Rock reamer

A hole reamer and rock technology, which is applied to drilling equipment, earthwork drilling, drill bits, etc., can solve problems such as accidents in the hole, large rotational torque, and drill pipe breakage, and reduce tool weight, reduce rotational torque, and enhance use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0029] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

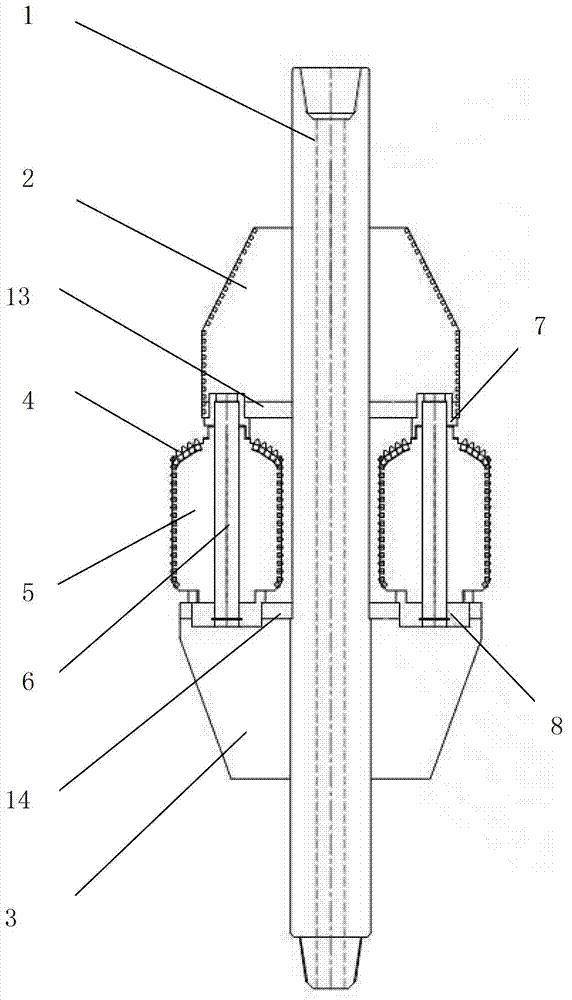

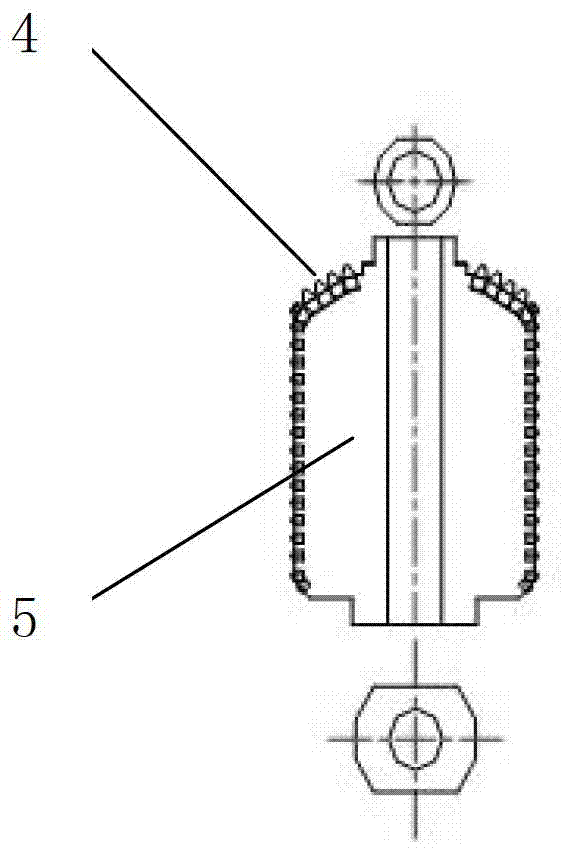

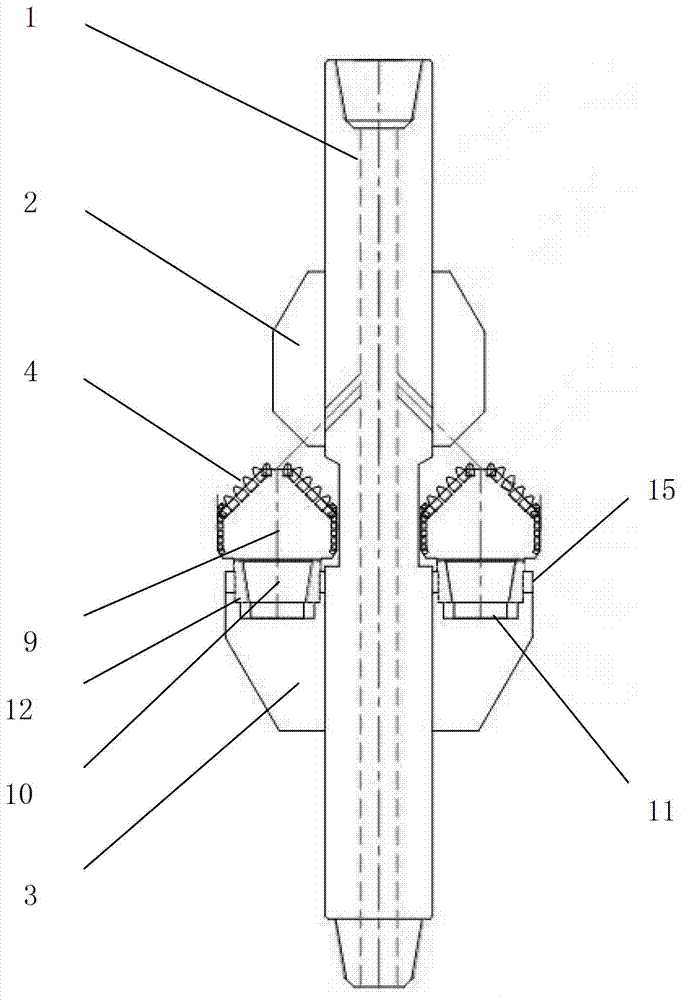

[0030] figure 1 with figure 2 One embodiment of the invention is shown. As shown in the figure, the reamer includes a hollow central shaft 1 whose two ends communicate with the drill rod, a front guide 2 , a rear guide 3 and a cylindrical hob 5 . The central axis 1 is provided with at least three said front guides 2 and at least three said rear guides 3 in the circumferential direction, and the three said front guides 2 and rear guides 3 are uniformly arranged in the circumferential direction, and said front guides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com