Butterfly valve with O-shaped sealing ring and bearing

A sealing ring and bearing technology, used in shaft seals, lift valves, valve details, etc., can solve the problems of inconvenience of actual operation, increase valve stem torque, easy generation of gaps, etc., to reduce rotational torque and reliable sealing performance. , the effect of reducing the rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

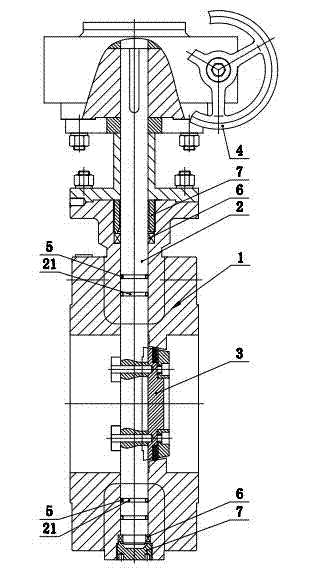

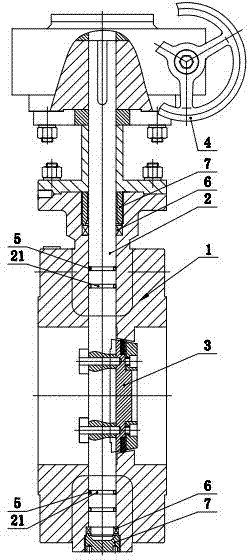

[0009] Such as figure 1 The figure shows a butterfly valve with an O-ring and a bearing, including a valve body 1, a valve stem 2, and a butterfly plate 3. The butterfly plate 3 is installed in the valve body 1, and the valve stem 2 is mounted on the valve body 1. One end of the valve stem 2 is fixedly connected with the butterfly plate 3 in the valve body 1, and the other end of the valve stem 2 is connected with the executive hand wheel 4, and an O-ring seal 5 is arranged between the valve stem 2 and the valve body 1 With the single-row radial ball bearing 6, several O-ring grooves 21 for accommodating the O-ring sealing ring 5 are opened on the circumferential surface of the valve stem 2, and the single-row radial ball bearing 6 is fixedly set by the bearing cover 7 on stem 2.

[0010] The O-shaped sealing ring 5 is used as the sealing structure between the valve stem 2 and the valve body 1. Compared with the sealing structure composed of flexible graphite and packing glan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com