Combined sealing ring with high sealability and low torque

A low-torque, combined technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large friction torque between the sealing lip and the dust cover, poor sealing effect, etc., to achieve no degradation of sealing performance and reduced friction. , the effect of reducing the rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate technical scheme of the present invention below in conjunction with accompanying drawing:

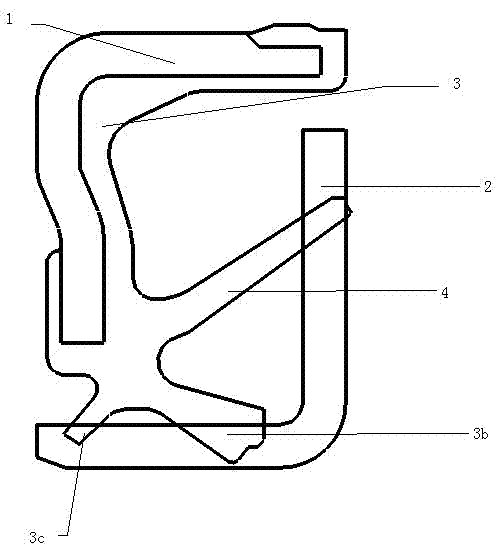

[0017] With the existing combined sealing ring such as figure 1 As shown, on the basis of the existing combined sealing ring, the present invention adopts a double-lip structure to reduce the radial interference of the main lip, thereby reducing the friction between the sealing lip and the dust cover, and reducing the rotational torque the goal of.

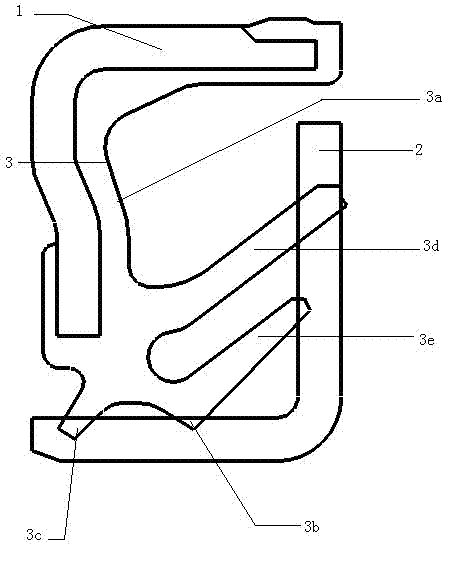

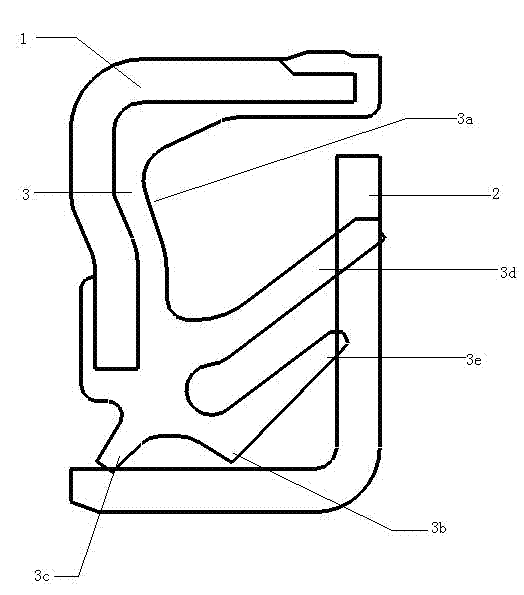

[0018] High-tightness low-torque combined seals, such as figure 2 , 3 As shown, the present invention is composed of an inner frame 1, a rubber body 3 and a dust cover 2, the inner frame 1 and the dust cover 2 form a sealed cavity, and a sealing rubber body 3 is placed in the sealed cavity, which is characterized in that: The sealing rubber body 3 described above includes a rubber body 3a matching the shape of the inner skeleton, a main lip 3b extending from the rubber body 3a, an auxiliary lip 3c, and a double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com