Wireless remote-control automatic-control rotary cement head

A technology of wireless remote control and cement head, which is applied in the direction of wellbore/well components, earthwork drilling and production, sealing/isolation, etc. Risk and other issues, to achieve the effect of novel control methods, convenient operation, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

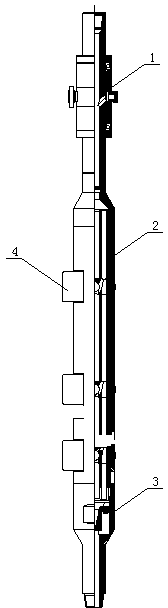

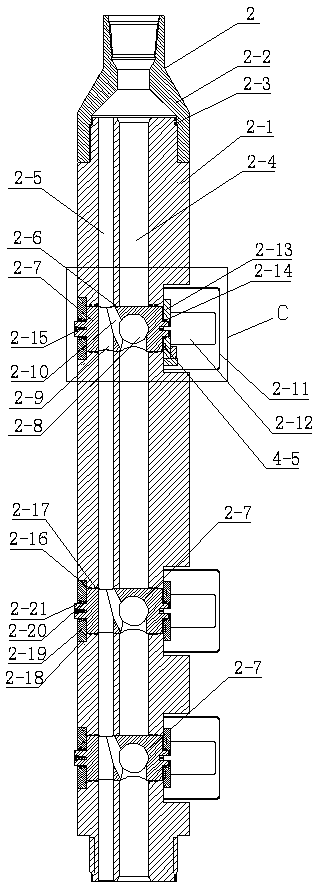

[0032] Such as figure 1 , 8 As shown, the wireless remote control automatically controls the rotary cement head, including the rotary injection head 1, the cement head 2, and the position indicator 3 connected sequentially from top to bottom, and the wireless remote control system 4 is set on the cement head 2.

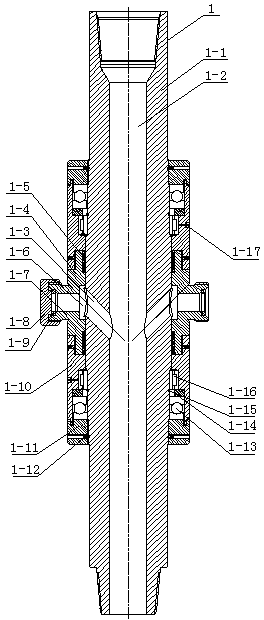

[0033] Such as figure 2 As shown, the rotary injection head 1 includes a central tube 1-1 with a central hole 1-2, and two through holes 1-3 communicated with the central hole 1-2 are arranged on the central tube 1-1 to form a four-way central tube . The rotary union 1-4 is sleeved on the center tube 1-1, and the combined sealing ring 1-5 is arranged between the upper and lower ends of the rotary union 1-4 and the center tube 1-1, and the rotary union 1-4 A ring cavity 1-6 connected to the through hole 1-3 of the central tube 1-1 is arranged inside, and two interfaces 1-7 connected to the ring cavity 1-6 are set on the rotating union 1-4. The two interfaces 1-7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com