Large-stroke internal expanding clamp for machining long hollow shaft

A large-stroke, hollow-shaft technology, applied in the field of large-stroke internal expansion fixtures, can solve problems such as difficulty in completely avoiding the production process, travel limitation of expansion sleeves and expansion clamps, easy damage or deformation of expansion sleeves, etc., to achieve simple structure and improve fixture rigidity , Facilitate the effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

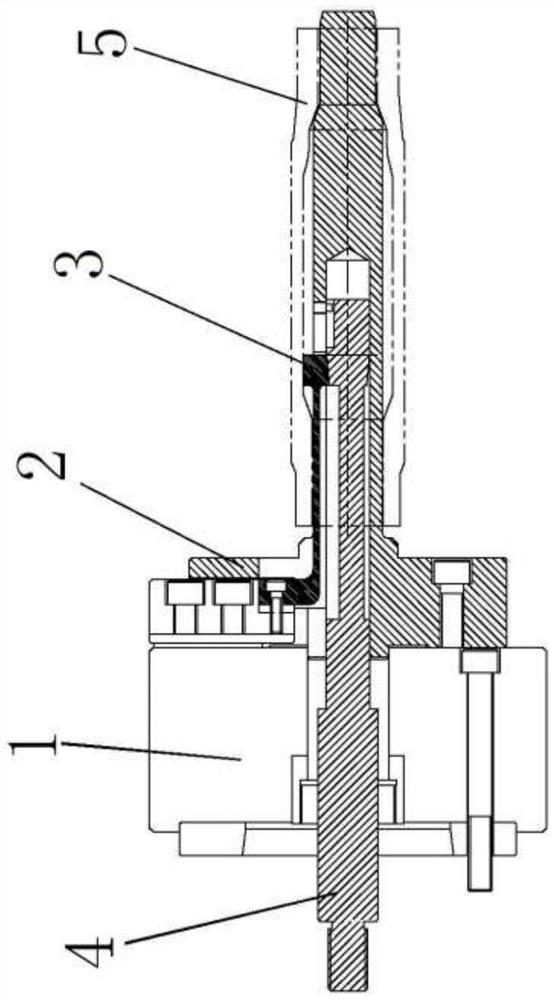

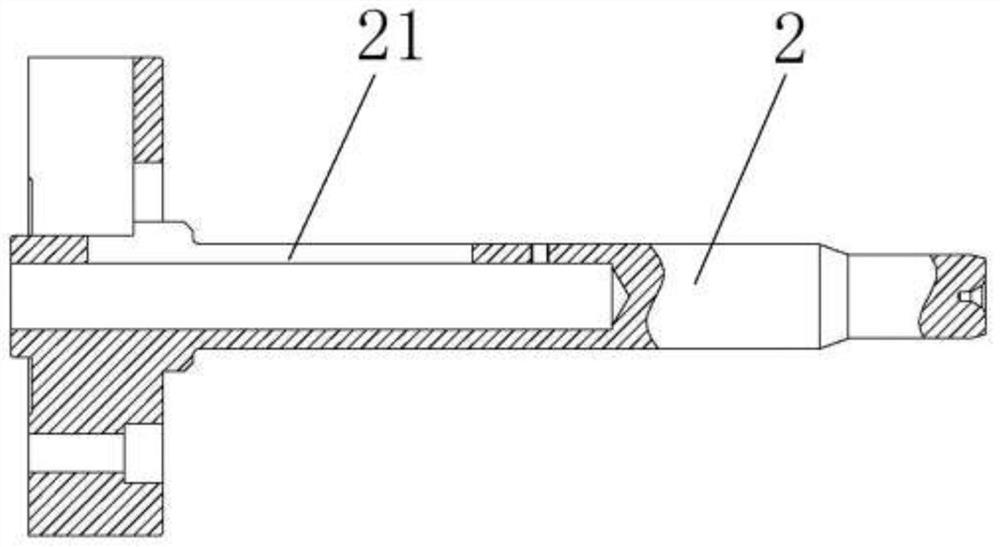

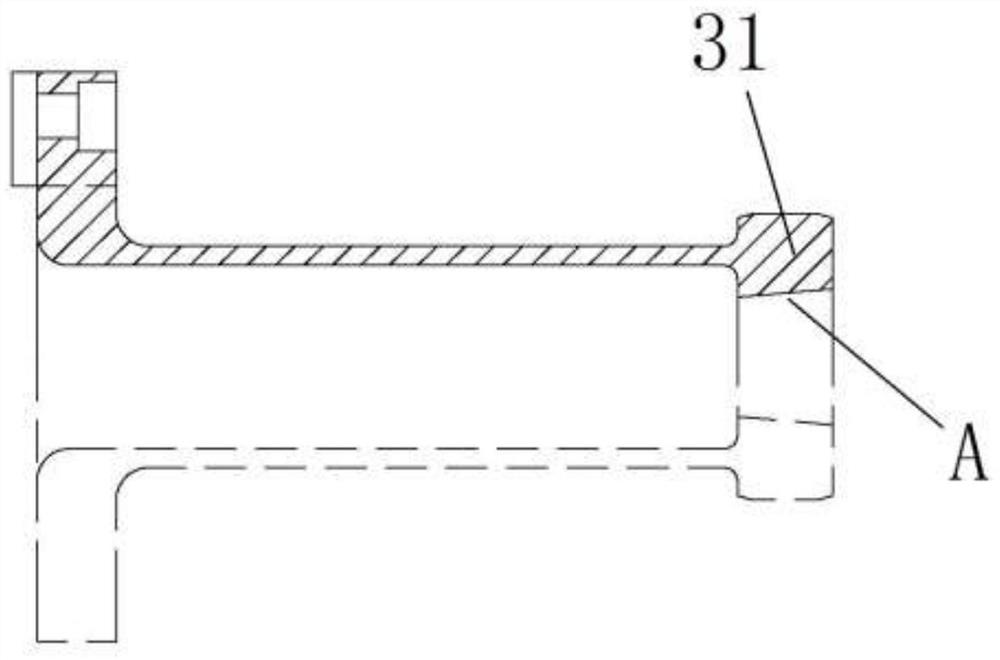

[0029] refer to Figure 1 to Figure 4 , the invention discloses a large-stroke internal expansion fixture for processing long hollow shafts, refer to figure 1 , which includes a hydraulic chuck 1, a positioning body 2, a claw 3, a pull rod 4 and a hollow shaft workpiece 5. The bottom end of the positioning body 2 is fixed on the hydraulic chuck 1 , and the other end passes through the inner hole of the hollow shaft workpiece 5 to fix it. The inner side of the positioning body 2 is provided with a tubular hollow structure, and the outer surface of the tubular hollow structure is uniformly provided with a plurality of through openings 21 . In one embodiment, the through opening 21 is a narrow opening, and the through opening 21 extends upward for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com