Variable cross-section spiral drilling tool and construction method of variable cross-section cast-in-situ bored pile

A technology of variable cross-section and helical drill rods, which is applied in the direction of drilling equipment and methods, rotary drilling, rotary drilling rigs, etc., which can solve the problems of inability to achieve reaming, inconvenient construction, and inability to open the drill tip, etc., to achieve increased connection , improve the service life and reduce the effect of rotating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a further description is made on the variable-section auger.

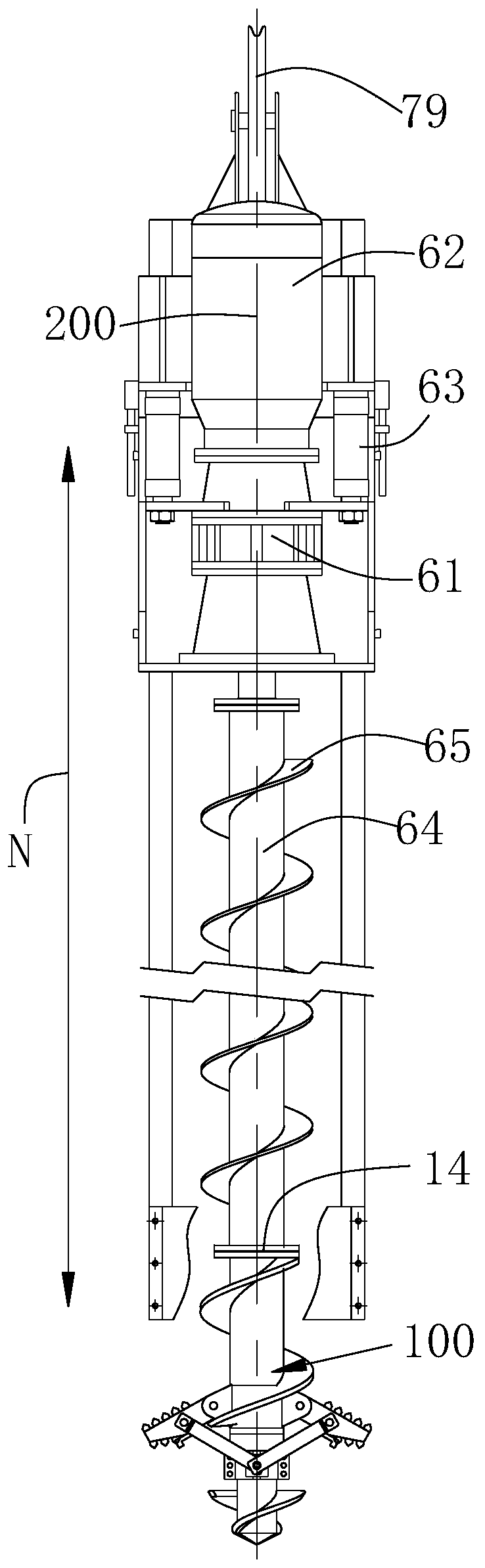

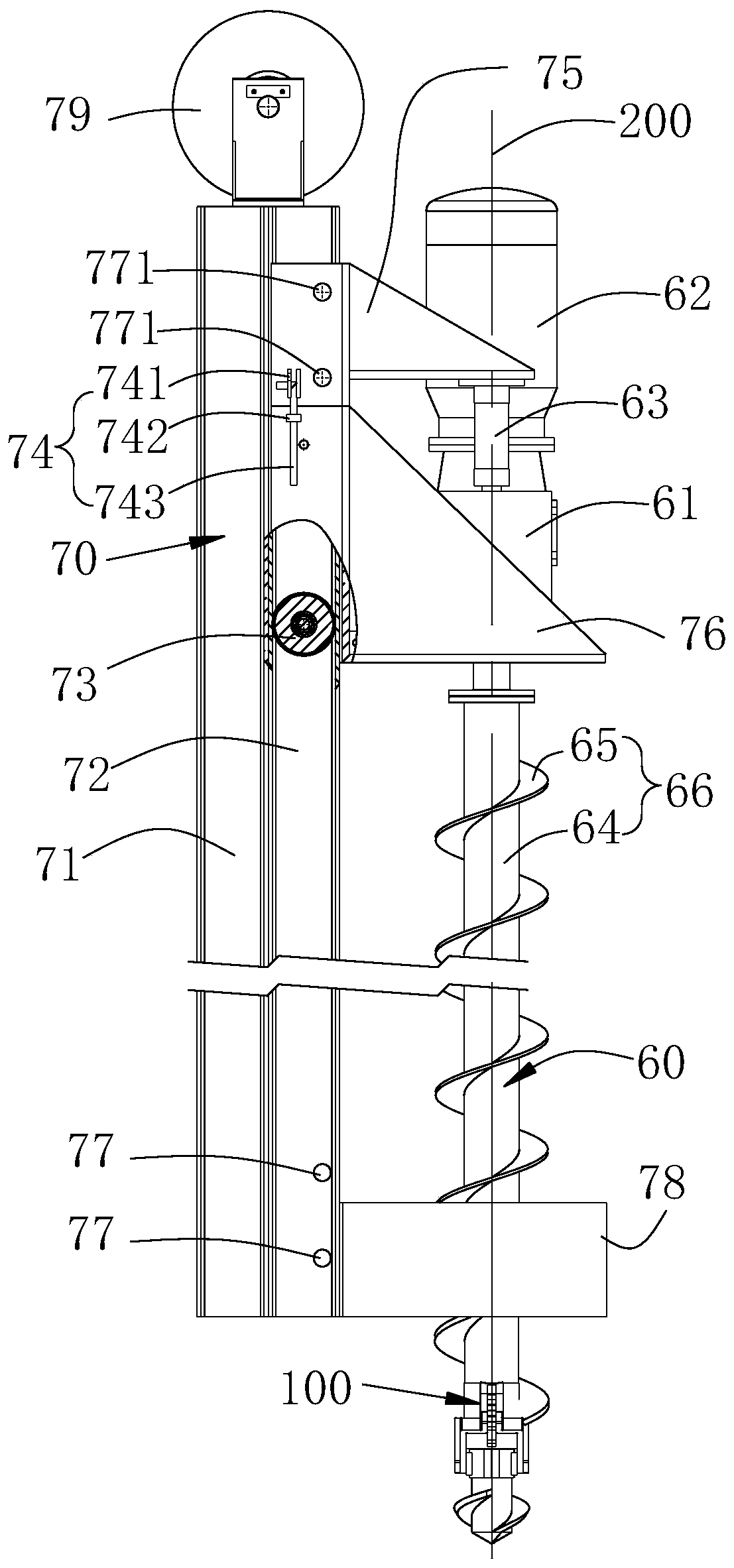

[0036] see figure 1 and figure 2 , is a specific embodiment of a variable cross-section auger, which includes a guide device 70 and an auger rod 60 installed on the guide device 70, the auger rod 60 has a central axis 200, and the central axis 200 is parallel to an axis N, the guide device 70 includes a guide frame 71 and a guide rail 72 installed on the guide frame 71 .

[0037] The auger rod 60 includes a helical rod 66 and a drill head 100 mounted on the bottom end of the auger rod. The auger rod 66 has a central rod 64 and a helical blade 65 spirally surrounding the central rod 64 . In this embodiment, the central rod 64 is a hollow rod.

[0038] see Figure 3-Figure 6 The drill head 100 includes an outer sleeve 11 , a guide rod 21 , a connecting rod 37 and an enlarged head blade 30 , and one end of the outer sleeve 11 is fixedly installed on the bottom end of the screw rod throu...

Embodiment 2

[0062] In this embodiment, the construction method of the bored pile is further described. In this embodiment, the variable-section helical drilling tool in Embodiment 1 is used. In this embodiment, the same reference numerals as in Embodiment 1 represent the same technical features.

[0063] This construction method comprises the steps:

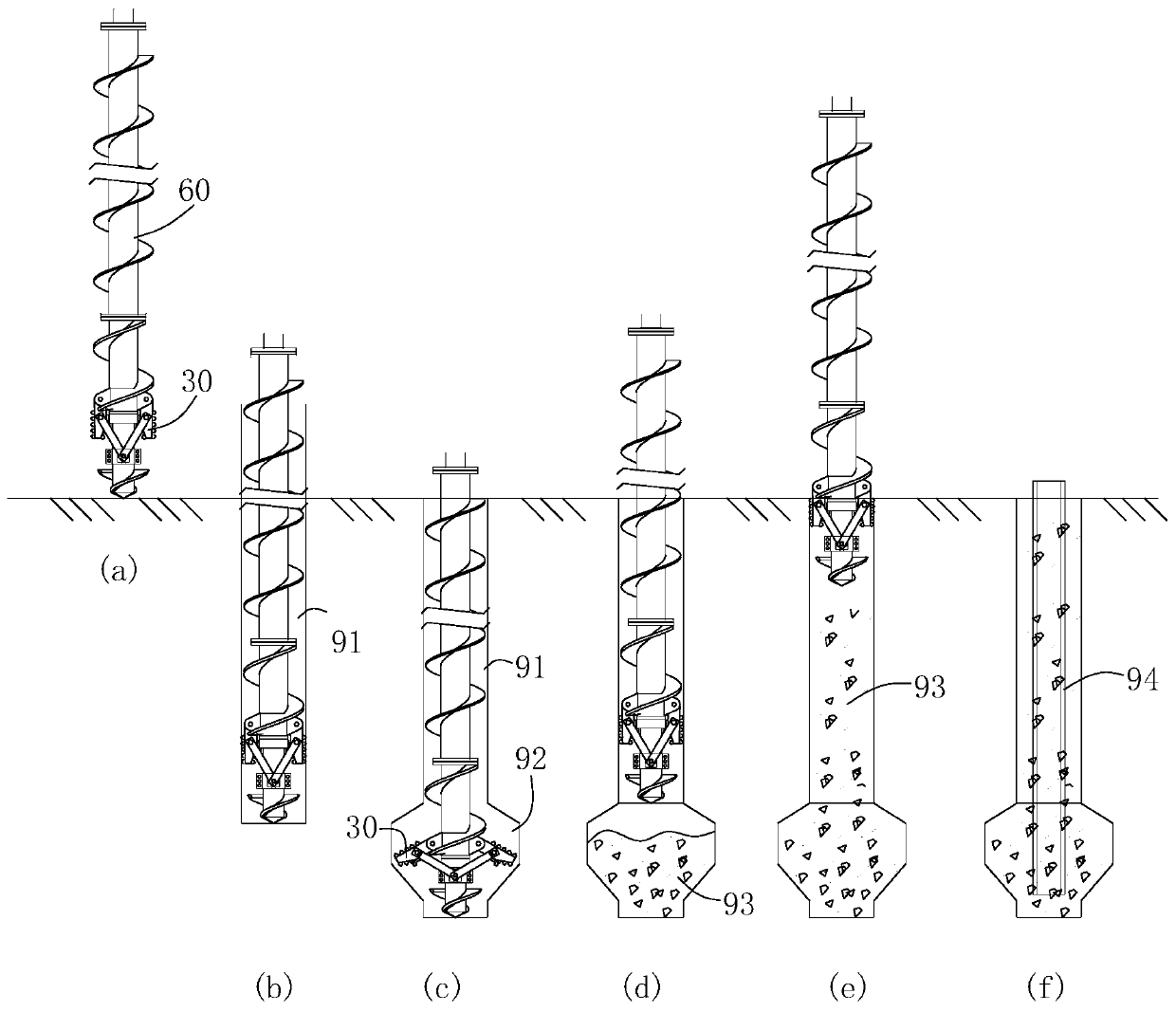

[0064] (1) Please refer to Figure 7 In steps (a) and (b), install the guide device of the variable-section auger to the set position, make the expanding head blade 30 in the retracted position, start the drive motor, and make the auger rod 60 rotate forward and move along the set position. Drill out the main pile hole 91 in the direction;

[0065] (2) See Figure 7 In step (c), the height position of the auger drill rod 60 is maintained, the clamping part is fixedly connected to the limit part, the limit part is fixed on the guide device, and then the auger drill rod is reversed, and the auger drill rod is at the original depth Rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com