Experimental device and experimental method for simulating the corrosion process of cement sheath in formation

A technology for cementing and corrosion process, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., which can solve the problems of ion concentration attenuation, lack of convincing, and inability to determine the corrosion of the cemented surface of the casing cement ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

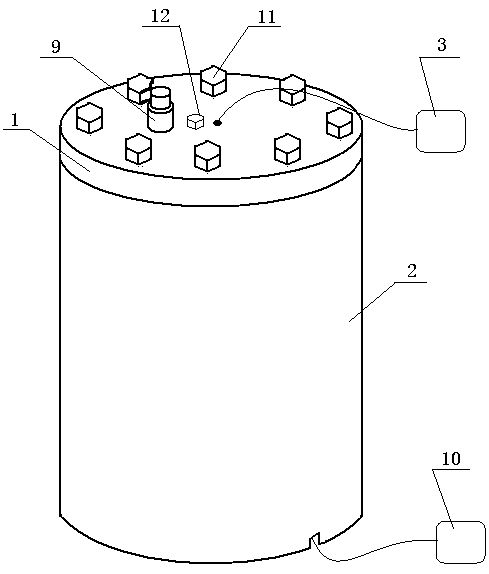

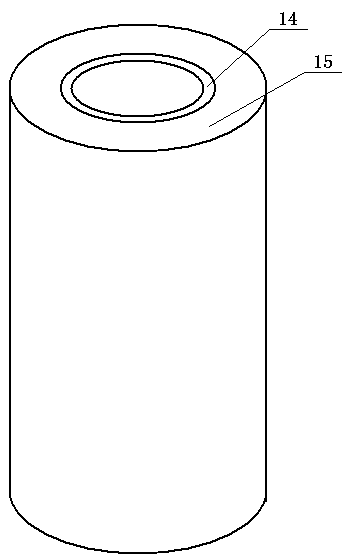

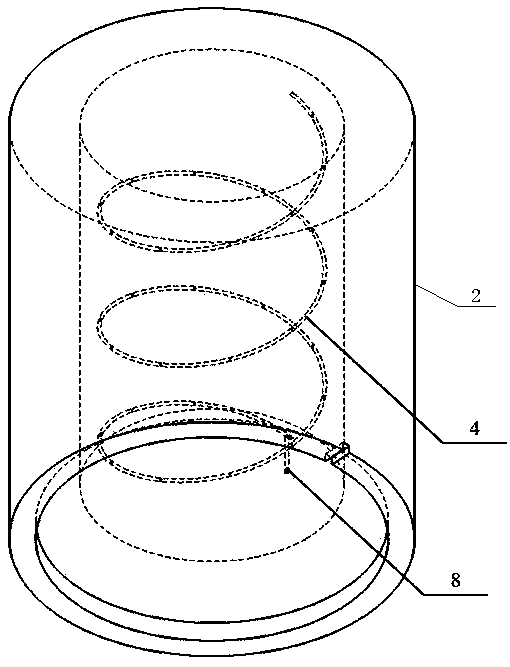

[0031] Such as figure 1 As shown, the experimental device for simulating the corrosion process of the cement sheath in the formation includes a sealing cover 1, a reaction vessel 2, a first constant current and constant pressure pump 3, a second constant current and constant pressure pump 10, an experimental specimen, a screw Screen tube 4, water inlet hole 5, overflow hole 6, valve hole 7 on sealing cover 1, experimental specimen is placed on the inner base of reaction vessel 2, spiral screen tube 4 is coiled between cement sheath 15 and reaction vessel 2 In the annular space between, a cylindrical positioning protrusion 16 is set in the center of the inner end surface of the sealing cover 1, and the sealing cover 1 is fixedly connected to the reaction vessel 2 by fixing bolts 11, and the positioning protrusion 16 is stuck in the casing 14, its purpose It is to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com