PoF (physics of failure) based method for calculating mission reliability of electronic product

A technology of fault physics and calculation methods, which is applied in computing, sustainable transportation, electrical digital data processing, etc., and can solve problems such as the reliability of computing product tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

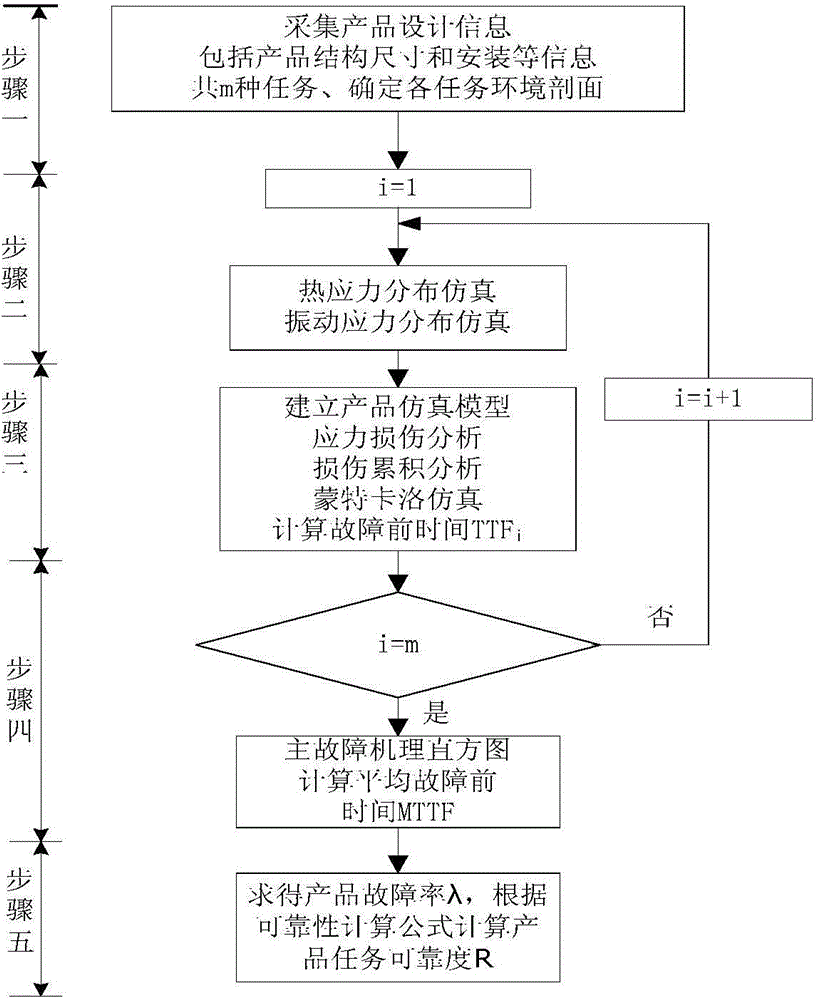

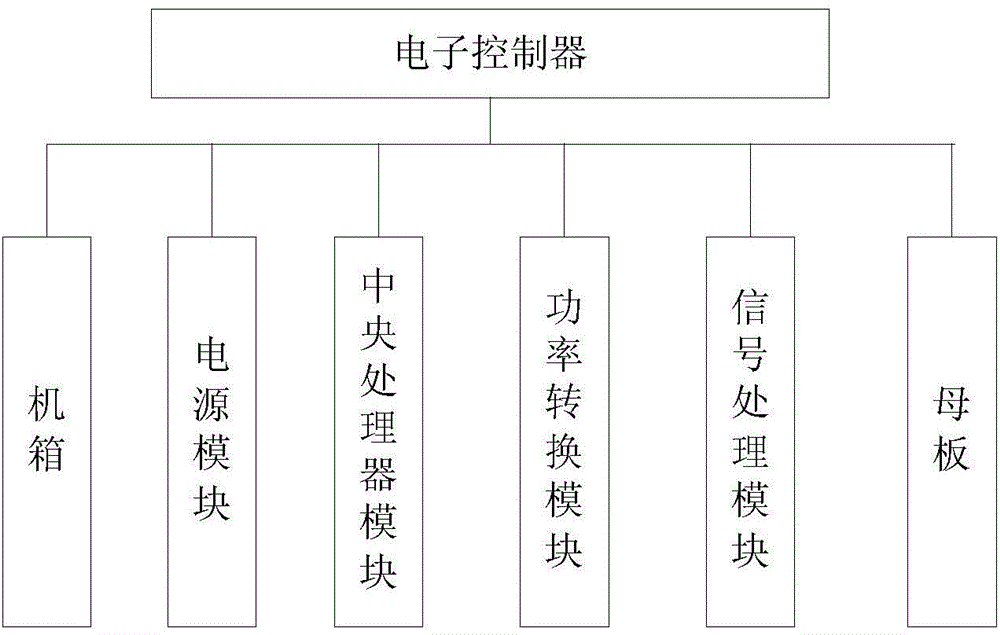

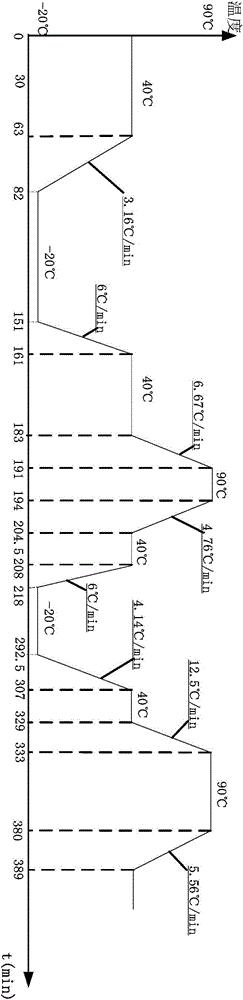

[0062] The following examples are as follows figure 1 The implementation of the flow shown mainly includes determining the temperature and vibration environment profile of each task of the electronic controller, using Flotherm to simulate the temperature stress of the software, using ANSYS software to simulate the distribution of vibration stress, stress damage analysis, damage accumulation analysis, and selection of fault physics. The model is simulated by Monte Carlo method to determine the main failure mechanism and time before failure of the electronic controller in each task, and to count the main failure mechanism of the electronic controller and calculate the average time before failure. Electronic controller hardware components such as figure 2 As shown, it includes chassis, power supply module, CPU module, power conversion module, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com