Self-centering shackle

A shackle oil cylinder and sliding frame technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of low efficiency, small shackle angle, large size of shackle, etc. The effect of large, long clamping stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

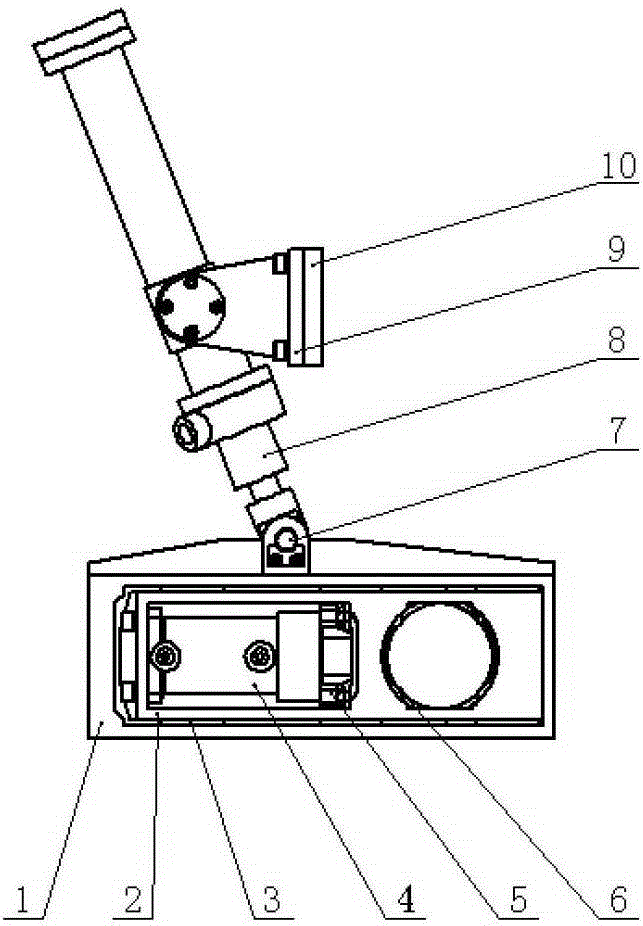

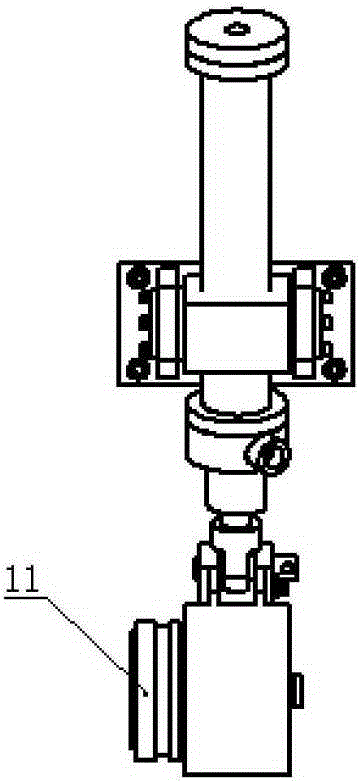

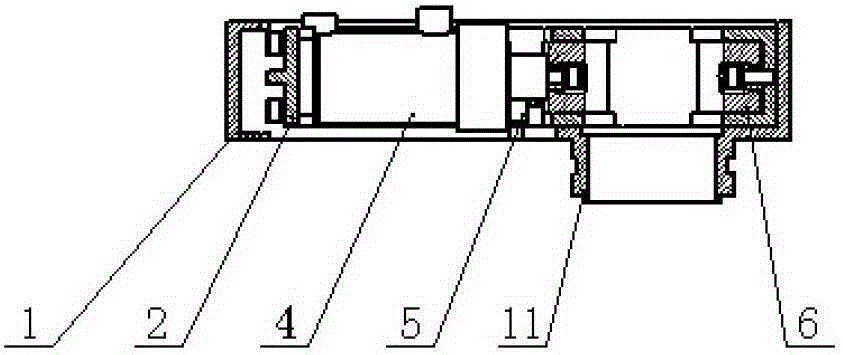

[0020] Attached below Figure 1-3 The present invention is described in further detail.

[0021] The automatic centering shackle of the present invention has an outer frame 1 on which the inner ring 11 of the limit ring is installed on the holder; the sliding frame 2 is installed inside the outer frame 1, and there are wear-resistant plates 3 on both sides of the sliding frame 2 , the wear-resistant plate 3 is in contact with the outer frame 1, and slides relative to the outer frame 1 during the working process, and the wear-resistant plate can be replaced after wear. Inside the sliding frame 2 there is a clamping cylinder 3 and a pair of slips 6, one piece of slips 6 is fixed on the piston rod of the clamping cylinder 3; Move towards each other and clamp the drill pipe. The shackle oil cylinder 8 is connected with the support 9 by a pin shaft, and the piston rod of the shackle oil cylinder 8 is connected with the outer frame 1 by a pin shaft 7 .

[0022] Two limit blocks a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com