High-temperature fatigue test clamp and method capable of continuously adjusting blade check section stress distribution

A stress distribution and fatigue test technology, applied in the direction of elasticity test, machine/structural component test, analysis of materials, etc., can solve the problem of discontinuous adjustment amount, etc., to achieve the effect of repeated disassembly and reliable loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is a high-temperature fatigue test fixture that can continuously adjust the stress distribution of blade assessment section, and its specific implementation is as follows:

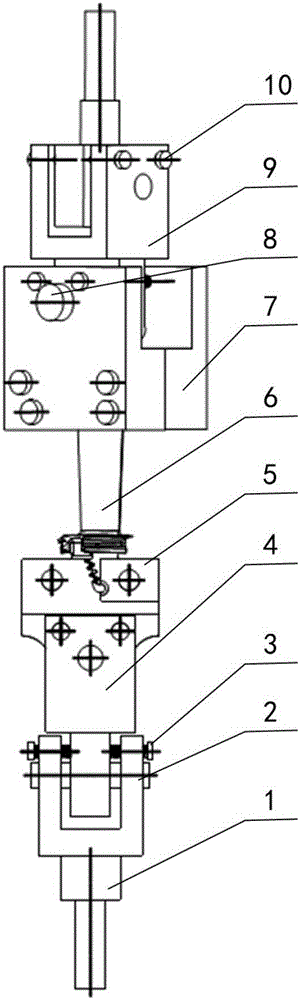

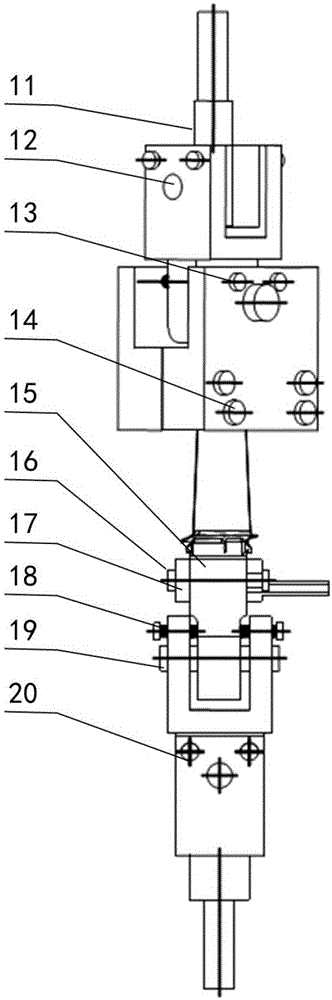

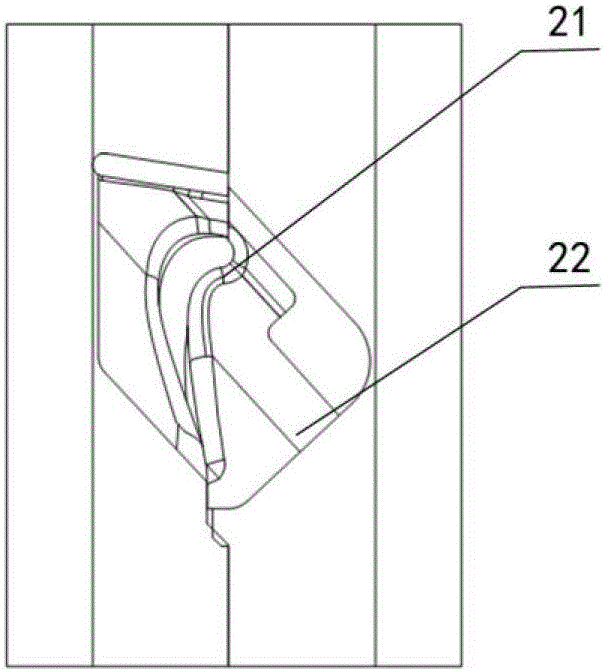

[0039] High temperature fatigue test fixture such as figure 1 , figure 2Shown, by lower chuck 1, lower fork 4, wheel disc approximation part 15, front baffle 5, rear baffle 17, blade combined fixture 7, last fork 9, upper chuck 11, 2 long pins (2, 8), 2 short pins (12, 19), 16 adjusting bolts (3, 10, 13, 18, four for each), 16 springs (3, 10, 13, 18, each Four), 6 long bolts (5,14, wherein 5 places two, 14 places have four) to form. Wherein, the upper chuck 11 and the lower chuck 1 are respectively fixed on the upper and lower clamps of the tensile fatigue testing machine. In order to facilitate the reliable transmission of mechanical loads, the blade combination fixture 7 is a half-step rectangular sheet structure with an inner hole 21 and a counterbore 22, such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com