Welding jig for welding cylinder

A technology for assembling welding jigs and cylinders, applied in the field of assembling and welding jigs, can solve problems such as affecting welding efficiency, and achieve the effects of reliable and convenient clamping, high efficiency, and accurate circumferential tightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

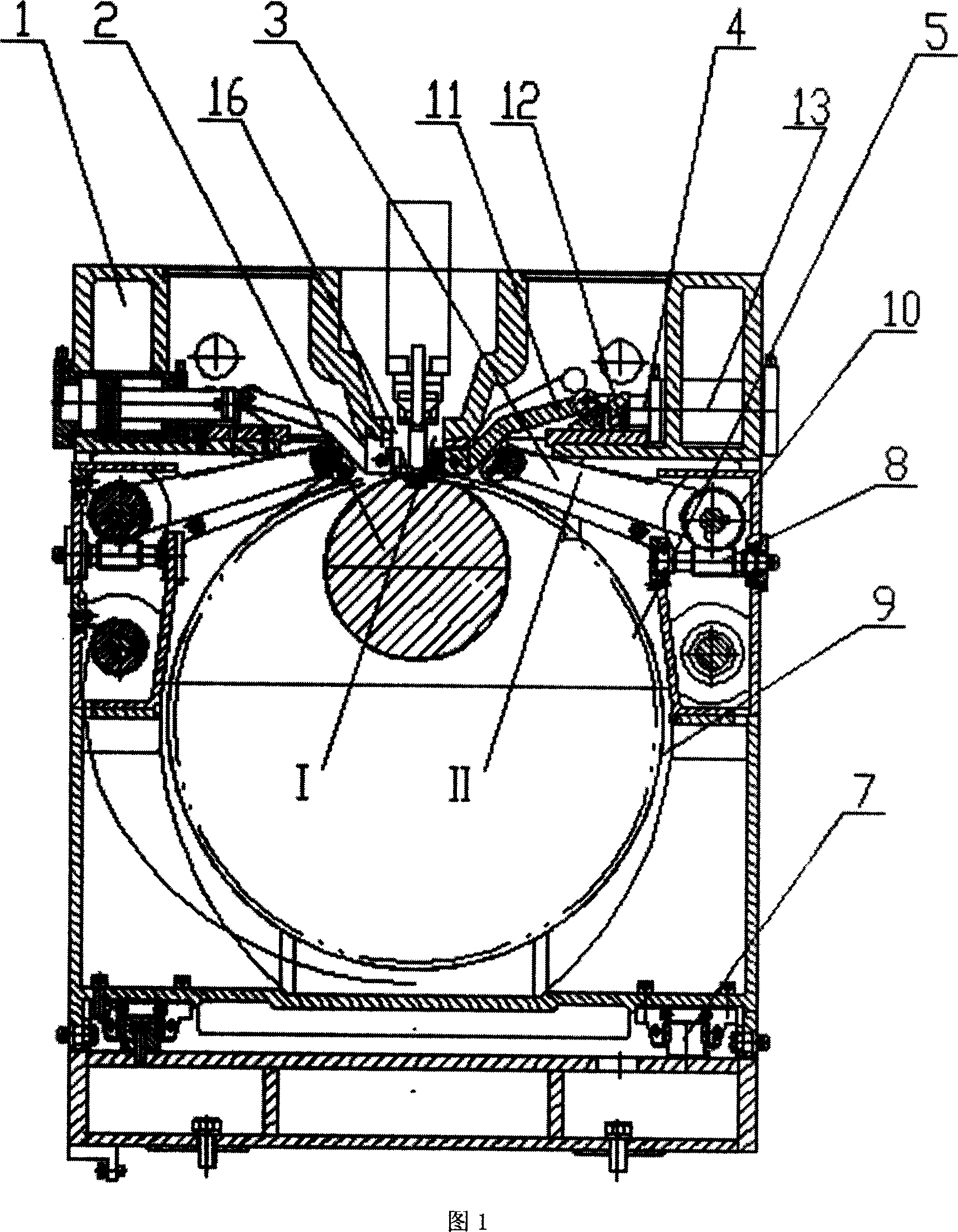

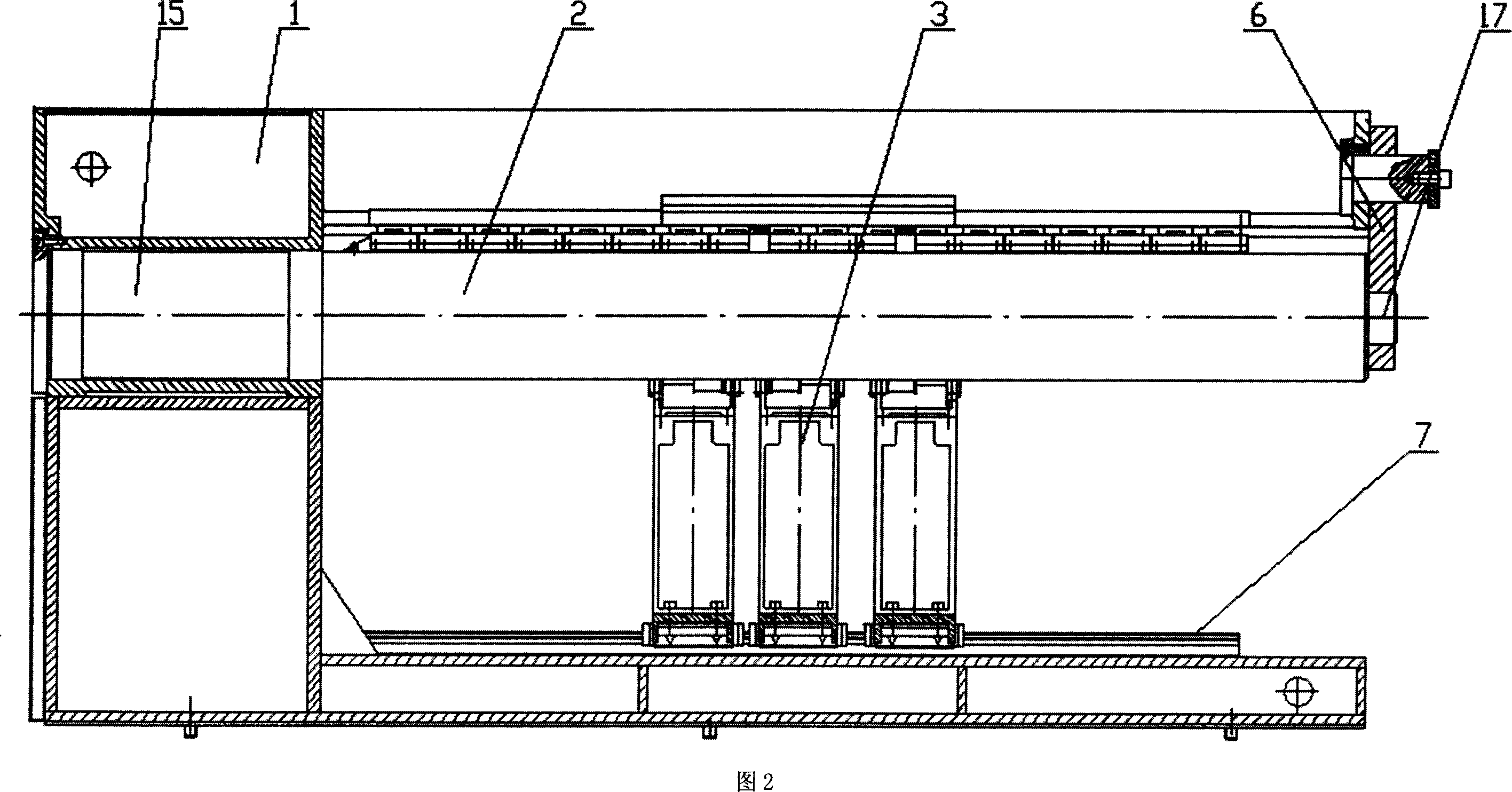

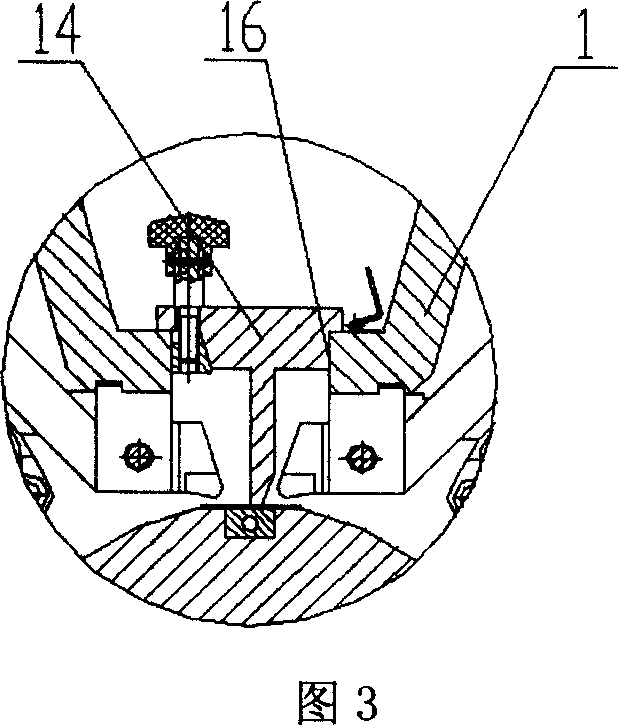

[0017] Fig. 1 is a structural schematic diagram of a welding jig for a welding cylinder of the present invention, and Fig. 2 is a left view of Fig. 1 . As shown in the figure, 1 is the frame, 2 is the mandrel, 3 is the steel belt tightening device, 4 is the clamping device, 5 is the workpiece, the positioning hole 15 is opened on one side of the frame 1, and one end of the mandrel 2 Installed in the positioning hole 15 of the frame 1, the other end of the mandrel 2 is installed in the positioning hole 17 of the pin plate 6, the inert gas can pass through the mandrel 2, and is used for welding that needs to be protected on the back of the workpiece, and the pin plate 6 is hung On one side of the frame 1, and can be disassembled when clamping the workpiece, the guide rail 7 is installed on the bottom of the frame 1, the steel belt tightening device 3 is installed on the guide rail 7, and can slide along the guide rail 7 for adjustment and tightening The number of steel belt tigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com