Blockage clearing machine with scraper rotating surface parallel to wall of polyhedral bin

A technology of rotating surfaces and polyhedrons, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, containers, etc., and can solve the problem of reducing the volume of rectangular cones and variable-diameter cones, and losing rectangular and variable-diameter cones The problems such as the mismatching of the body material bin and the angle of the scraper are achieved to prevent bending deformation and breaking, improve the service life and reduce the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

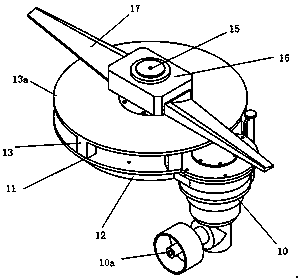

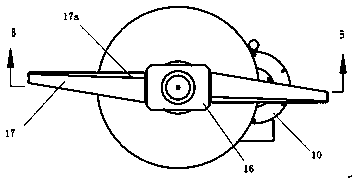

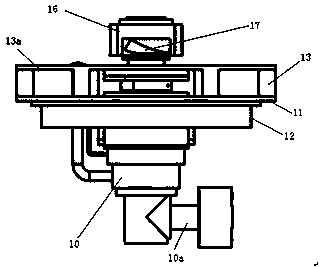

[0018] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings. in the following Figure 1-4 Although the direction of the main shaft is upward, in actual use, the main shaft is perpendicular to the surface of the tetrahedral inverted cone silo.

[0019] The technical solution of the present invention is a blockage clearing machine in which the rotating surface of the scraper is parallel to the wall of the polyhedral silo. figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic diagram of the scraper side of the blockage clearing machine, image 3 It is a schematic diagram of the side structure of the present invention, Figure 4 is along figure 2 Schematic diagram of the cross-sectional structure of B-B. The blockage clearing machine includes a motor and a reducer 10, the blockage remover includes a scraper 17 and a scraper driving part, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com