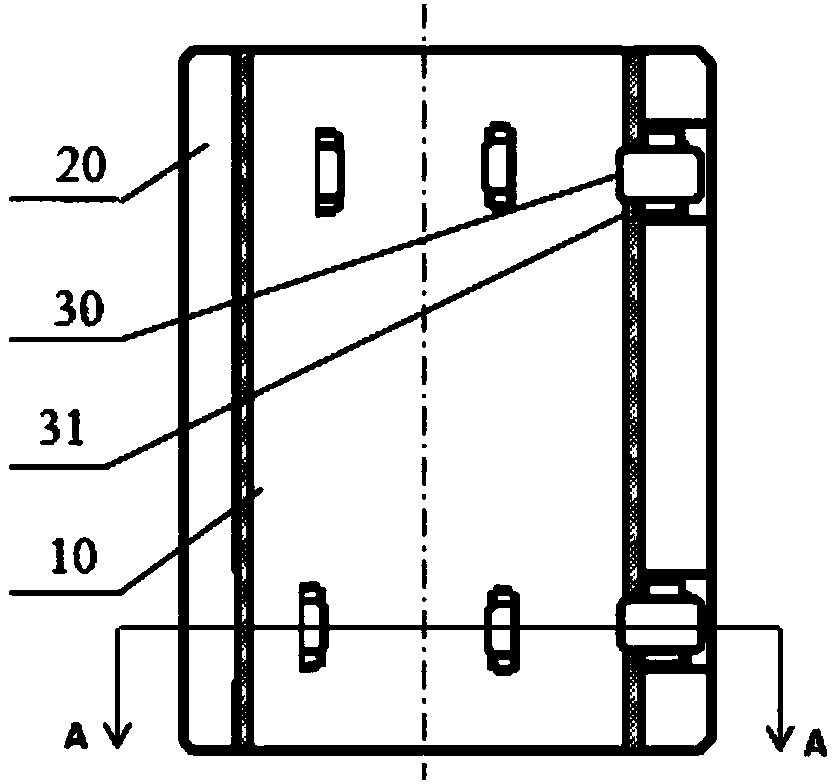

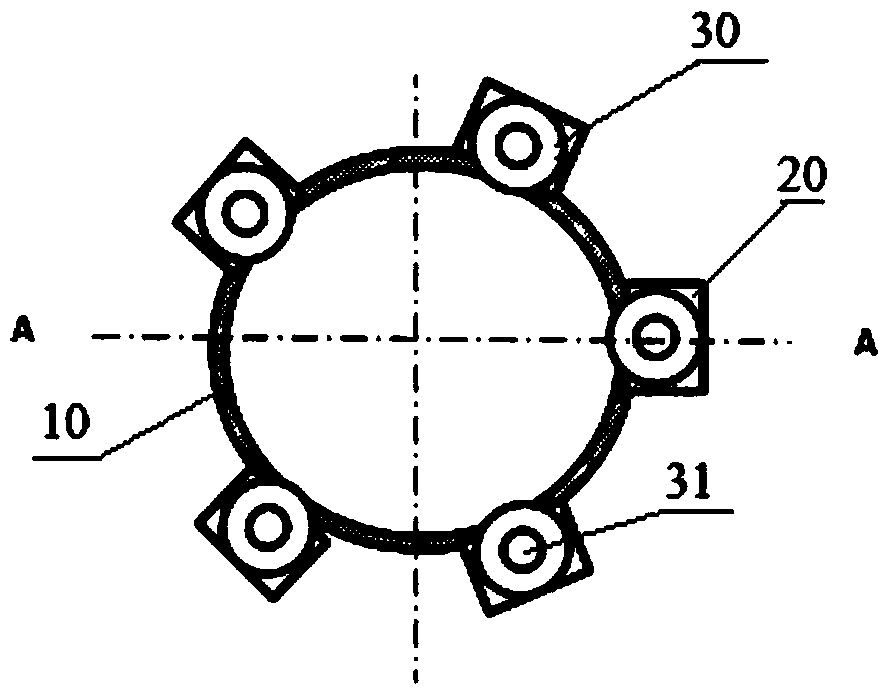

Rigid centering device

A technology of rigid centralizer and centralizing bar, which is applied in the direction of drilling equipment, earthwork drilling and production, drill pipe, etc., and can solve the problems affecting the rotary cementing process of rotary liner and casing, damage to the side of the centralizing rib, unfavorable casing rotation, etc. , to achieve the effect of improving cementing quality, protecting the well wall and facilitating rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Southern shale gas well D194-1HD is drilled with oil-based mud, the friction coefficient of oil-based drilling fluid is 0.31, and the density is 1.45g / cm 3 ,The inclination angle was 87.5° when the drilling was completed, the horizontal section length was 1524.m, the inclination depth was 4460.0m, the vertical depth was 2784.0m, the kickoff point was 2220m, the drill bit size was 215.9mm, the casing outer diameter was 139.7mm, and the wall thickness was 12.34mm . The whole well adopts 188 rigid centralizers provided by the present invention, of which one centralizer is placed for each casing in the horizontal section and the high-inclination section, and one centralizer is placed for 3-4 casings in the vertical well section. In order to ensure the normal running of the casing, when the casing is lowered to the bottom of the well at 3001m, the casing is rotated with a rotational torque of 2400N·m, and when the casing is lowered to the bottom of the hole at 4460m, the cas...

Embodiment 2

[0029] A well in the Biyang Sag of Henan Oilfield, the well type is a vertical well, the drilling depth is 3100m, the drilling bit size is 215.9mm, the casing outer diameter is 139.7mm, the casing wall thickness is 9.17mm, and the drilling fluid density is 1.25g / cm 3 . The whole well adopts 72 rigid centralizers provided by the present invention, and one centralizer is placed in 4 casings in the vertical well section. After the casing is run in, the casing is rotated to realize rotary casing cementing. 3 / min Displacement During well washing, the casing is rotated with a rotation torque of 2600N m. During the cement sheath, the casing is rotated at 20 rpm to achieve rotary casing cementing. The rotation torque is 2870N m. After 7 days Solid quality and sound amplitude logging, the quality of the whole well is high.

Embodiment 3

[0034] A well in Xinjiang Tahe Oilfield, the well type is a vertical well, the drilling depth is 6300m, the drilling bit size is 215.9mm, the liner pipe outer diameter is 139.7mm, the casing wall thickness is 9.17mm, the liner length is 1109m, and the drilling fluid density at completion 1.45g / cm 3 . The whole well adopts 34 rigid centralizers provided by the present invention, and one centralizer is placed in three casings of the liner section. After the liner is run in, the casing is rotated to realize rotary casing cementing, and the 1.8m 3 / min Displacement During well washing, the casing is rotated with a rotation torque of 5200N m. During the cement sheath, the casing is rotated at 20 rpm to achieve rotary casing cementing. The rotation torque is 5700N m. After 7 days Solid quality and sound amplitude logging, the quality of the whole well is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com