Outer-supporting expansion work piece clamping device used for spin forming of large rotating body section piece

A technology of spinning forming and clamping device, which is applied in the direction of feeding device, positioning device, storage device, etc., and can solve the problems of clamping, slow clamping action, and small clamping stroke that are not suitable for large-diameter rotary plate parts. problem, to achieve the effect of large clamping stroke, fast clamping action and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

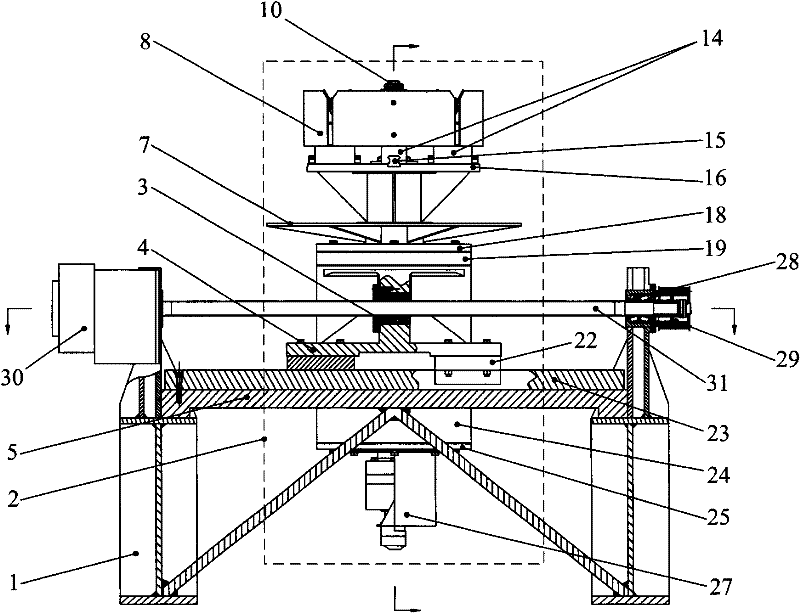

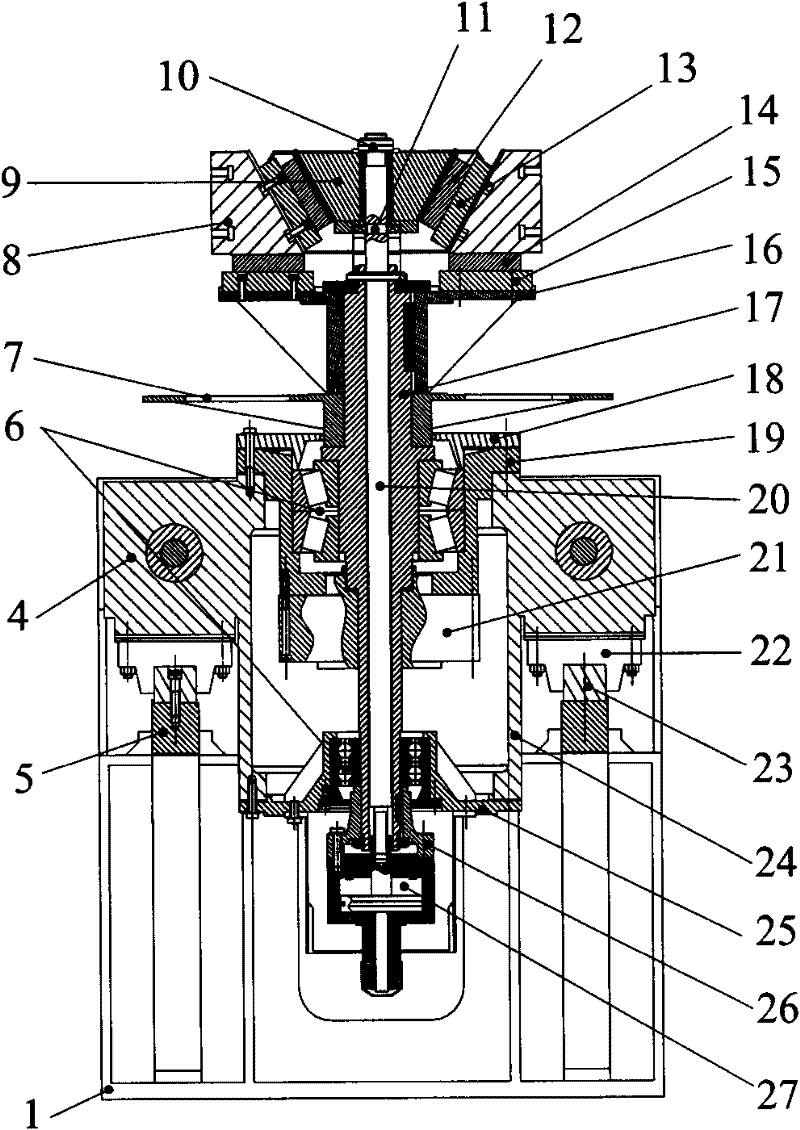

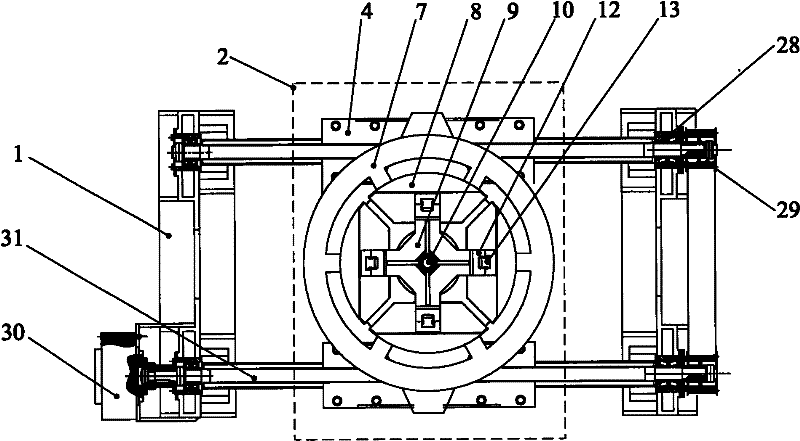

[0016] Such as Figure 1-Figure 3 As shown, the external support expansion type workpiece clamping device for spinning and forming large-scale rotary plate parts includes a clamp bracket 1 and a clamping device main body 2 installed thereon. The clamp bracket 1 includes a beam 5, The crossbeam 5 is fixed with a horizontally moving guide rail 23, and the horizontal slider 22 on the clamping device main body 2 cooperates with the horizontally moving guide rail 23 on the crossbeam 5, so that the clamping device main body 2 is connected with the clamping bracket 1.

[0017] The main body 2 of the clamping device includes a pull rod 20, the pull rod 20 is connected to the wedge 9 through the pin 11 thereon, the upper end of the pull rod 20 is equipped with a fastening nut 10, and the fastening nut 10 fastens the wedge 9 to the pull rod 20, the bottom end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com