Variable diameter centralizer activated by chemical signal and method of use thereof

A centralizer and variable technology, applied in earth-moving drilling, drilling pipe, casing and other directions, can solve the problems of increased frictional resistance of casing downhole, small outer diameter of rigid centralizer, large casing frictional resistance, etc. The effect of improving quality, shortening downhole time, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention provides a chemical signal-activated variable-diameter centralizer and its use method. The present invention will be further described in detail below in conjunction with the accompanying drawings.

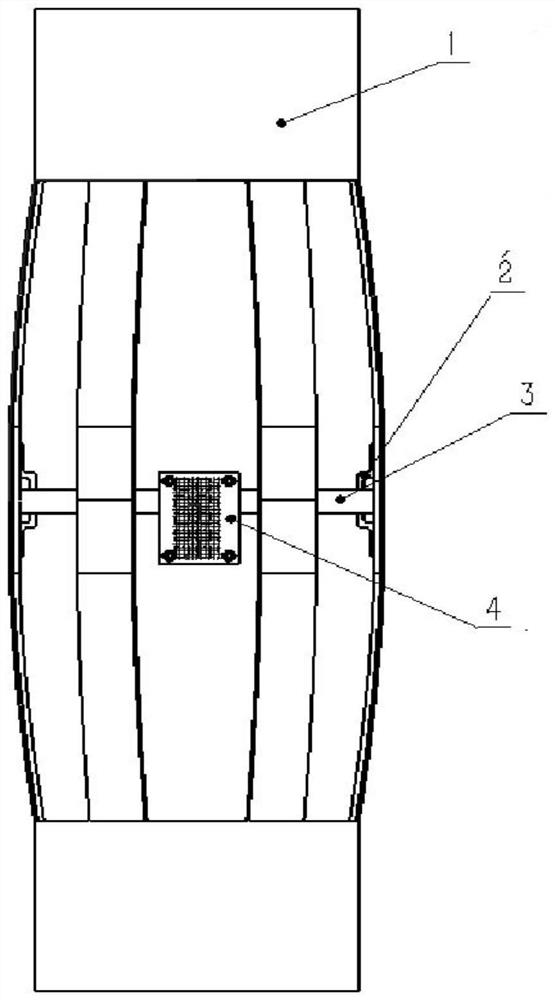

[0016] figure 1 Shown is a schematic diagram of the structure of the variable-diameter centralizer. Among them, the steel belt buckle 2 of the single-bow elastic centralizer 1 is fixed to the central position of the centralizer bar of the single-bow elastic centralizer 1 by welding, the steel belt 3 is located at the middle position of the steel belt buckle 2, and the chemical signal activation lock 4 is fixed on the The head of the strip 3.

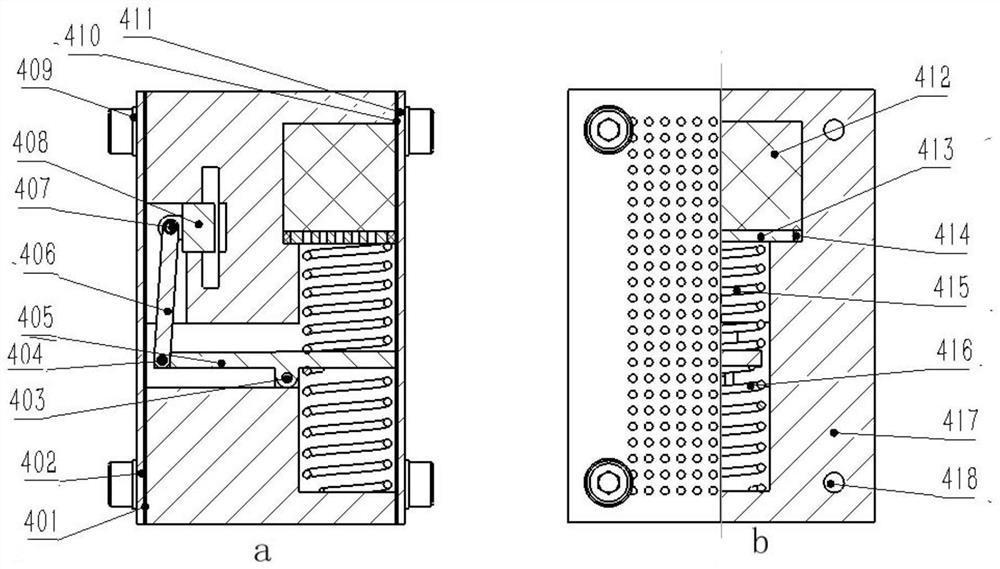

[0017] The structural composition of the chemical signal activation lock includes a cylinder body, a cylinder body cover, a rotating plate, a pull rod, a pull block, a spring, a baffle plate, an anti-friction ring, a filter paper, a screw, a rotating shaft and a washer; wherein, the I# filter paper 401 is sandwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com