Position correction method, scanning control method, medium and equipment for selective laser melting

A laser melting and selective technology, applied in the field of medium and equipment, scanning control method, position correction method of selective laser melting, can solve the problem of low forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

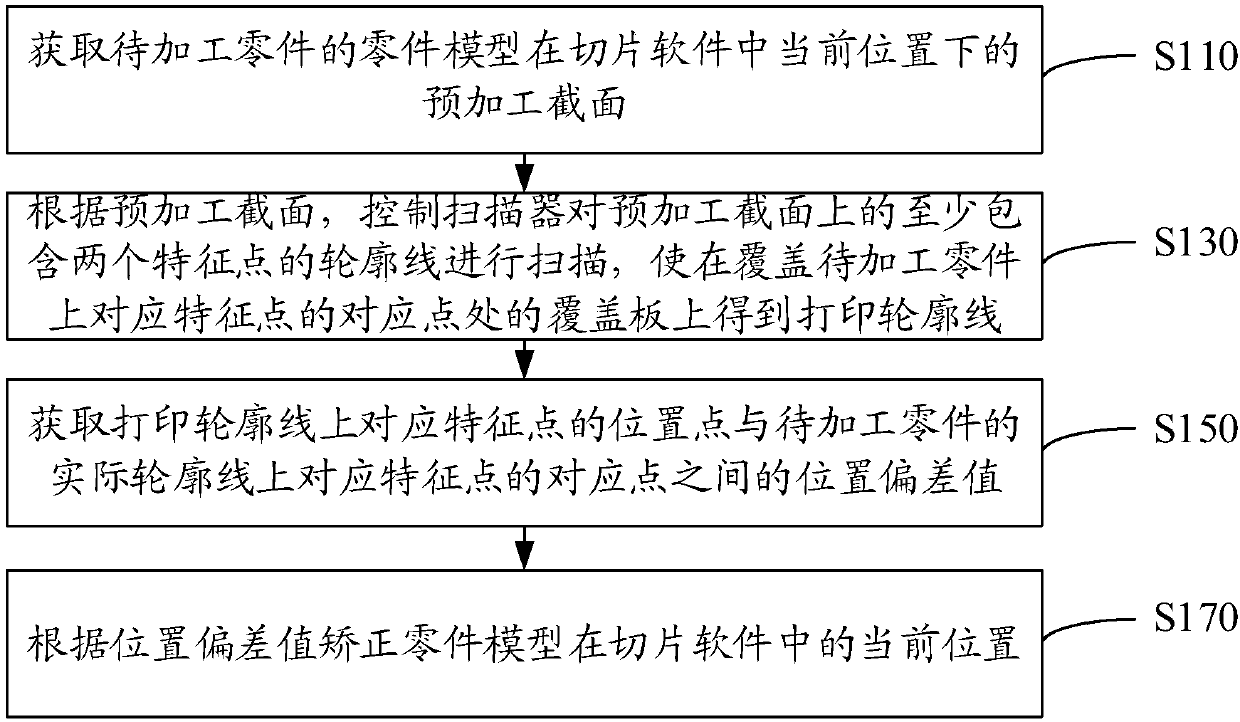

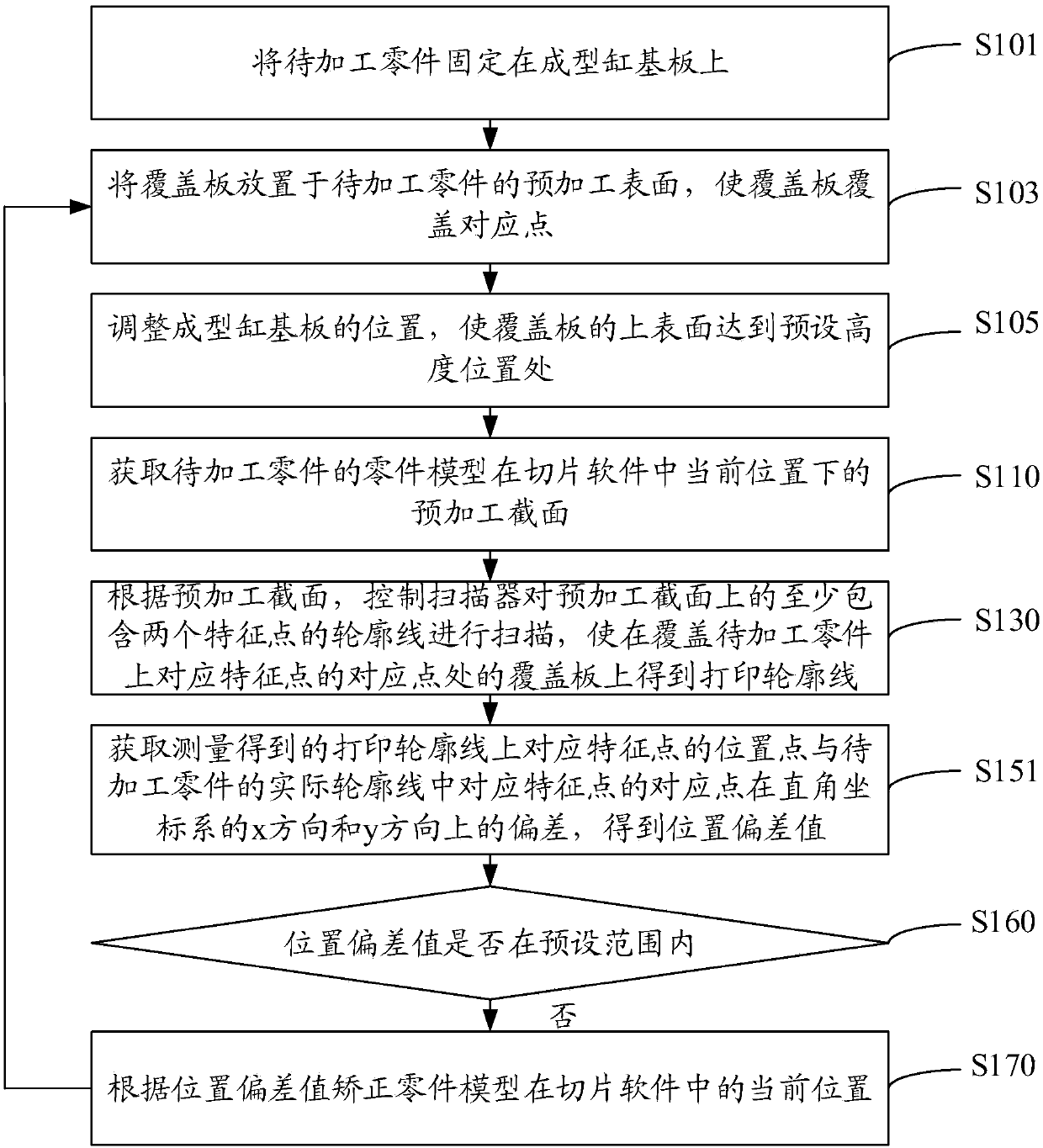

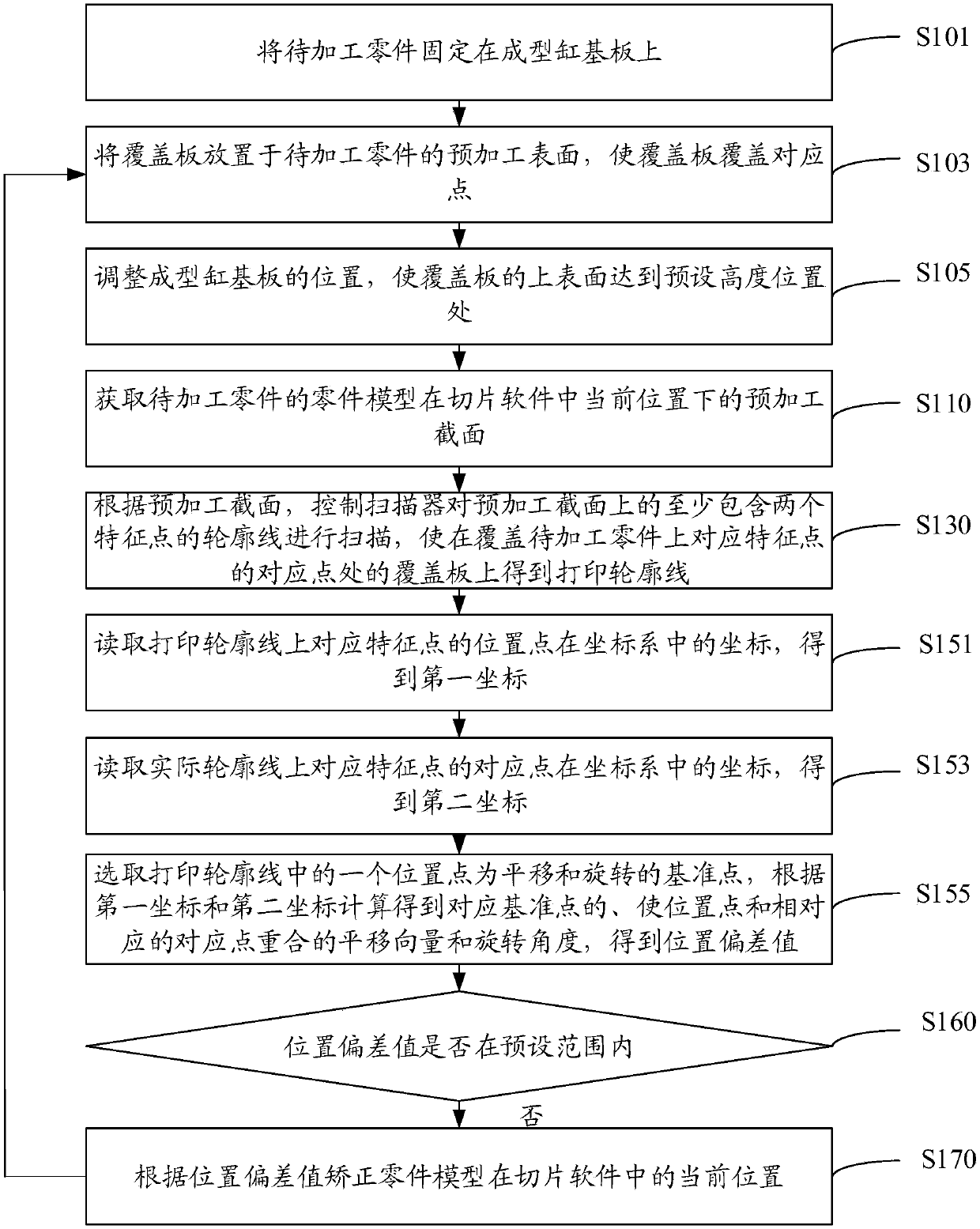

[0027] refer to figure 1 , in a first embodiment, a position correction method of selective laser melting is provided, comprising the following steps:

[0028] S110: Obtain a pre-processed section of the part model of the part to be processed at the current position in the slicing software.

[0029] To print parts by selective laser melting process, the part model needs to be imported into the slicing software first, and the slicing software performs slicing processing according to the part model to obtain the cross-section of each layer. Among them, the part to be processed refers to the part to be repaired, continued or compounded; the current position refers to the position of the part model in the slicing software; The prepared surface for the operation corresponds to the section in the part model. The shape of the pre-machined section is the same as the shape of the pre-machined surface in the part to be machined. Specifically, the pre-processing section may be obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com