casing centralizer

A technology of centralizer and casing, which is applied to casing, drill pipe, drilling equipment, etc., can solve the problems of limited centralizing effect, difficulty in centering the casing, and high risk, and achieves strong pressure bearing capacity and ensures the centering degree. , Improve the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

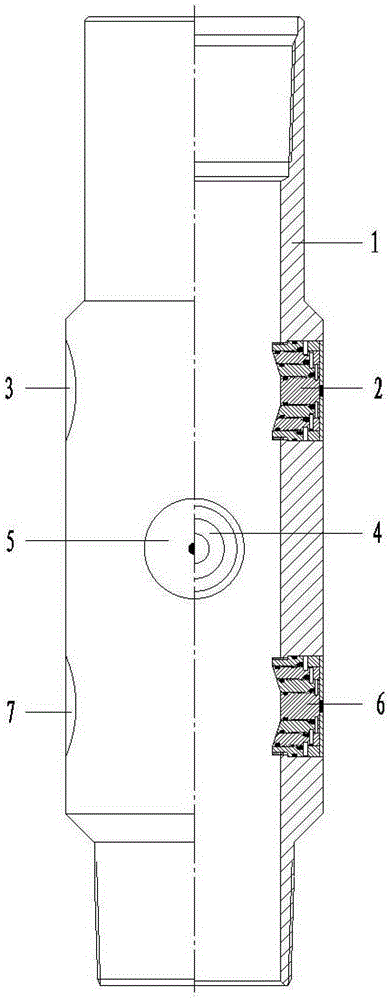

[0010] Such as figure 1 As shown, the casing centralizer of the present invention mainly includes pipe body 1, centralizing block I2, centralizing block II3, centralizing block III4, centralizing block IV5, centralizing block V6, and centralizing block VI7. The six centralizing blocks have the same structure and are evenly distributed in Tube 1. Before work, the centralizing block is shrunk in the inner wall of the pipe body 1 to ensure the minimum outer diameter of the centralizer and avoid construction hidden dangers caused by the large outer diameter of the centralizer during casing running.

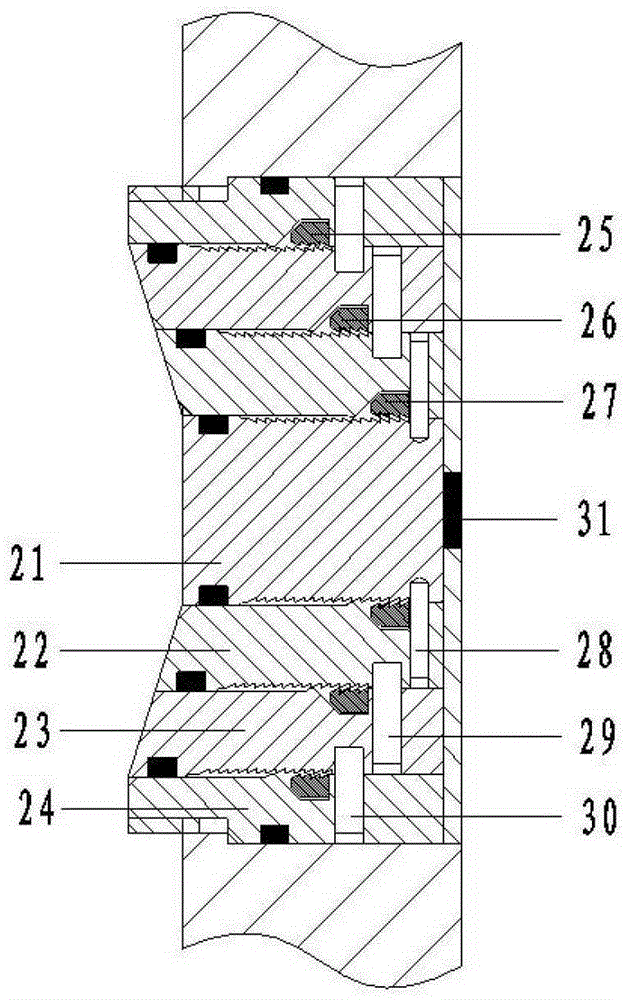

[0011] Such as figure 2 As shown, the above-mentioned centralizing blocks I-VI all include piston I21, piston II22, piston III23, piston seat 24, locking ring III25, locking ring II26, locking ring I27, shear nails I28, shear nails II29, and shear nails III30 , Piston cover 31. The piston seat 24 is connected with the pipe body 1 through threads, and the inner wall has a groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com