Developing roller and developing box

A developing roller and developing cartridge technology, applied in the field of developing cartridges, can solve the problems of increased local friction in assembly or processing, deterioration of the developing roller body, and adhesion, etc., and achieve reduction of rotational torque and its fluctuations, reduction of frictional contact area, temperature evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

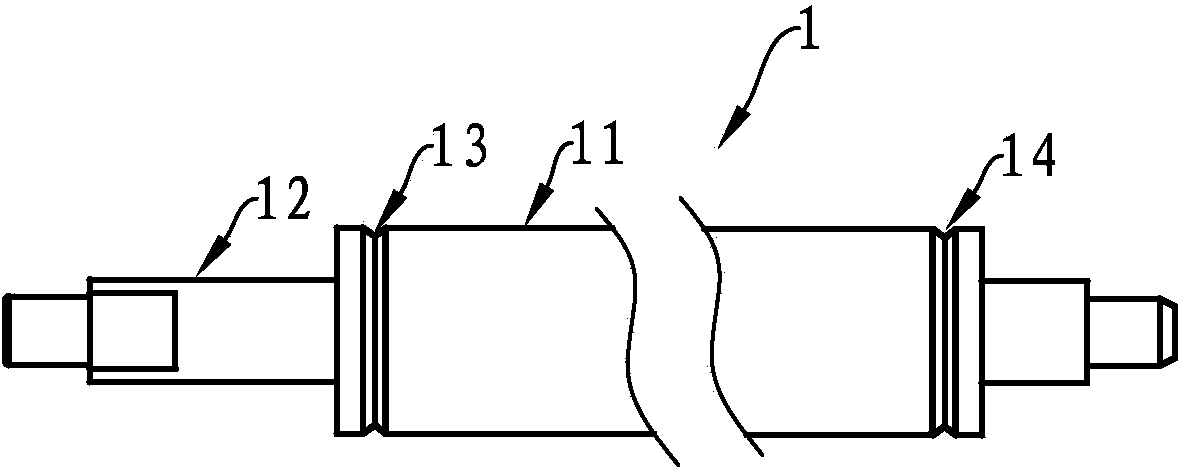

[0034] see figure 1 , figure 1 It is a structural schematic diagram of a developing roller according to the concept of the present invention. The developing roller 1 is composed of a developing roller body 11 and a developing roller shaft 12. The developing roller body 11 is sleeved outside the developing roller shaft 12. On the non-developing areas at both ends of the developing roller body 11, a circumferential concave groove 13 and Indented groove 14.

no. 2 example

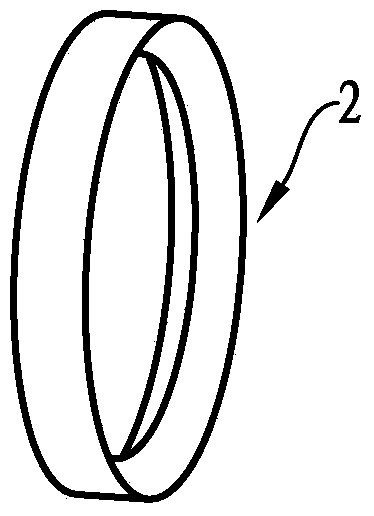

[0036] see figure 2 , figure 2 It is a structural schematic diagram of the collar in the second embodiment of the developing roller according to the concept of the present invention. Sleeve ring 2 is made of elastic wear-resistant material; Its structure can be a closed annular body with the same cross-section of the concave groove on the non-developing area at the two ends of the developing roller; Its structure is also It can be a strip whose cross section is the same as that of the concave groove on the non-developing area at both ends of the developing roller. One end of the strip is formed with a pin, and the other end is formed with a hole matched with the pin. Through the pin The fit with the hole constitutes as figure 2 The collar of the ring structure. The collar 2 can also be bonded by sealing felt or sealing sponge, etc. figure 2 The collar of the ring structure is shown.

[0037] The first embodiment of the developing cartridge

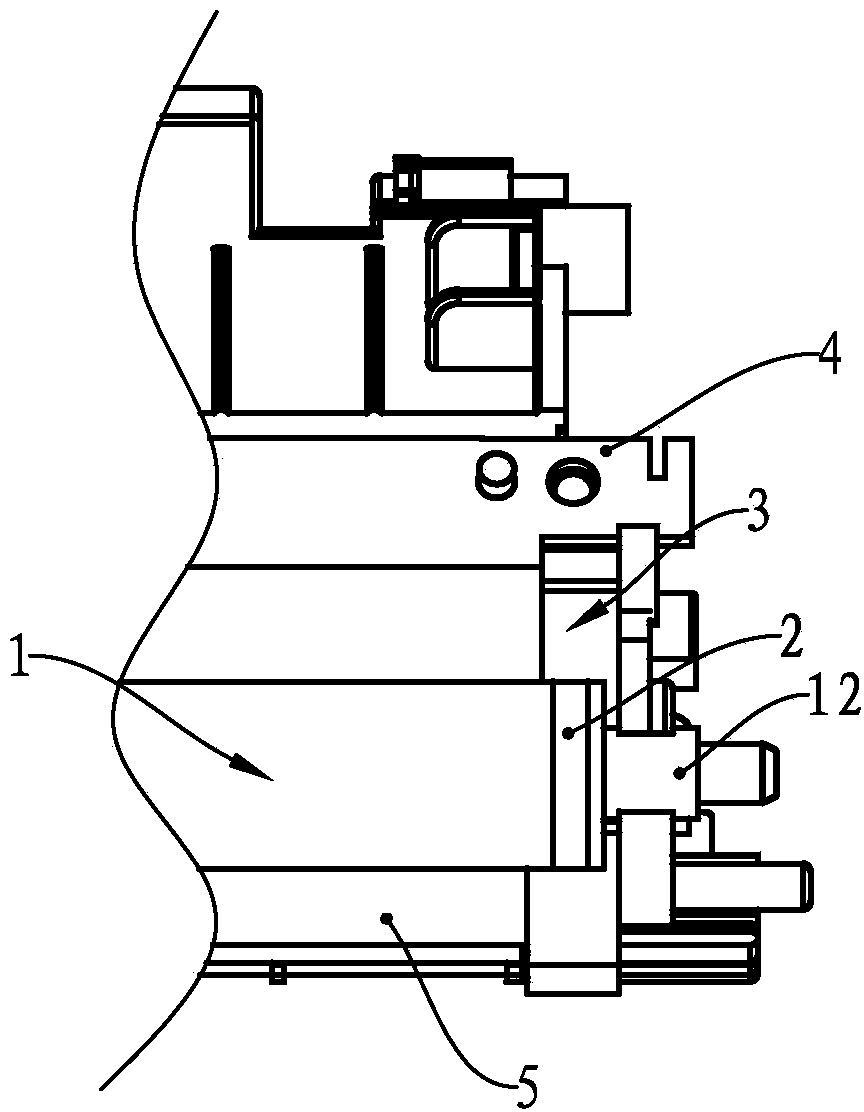

[0038] see image 3 , ...

no. 3 example

[0042] As the third embodiment of the developer cartridge according to the concept of the present invention, only the differences from the previous embodiment are described, and the semi-annular collar is used to replace the annular collar of the previous embodiment; The cross-section of the collar has the same part as the cross-section of the concave groove; the outer peripheral surface of the semi-circular collar is sealed with the corresponding box body of the developing cartridge by bonding or the like; the semi-circular collar and the concave The gap of the groove is filled with solid lubricant; the side of the semi-circular collar close to the developing area of the developing roller is sealed with the end of the powder outlet knife and the sealing blade. The semi-circular ring, the concave groove and the corresponding box body of the developing cartridge together constitute a sealing system at the end of the developing roller.

[0043] The concept of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com