Stabilizer of gas drill horizontal well

A technology for horizontal wells and centralizers, applied in the direction of drilling equipment, drill pipes, drill pipes, etc., which can solve the problems of hindering the movement of cuttings, difficult migration, and inability to be broken again, so as to achieve uniform flow rate, eliminate low-velocity areas, and Lower friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

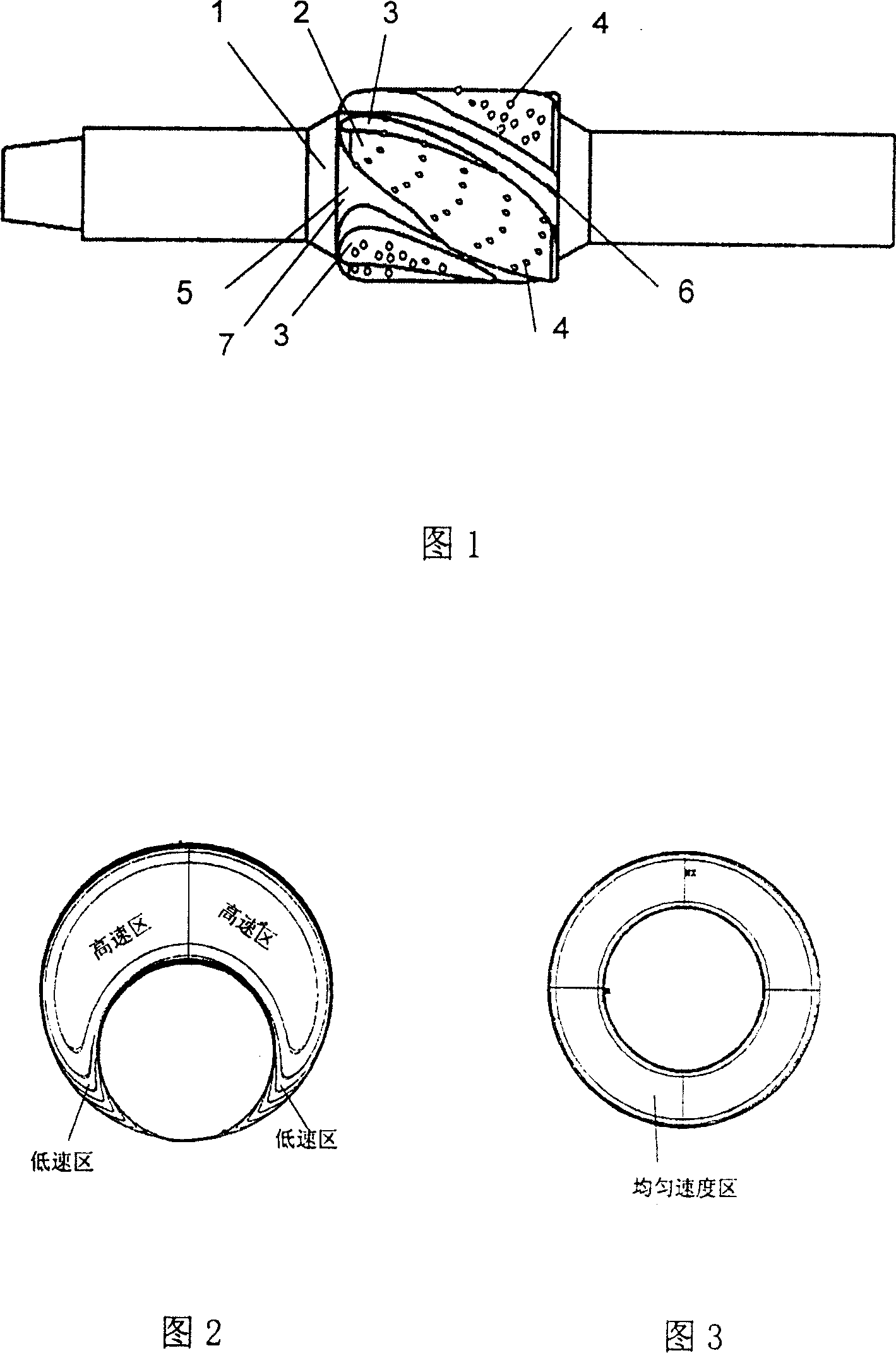

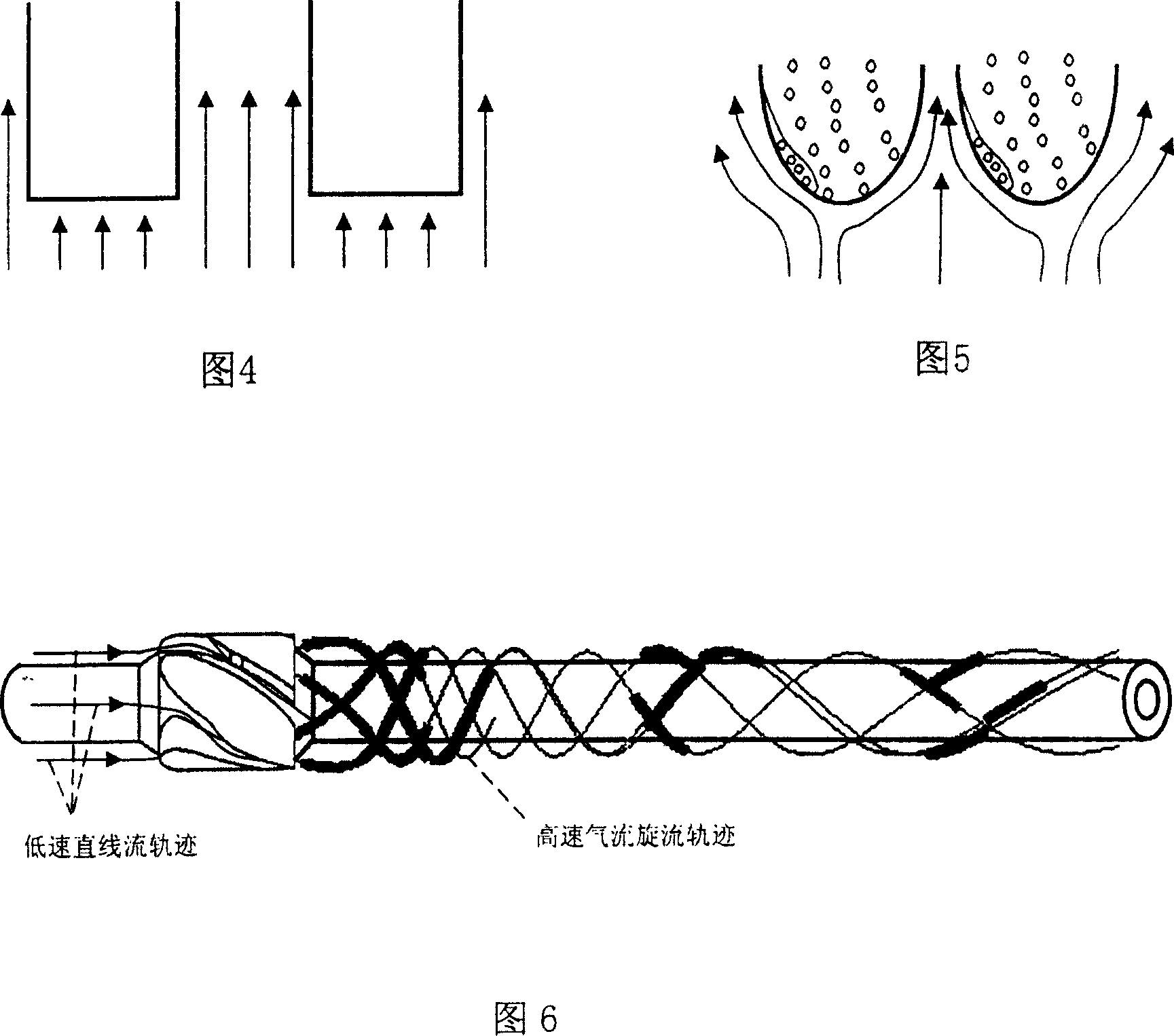

[0015] Referring to Fig. 1, a drilling tool centralizer for gas drilling horizontal wells is mainly composed of a centralizer body 1, a diversion groove 7, a centralizing strip 2, etc., and is characterized in that the diversion groove 7 is helical and has Wide inlet channel 5, narrow outlet channel 6, and the raised helical centralizing strip 2 sandwiched between the diversion grooves have a helix angle of 18° to 25°, and the centralizing strip has a cuttings introduction groove 3 , the width of the cuttings import groove corresponding to the wide inlet flow path and the narrow outlet flow path of the diversion groove gradually decreases, and the surface of the cuttings introduction groove 3 and the surface of the centralizing strip 2 are inlaid with cemented carbide teeth 4 .

[0016] Referring to Fig. 2 and Fig. 3, the centralizer has the function of lifting and straightening the drill string, reducing or even eliminating the flow field in the low-velocity zone of the eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com