Motor

A motor and armature technology, which is applied in the field of electric motors, can solve the problems of reduction of motor rotation torque and electromotive force, and achieve the effect of reducing cogging torque and inhibiting the reduction of rotation torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

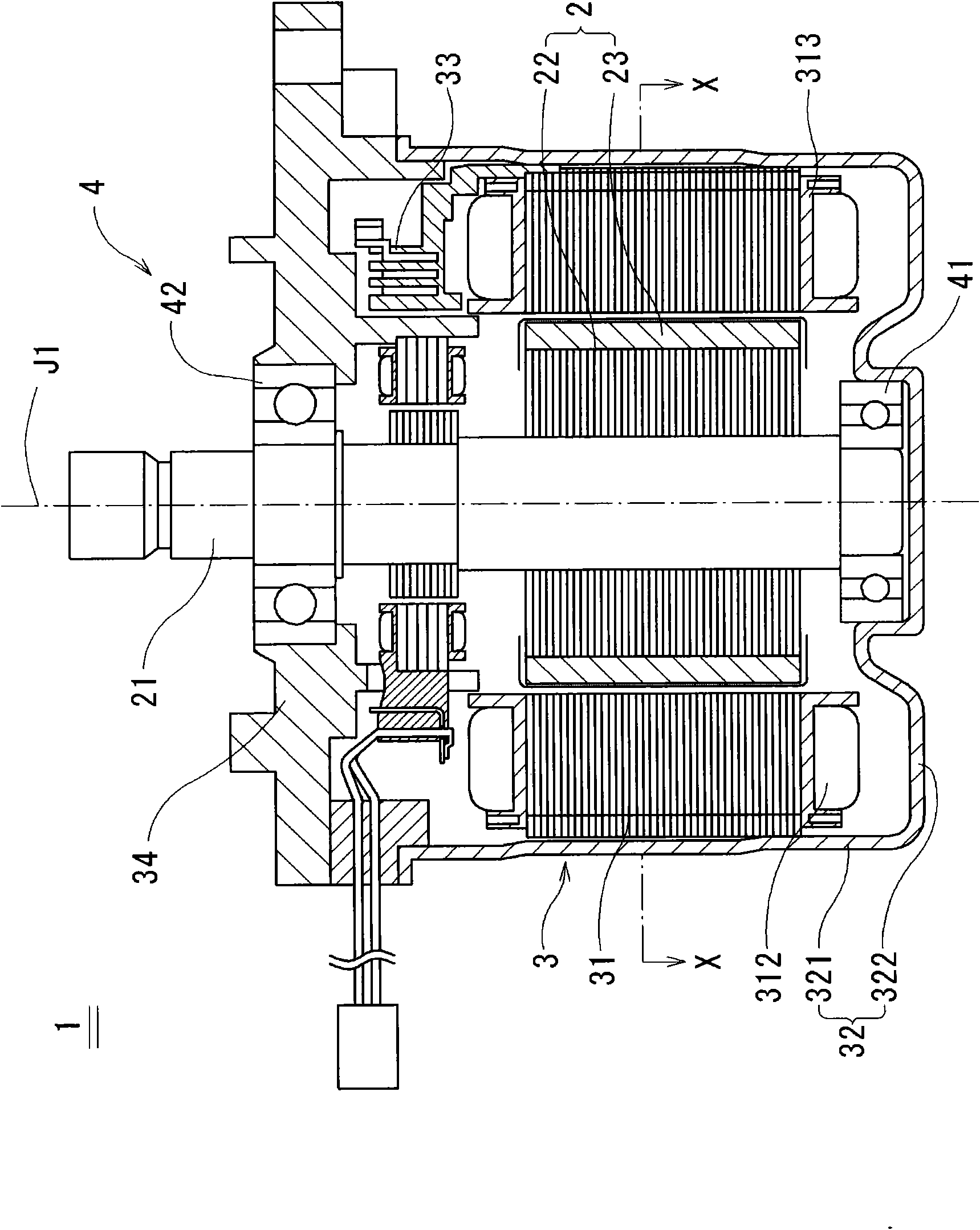

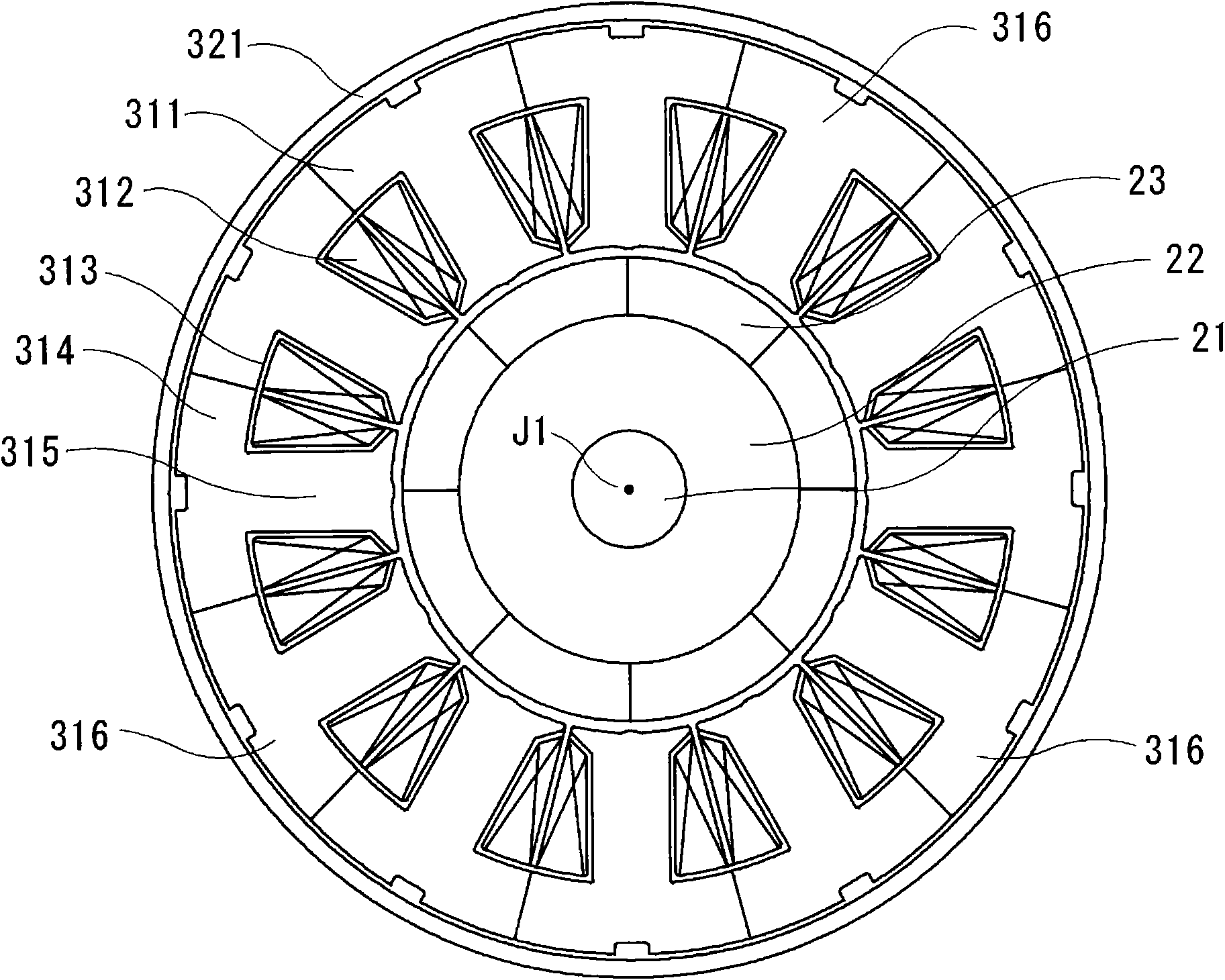

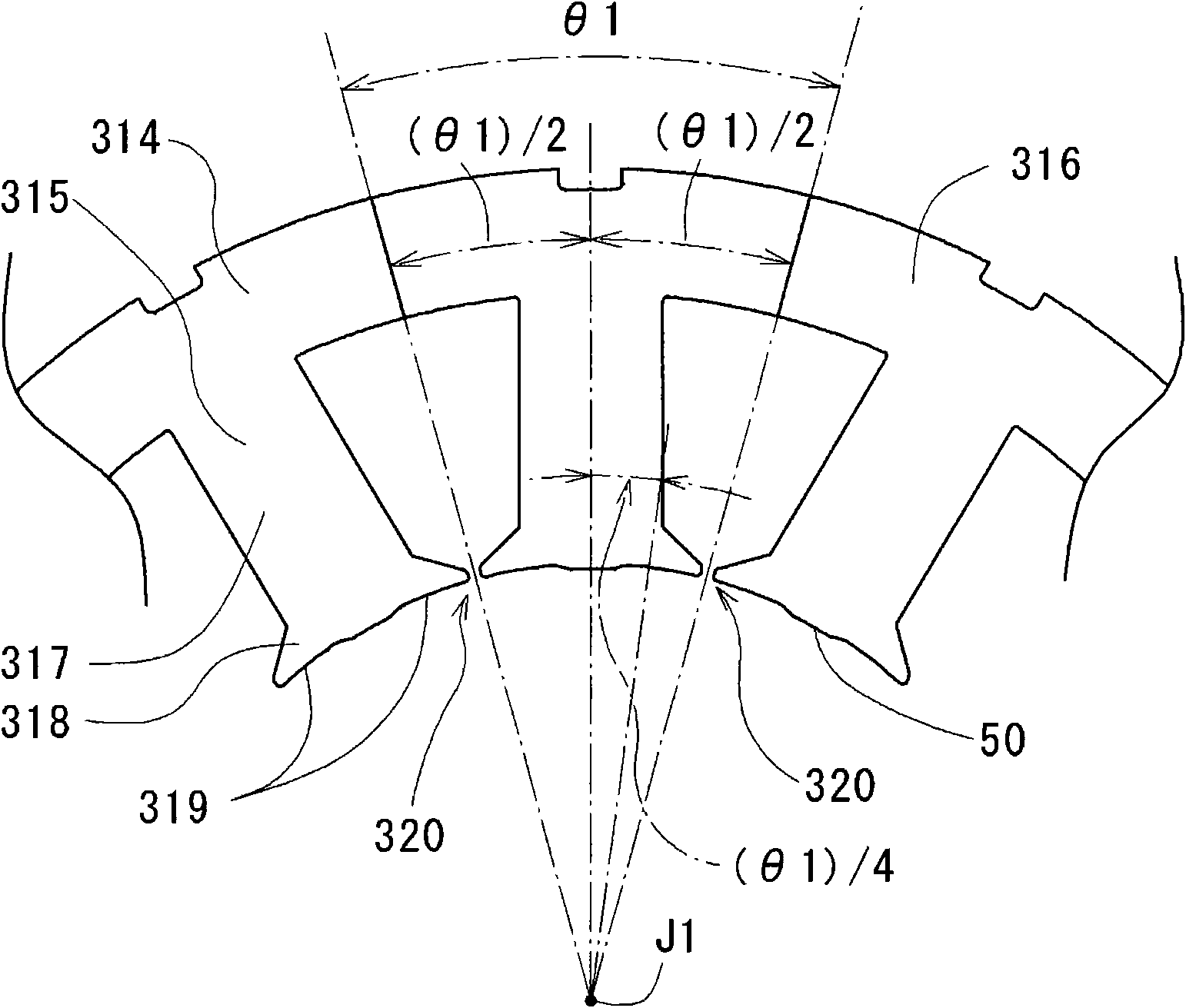

[0027] figure 1 It is a cross-sectional view schematically showing the motor 1 according to the first preferred embodiment of the present invention. Such as figure 1 As shown, the motor 1 has a rotating body 2 , a fixed body 3 and a bearing mechanism 4 . The rotating body 2 has a rotor magnet 23 composed of permanent magnets having a substantially annular shape centering on the central axis J1. The fixed body 3 has an armature 31 disposed radially opposite to the rotor magnet 23 . The bearing mechanism 4 supports the rotating body 2 such that the rotating body 2 can rotate about the central axis J1 relative to the fixed body 3 . The motor 1 of this embodiment is a three-phase brushless motor. Furthermore, the electric motor 1 of the present embodiment is mounted on an electric power steering device. Accordingly, it is possible to provide an electric power steering device that achieves a low cogging torque and achieves miniaturization.

[0028] The rotating body 2 has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com