A dual-drive micro-nano dual-gripper

A gripper and dual-drive technology, applied in the field of micro-nano operation, can solve the problems of difficult to meet the practical application, small stroke of the micro-gripper, single clamping, etc., to improve the clamping operation efficiency, low manufacturing cost, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

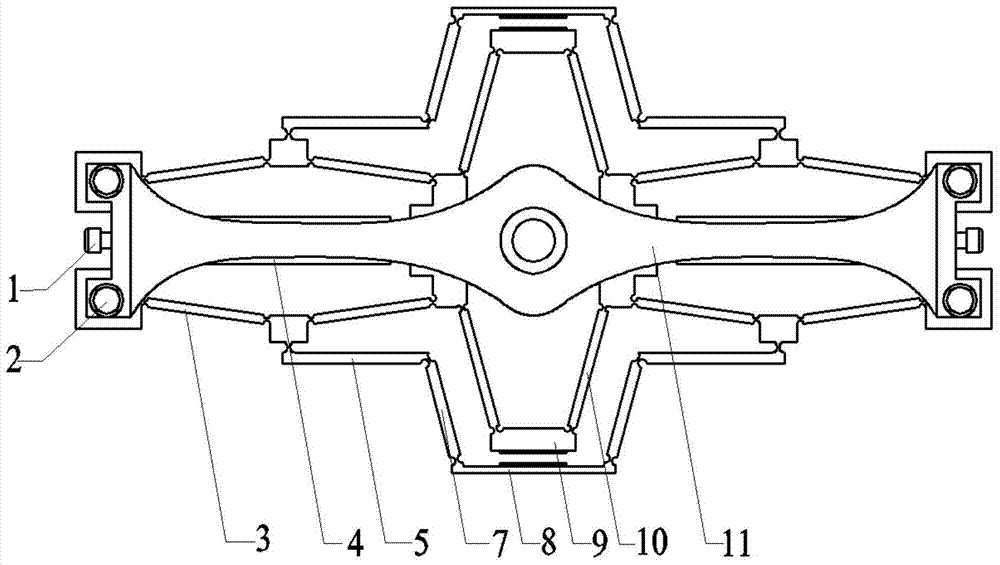

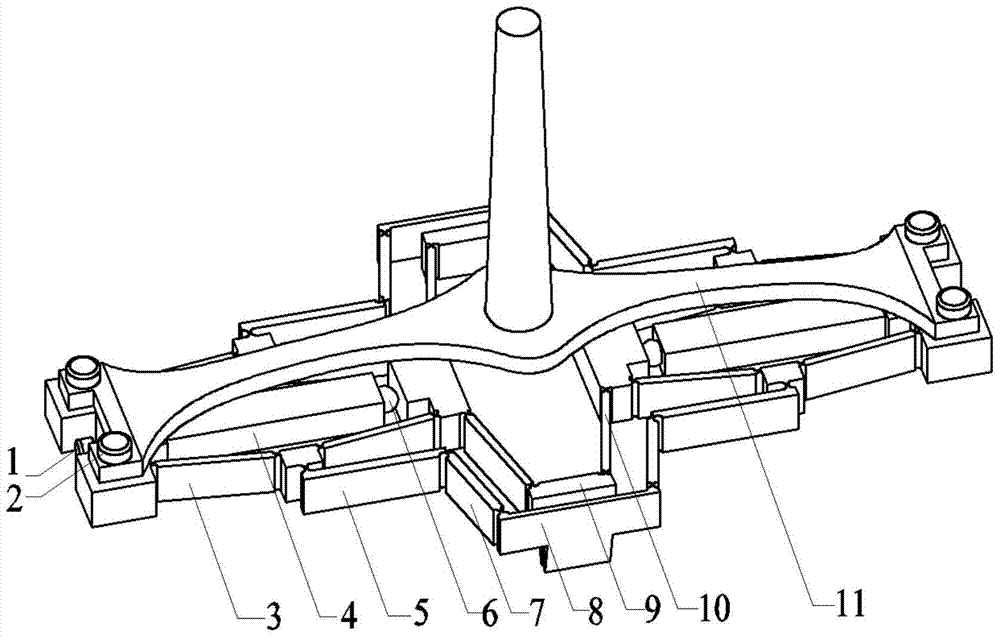

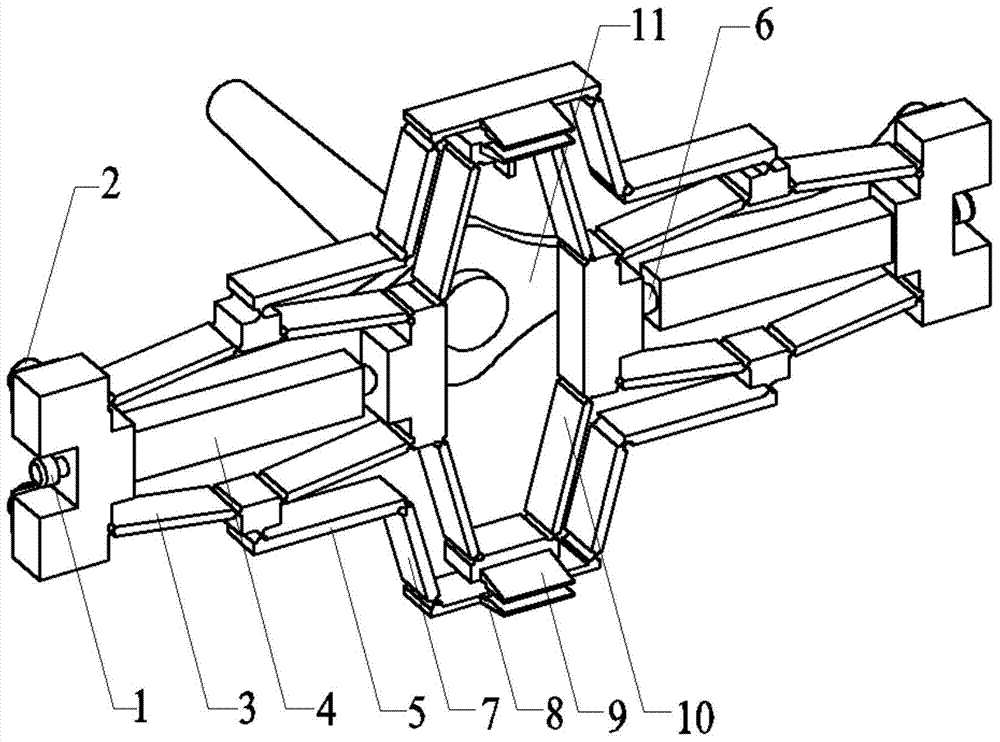

[0014] see Figure 1 ~ Figure 3 , a dual-drive micro-nano double gripper, the gripper adopts a double symmetrical structure, including two clamping jaws arranged symmetrically up and down, two piezoelectric ceramic drivers 4 arranged symmetrically left and right, and a secondary flexible bridge Type amplifying mechanism 10 and two first-stage flexible bridge amplifying mechanisms 3 arranged symmetrically left and right.

[0015] An input terminal is provided on the left and right sides of the secondary flexible bridge amplifying mechanism 10 , and an output terminal is respectively provided on the upper and lower ends of the secondary flexible bridge amplifying mechanism 10 .

[0016] The two primary flexible bridge amplifying mechanisms 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com