Maintenance policy formulation method, terminal and computer storage medium

A maintenance strategy and computer program technology, applied in computing, instruments, data processing applications, etc., can solve problems such as over-repair or unreasonable maintenance investment, achieve the balance between safety and maintenance economy, and reduce the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

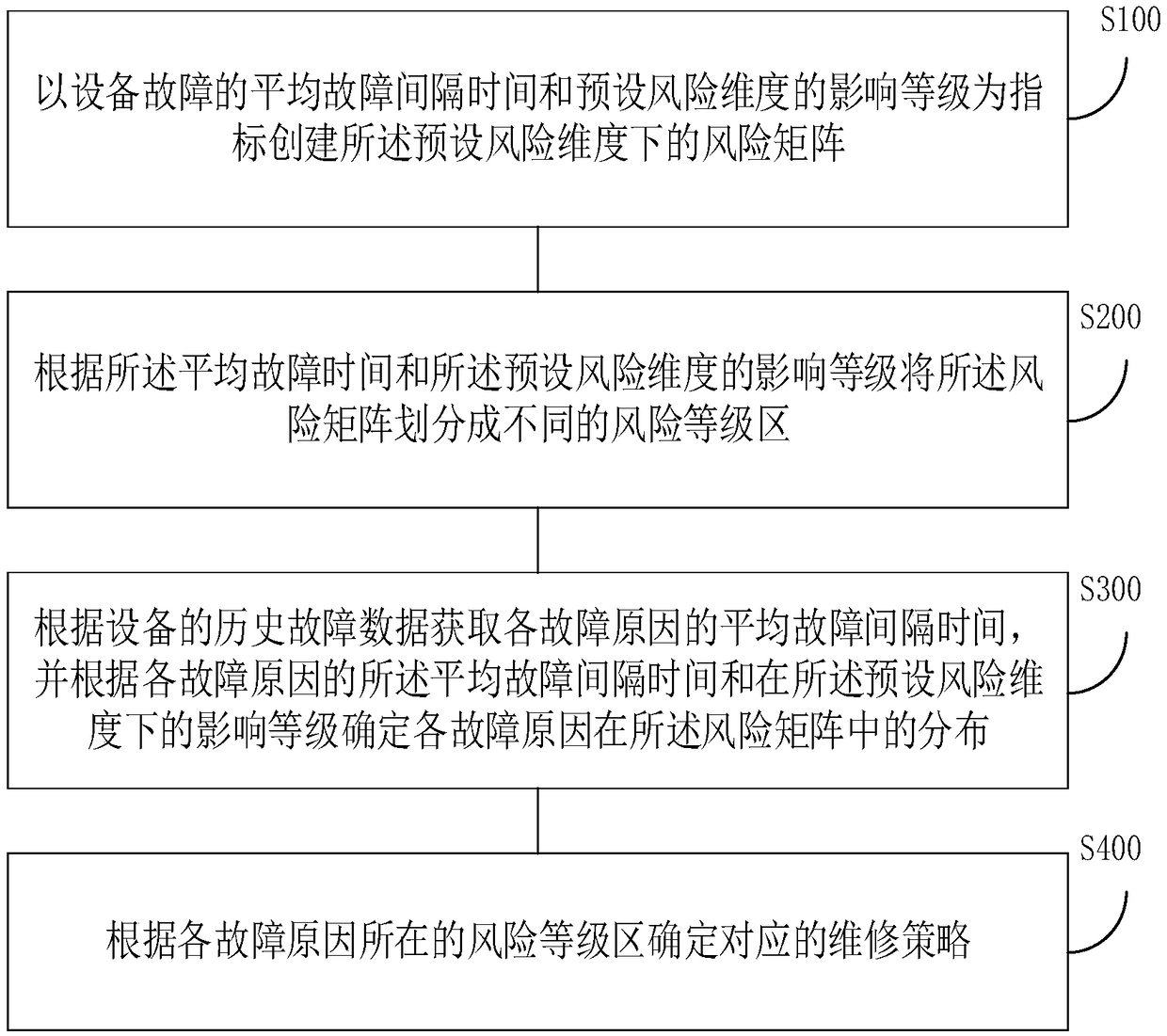

[0041] Please refer to figure 1 This embodiment provides a maintenance strategy formulation method that can be applied to the maintenance management of equipment failures. By establishing a risk matrix and using the different distributions of equipment failure causes in the risk matrix, not only can the risk of each failure cause be clarified Sorting, to formulate or adjust the maintenance strategy for each failure cause, and also to evaluate whether the corresponding maintenance strategy is reasonable. The following describes the maintenance strategy formulation method in detail.

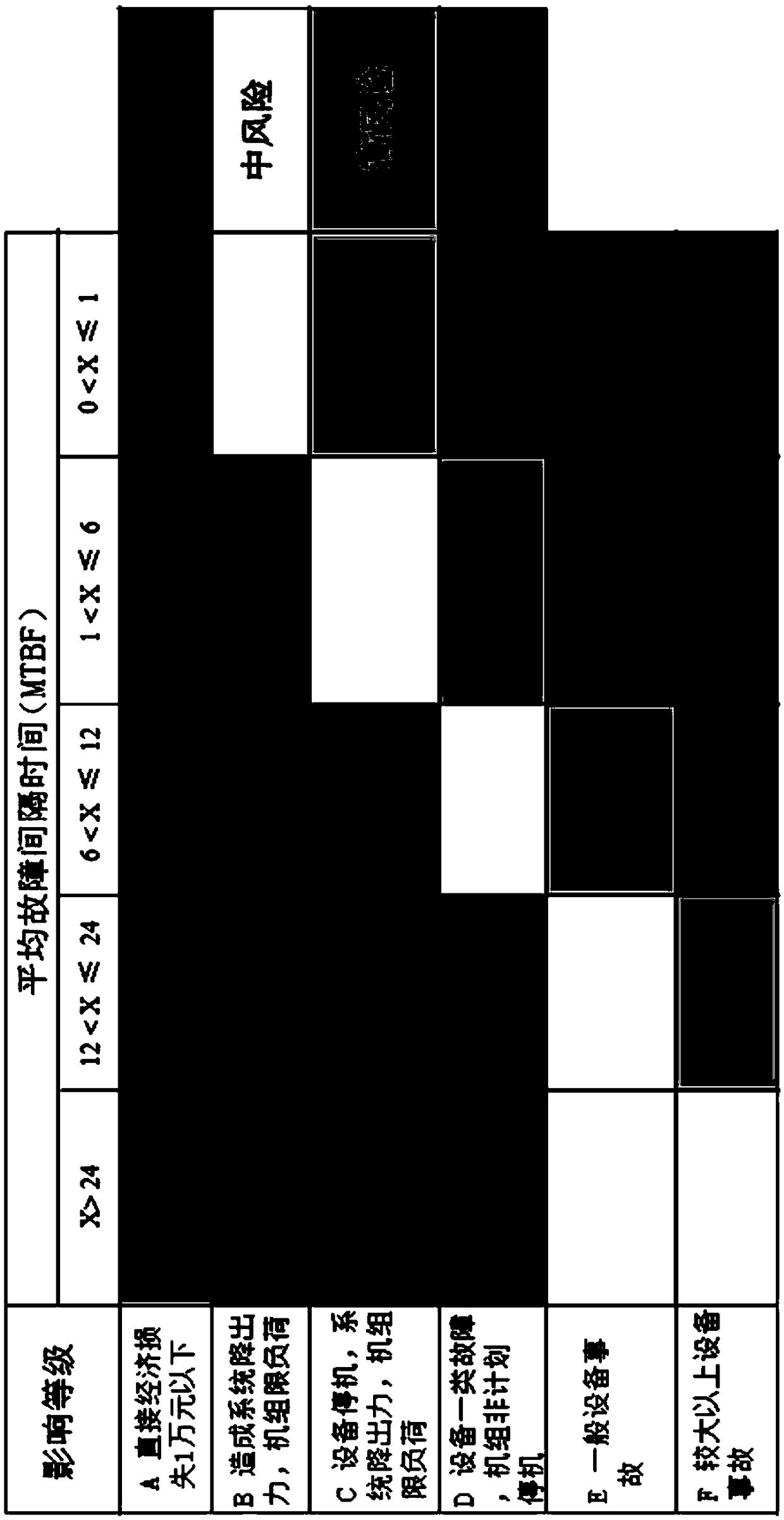

[0042] Step S100: Create a risk matrix under the preset risk dimension using the mean time between failures of the equipment and the impact level of the preset risk dimension as indicators.

[0043] Considering that for different equipment failures, the probability or frequency of their occurrence may not be the same. In this embodiment, in order to understand the risk of each failure cause and then fo...

Embodiment 2

[0072] Please refer to Image 6 Based on the maintenance strategy formulation method of Embodiment 1 above, this embodiment provides a maintenance strategy evaluation device 100 based on a risk matrix, which can be applied to evaluate equipment failure risks and optimize corresponding maintenance strategies. The risk matrix-based maintenance strategy evaluation device 100 includes:

[0073] The risk matrix creation module 10 is configured to create a risk matrix under the preset risk dimension using the mean time between failures of equipment failures and the impact level of the preset risk dimension as indicators.

[0074] The risk level zone dividing module 20 is configured to divide the risk matrix into different risk level zones according to the mean time to failure and the impact level of the preset risk dimension.

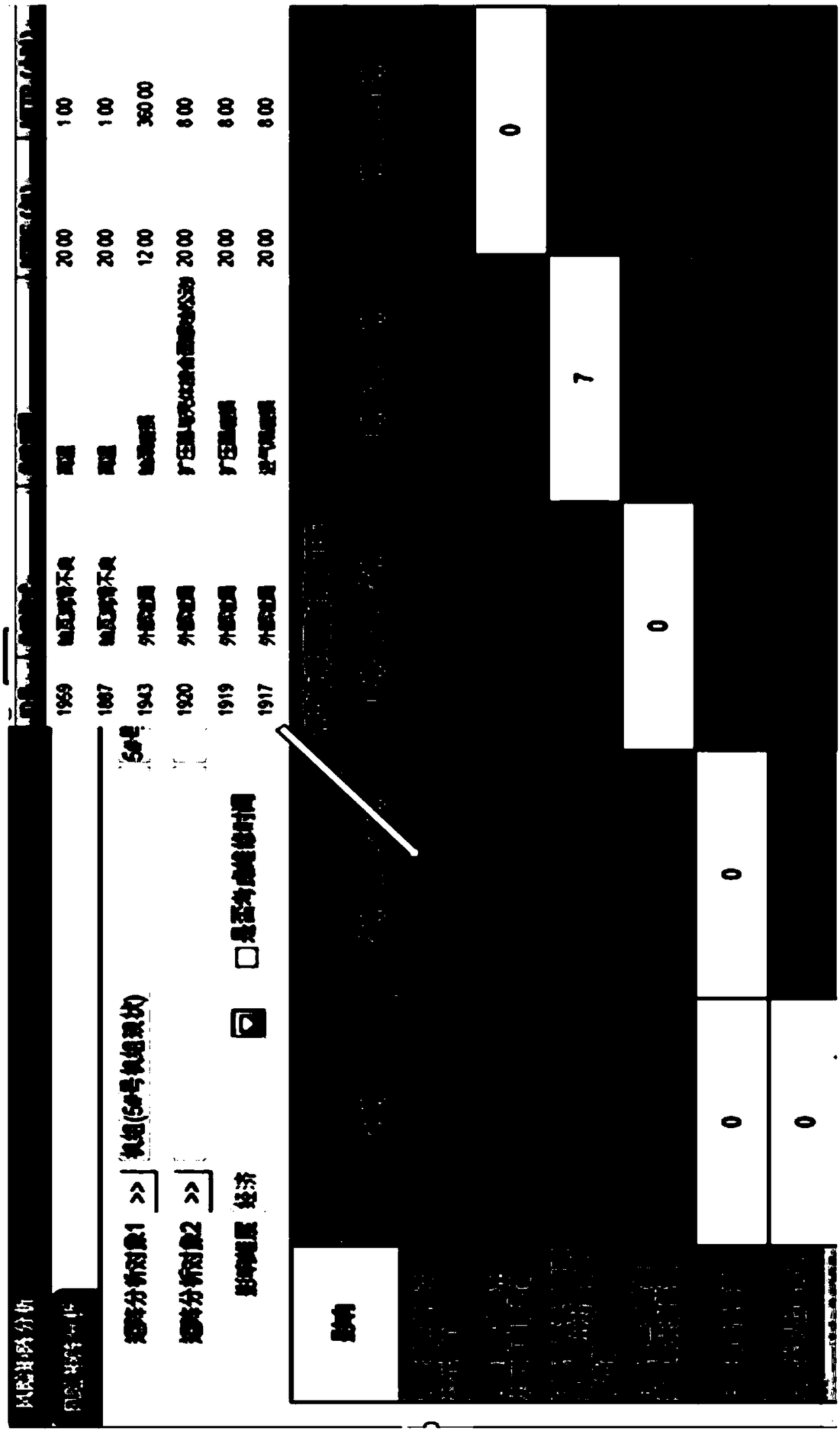

[0075] The fault cause distribution module 30 is configured to obtain the mean time between failures of each fault cause according to the historical fault data of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com