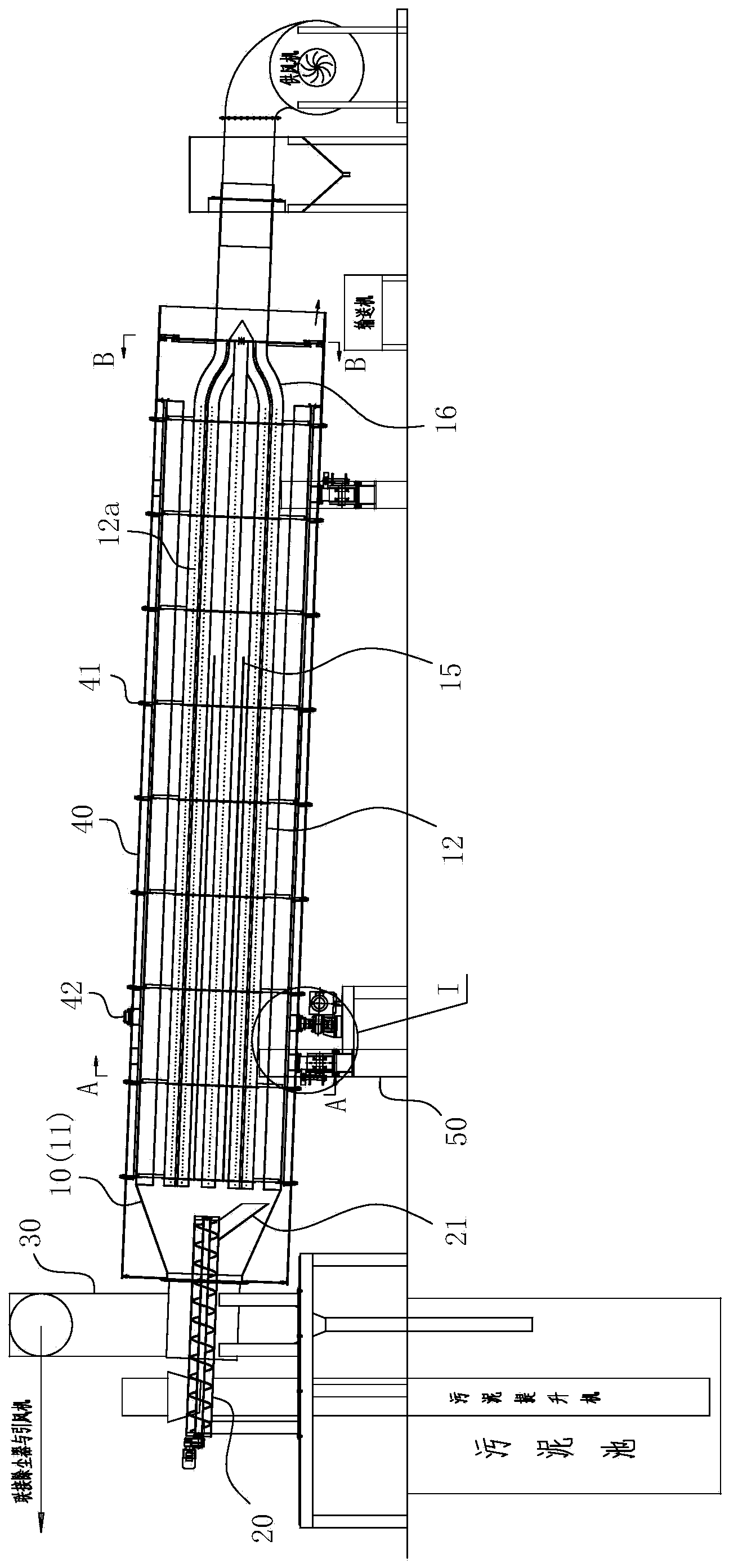

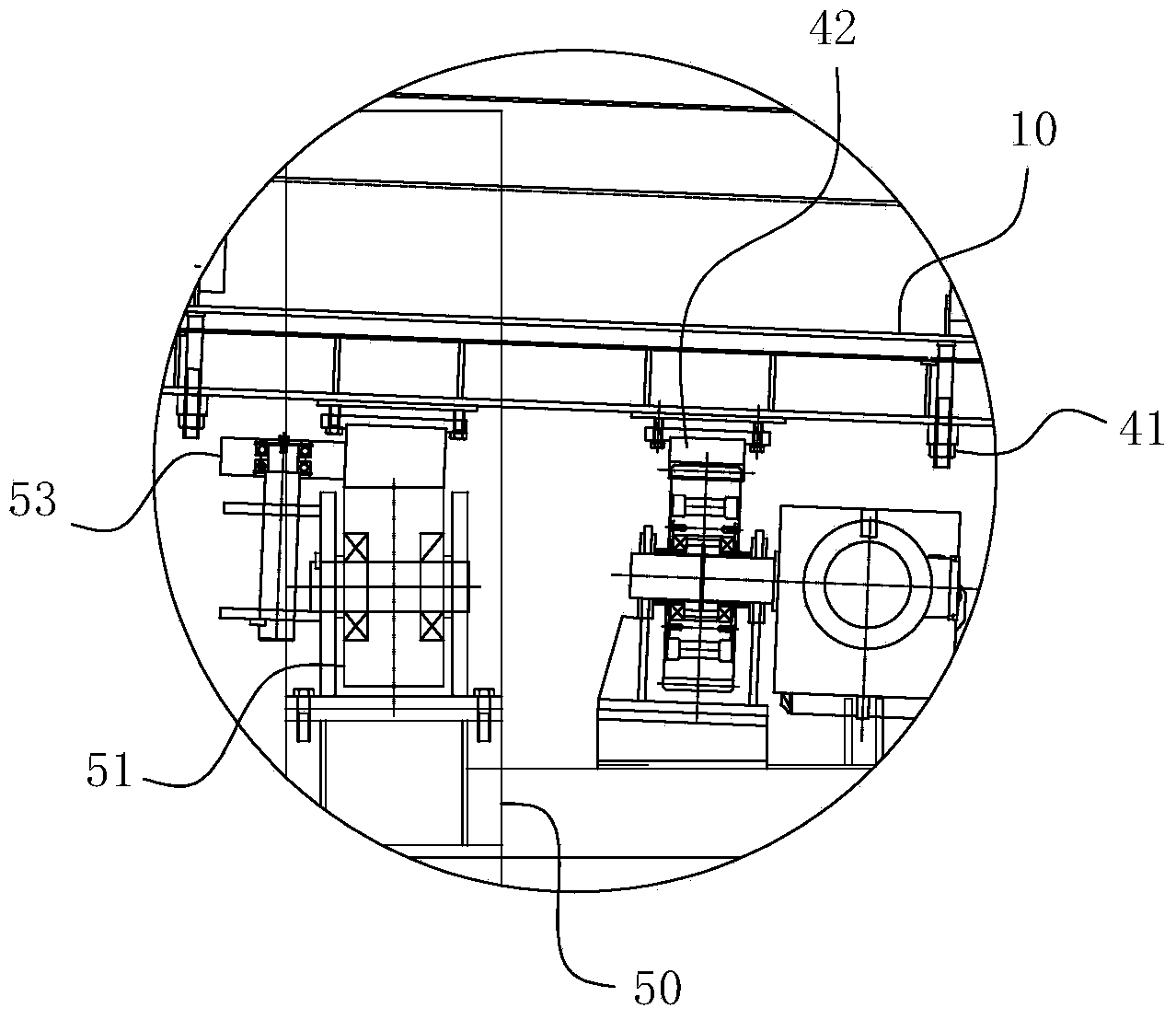

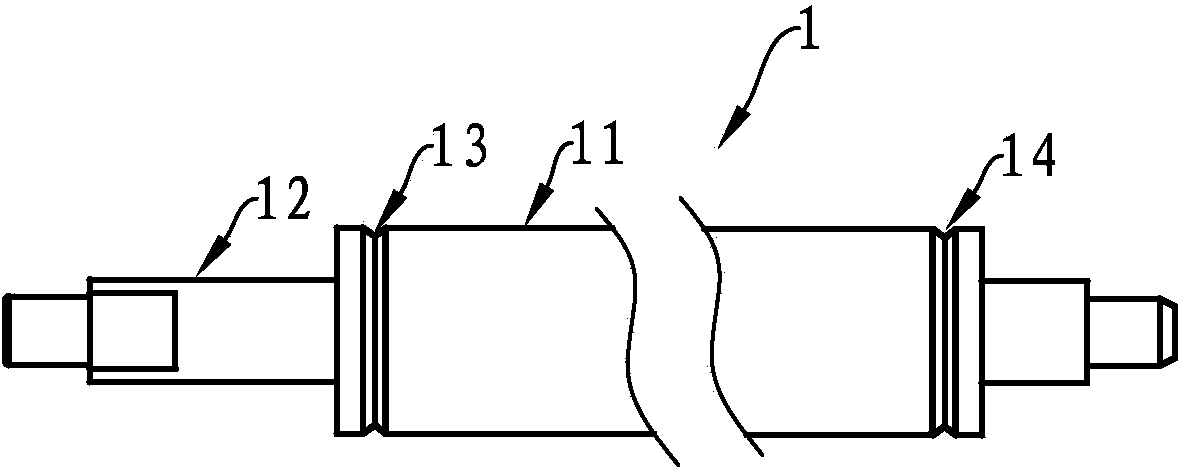

Sludge drying equipment

InactiveCN103588377ASolve the problem of fast bakingThe rapid baking problem reachesSludge treatment by de-watering/drying/thickeningSludgeWaste treatment

The invention belongs to the field of solid waste treatment, in particular relates to sludge drying equipment based on drying treatment of urban sludge. The sludge drying equipment comprises a drum with an inclined axis, and a driving assembly for driving the drum to rotate along the axis of the drum, wherein the drum is provided with an accommodating cavity for accommodating sludge; the accommodating cavity is arranged in the axial direction of the drum and in a penetrating manner; the feeding end of the accommodating cavity is arranged at the high end part of the drum, and the discharging end of the accommodating cavity is arranged at the lower end part of the drum; the sludge drying equipment further comprises heat supply pipes for supplying heat to the accommodating cavity; the heat supply pipes are arranged in the accommodating cavity; two or more heat supply pipes are arranged in the axial direction of the accommodating cavity; air vent holes communicated with the cavities of the heat supply pipes and the accommodating cavity are formed in the walls of the heat supply pipes. The heat supply pipes of the invention are used as stirring pipes of the whole accommodating cavity while performing the functions of supplying heat and drying. The sludge drying equipment has the advantages of simple structure, easy and reliable operation, effective achievement of purpose of drying existing wet sludge and extremely-high drying efficiency.

Owner:HEFEI HUANKUN SLUDGE DRYING EQUIP

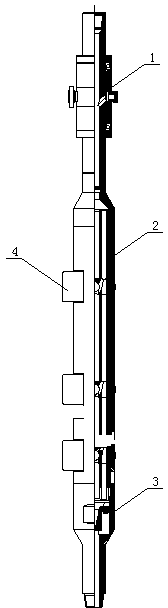

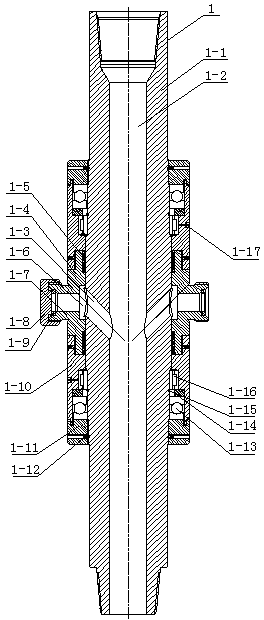

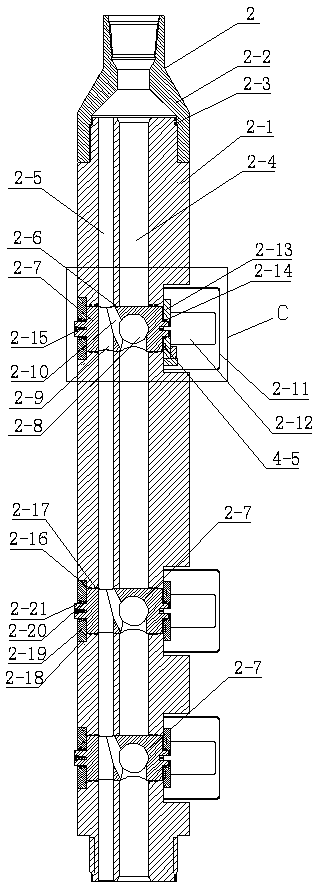

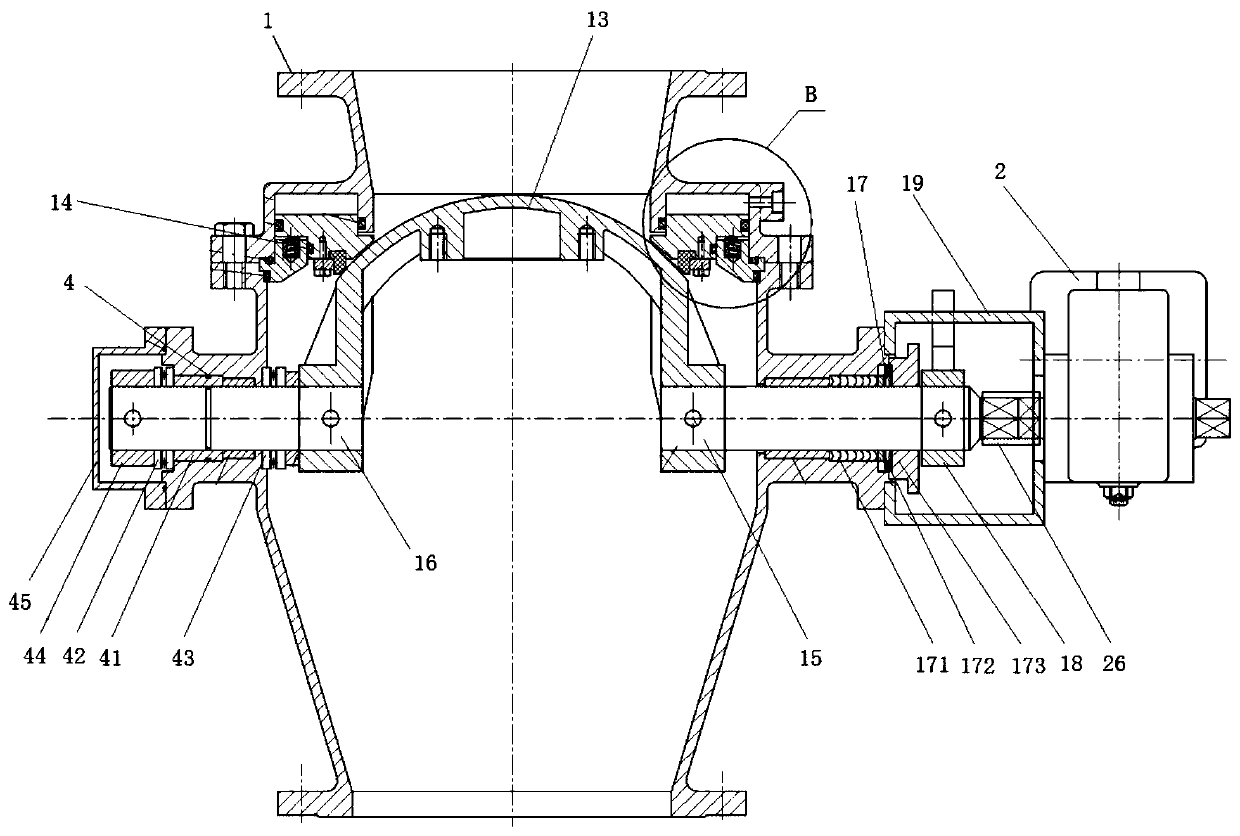

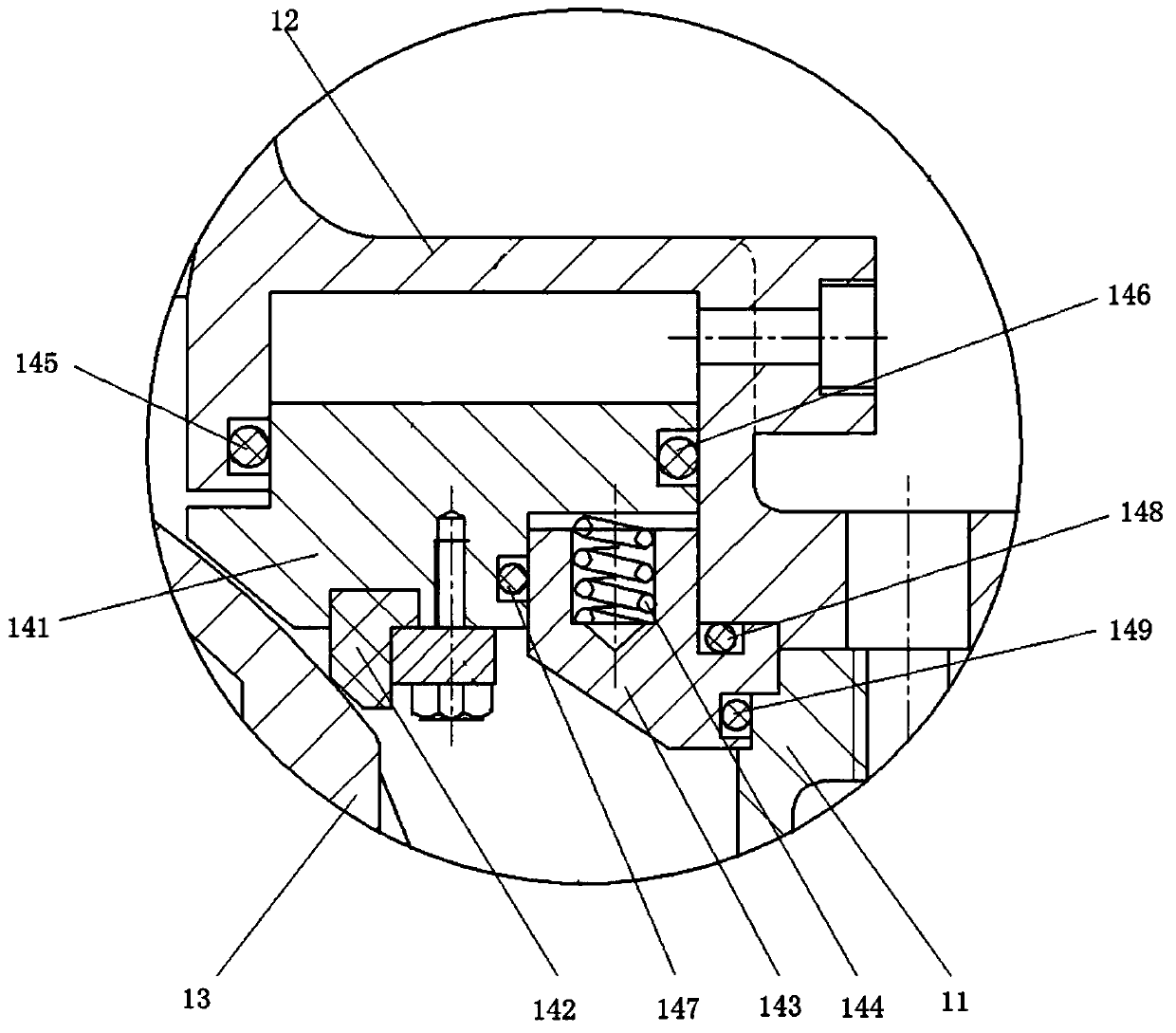

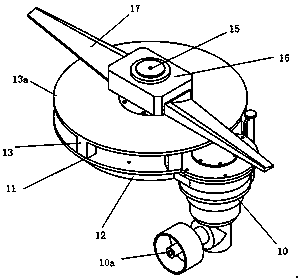

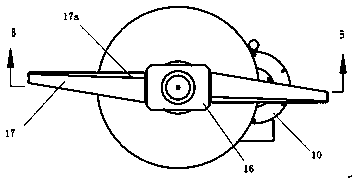

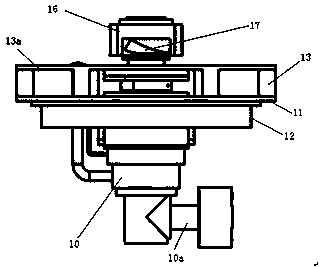

Wireless remote-control automatic-control rotary cement head

InactiveCN104929569AImprove operational safetySimple structural designSealing/packingAutomatic controlRemote control

The invention provides a wireless remote-control automatic-control rotary cement head, and relates to the field of oil development and well drilling, in particular to a cement head used during drilled well cementing. The wireless remote-control automatic-control rotary cement head comprises a rotary injection head, a cement head body and a position indicator which are sequentially connected to one another from top to bottom; and a wireless remote-control system is arranged on the cement head body. A process of opening a stop pin cock and feeding a rubber plug or a setting ball can be finished automatically in a wireless remote-control manner, torque can be transmitted to a lower drill in a rotating manner, so that the lower drill can rotate, and the well cementation quality is improved.

Owner:YANGZHOU CHICHENG GASOLINEEUM MACHINERY

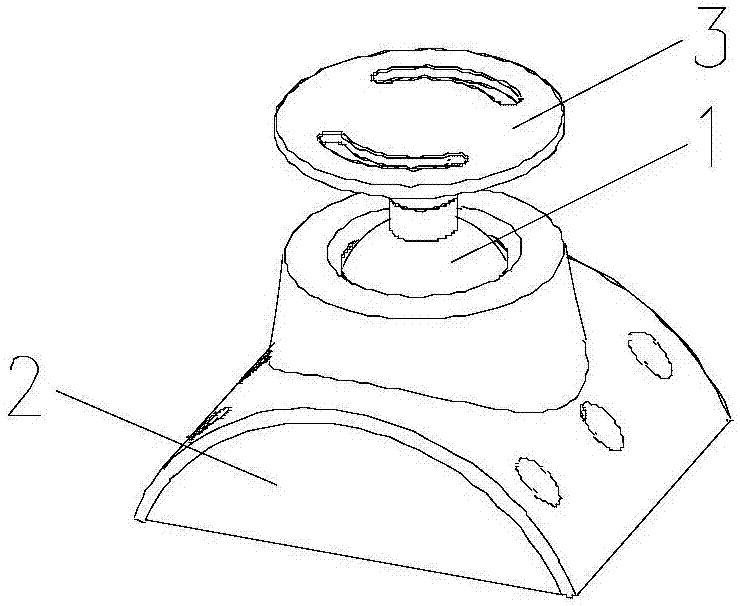

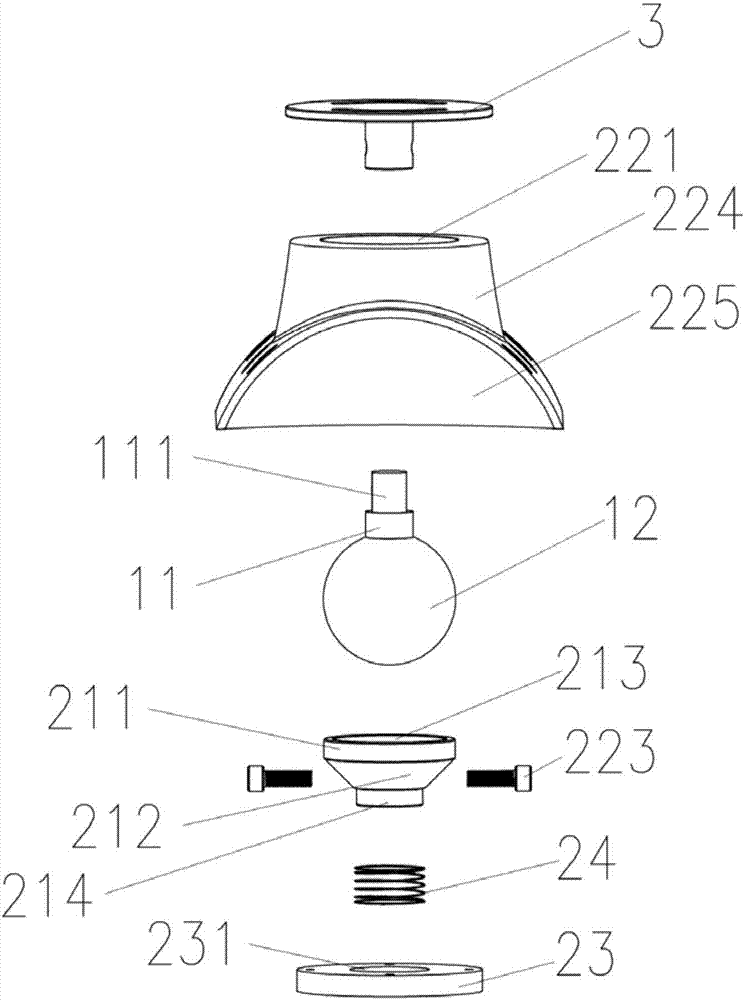

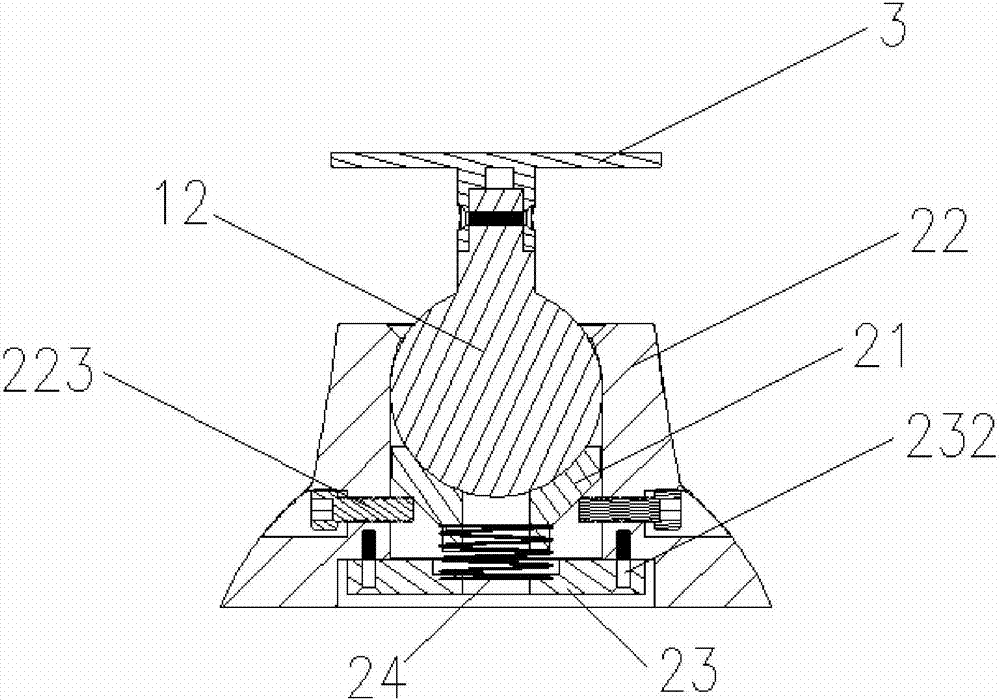

Multidirectional rotary joint and license plate recognition device

PendingCN107120502AEasy to adjustSave manpower and material resourcesRoad vehicles traffic controlStands/trestlesMaterial resourcesIdentification device

The invention provides a multidirectional rotary joint and a license plate recognition device. The multidirectional rotary joint comprises a rotary mechanism and a fixed mechanism which sleeves outside the rotary mechanism, wherein the rotary mechanism comprises a rotary shaft and a rotary ball head fixedly arranged at one end of the rotary shaft; the fixed mechanism comprises a supporting base and a pedestal; the supporting base is arranged in an accommodating cavity of the pedestal in a sliding sleeved mode; and the rotary ball head is arranged between the top of the accommodating cavity and the supporting base. The license plate recognition device comprises a license plate recognition camera, the multidirectional rotary joint, a display-control all-in-one machine and a stand column which are fixedly arranged from top to bottom, and further comprises a light supplementing lamp which is arranged in the display-control all-in-one machine or on the stand column, wherein the license plate recognition camera is fixedly connected with the other end of the rotary shaft; and the pedestal of the multidirectional rotary joint is fixedly connected with the display-control all-in-one machine. According to the multidirectional rotary joint and the license plate recognition device provided by the invention, regulation of the license plate recognition camera is simple and convenient, and manpower and material resources are saved.

Owner:北京易泊时代科技有限公司

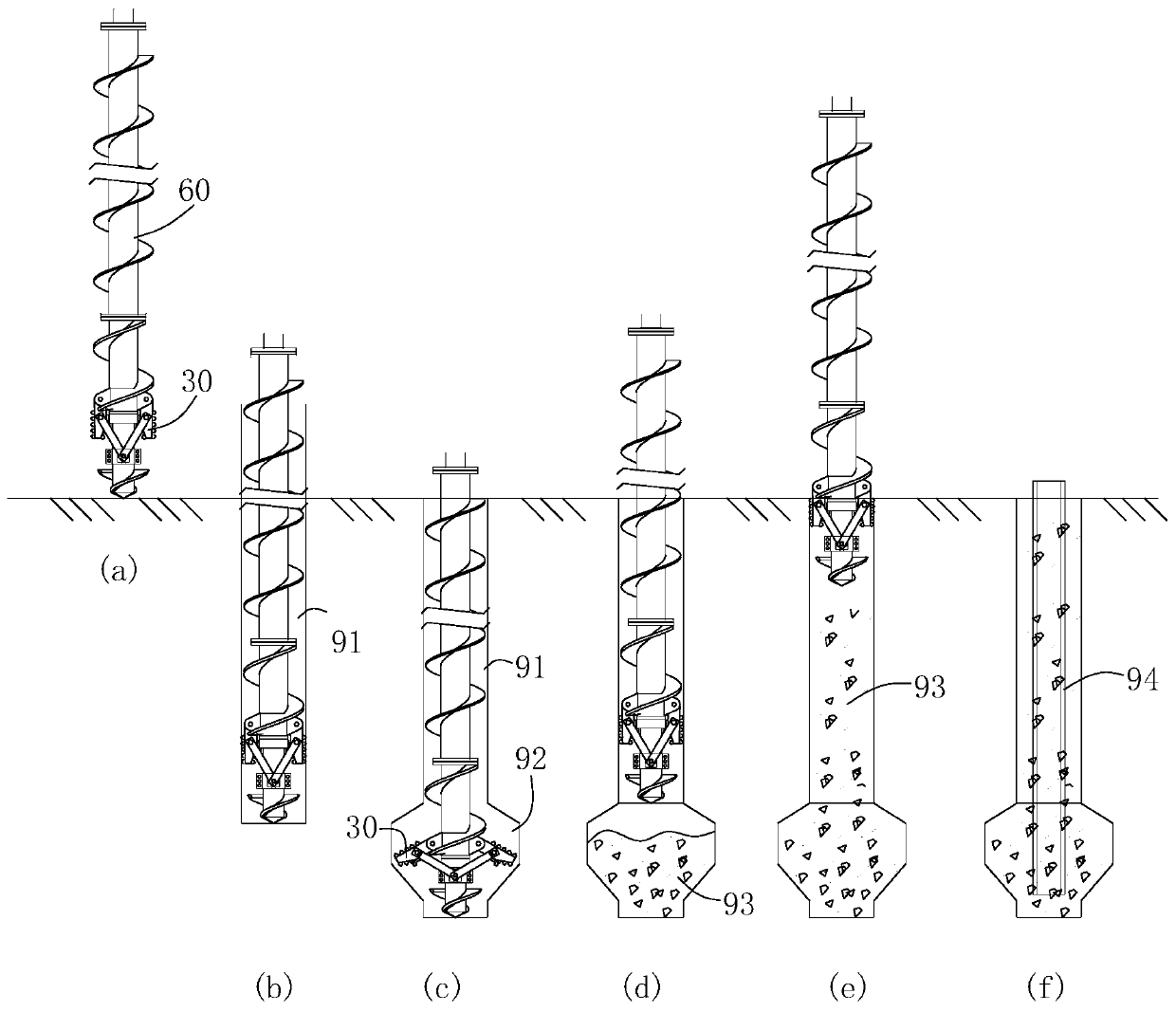

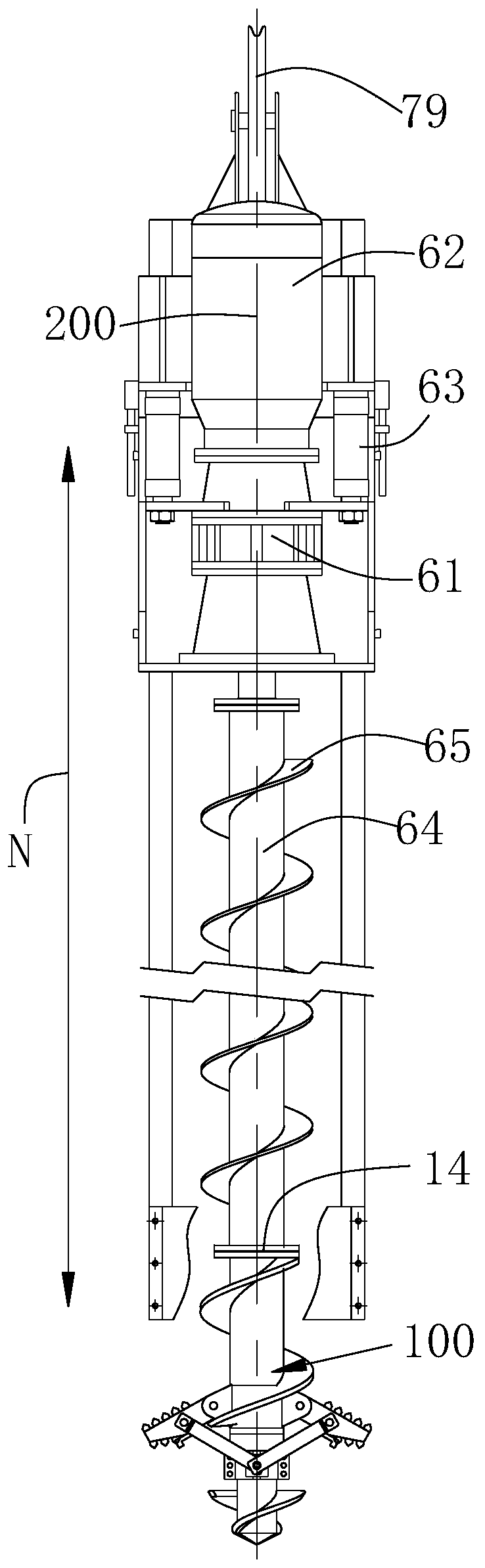

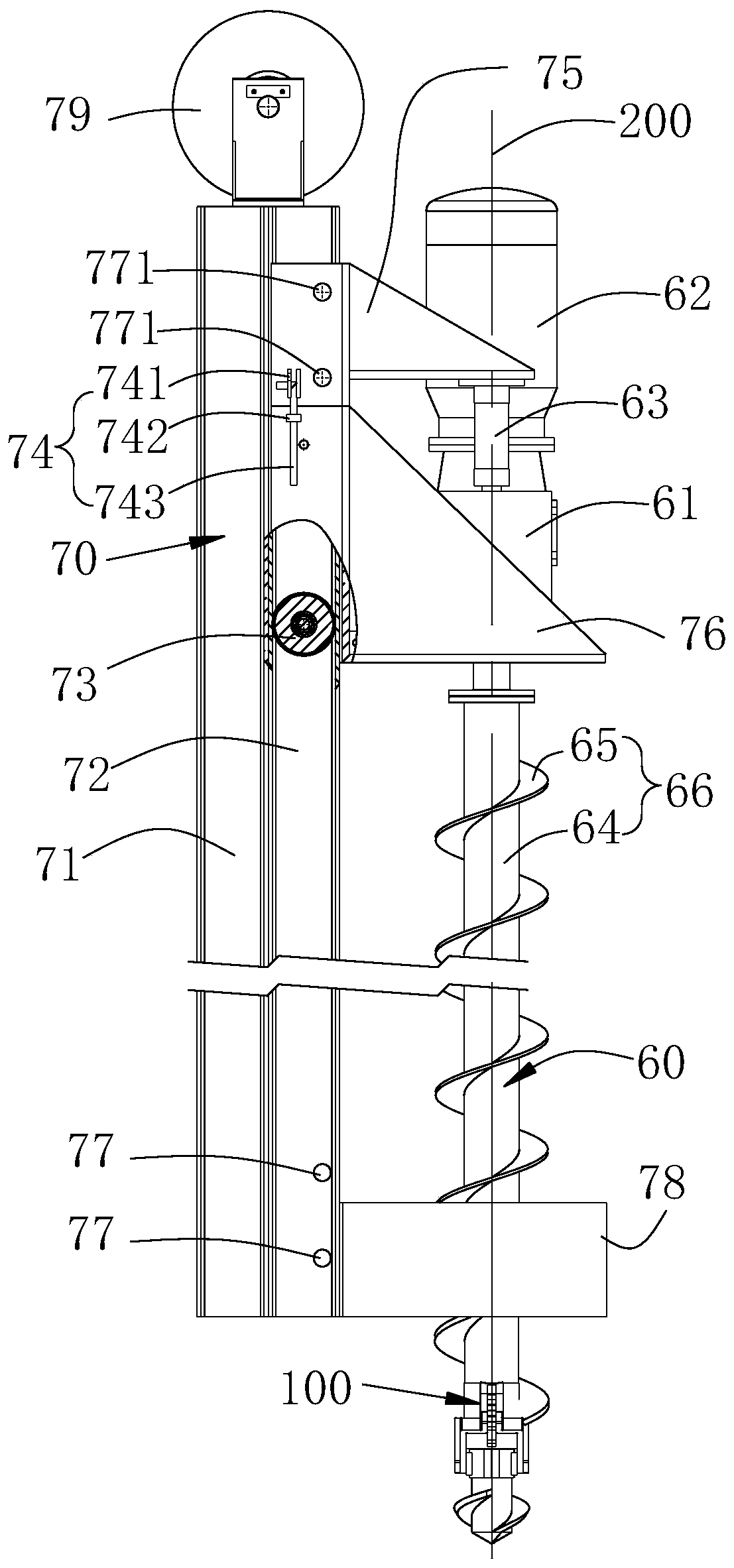

Variable cross-section spiral drilling tool and construction method of variable cross-section cast-in-situ bored pile

PendingCN109736715AHigh precisionFirmly connectedDrill bitsDrilling rodsArchitectural engineeringHelix

The invention discloses a variable cross-section spiral drilling tool which comprises a guiding device and a spiral drilling rod installed on the guiding device, the spiral drilling rod comprises a spiral rod and a drill bit portion installed at the bottom end, the drill bit portion comprises an outer sleeve, a guiding rod, a connecting rod and an expanding head blade, and one end of the outer sleeve is fixedly installed at the bottom end of the spiral rod; the guide rod is sleeved by the outer sleeve, and one end of the guide rod extends out of the outer sleeve to form a drill bit; one end ofthe expanding head blade is hinged to the outer sleeve, one end of the connecting rod is hinged to the guide rod, and the other end of the connecting rod is hinged to the expanding head blade; and when the guiding rod moves along the axis direction, the expanding head blade is unfolded or folded. The invention further discloses a construction method for a variable cross-section cast-in-situ boredpile by utilizing the variable cross-section spiral drilling tool. The drilling tool integrates high efficiency and rapidness, integrates drilling, chambering, pouring and detection, and has good operation performance. The construction method has the advantages of high efficiency and high construction precision.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

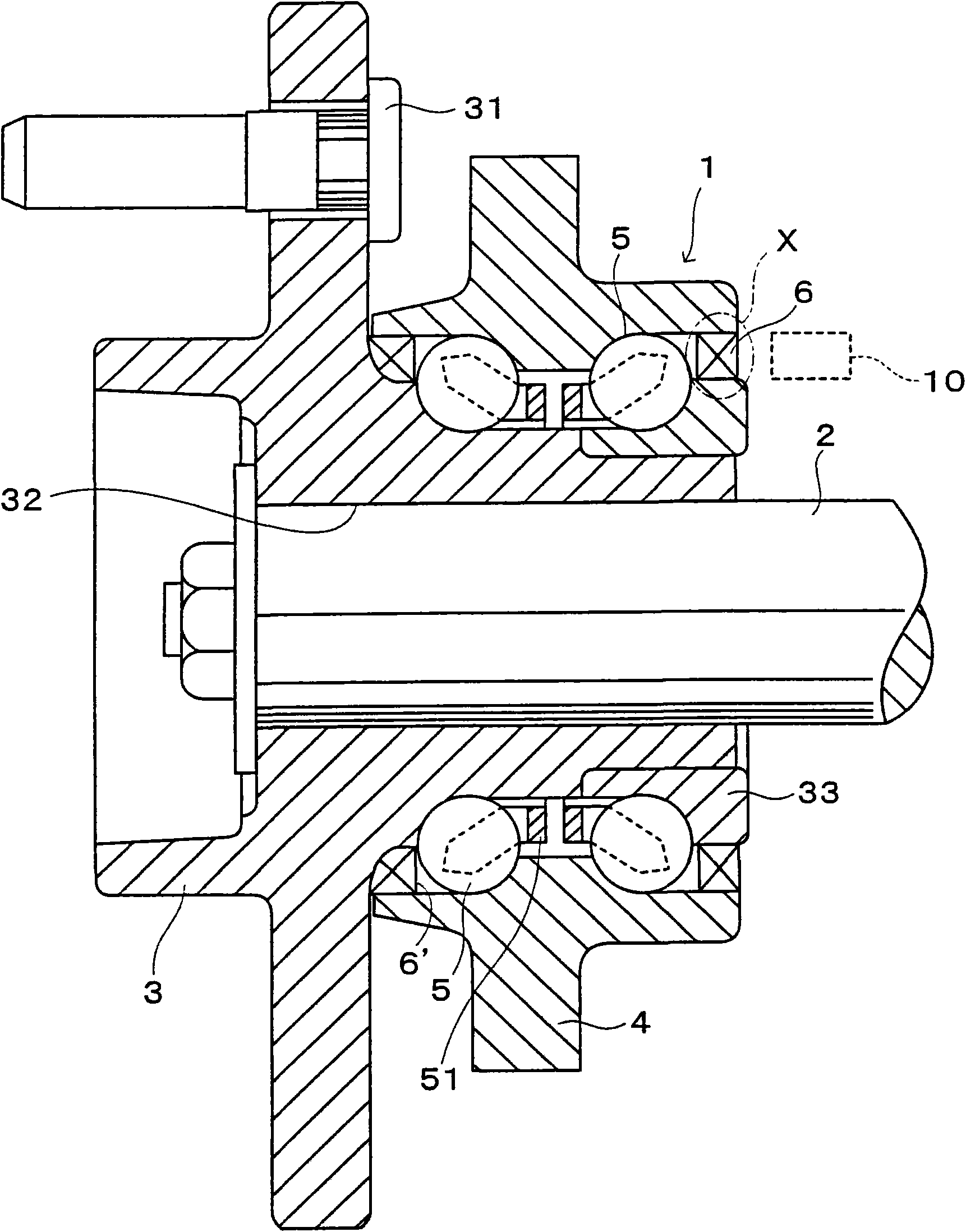

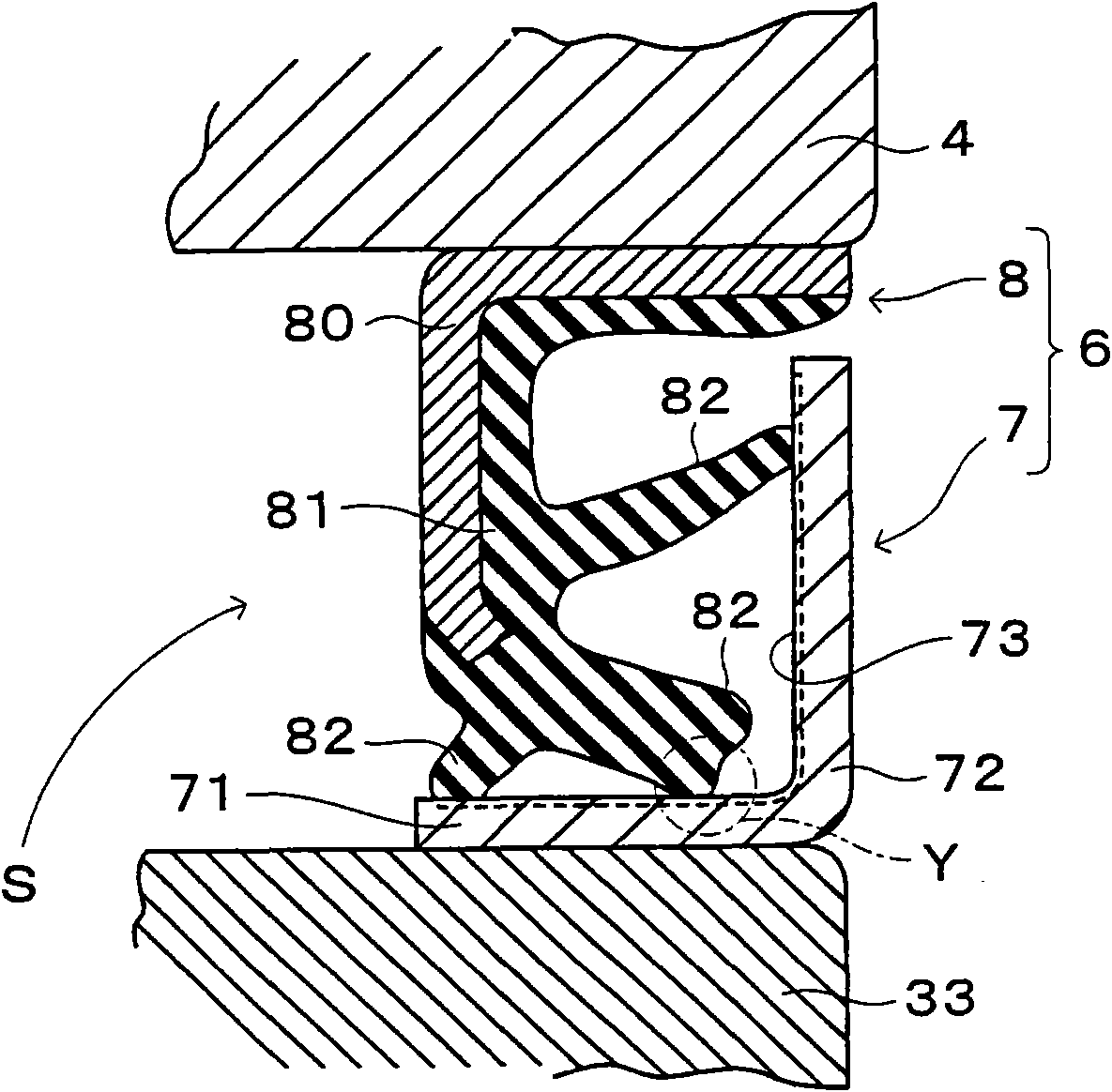

Sealing device

ActiveCN101660608AReduce rotational torqueLow heating temperatureEngine sealsRolling contact bearingsMechanical engineeringRoot mean square

A sealing device for sealing space between two members concentrically and relatively rotating comprising a core member fixedly fitted into one of the two members, a metal slinger fixedly fitted into the other of the two members, and an elastic seal member fixedly attached to the core member and having a seal lip which elastically and slidably contacts the slinger. The slinger has a slidably contacting treated surface for the seal lip as is processed such a surface-treatment as defined by the following parameters: arithmetic mean roughness Ra in the range from 0.5 [mu]m to 1.5 [mu]m, root-mean-square roughness Rq in the range from 0.6 [mu]m to 2.0 [mu]m, mean surface irregularity interval Sm in the range from 0.05 mm to 0.17 mm and peak count Pc (50%) in the range from 20 to 60.

Owner:UCHIYAMA MFG

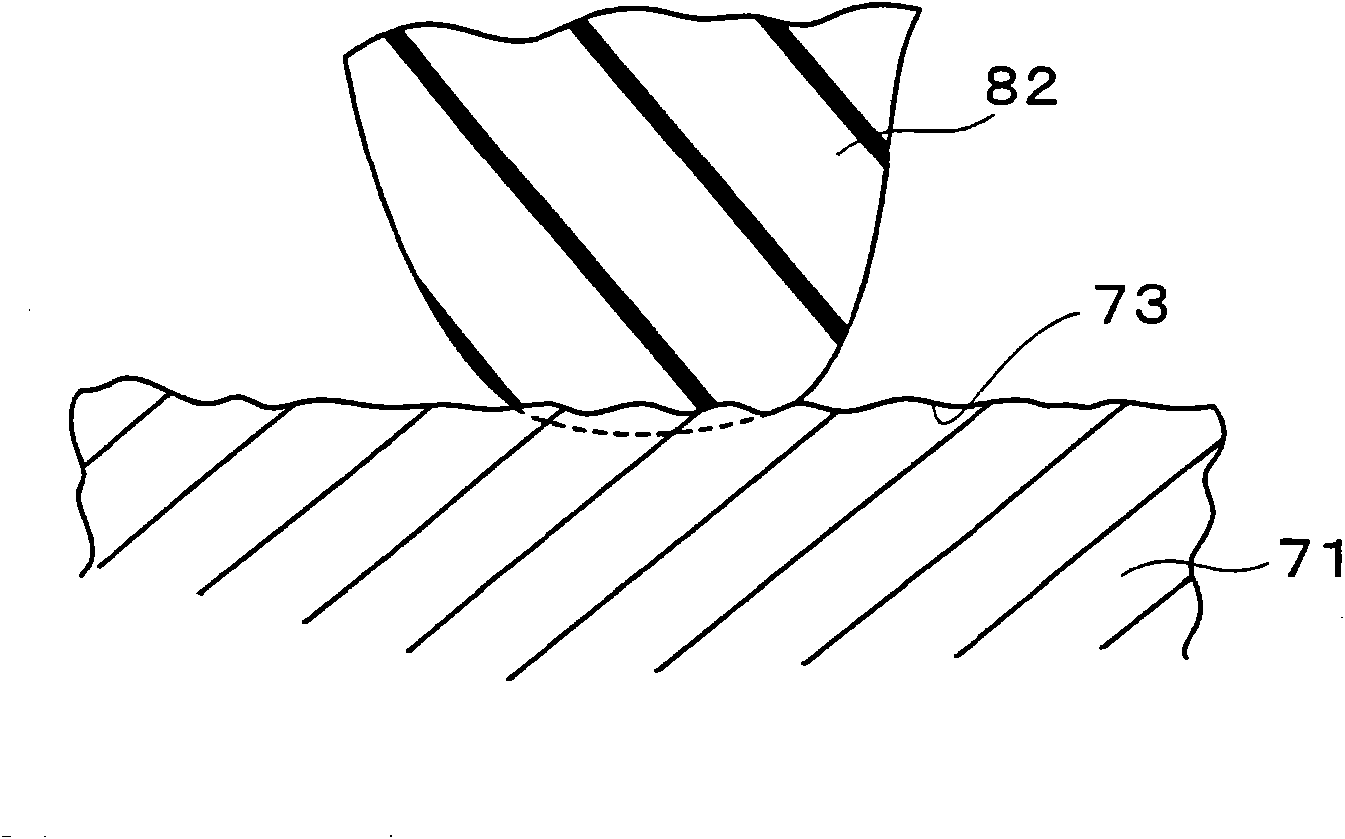

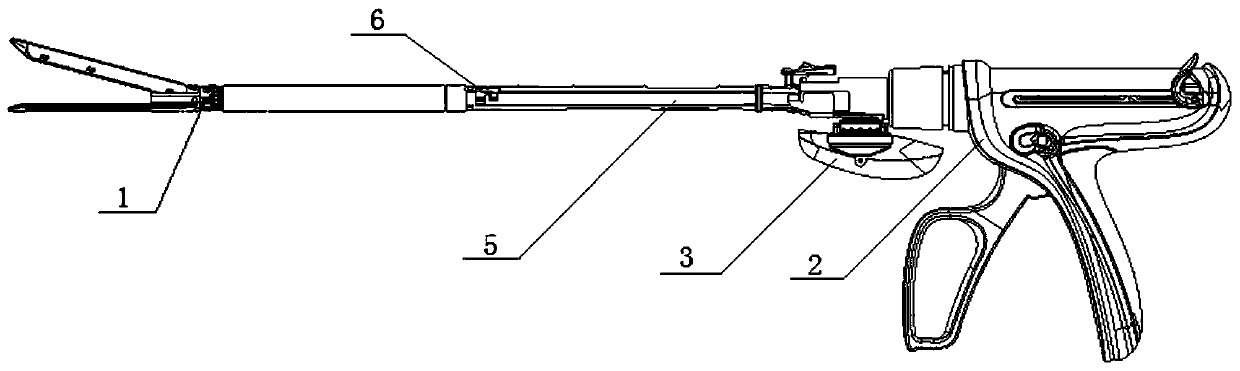

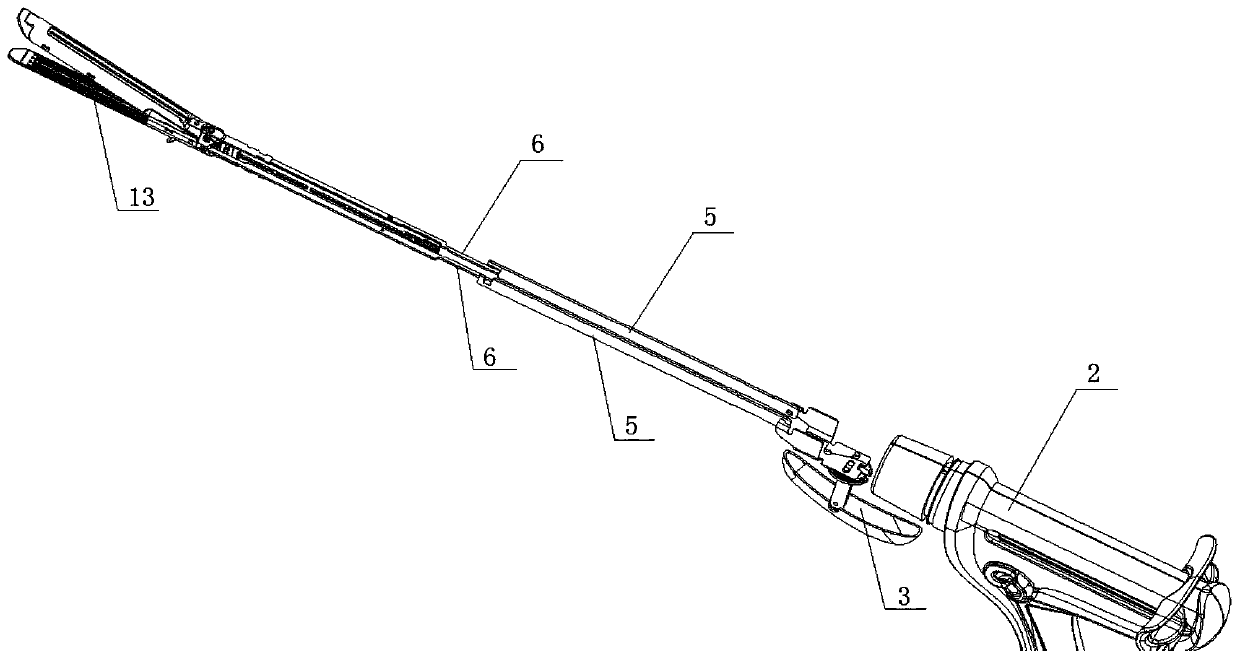

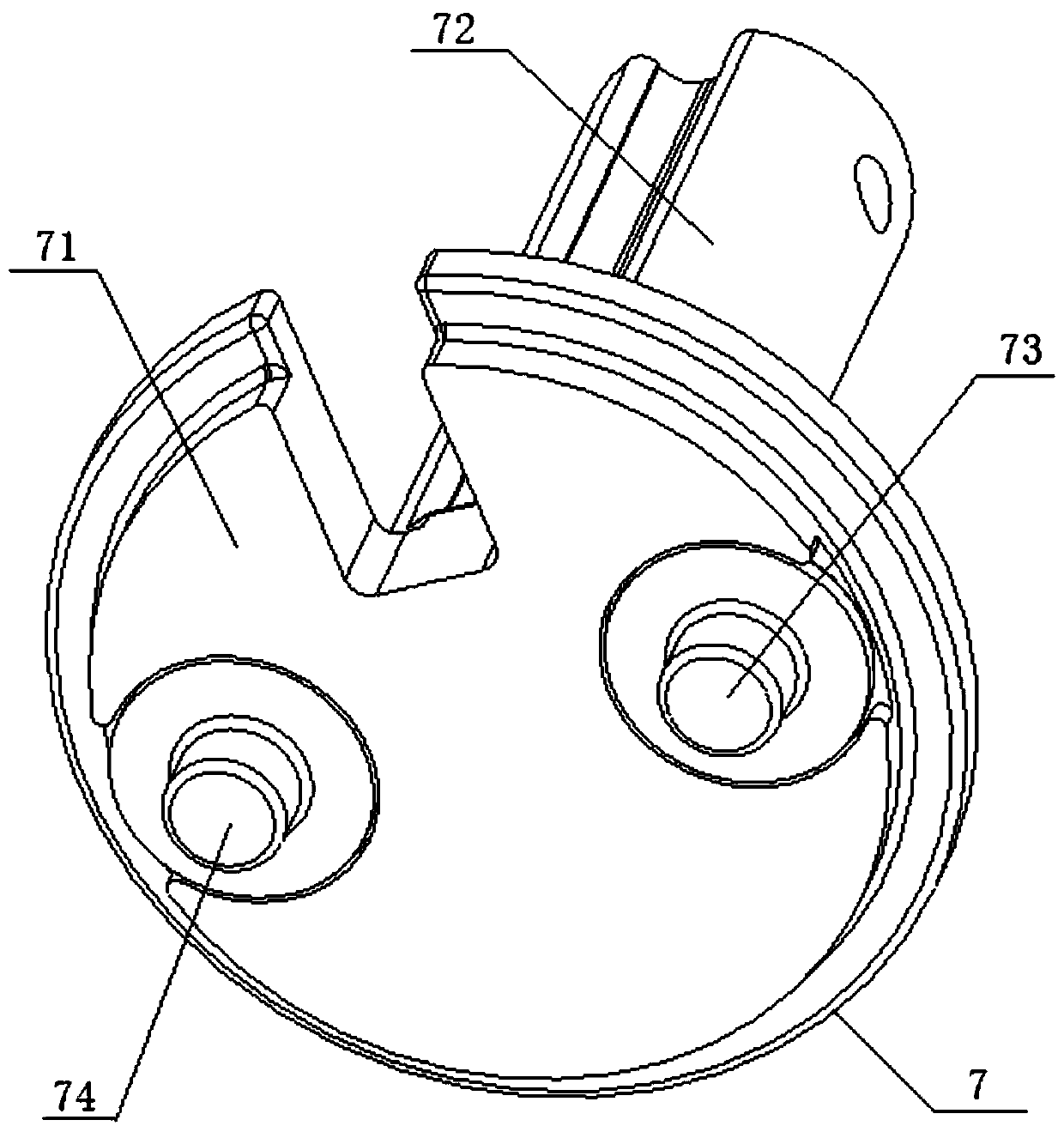

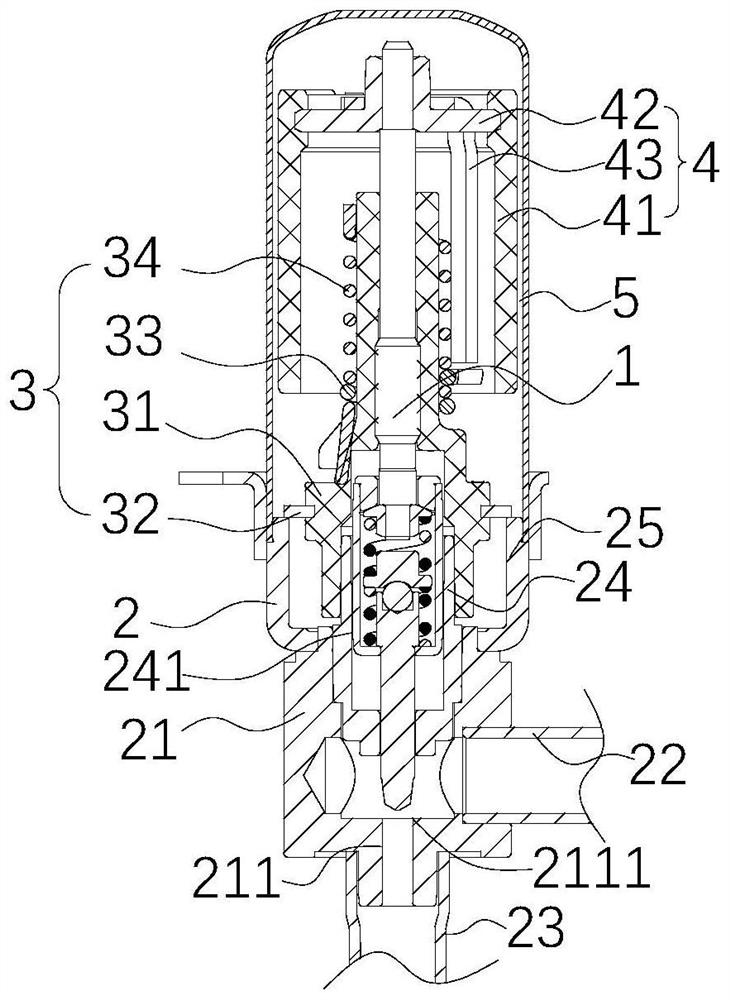

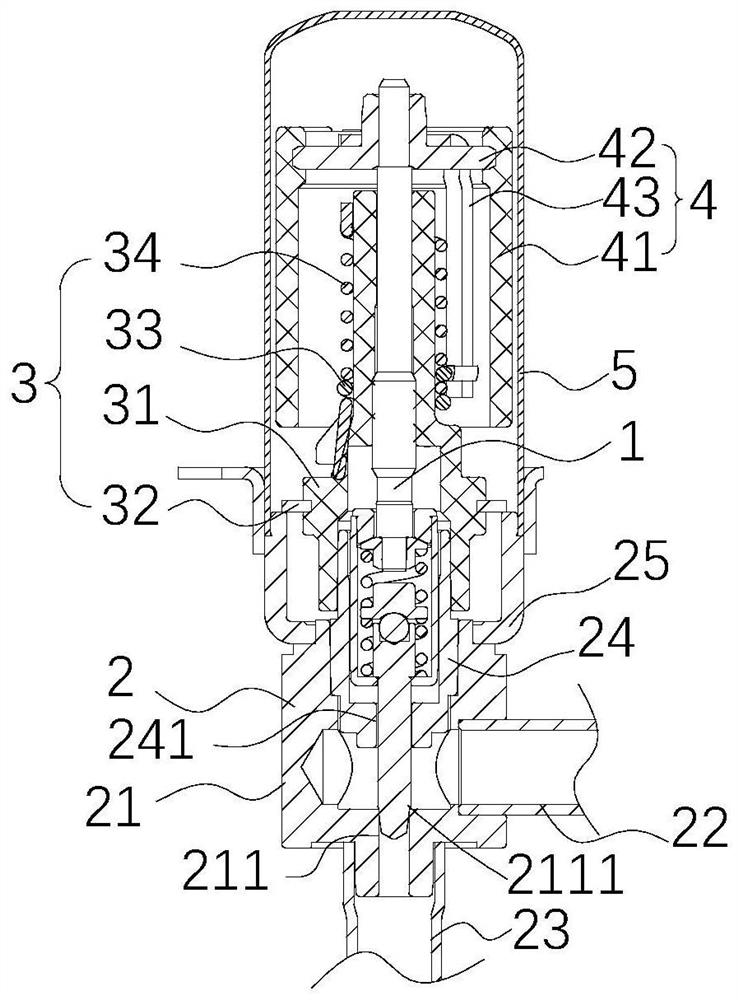

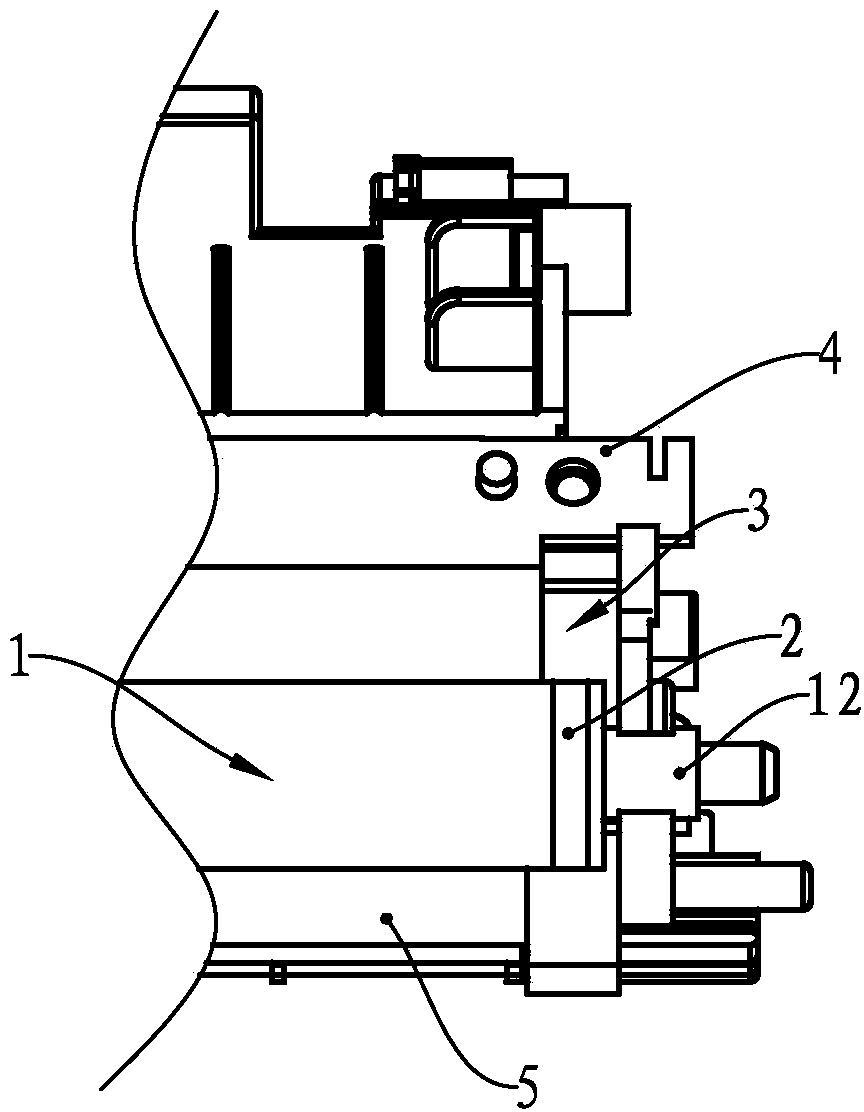

Cutting stapling device

ActiveCN111513782AGuaranteed uptimePlug-in assembly is simple and convenientSurgical staplesStructural engineeringApparatus instruments

The invention relates to the field of medical instruments, in particular to a cutting stapling device. The cutting stapling device comprises a staple box, a stapler, a staple box steering connecting rod assembly and a stapler steering connecting rod assembly, wherein a staple box locking bump is arranged on a staple box cover assembly of the staple box; the two ends of the staple box steering connecting rod assembly are connected with a bent head of the staple box and a stapler steering connecting rod respectively; the stapler is provided with an stapler gun barrel inner core and a two-way drive rotating mechanism connected with the stapler steering connecting rod; the inner side wall of the stapler gun barrel inner core is provided with a guide surface, a guide groove matched with a clamping block and a locking groove matched with the staple box locking bump; the clamping block slides to a preset position along the guide groove and rotates to be connected with the stapler steering connecting rod assembly; and the two-way drive rotating mechanism rotates for enabling the bent head to be bent. The cutting stapling device has the beneficial effects that the staple box and the staplerare inserted and assembled more simply and conveniently, and the bent head is driven to be bent through the two-way drive rotating mechanism, so that the bent head runs more stably.

Owner:MICONVEY TECH CO LTD

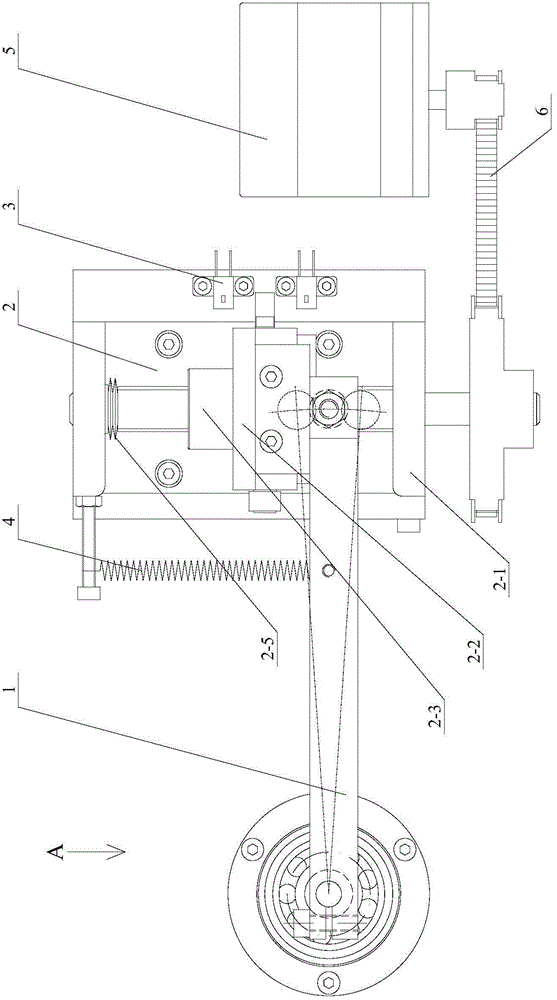

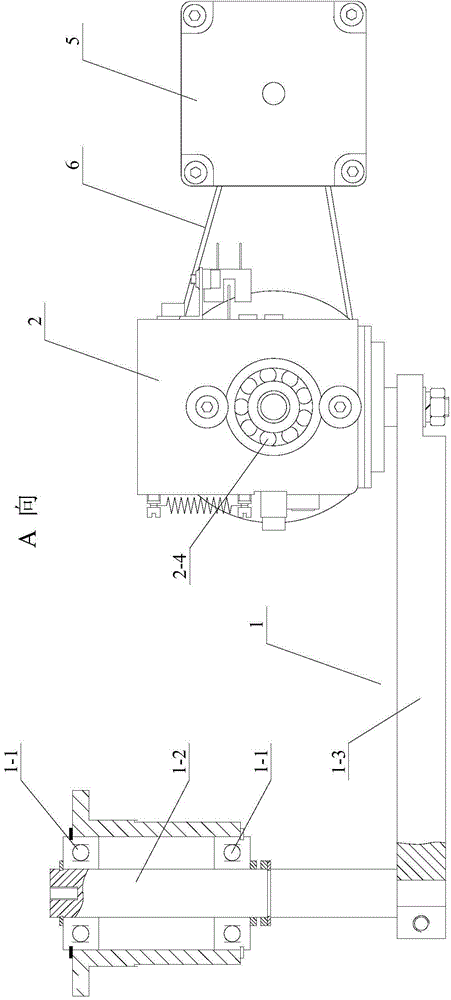

Accurate rotation mechanism

ActiveCN104482158ASimple structureGuaranteed uptimeGearingMechanical energy handlingBall screwEngineering

The invention provides an accurate rotation mechanism and belongs to the technical field of a rotation mechanism. A ball screw pair-screw rod and a ball screw pair-nut are in rotary connection; a bearing II is arranged on the upper portion of a support; a bearing pre-tension disc spring is arranged between the bearing II and the ball screw pair-screw rod; one end of a rotary arm is abutted against one side of the ball screw pair-nut; the other end of the rotary arm is connected with one end of a rotary shaft; a bearing I is installed at the other end of the rotary shaft; one end of a tension spring is connected with the support; the other end of the tension spring is connected with the rotary arm. According to the accurate rotation mechanism, the rotary shaft is erected by the two high-accuracy bearings, the operation is stable, the rotation torque is small, the rotation accuracy is high, and the high-accuracy bearings control influences from circumferential bounce and axial bounce, a high-accuracy straight line ball screw is free of axial clearance displacement, the installation clearance between the ball screw pair and the two high-accuracy bearings is eliminated through a plurality of groups of bearing pre-tension disc springs, and the installation requirement of the disc springs is that the ball screw pair after pre-tension is free of axial transmission clearance.

Owner:BEIJING BOHUI INNOVATION TECH

Butterfly valve with O-shaped sealing ring and bearing

InactiveCN102401187ALoading and unloadingReduce rotational torqueSpindle sealingsLift valveGraphiteEngineering

The invention discloses a butterfly valve with an O-shaped sealing ring and a bearing, comprising a valve body, a valve rod and a butterfly plate, wherein the butterfly plate is arranged in the valve; the valve rod is arranged on the valve body in a penetrating manner and is fixedly connected with the butterfly plate in the valve body; the O-shaped sealing ring and the bearing are arranged between the valve rod and the valve body; and the O-shaped sealing ring is adopted as a sealing structure between the valve rod and the valve body, and compared with the sealing structure formed by adopting flexible graphite and a packing gland, not only are the assembly and the disassembly of operators convenient, but also the rotating torque of the valve rod also can be reduced, and the sealing performance is more reliable. In addition, the bearing is added between the valve rod and the valve body, the rotating torque of the valve rod can be further reduced, and the labor intensity of the operators is greatly reduced.

Owner:KAIRUITE VALVE

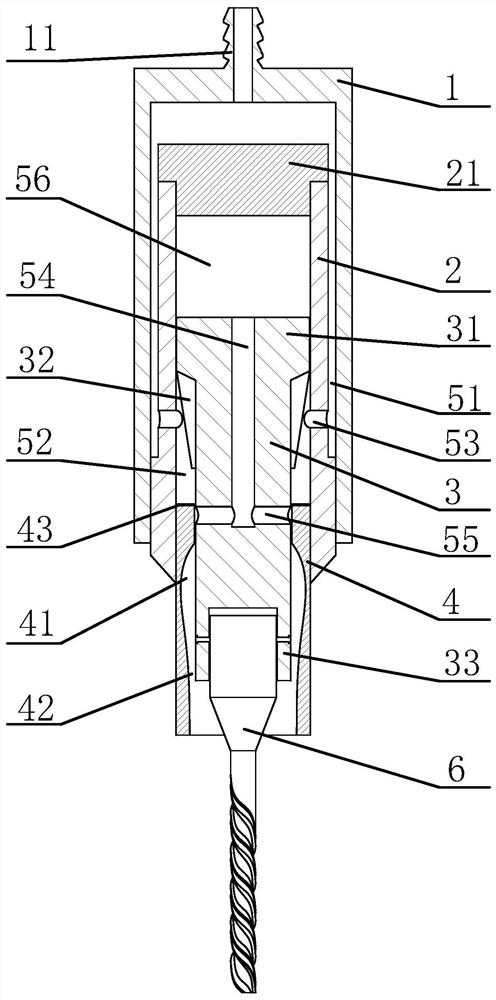

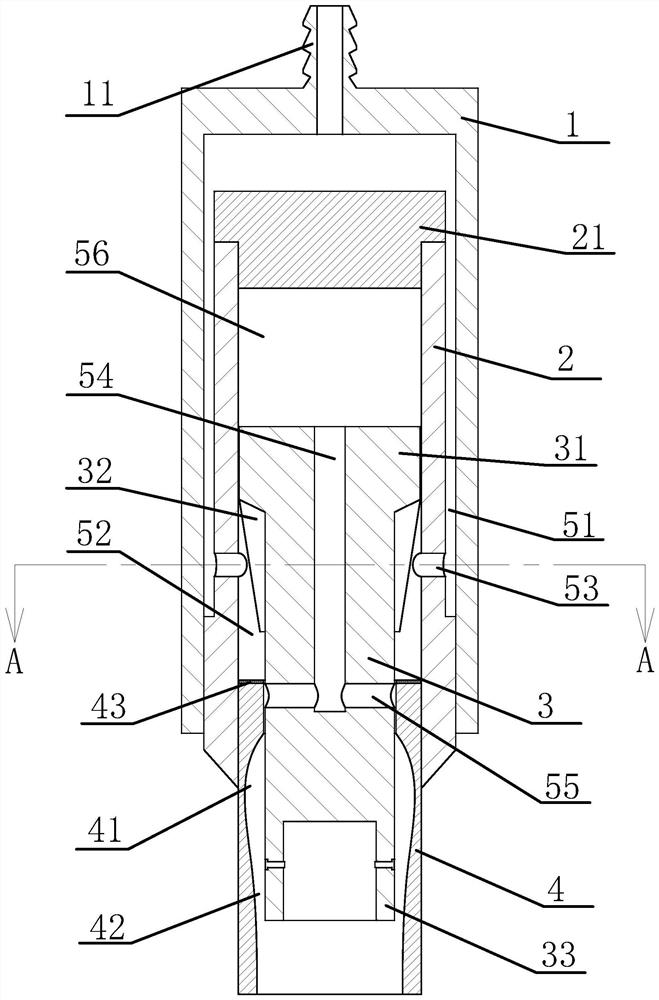

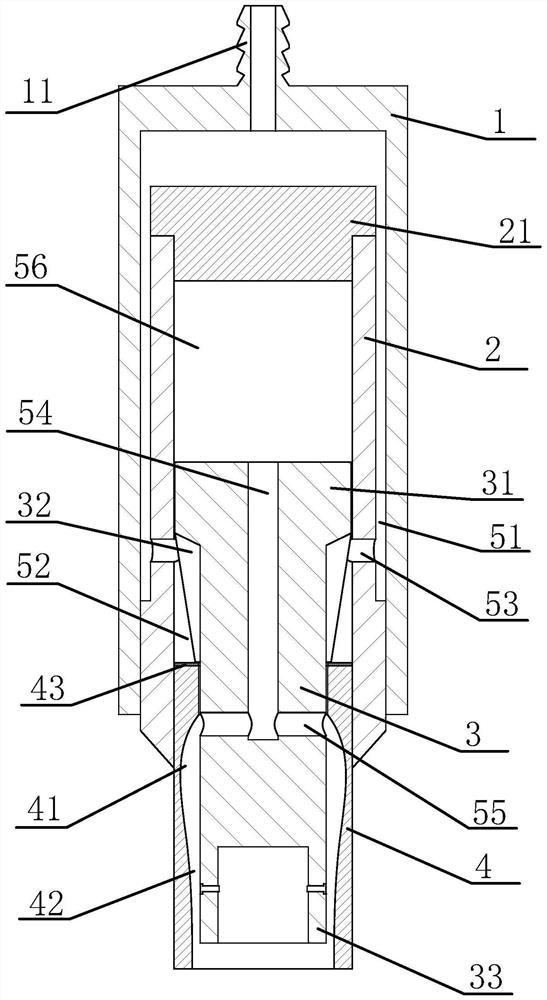

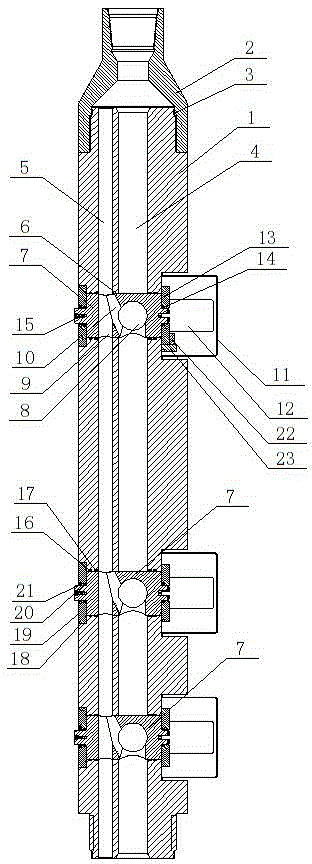

Micro-drill driving device with adjustable stroke

PendingCN111970834AReduce the length of the duty cycleReduce impactPrinted circuit manufactureMetal working apparatusImpellerEngineering

The invention provides a micro-drill driving device with adjustable stroke, and belongs to the technical field of precision machinery. The driving device comprises a shell, a middle sleeve and a plunger, the middle sleeve is fixed in the shell; an air inlet channel is formed between the middle sleeve and the shell; a piston rotationally connected with the inner wall of the middle sleeve is arranged at the upper end of the plunger; an impeller is arranged in the middle of the plunger; an adjusting sleeve is connected between the lower end of the plunger and the middle sleeve; a driving air cavity is formed between the upper end of the adjusting sleeve and the lower end of the piston; the middle sleeve is provided with a plurality of air inlet holes communicating with the driving air cavityand the air inlet channel. An airflow reciprocating channel with the upper end penetrating through the upper end face of the plunger is formed in the plunger, a cover plate for blocking an opening inthe upper end of the middle sleeve is fixedly connected to the top of the middle sleeve, a compressed air cavity communicating with the airflow reciprocating channel is formed between the lower end face of the cover plate and the upper end face of the plunger, and multiple functional holes communicating with the airflow reciprocating channel are formed in the middle of the plunger; a micro-drill mounting head is arranged at the lower end of the plunger. The driving device has the advantages of high operation efficiency and the like.

Owner:HUBEI UNIV OF SCI & TECH

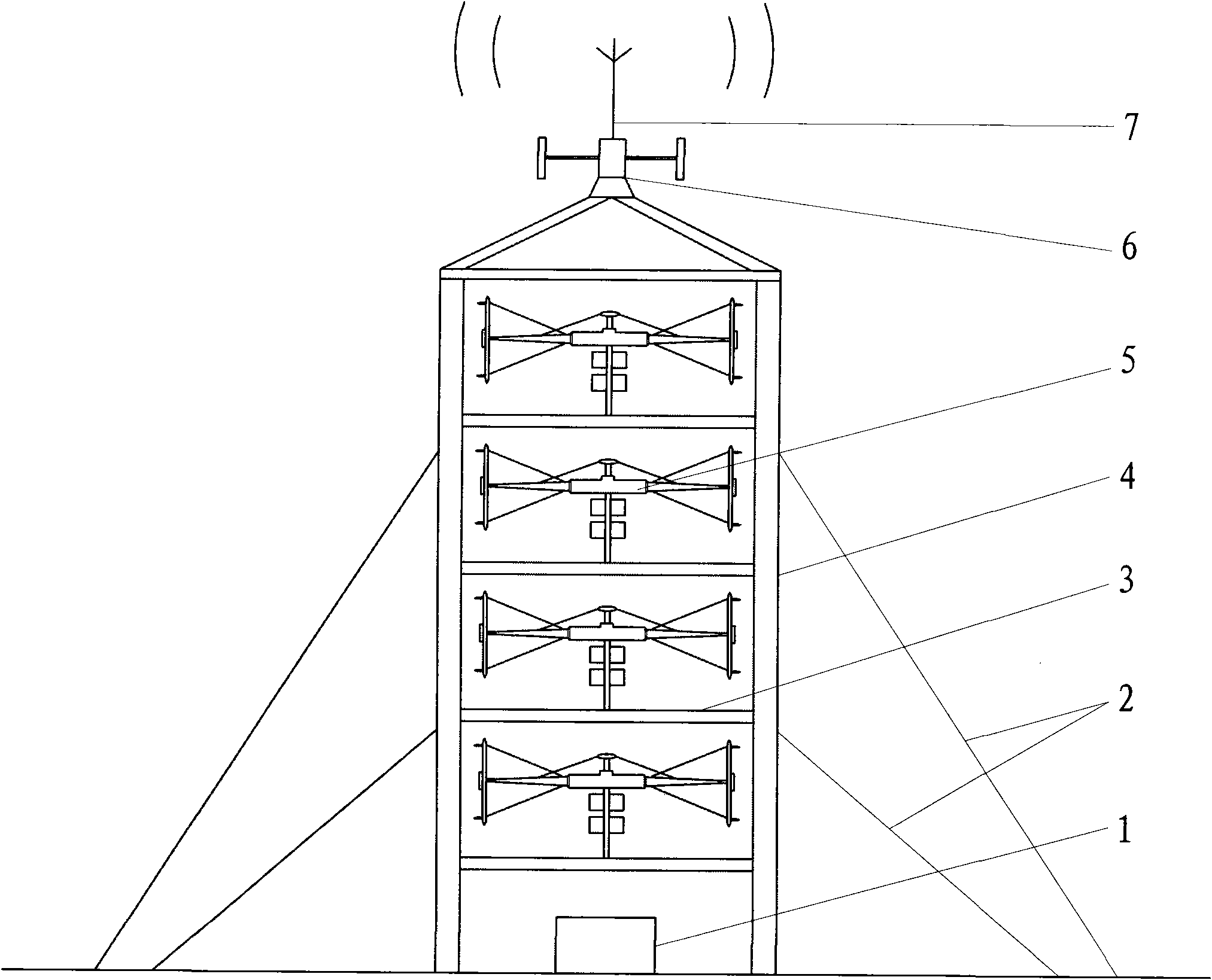

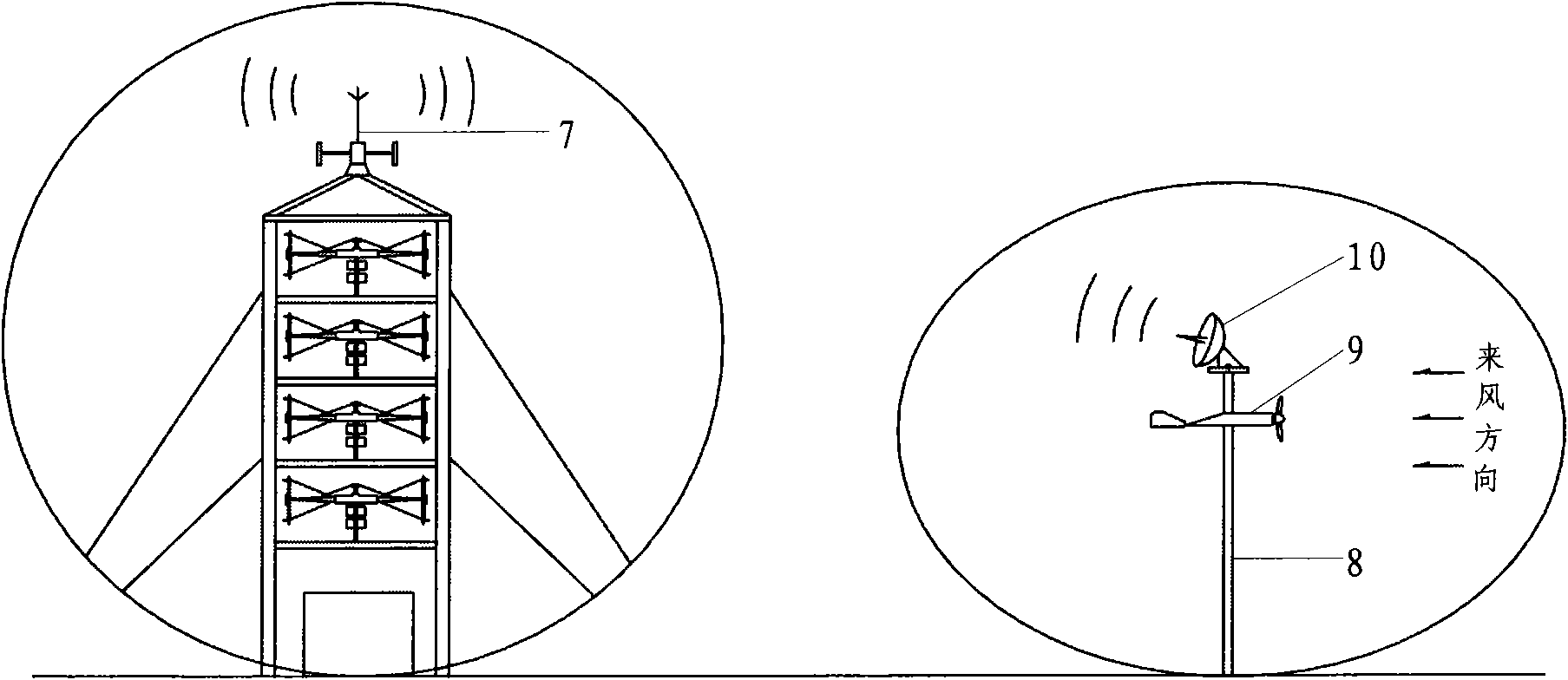

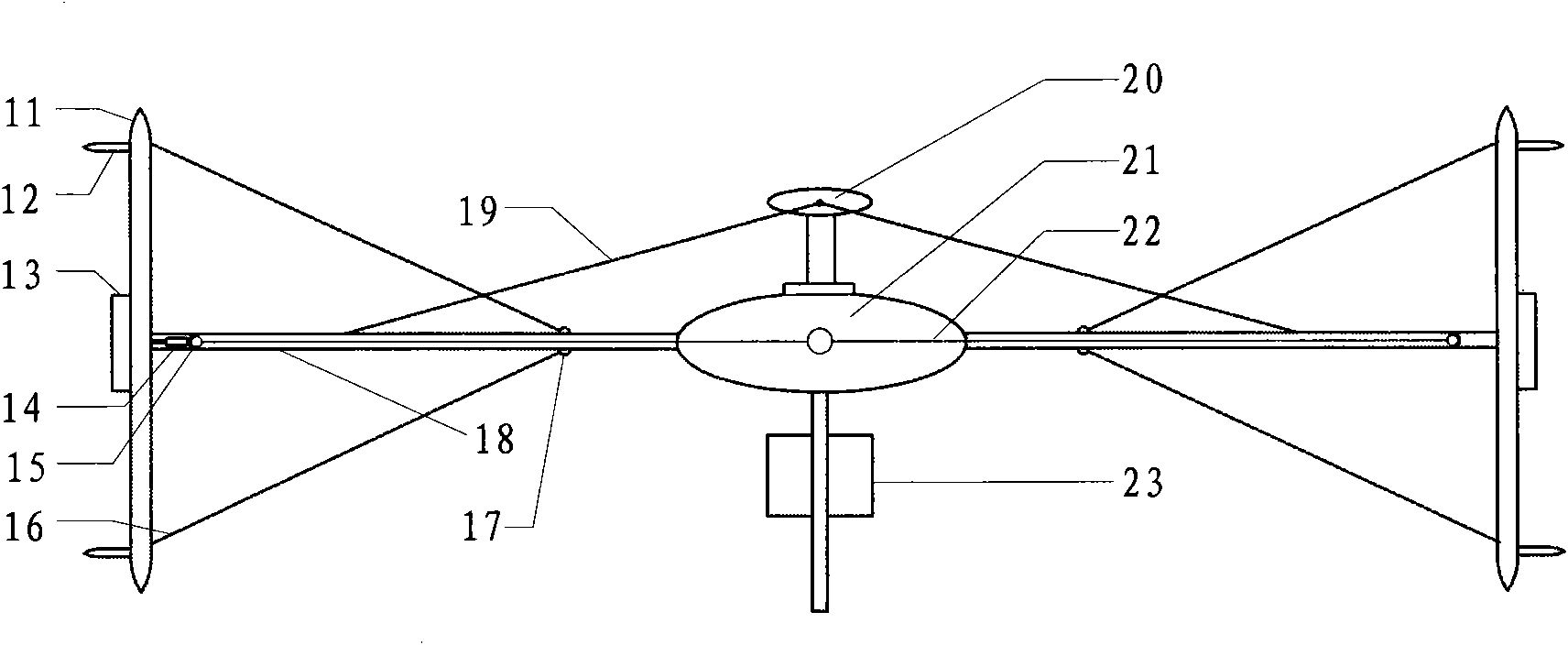

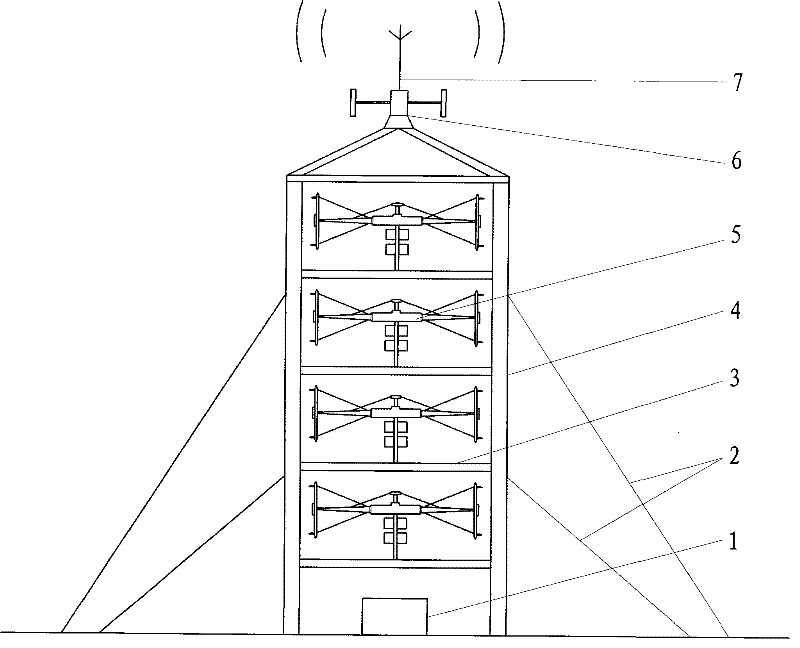

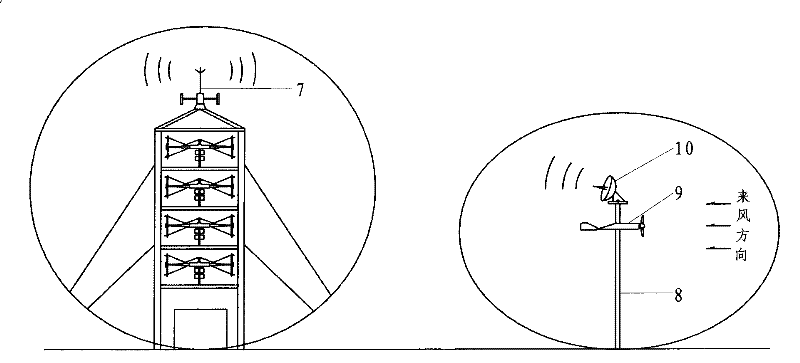

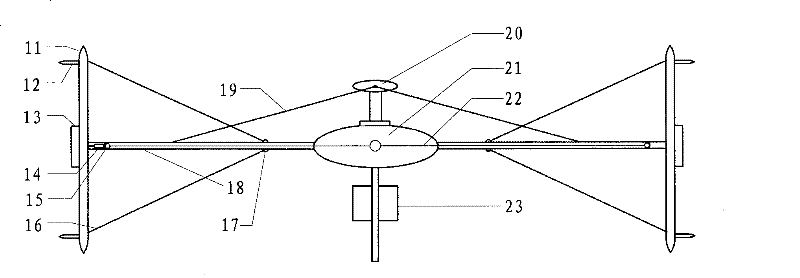

Multilayer multi-column combined type vertical shaft wind power generating system being capable of avoiding strong wind

InactiveCN101660497AEfficient use ofSafe and stable operationWind motor controlWind motor supports/mountsEarly warning systemTower

The invention relates to a multilayer multi-column combined type vertical shaft wind power generating system which can effectively prevent a rugged strong wind environment from damaging a system, effectively utilizes wind power and runs more safely and stably. A multilayer combined type structure comprising a plurality of tower columns and a plurality of generating units is arranged; the wind power is utilized to directly drive main wind wings of the generating units of the vertical shaft wind power, and a main cantilever, a main cantilever fixed hub and a main shaft are utilized to drive a generator to generate electric power; whereas, when the rugged strong wind environment comes, the front face area of the main wind wing is regulated so as to effectively prevent the strong wind from damaging the system; a strong wind early warning system is arranged, when that the strong wind attacks is detected, the strong wind early warning system can send an instruction to the system in advance so as to take a strong wind avoiding measure, thereby greatly improving the running state, the safety and the stability of the wind power generating system.

Owner:ZHONGJIN FUHUA ENERGY TECH

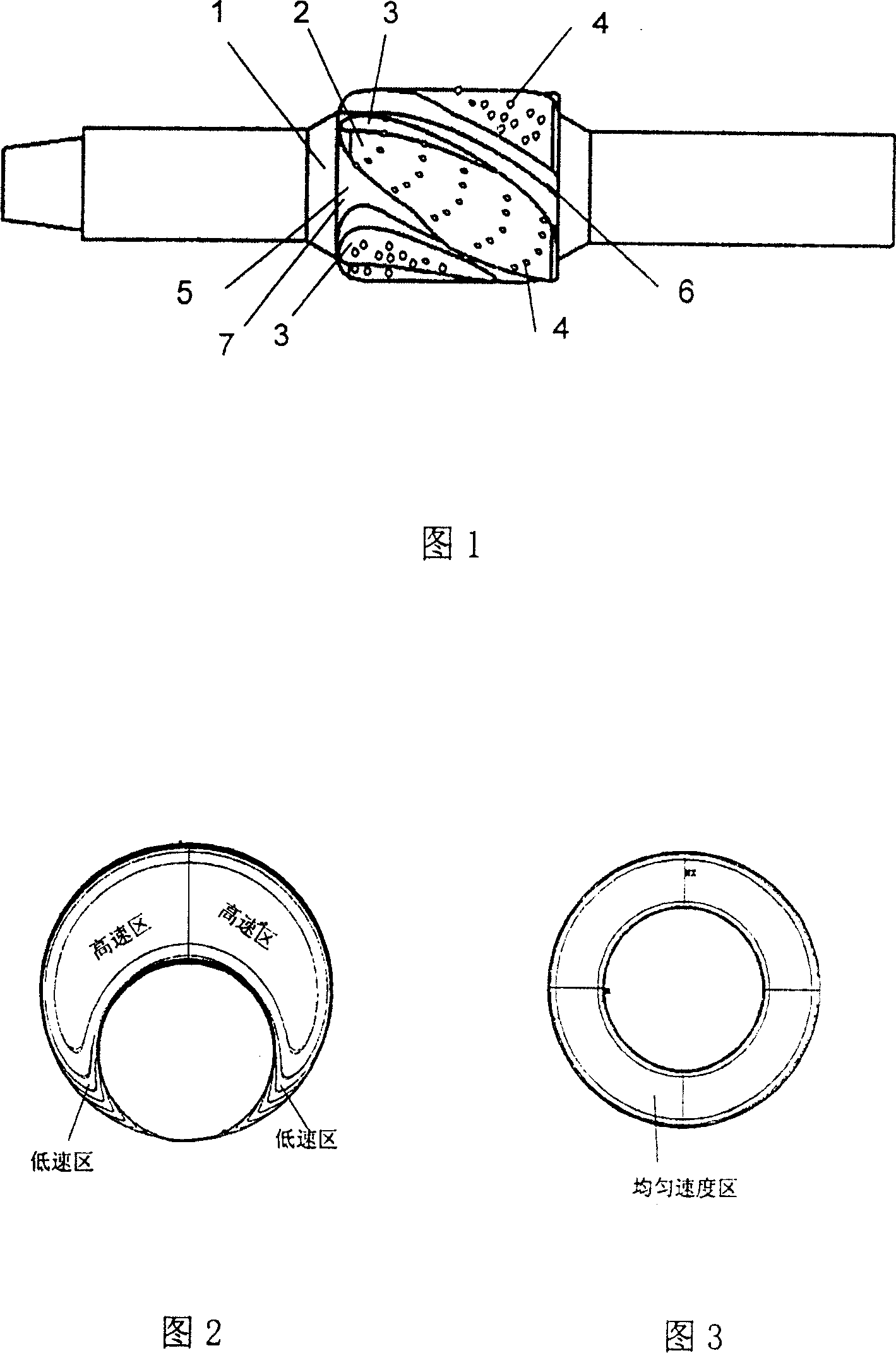

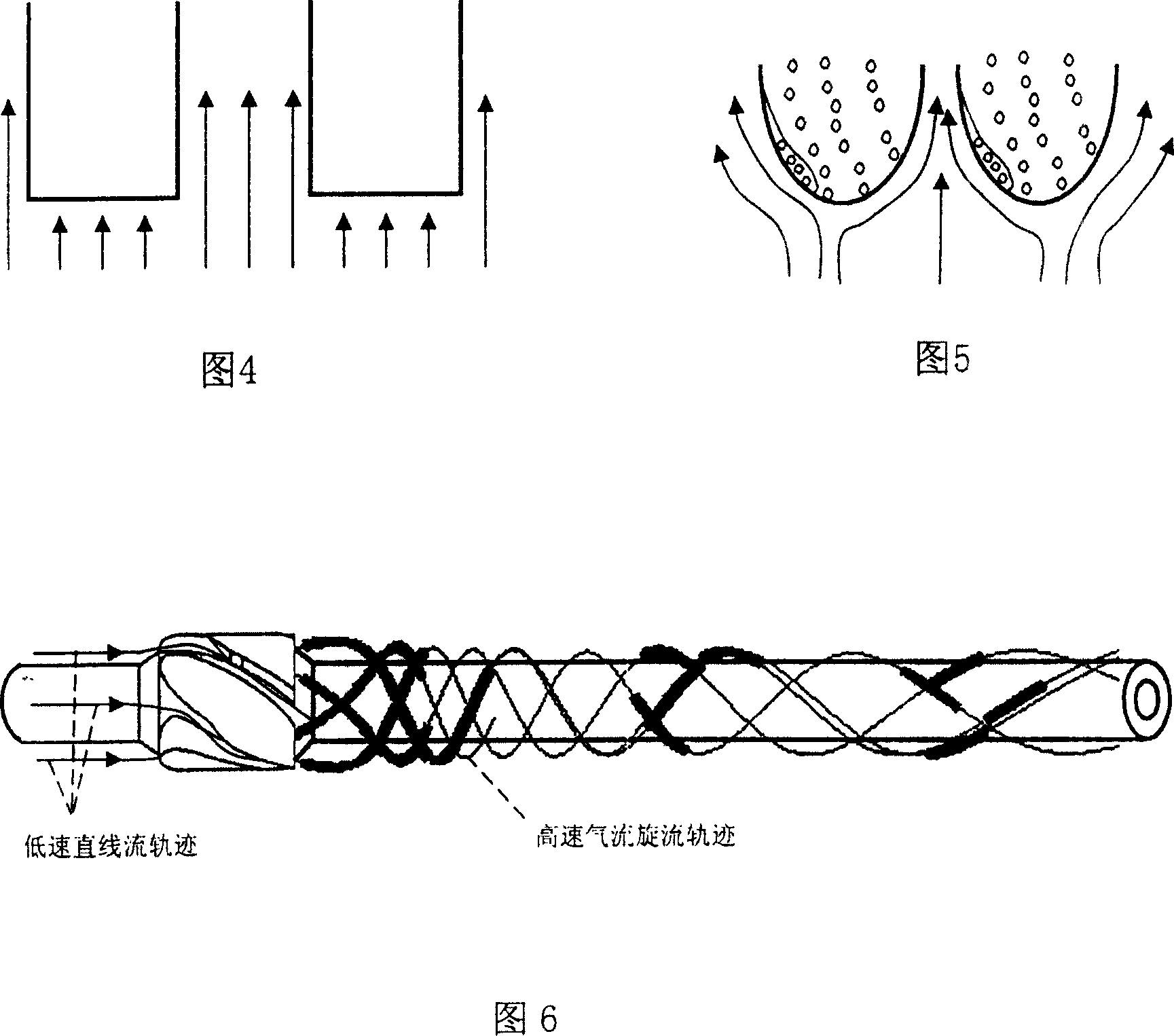

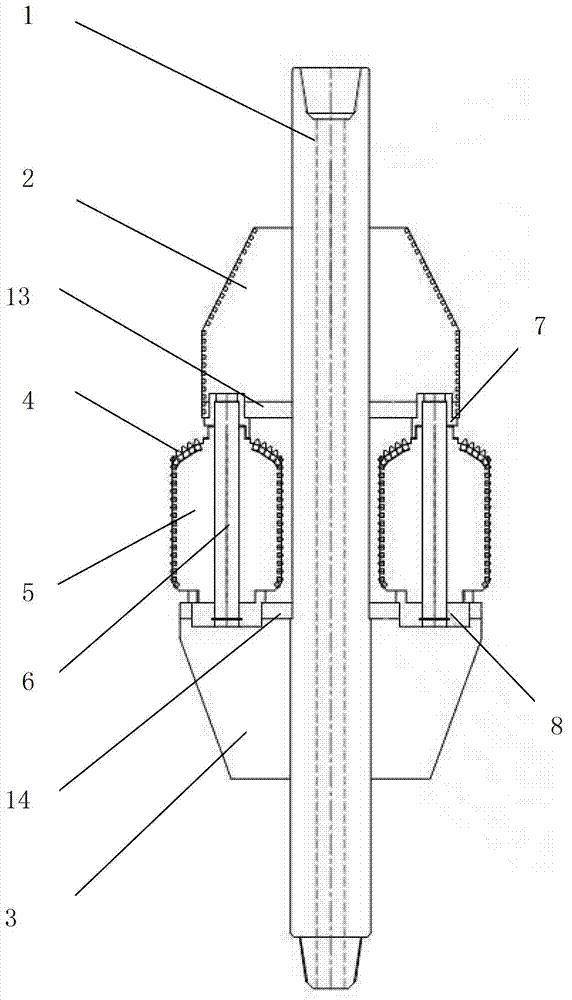

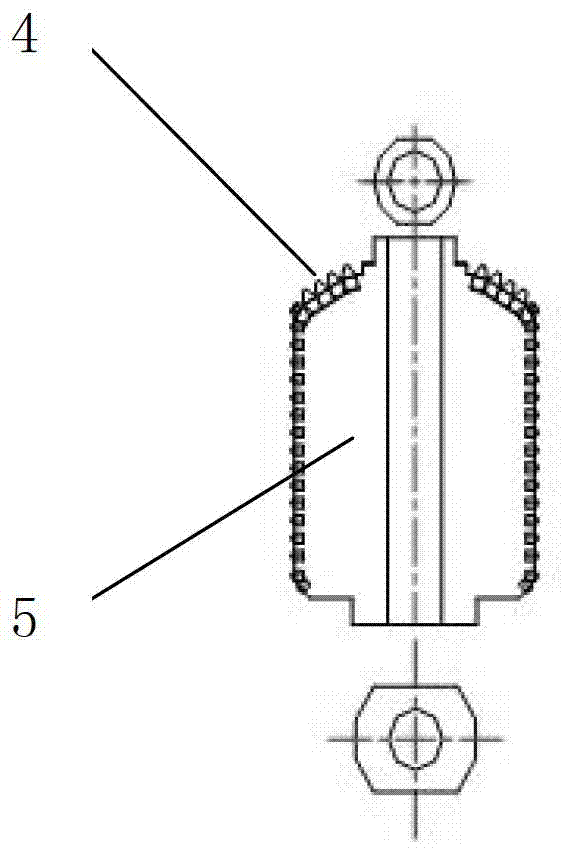

Stabilizer of gas drill horizontal well

InactiveCN1318726CSmall up and down frictionReduce rotational torqueDrilling rodsDrilling casingsAlloyEngineering

A centralizer of drilling rod for the pneumatic drilling of horizontal well is composed of a main body, the spiral flow guide slots with wide inlet and narrow outlet, and spiral centralizing strips with rock bit leading-in slots. The hard alloy teeth are inlaid on the surfaces of said spiral flow guide slots and spiral centralizing strips.

Owner:SOUTHWEST PETROLEUM UNIV

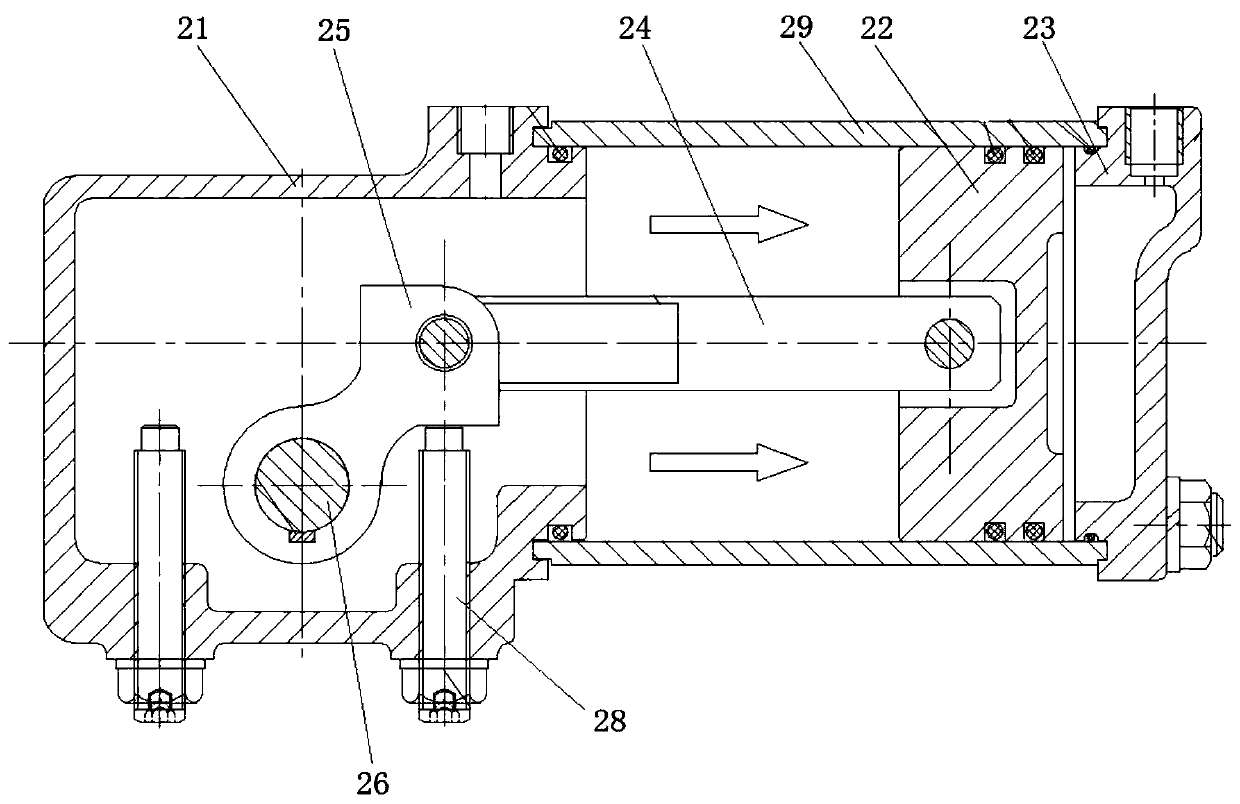

Air seal type friction-free pneumatic semispherical valve and control device thereof

ActiveCN109780253ANo wearReduce rotational torqueSpindle sealingsPlug valvesAutomatic controlEngineering

The invention discloses an air seal type friction-free pneumatic semispherical valve and a control device thereof. The air seal type friction-free pneumatic semispherical valve comprises a semispherical valve body, a pneumatic driving apparatus and an automatic control apparatus; the pneumatic driving apparatus is movably connected with the semispherical valve body; the pneumatic driving apparatuscomprises an executing mechanism, a piston, a rear cover, a connecting rod, a crank, a rotary shaft, a copper sleeve, an inner hexagonal adjusting positioning shaft and a cylinder barrel; and one endof the rotary shaft is connected with the semispherical valve body. By means of the air seal type friction-free pneumatic semispherical valve and the control device thereof, the valve adopts an air seal type sealing structure and a sphere rotation and seal ring friction-free structure which are combined, a seal ring is protected against abrasion to the maximum degree, the rotation torque of an existing valve is reduced to the maximum degree, and the service life of valve sealing is improved; and through the semispherical structure, the weight is low, the material cost is reduced greatly, whole rotation is flexible, and meanwhile the effect of automatic compensation can be achieved.

Owner:吴金龙

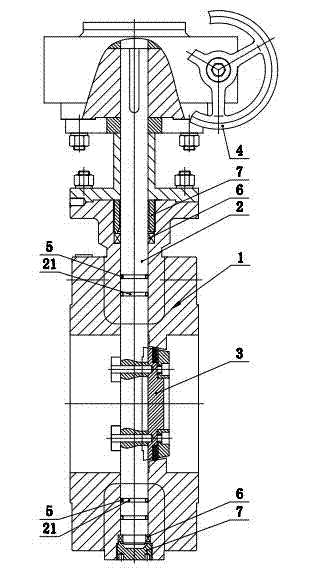

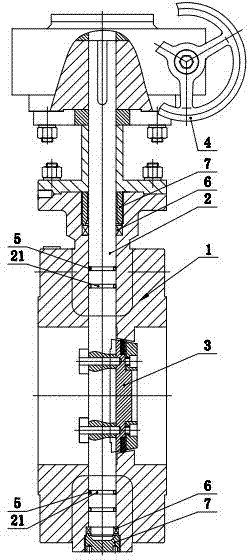

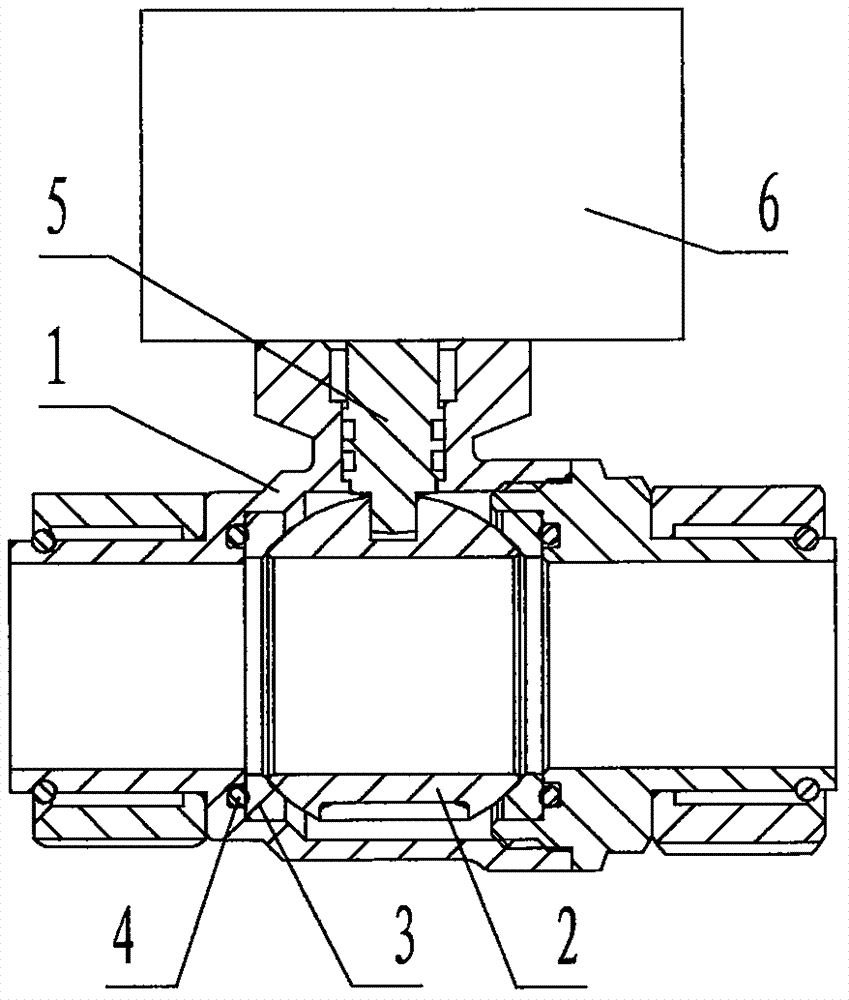

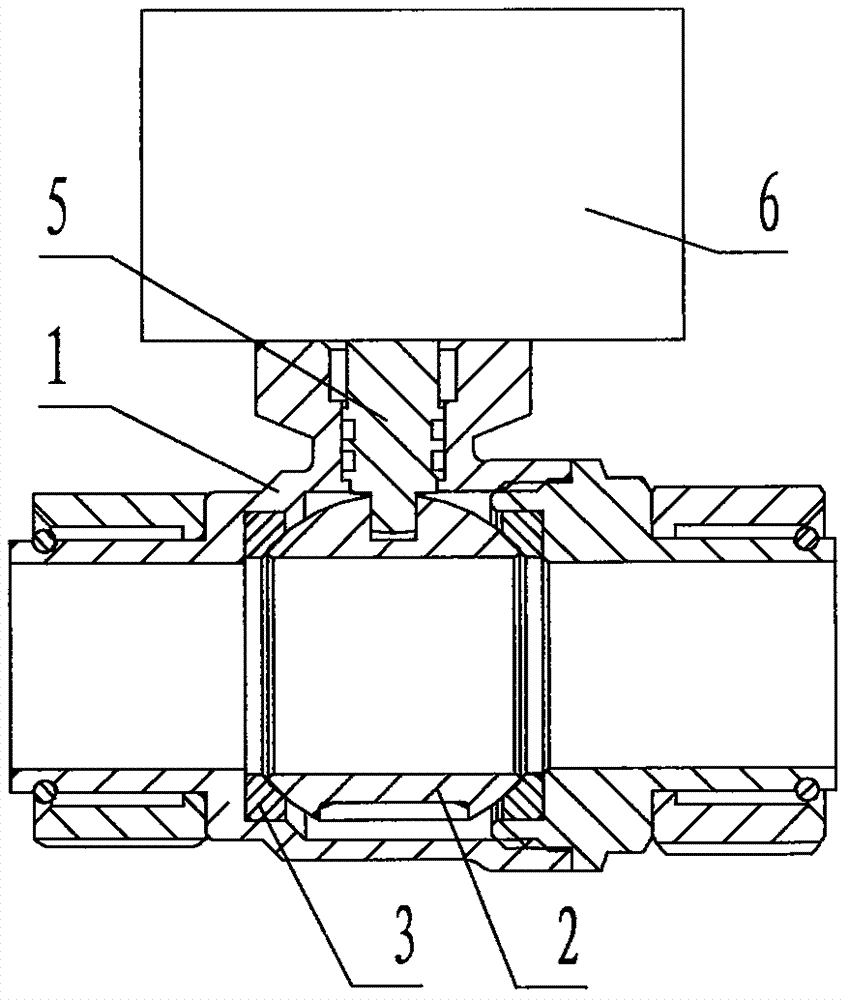

Small-torque electric ball valve

InactiveCN107084257ADecreased static adhesionStatic adhesion overcomePlug valvesOperating means/releasing devices for valvesStatic frictionEngineering

The invention discloses a small torque electric ball valve, which comprises a valve body (1), a ball valve core (2), a sealing ring (3), an O-ring (4), a valve stem (5) and an electric driver (6). In the present invention, an elastic and silicon rubber O-ring is arranged between the sealing ring and the valve body. When the electric ball valve is started, a shearing and sliding tendency occurs between the ball valve core and the sealing ring, and the elasticity of the O-ring is used to make the sealing ring produce Elastic retreat, reducing and overcoming the static adhesion between the ball valve core and the sealing ring, using a small torque to make the static friction between the ball valve core and the sealing ring transition to dynamic friction, thereby reducing the technical scheme of the starting torque, making the electric ball valve , to achieve the purpose of reducing the starting torque and turning torque.

Owner:华英伦科技(宁波)有限公司

Sealing ring

ActiveCN107407418AContainment leakReduce rotational torqueEngine sealsDynamic pressureBiomedical engineering

Provided is a sealing ring that suppresses leakage of a fluid to be sealed and that is capable of stably reducing rotational torque. A sliding surface side is provided with a groove portion (120) that comprises a first groove (121) extending in the circumferential direction and a second groove (122) that extends from a central position of the circumferential direction in the first groove (121) to an inner circumferential surface and that guides the fluid to be sealed into the first groove (121), characterized in that the first groove (121) comprises a groove for generating dynamic pressure (121a) formed such that the groove bottom is shallower in the end portions of the circumferential direction when compared to the center of the circumferential direction and a groove for capturing foreign objects (121b) capable of capturing foreign objects, the groove bottom of which is deeper than the groove bottom of the groove for generating dynamic pressure (121a), and in that the first groove (121) is provided in a position fitting into a sliding region that slides with respect to a side wall surface.

Owner:NOK CORP

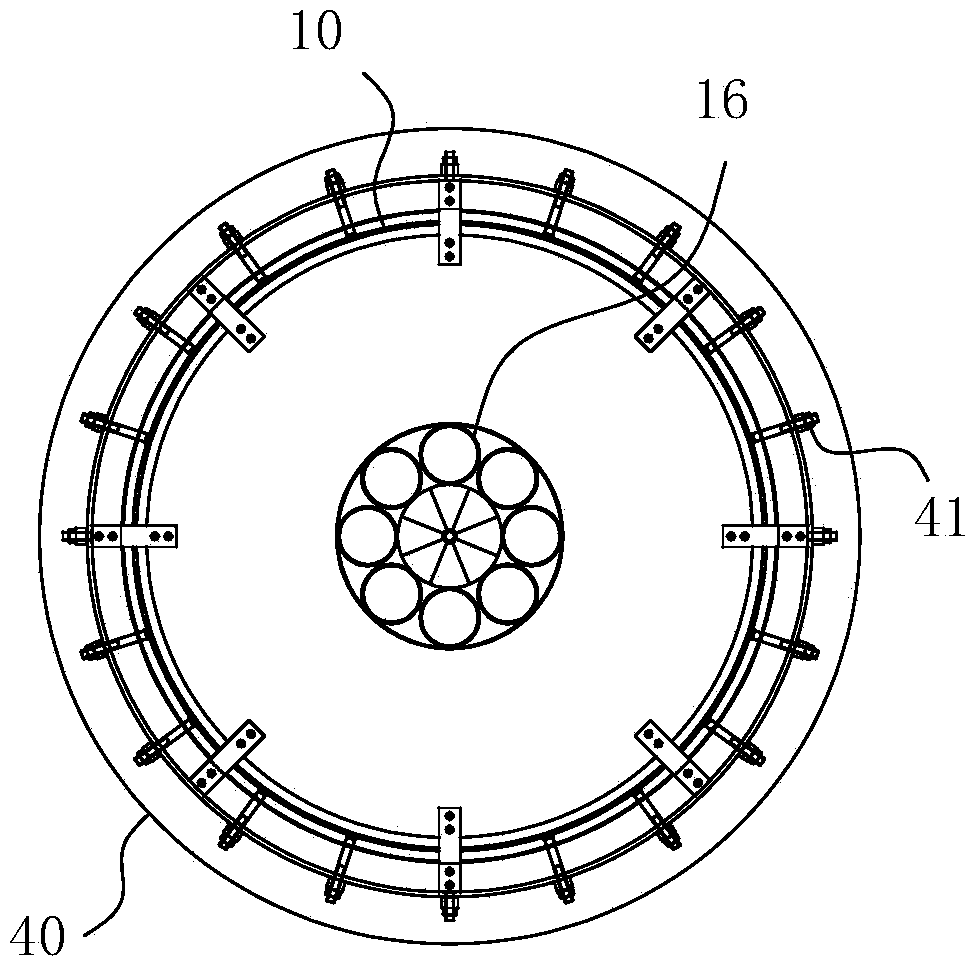

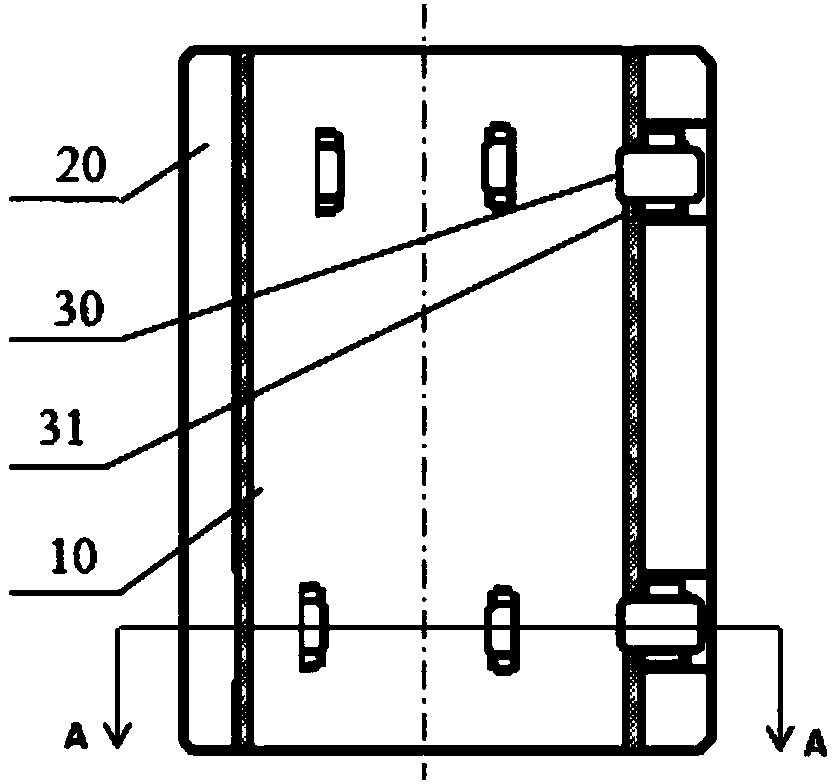

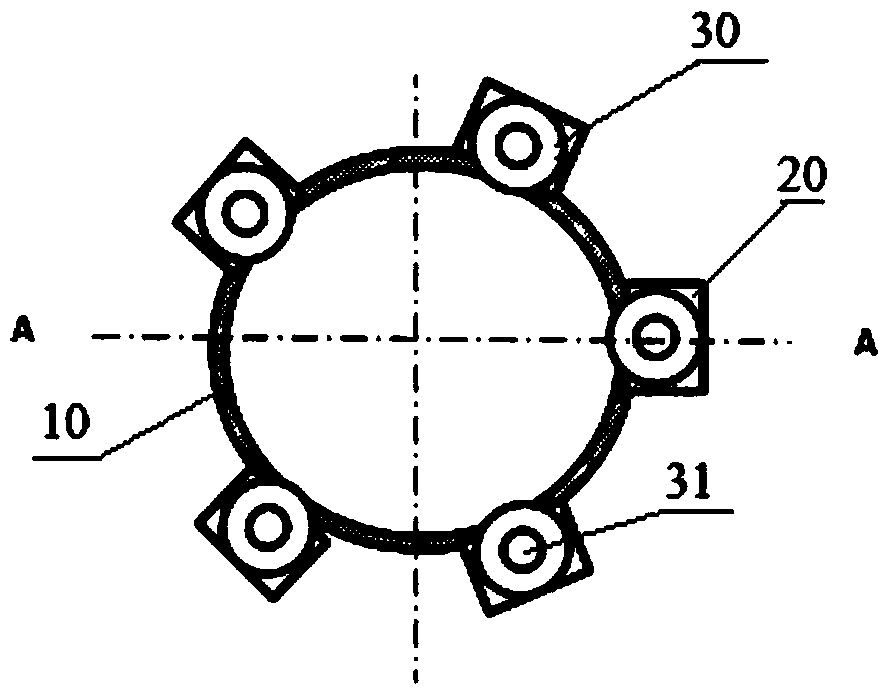

Rigid centering device

InactiveCN107762427AGuaranteed centerednessSmooth rotationDrilling rodsDrilling casingsWell cementingEngineering

The invention provides a rigid centering device. The rigid centering device is applied to a casing pipe, and comprises a barrel, centering strips and rotary wheels, wherein the barrel is in a hollow shape, the centering strips are arranged on the barrel in the axial direction, the rotary wheels are rotatably fixed to the interiors of the centering strips through rotary shafts, and the side walls of the rotary wheels penetrate through the side wall of the barrel. According to the rigid centering device, frictional force between rotation of the centering device and the well wall is reduced, therotating friction resistance of the casing pipe is greatly reduced, the casing pipe rotating function in the casing pipe tripping-in and well cementing processes is achieved, the casing pipe rotatingresistance is effectively reduced, a torque when the casing pipe rotates is reduced, normal rotation of the casing pipe is ensured, a screw thread of the casing pipe is protected, and meanwhile casingpipe rotation is prevented; and the centering degree of the casing pipe is ensured, implementation of a technology of rotary casing pipe well cementing and rotary tail pipe well cementing can be ensured, rotation of the casing pipe in the casing pipe tripping-in process can be ensured, and sticking of the casing pipe is prevented.

Owner:CHINA PETROLEUM & CHEM CORP +1

Well drilling cementing cement head

The invention discloses a well drilling cementing cement head, and relates to the field of petroleum development well drilling. The well drilling cementing cement head comprises a cement head body. An upper connector is connected to the upper end of the cement head body in a threaded manner, a main cement head through hole and an auxiliary cement head through hole are formed in the cement head body, stop pin cock holes are radially formed in the cement head body, stop pin cocks are arranged in the stop pin cock holes, main cock through holes, auxiliary cock through holes and oblique cock through holes are formed in the stop pin cocks, the main cock through holes are formed in the stop pin cocks in the main cement head through hole, the auxiliary cock through holes are formed in the stop pin cocks in the auxiliary cement head through hole, the main cock through holes are perpendicular to the auxiliary cock through holes, one end of each oblique cock through hole is communicated with the corresponding auxiliary cock through hole, and the other end of each oblique cock through hole is communicated with the main cement head through hole; one end of each stop pin cock is connected with a stepper motor, and the other end of each stop pin cock is connected with a cock position indicating rod. The well drilling cementing cement head has the advantages that the main through holes and the auxiliary through holes can be reliably and accurately opened or closed without manual operation, and the cement head can be developed towards the automation direction and can be easily and safely operated.

Owner:YANGZHOU CHICHENG GASOLINEEUM MACHINERY

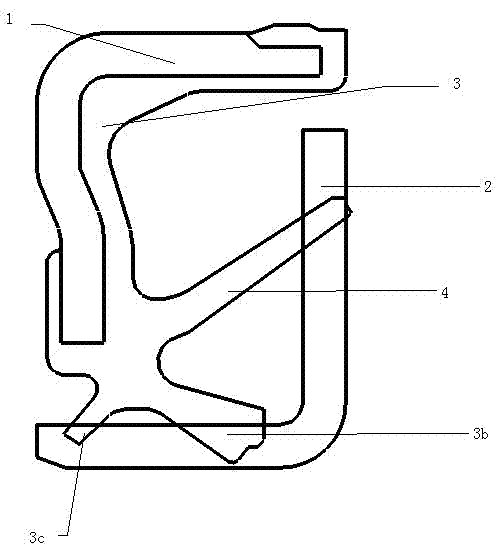

Combined sealing ring with high sealability and low torque

InactiveCN103032473AReduce frictionReduce rotational torqueBearing componentsLip structureFinite element method

The invention relates to a combined sealing ring with high sealibility and a low rotary torque. The combined sealing ring consists of an inner framework, a rubber body and a dust cover, wherein the inner framework and the dust cover form a sealing cavity; the sealing rubber body is placed in the sealing cavity; the sealing rubber body comprises a rubber main body with the shape matched with the shape of the inner framework, and a main lip, an auxiliary lip and a double side lip structure that extend from the rubber main body; the auxiliary lip is in interference fit with an inner wall of the dust cover; the double side lip structure comprises a first side lip and a second side lip; and the first side lip and the second side lip are in interference fit with the inner wall of the dust cover. According to the combined sealing ring, as the double side lip structure is adopted based on the existing combined sealing ring, the radial magnitude of interference of the main lip is reduced, and friction between the sealing lips and the dust cover, and the rotary torque are reduced. According to inelastic FEM (Finite Element Method) analysis, the waist shapes of the side lips are scientifically designed, the rubber lips are automatically and elastically recovered and compensated after being abraded, and the sealibility is not reduced.

Owner:WAFANGDIAN BEARING GRP CO LTD

Multilayer multi-column combined type vertical shaft wind power generating system

InactiveCN101660497BEfficient use ofSafe and stable operationWind motor controlWind motor supports/mountsEarly warning systemTower

The invention relates to a multilayer multi-column combined type vertical shaft wind power generating system which can effectively prevent a rugged strong wind environment from damaging a system, effectively utilizes wind power and runs more safely and stably. A multilayer combined type structure comprising a plurality of tower columns and a plurality of generating units is arranged; the wind power is utilized to directly drive main wind wings of the generating units of the vertical shaft wind power, and a main cantilever, a main cantilever fixed hub and a main shaft are utilized to drive a generator to generate electric power; whereas, when the rugged strong wind environment comes, the front face area of the main wind wing is regulated so as to effectively prevent the strong wind from damaging the system; a strong wind early warning system is arranged, when that the strong wind attacks is detected, the strong wind early warning system can send an instruction to the system in advance so as to take a strong wind avoiding measure, thereby greatly improving the running state, the safety and the stability of the wind power generating system.

Owner:ZHONGJIN FUHUA ENERGY TECH

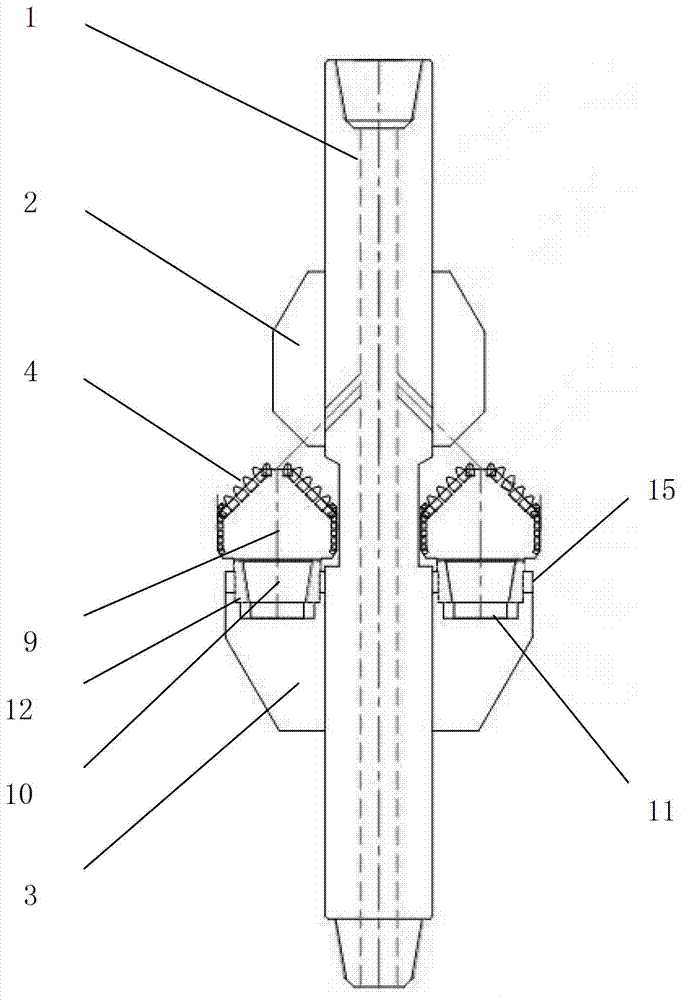

Rock reamer

The invention discloses a rock reamer. The rock reamer comprises a hollow central shaft which is connected with a drill rod, a front pilot and a back pilot which are fixedly arranged on the hollow central shaft, and a hobbing cutter which can conduct autorotation and is arranged between the front pilot and the back pilot. A central axis of the hobbing cutter and the central shaft are parallelly arranged, the hobbing cutter comprises a cylindrical section which has a righting function and a front end face formed at the front end of the cylindrical section, and hard alloy teeth used for crushing rocks are evenly distributed on the front end face and the peripheral surface of the cylindrical section. By improving a hobbing cutter structure and arranging positions, the phenomenon that a matched righting machine is additionally arranged on a reamer is effectively avoided, weight of tool is reduced, rotation torsion moment is reduced, cost is lowered, and service life of the tool is prolonged. In addition, the hobbing cutter is clamped or connected between the front pilot and the back pilot in a threaded mode, and therefore disassembly of the hobbing cutter is convenient.

Owner:天津博为中天钻具有限公司

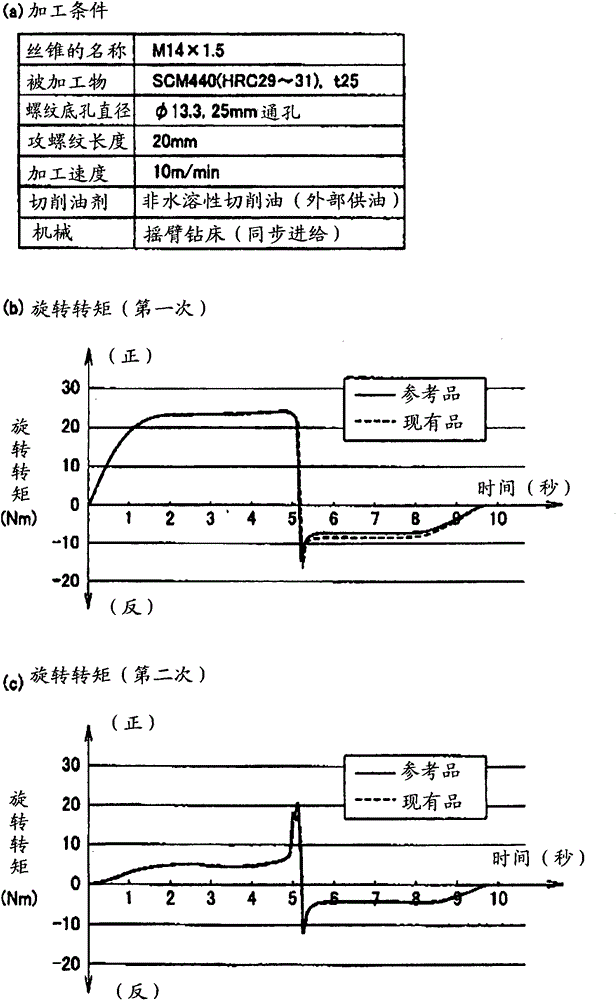

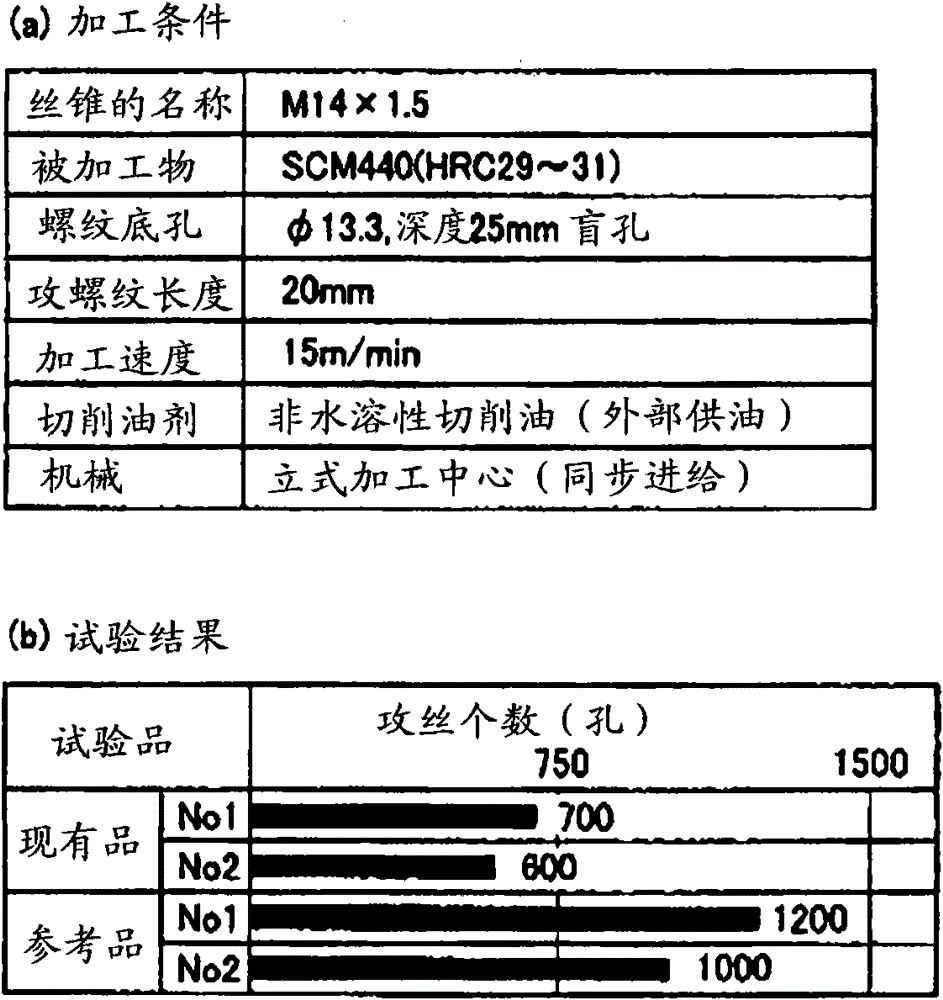

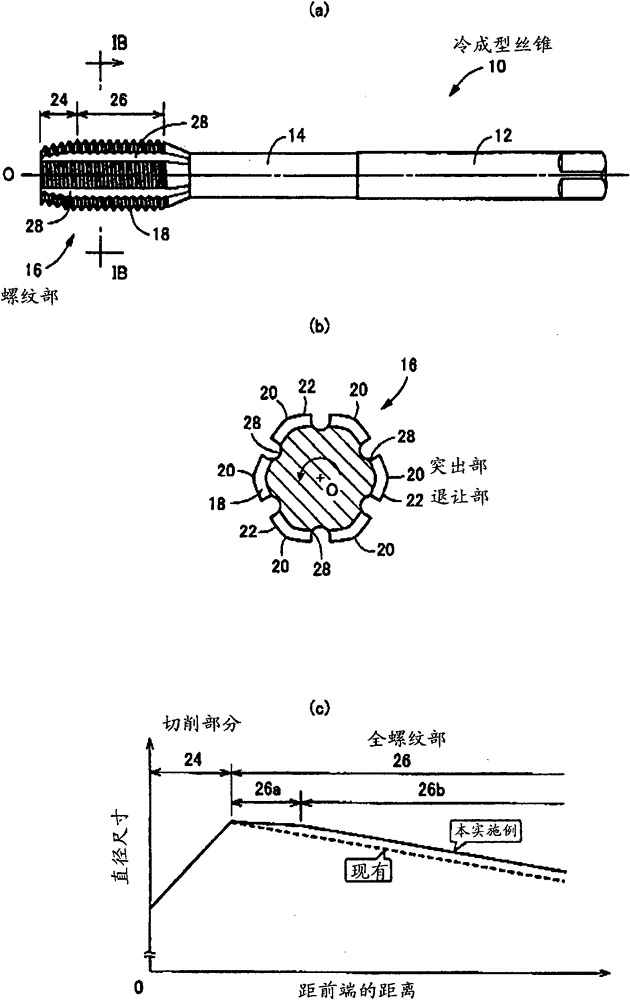

Thread forming tap

ActiveCN101977718BExtend your lifeHigh degree of completionThread cutting toolsOther manufacturing equipments/toolsEngineeringScrew thread

Owner:OSG

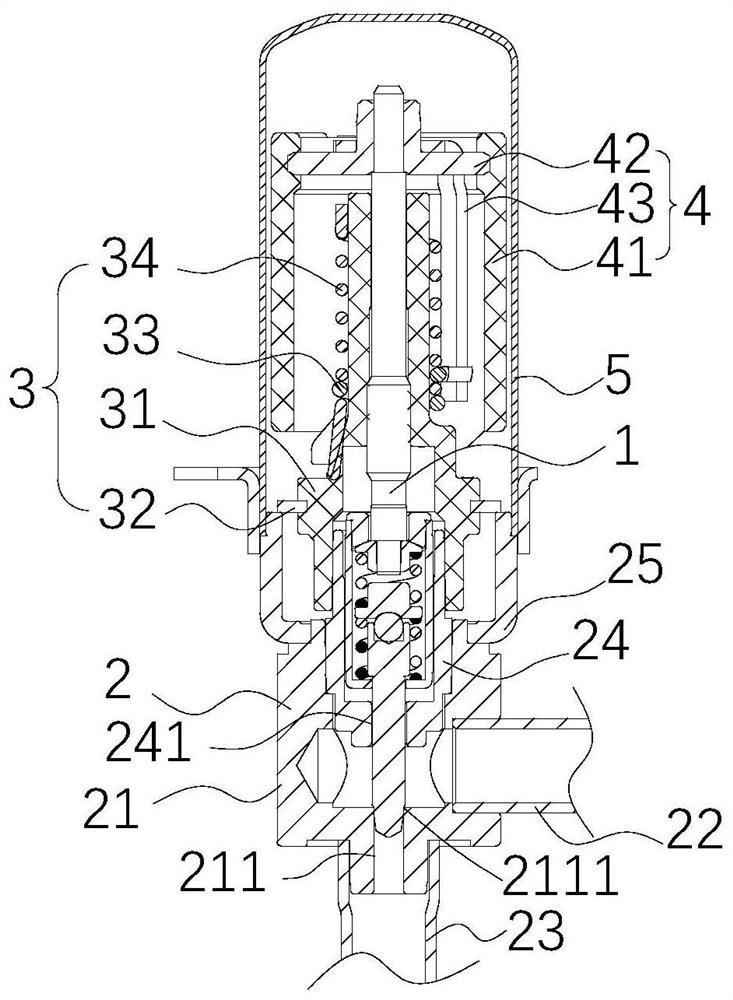

Electronic expansion valve

PendingCN112879573AIncrease elasticityReduce rotational torqueFluid circulation arrangementLift valveEngineeringElectronic expansion valve

The invention relates to an electronic expansion valve which comprises a valve needle screw rod assembly. The valve needle screw rod assembly comprises a valve needle, a sleeve component, an upper spring, a lower spring, an elastic carrier component and a screw rod component; the screw rod component comprises a screw rod body part and an abutting part; the screw rod body part and the abutting part are fixedly connected or are of an integrated structured; the screw rod component is connected with the sleeve component in a limiting mode; the valve needle comprises a large-diameter section and a small-diameter section; the valve needle is connected with the sleeve component in a limiting mode; the upper spring, the lower spring and the elastic carrier component are located in the sleeve component; the upper end of the upper spring abuts against the abutting part; the lower end of the upper spring abuts against the elastic carrier component; the upper end of the lower spring abuts against the elastic carrier component; and the lower end of the lower spring abuts against the sleeve component. The abrasion of the valve needle and a valve port caused by relative rotation can be reduced conveniently by changing the elastic force of the upper spring and the lower spring to the elastic carrier component in the initial state.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Resin retainer for tapered roller bearing, and tapered roller bearing

ActiveCN102089541BReduce stirring resistanceImproves ease of installationRoller bearingsShaftsCircular coneMechanical engineering

There is provided a resin cage of a tapered roller bearing. The cage includes a small diameter annular portion, a large diameter annular portion, and a plurality of bar portions arranged at intervals in a circumferential direction to connect the annular portions. The bar portion has a pair of circumferentially-directed side surfaces, each having a roller guide surface, and an inner-side inner peripheral surface, a circumferential width of which is smaller on a side of the large diameter annular portion than on a side of the small diameter annular portion, and has a roller retaining region in which a radially outer side pocket width and a radially inner side pocket width between the opposed circumferentially-directed side surfaces of the adjacent bar portions are smaller than a diameter of the roller.

Owner:NSK LTD

Developing roller and developing box

ActiveCN103472697AUniform temperature distributionReduce frictionElectrographic process apparatusPulp and paper industryFriction force

The invention relates to a developing roller for a laser printer, and particularly relates to a developing roller with small rotation torque and good end part sealing property. The developing roller comprises a developing roller body and a developing roller shaft, wherein the developing roller body is sleeved outside the developing roller shaft, and inwards-concave grooves matched with sealing members at end parts of the developing roller are respectively formed in non-developing regions at two ends of the developing roller body along the circumferential direction. The invention also provides a developing box comprising the developing roller. The developing box comprises a developing roller and sealing members, wherein the developing roller is rotatably supported on a developing roller bracket; inner circumferential surfaces of the sealing members are matched with the inwards-concave grooves in a sealing manner; outer circumferential surfaces of the sealing members are matched with two ends of the developing box in a sealing manner. Because the inwards-concave grooves matched with the sealing members at end parts of the developing roller are respectively formed in the non-developing regions at two ends of the developing roller body, the sealing property of two ends of the developing roller is better, the friction force between the developing roller and the sealing members is reduced, the rotation torque of the developing roller and the developing box is reduced, and the printing quality is improved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Blockage clearing machine with scraper rotating surface parallel to wall of polyhedral bin

PendingCN111086777AAvoid damageImprove the uniform forceHollow article cleaningLarge containersElectric machineryStructural engineering

The invention relates to a blockage clearing machine with a scraper rotating surface parallel to a wall of a polyhedral bin, and belongs to the field of blockage clearing machines. The blockage clearing machine comprises a scraper and a scraper driving part, wherein the scraper driving part comprises a motor, an output shaft of the motor is connected with an input shaft of a speed reducer, a driving gear is arranged on an output shaft of the speed reducer, a large gear is meshed on the driving gear, the large gear is arranged on a scraper main shaft, and the front end of the main shaft is provided with the scraper, the scraper is positioned in the bin, the scraper driving part is fixedly arranged outside the bin, the scraper rotating surface is parallel to the inner wall of the bin, the blockage clearing machine is respectively arranged a plurality of bin surfaces of the polyhedral bin body, the blockage clearing machine is used for carrying out large-area scraping or local stirring onthe powder on the inner wall of the polyhedral bin, the powder on the inner wall of the bin can be prevented from bonding, the flow of the powder is accelerated, and normal use of the bin is guaranteed.

Owner:HENAN MINGYU WEAR RESISTING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com