Elastic element creep testing method and tester thereof

A creep test and elastic element technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of test failure, large investment, expensive purchase price, etc., and achieve stable and reliable loading, convenient maintenance, and economic benefits Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

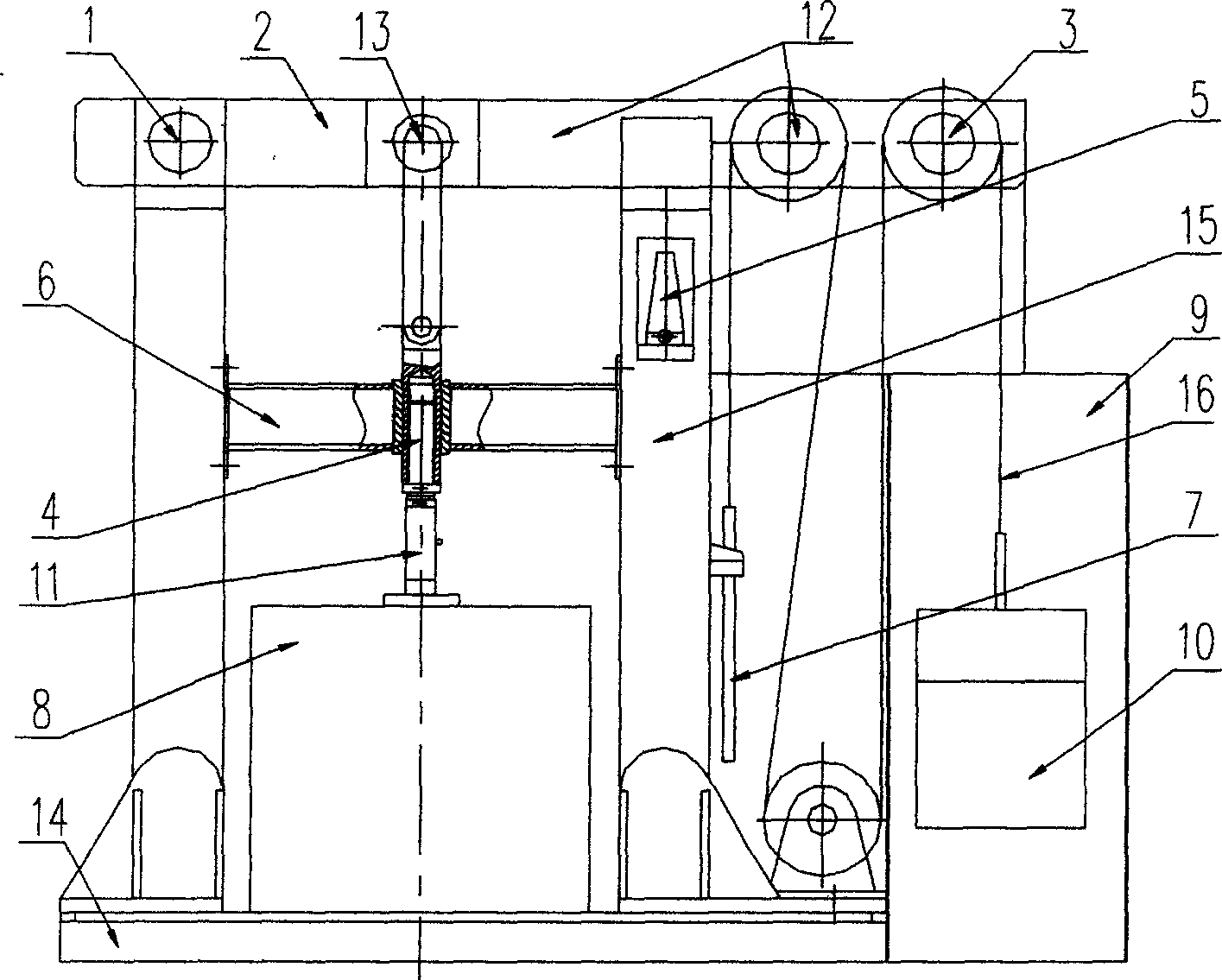

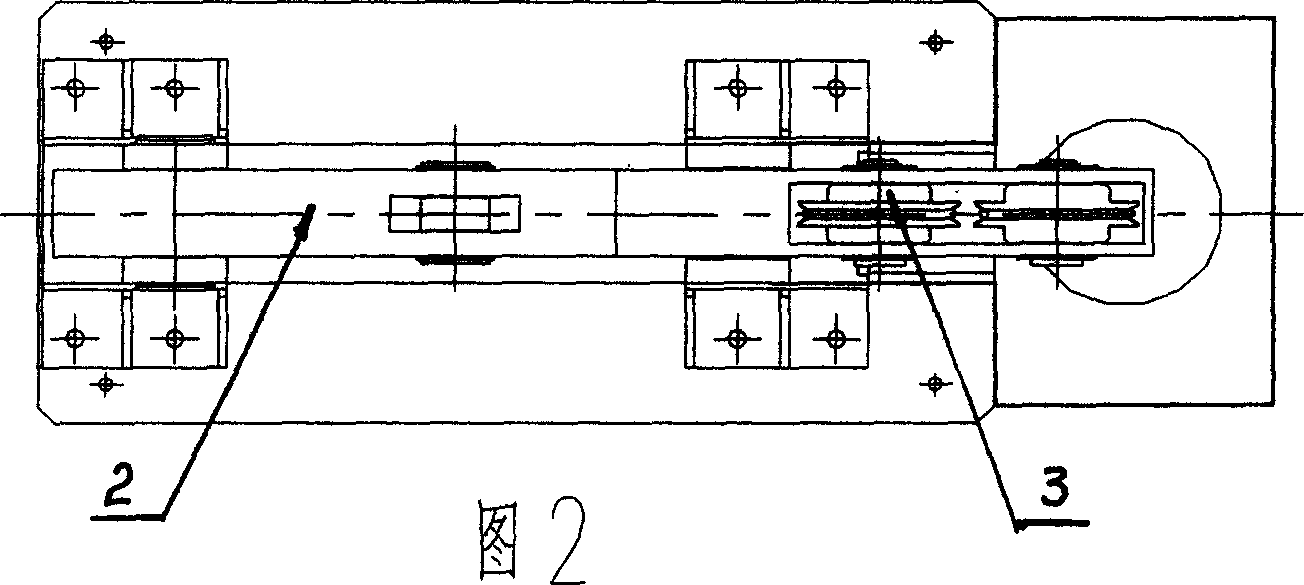

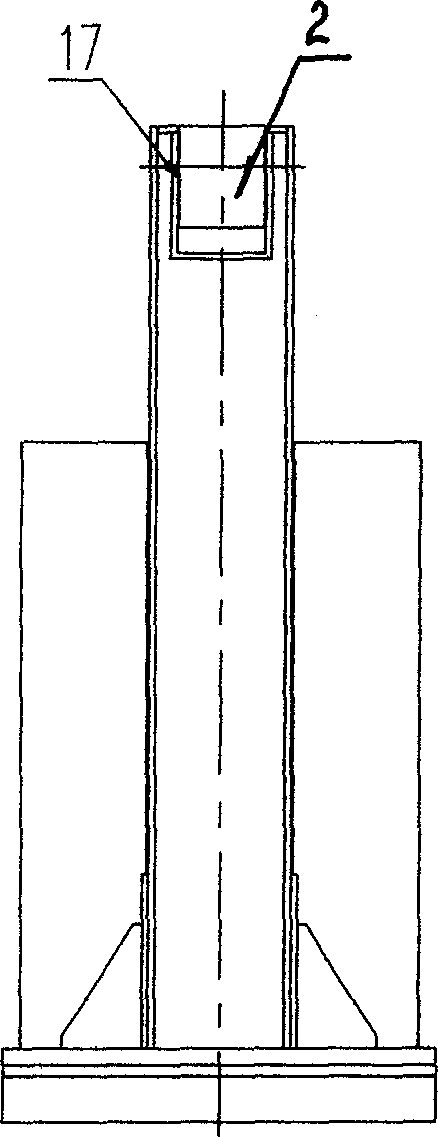

[0014] The accompanying drawings show a specific embodiment of the present invention, and the present invention will be further described in detail below in conjunction with the accompanying drawings. It can be seen from the attached drawings that this elastic body creep testing machine includes frame 6, test box 8, creep test loading mechanism 12, and its feature is: the creep test is combined by a lever and weight The mechanical device is loaded for the creep test. The loading mechanism 12 is a composite mechanical loading structure combined with a loading lever 2 and a weight 10. The creep test is loaded by the weight 10 to the loading lever 2, and then the loading lever 2 passes the loading force through The loading point 13 is transmitted to the adjustable guide rod 4, and the adjustable guide rod 4 loads the creep specimen. The specific structure is: a high and low temperature experiment box 8 is placed on the base 14 of the rack, a test sample is placed in the high and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com