Accurate rotation mechanism

A rotating mechanism, precise technology, applied in the direction of electromechanical devices, mechanical equipment, control of mechanical energy, etc., can solve the problems of the rotation angle accuracy not meeting the requirements, the wear of the meshing gap, etc., and achieve the effect of small failure rate, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

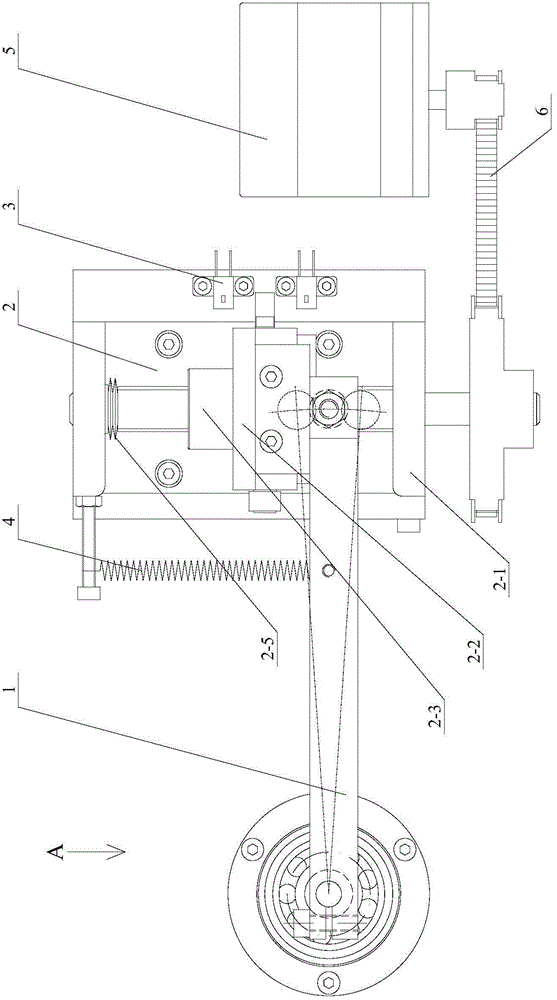

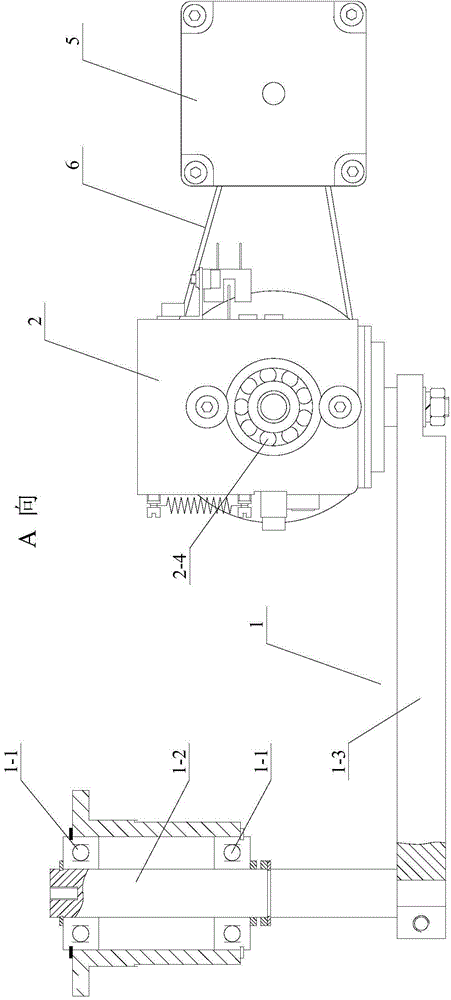

[0012] Such as figure 1 with figure 2 As shown, a precise rotating mechanism involved in this embodiment includes: a rotating arm mechanism 1, a linear motion pair 2, a limit detection mechanism 3, a tension spring 4, a motor 5 and a transmission mechanism 6, and the rotating arm mechanism 1 Including a bearing 1-1, a rotating shaft 1-2 and a rotating arm 1-3, the linear motion pair 2 includes a bracket 2-1, a ball screw pair-screw nut 2-2, a ball screw pair-screw rod 2- 3. Bearing 2 2-4 and bearing pre-tightening disc spring 2-5, the ball screw pair-screw nut 2-2 is arranged in the bracket 2-1, the ball screw pair-screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com