Well drilling cementing cement head

A technology for drilling and cementing and cementing heads, which is used in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of oil wells not being put into production normally, cementing cannot be carried out smoothly, and workover costs are expensive, etc. Achieve accurate opening or closing, long service life, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

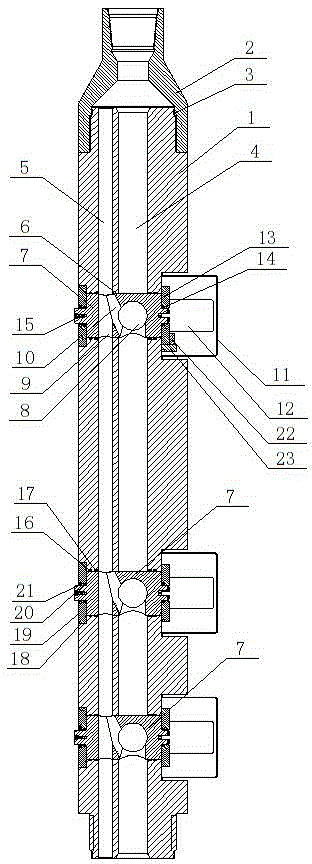

[0011] Such as figure 1 As shown, the drilling and cementing cement head includes a cement head body 1 , the upper end of the cement head body 1 is screwed to an upper joint 2 , and a first O-ring 3 is arranged between the upper joint 2 and the cement head body 1 . A cement head main through hole 4 and an axially arranged cement head auxiliary through hole 5 are arranged in the cement head body 1, and three stop pin cock holes 6 are arranged radially on the cement head body 1, each stop pin The stopcock cocks 7 are arranged in the cock holes 6, and the cock main through hole 8, the cock auxiliary through hole 9, and the cock oblique through hole 10 are set on the stop pin cock 7, and the cock main through hole 8 is set in the main through hole 4 of the cement head On the stop pin cock 7 of the cock, the cock secondary through hole 9 is set on the stop pin cock 7 in the cement head secondary through hole 5, and the cock main through hole 8 is vertically arranged with the cock s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com