Sealing ring

A sealing ring and dynamic pressure technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of fluid leakage and increased leakage, and achieve the effects of suppressing leakage and reducing rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

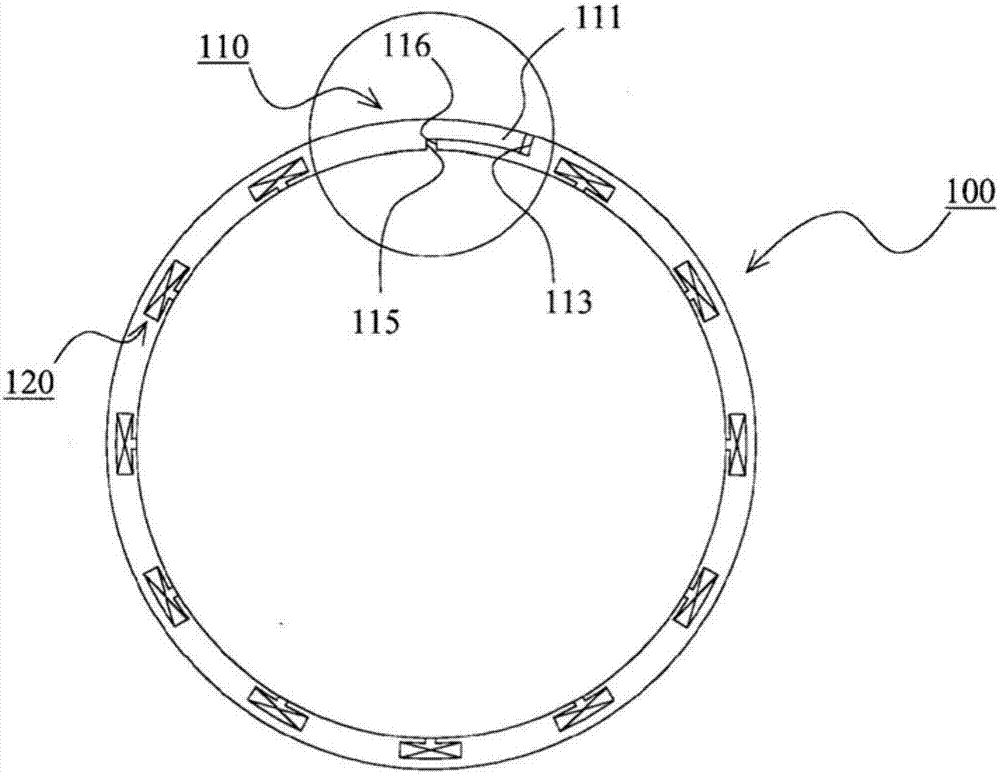

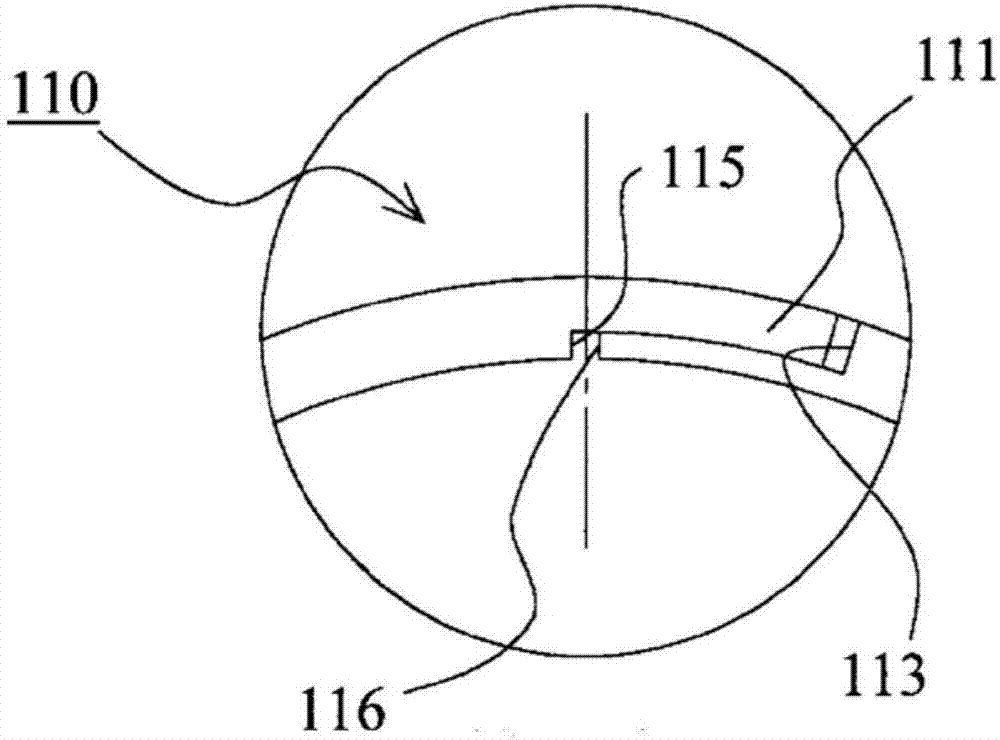

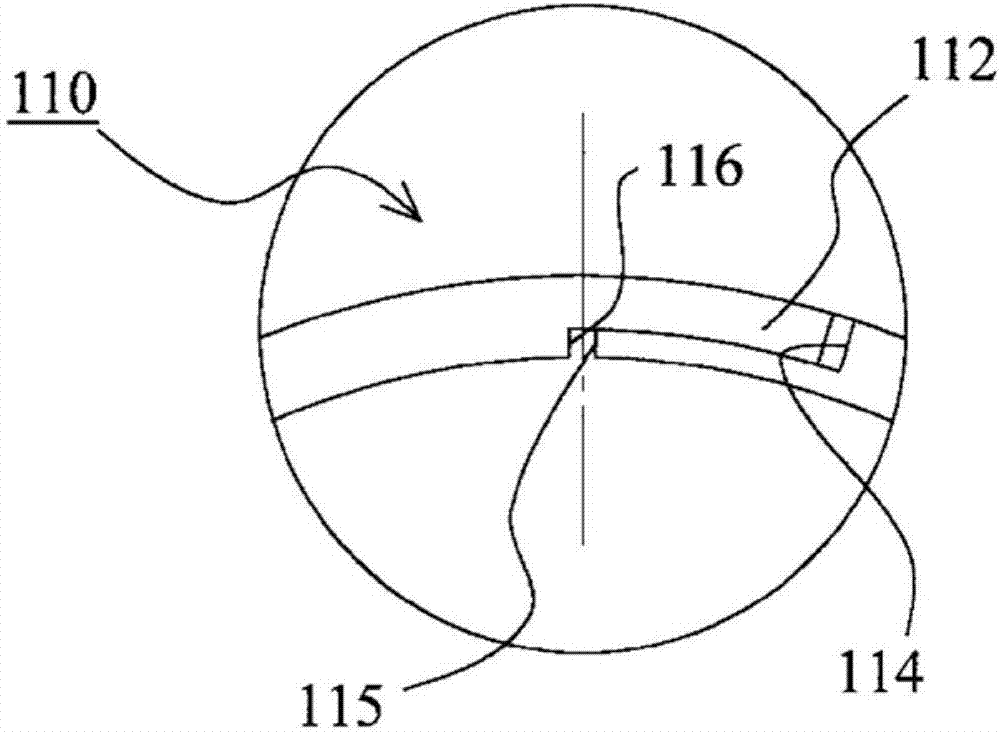

[0121] refer to Figure 1 to Figure 6 The seal ring according to Embodiment 1 of the present invention will be described. figure 1 It is a side view of the seal ring according to Embodiment 1 of the present invention. figure 2 It is a partial enlarged view of the side view of the seal ring according to Embodiment 1 of the present invention, and is figure 1 A magnified view of the portion surrounded by a circle in . image 3 It is a partial enlarged view of the side view of the seal ring according to Embodiment 1 of the present invention, viewed from the opposite side figure 1 A magnified view of the portion surrounded by a circle in . Figure 4 It is a partially enlarged view of the seal ring according to Embodiment 1 of the present invention viewed from the outer peripheral surface side, and is viewed from the outer peripheral surface side figure 1 A magnified view of the portion surrounded by a circle in . Figure 5 It is a partial enlarged view of the sealing ring acc...

Embodiment 1

[0137] refer to Figure 7 ~ Figure 9 The groove portion 120 according to the first embodiment will be described. Figure 7 It is a partial enlarged view of the side view of the seal ring according to Embodiment 1 of the present invention, and is an enlarged view of the vicinity where the groove portion 120 is provided. Figure 8 is a schematic cross-sectional view of the seal ring according to Embodiment 1 of the present invention, and is Figure 7 AA sectional view in . Figure 9 is a schematic cross-sectional view of the seal ring according to Embodiment 1 of the present invention, and is Figure 7 BB section view in .

[0138] As described in the above embodiment, the groove portion 120 is provided on the sliding surface side of the seal ring 100 . The groove part 120 involved in this embodiment consists of the first groove 121 extending in the circumferential direction and extending from the circumferential center of the first groove 121 to the inner peripheral surface...

Embodiment 2

[0145] Figure 10 Example 2 of the present invention is shown. This embodiment is a modified example of the above-mentioned first embodiment, and differs from the first embodiment in the arrangement area of the dynamic pressure generating groove 121a and the foreign matter capturing groove 121b. Figure 10 It is a partial enlarged view of the side view of the seal ring according to Example 2 of the present invention, and is an enlarged view of the vicinity where the groove portion 120 is provided.

[0146] In the present embodiment, in the first groove 121, the dynamic pressure generating grooves 121a are respectively provided on both sides of the center in the circumferential direction. In addition, the pair of dynamic pressure generating grooves 121a is formed so as to gradually become shallower from the center side in the circumferential direction toward the ends in the circumferential direction. Although not shown in the present embodiment, the groove bottom of the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com