Integrated clamp for dovetail tenon turbine blade vibration fatigue test and test method

A turbine blade and vibration fatigue technology, applied in the field of engine dovetail tenon turbine blade vibration fatigue test fixture, can solve the problems of blade fracture, test failure, small blade body, etc., and achieve the effect of reducing quantity and test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

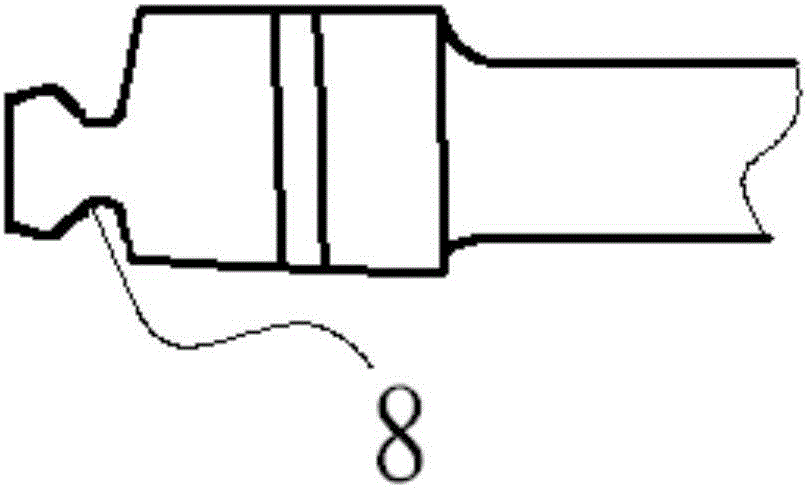

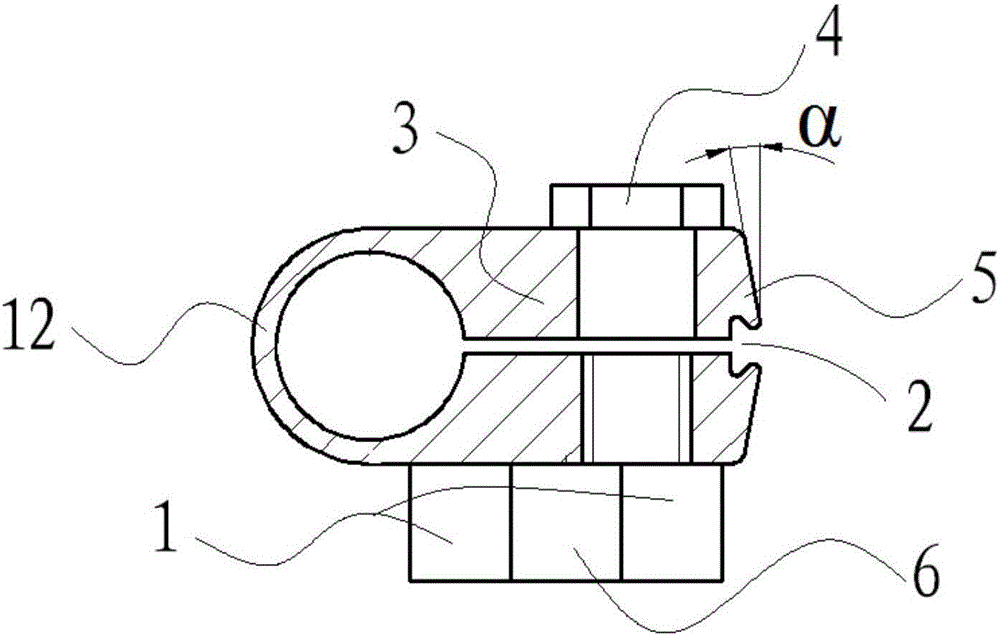

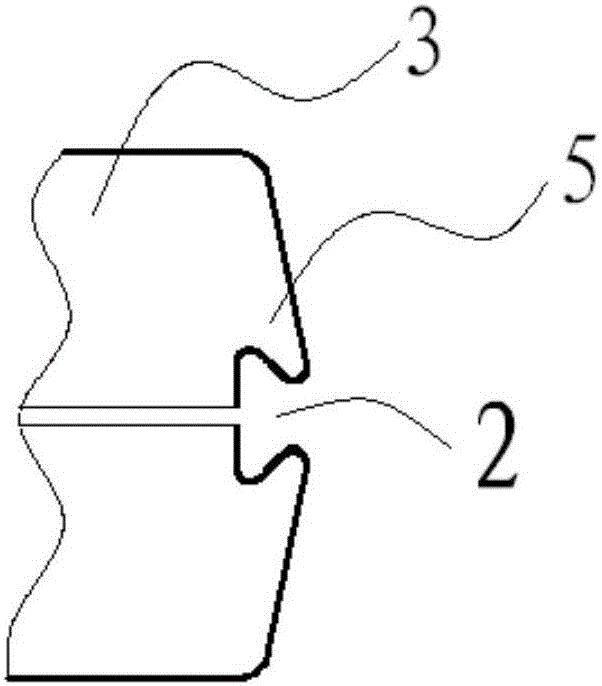

[0036] refer to figure 2 , image 3 and Figure 4 , an integrated fixture for the vibration fatigue test of dovetail-shaped tenon turbine blades includes a forged integral fixture body 3 and a connecting flange 1, and one end of the integrated fixture body 3 is provided with a tongue and groove jaw 5, so The mortise and groove jaw 5 is provided with a mortise 2 for clamping a dovetail-shaped tenon, and the top of the integrated fixture body 3 is provided with an adjusting fastening bolt 4, which runs through the integrated fixture body 3, and is passed through the precision The thread adjusts the size of the mortise 2 to ensure that the clamping position of each dovetail-shaped mortise-shaped turbine blade is consistent with the point of application of force, and at the same time ensures a more accurate position and verticality during use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com