Patents

Literature

37results about How to "Reliable loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

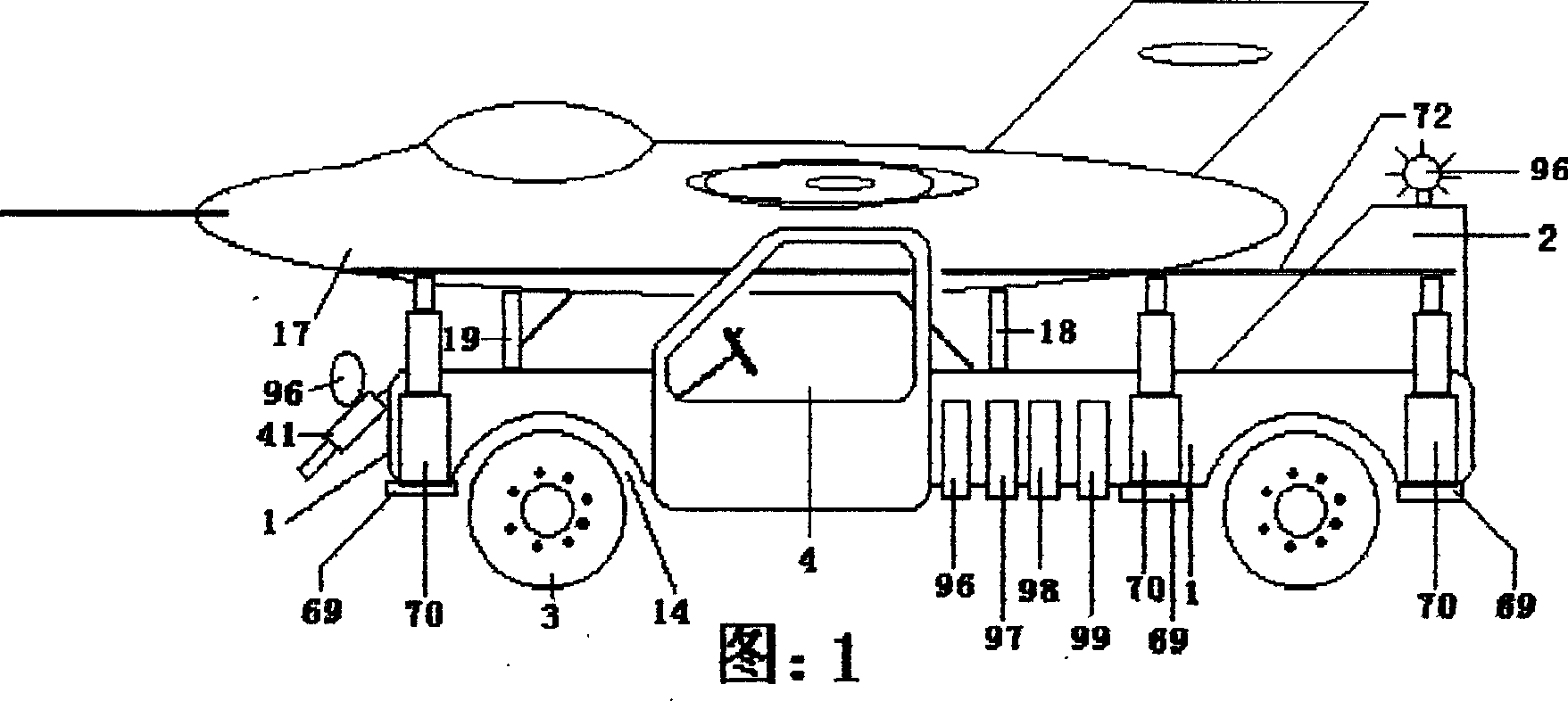

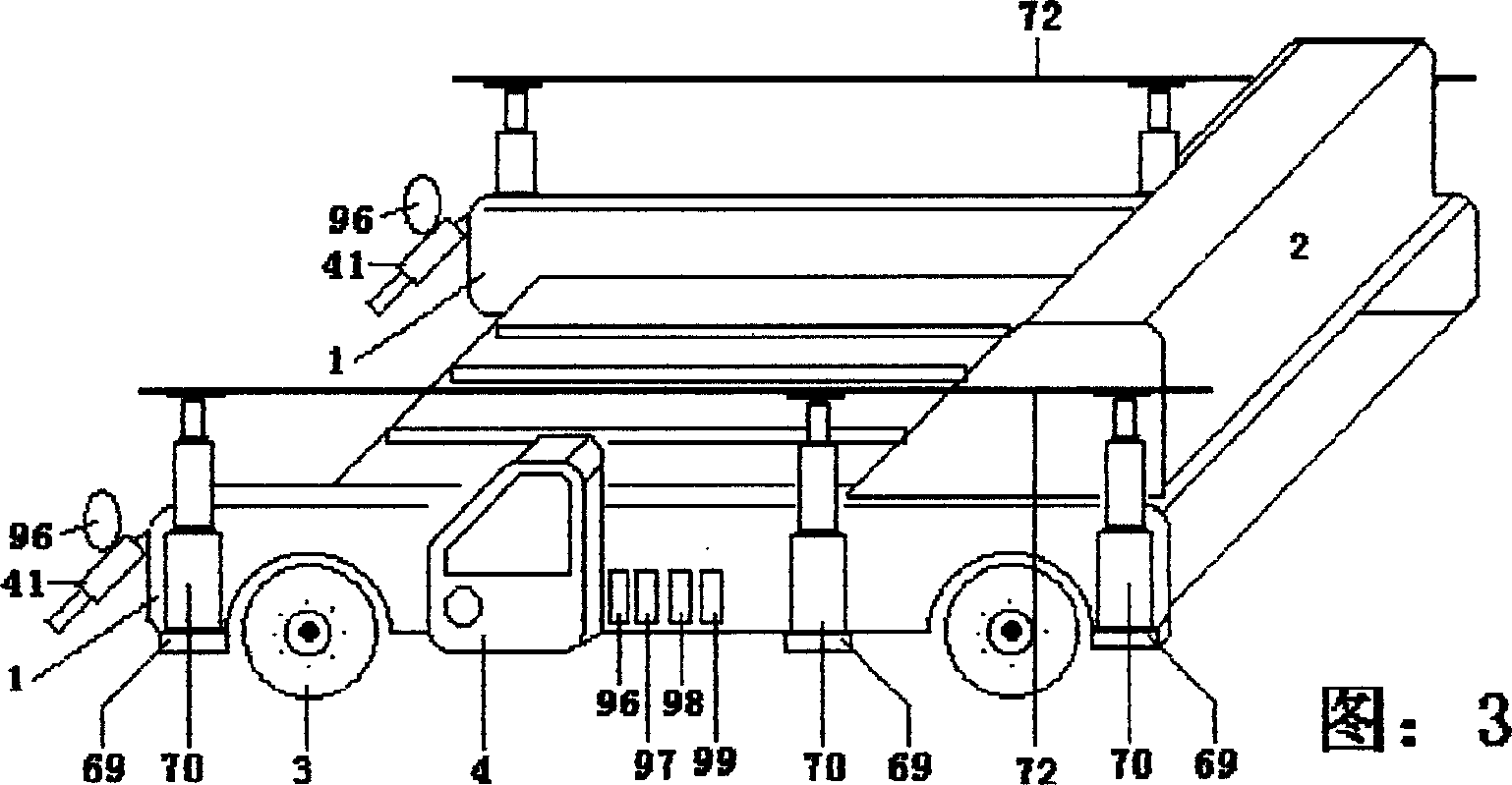

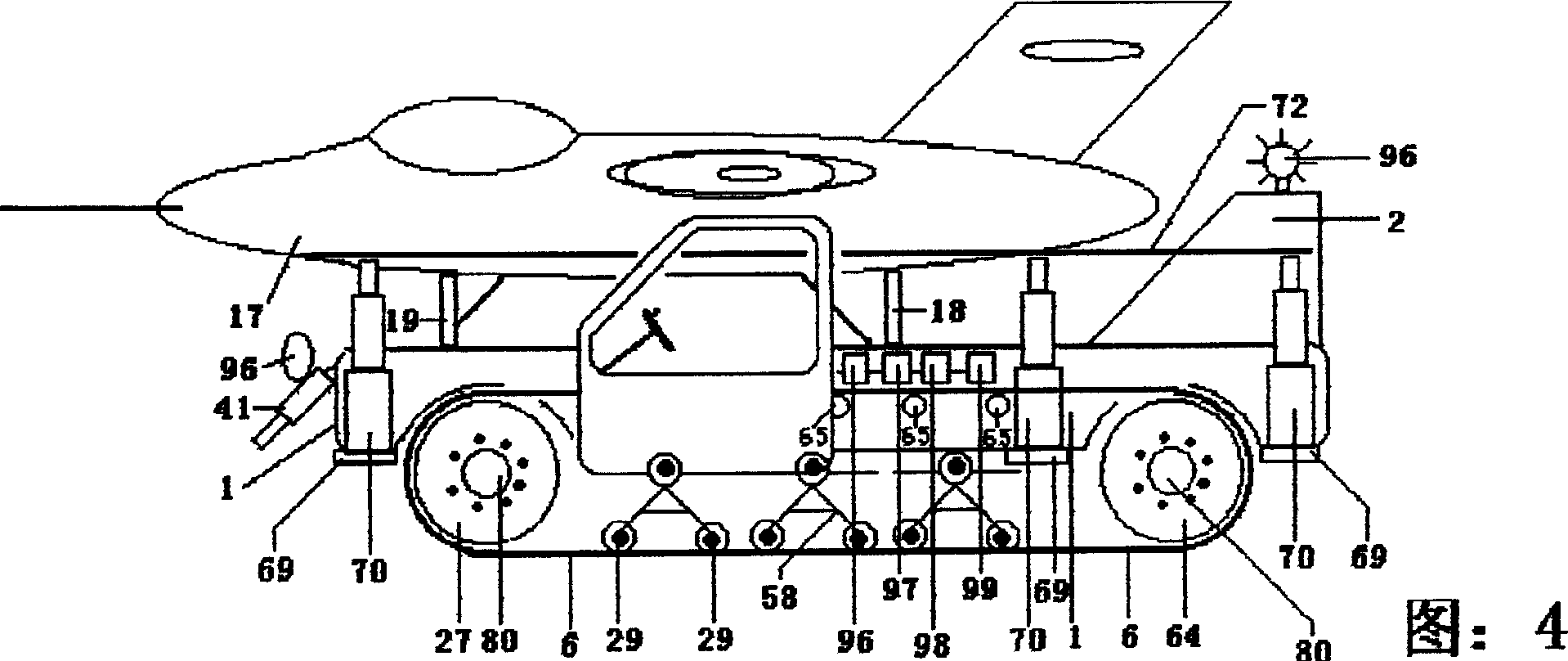

Aeroplane rescure car

The aeroplane rescue vehicle consists of chassis, accepting and stabilizing unit, running up runway, fly-aiding push board and airplane support for the forced landing airplane. It has also cleaning shovel inside a cavity, explosion-proof cab, salvage equipment, fire extinguishing equipment, medicine, drawing unit, guide wheel, load bearing wheel, shock absorbing unit, etc. It is suitable for aeroplane rescue in any fields owing to annular crawler belt on the load bearing wheels.

Owner:李京岐

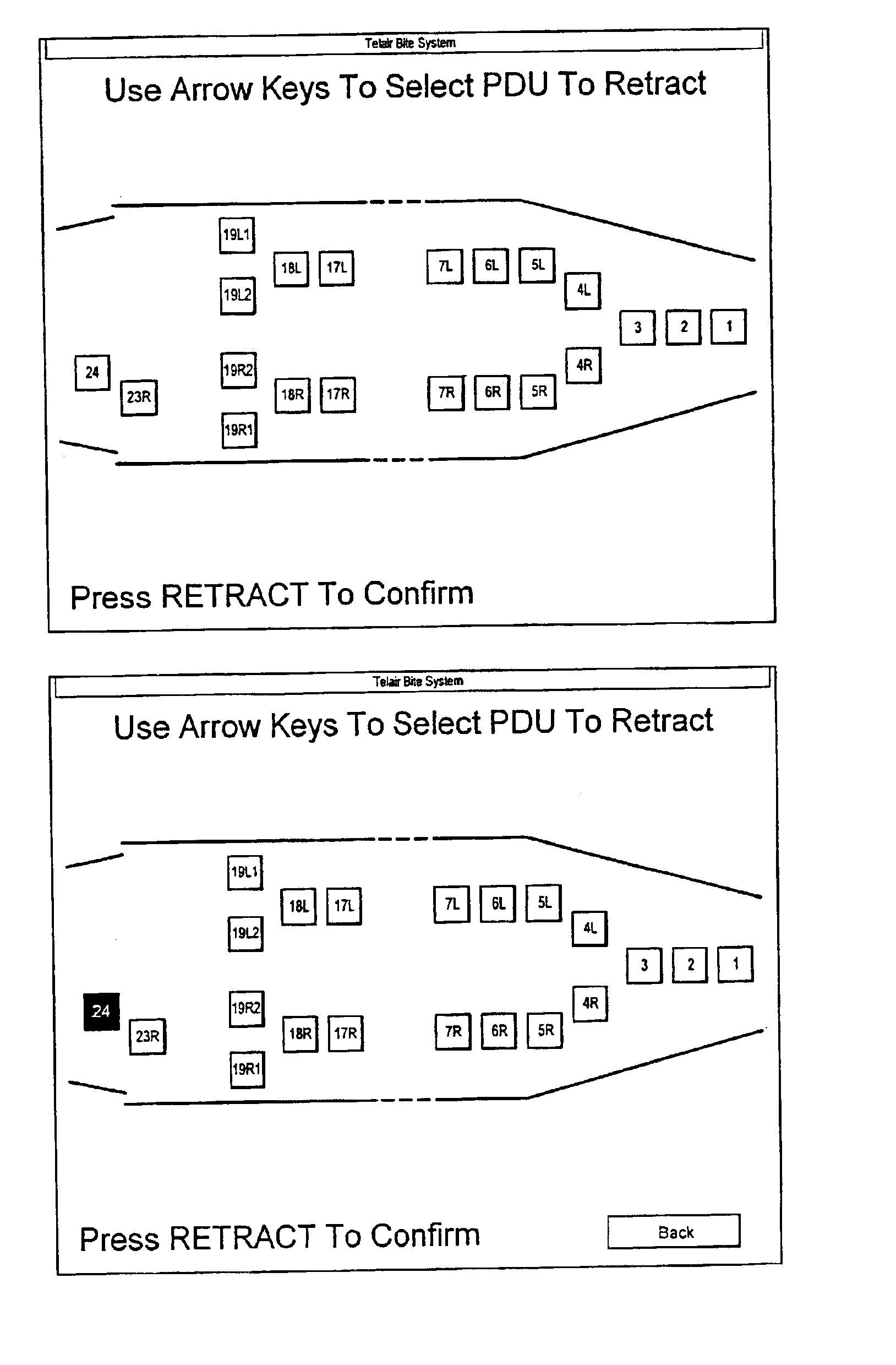

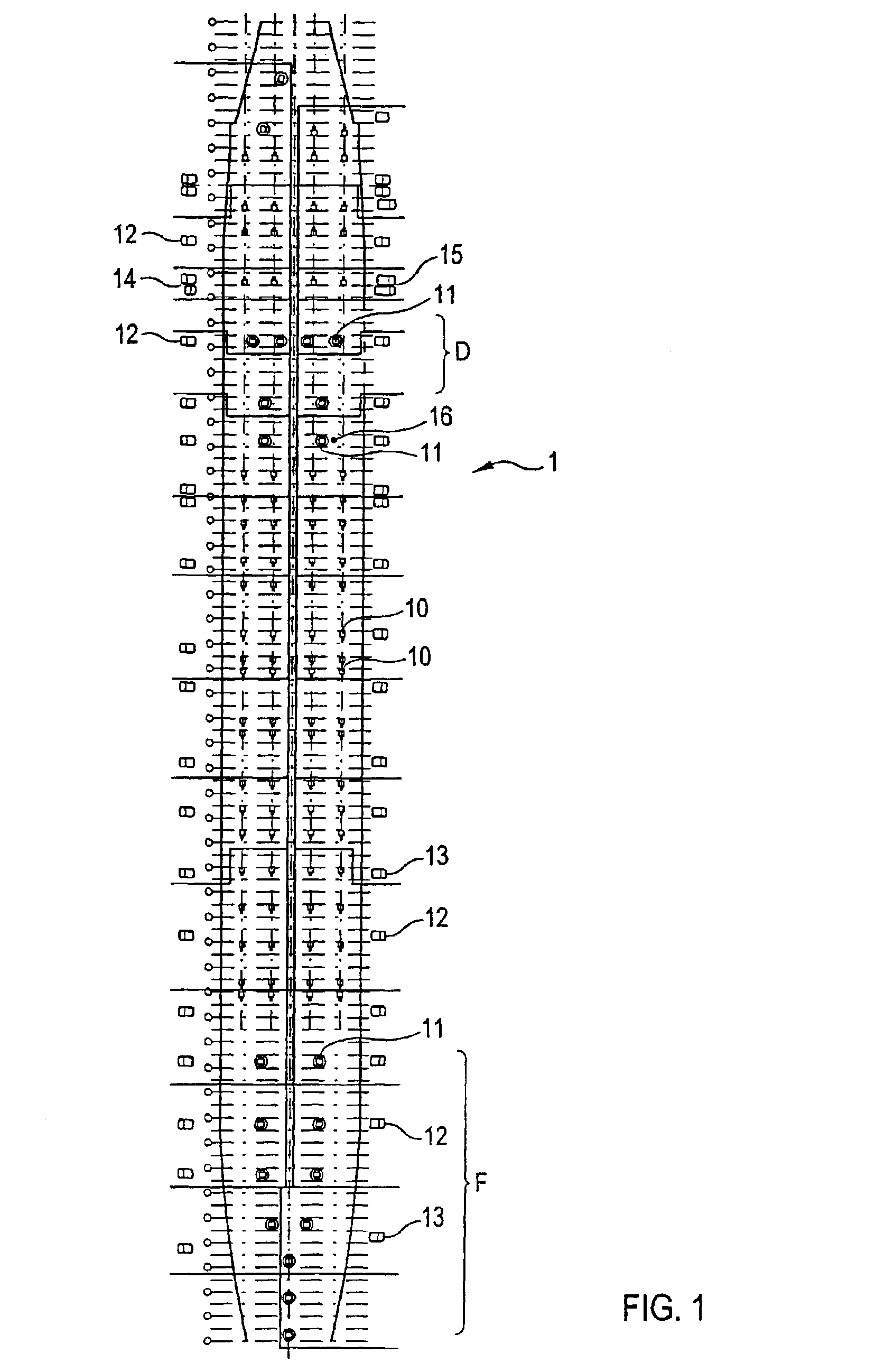

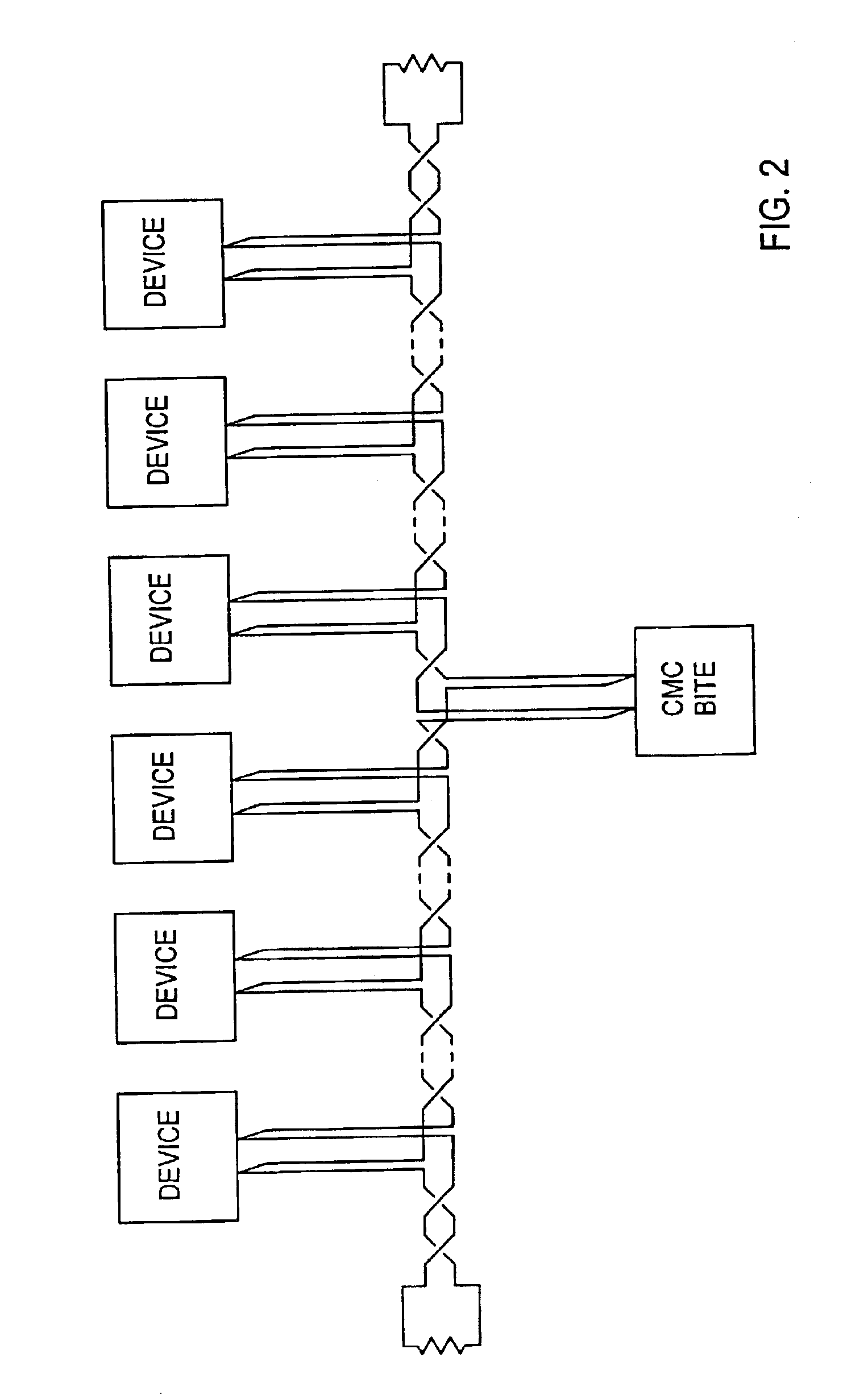

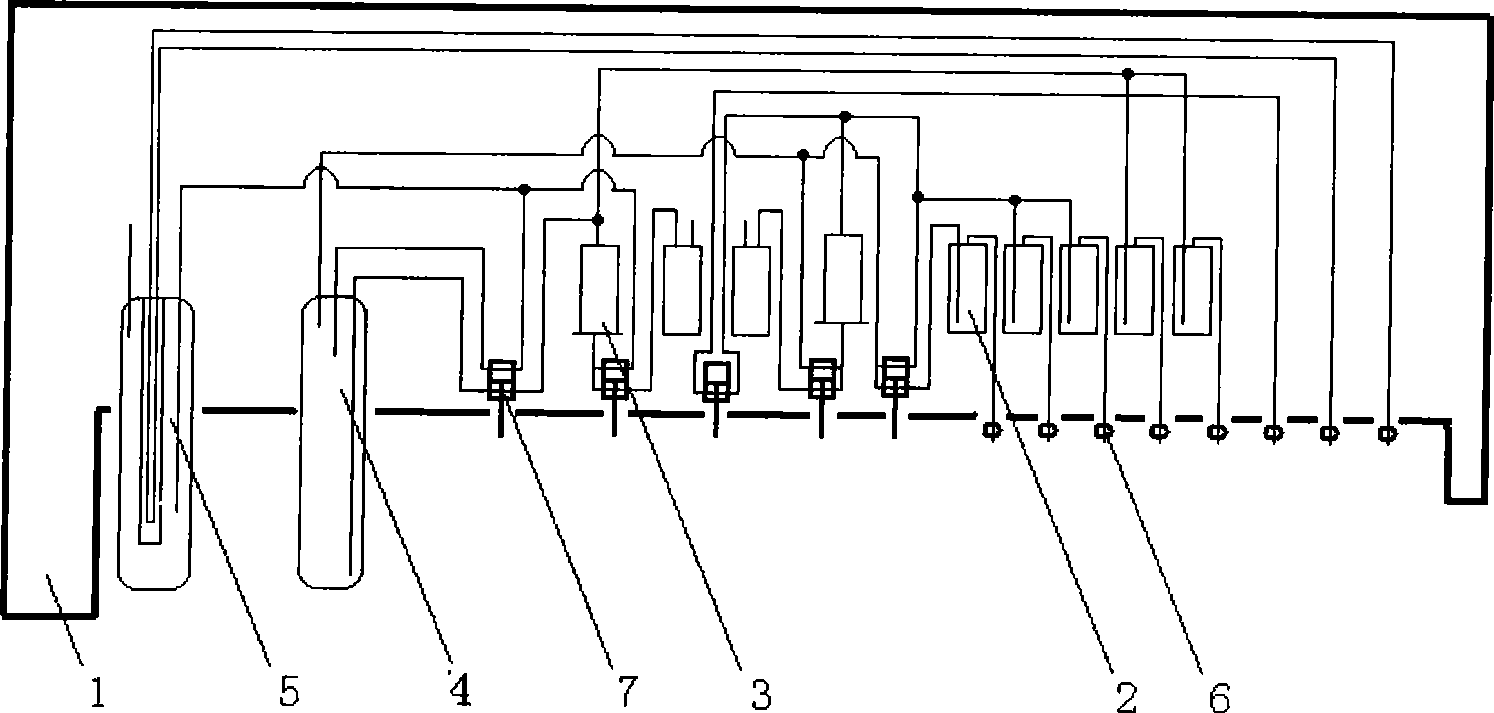

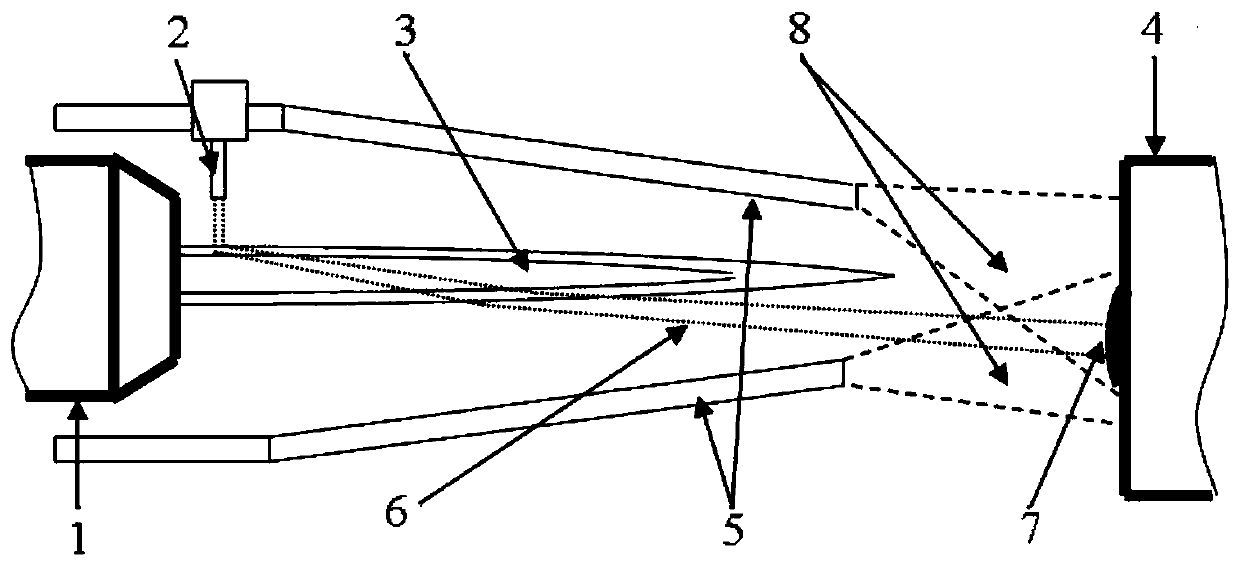

Freight-loading system for an aircraft

InactiveUS6867702B2Reliable unloadingReliable loading and unloadingData processing applicationsControl devices for conveyorsControl signalEngineering

A freight-loading system in a cargo hold of an aircraft is provided that offers enhanced operating safety. The freight-loading system comprises a plurality of power drive units (PDUs), which can be actuated by control signals in such a way that items of freight can be maneuvered into or out of the cargo hold as well as within it. The power drive units (PDUs) are connected by control leads to control panels for actuation by personnel. A control maintenance computer (CMC) is provided and connected to the power drive units (PDUs) and the control panels, and is so designed that status information from the power drive units (PDUs) and the control panels can be read out, and that the power drive units (PDUs) and / or the control panels are controllable by the control maintenance computer (CMC).

Owner:TELAIR INTERNATIONAL GMBH

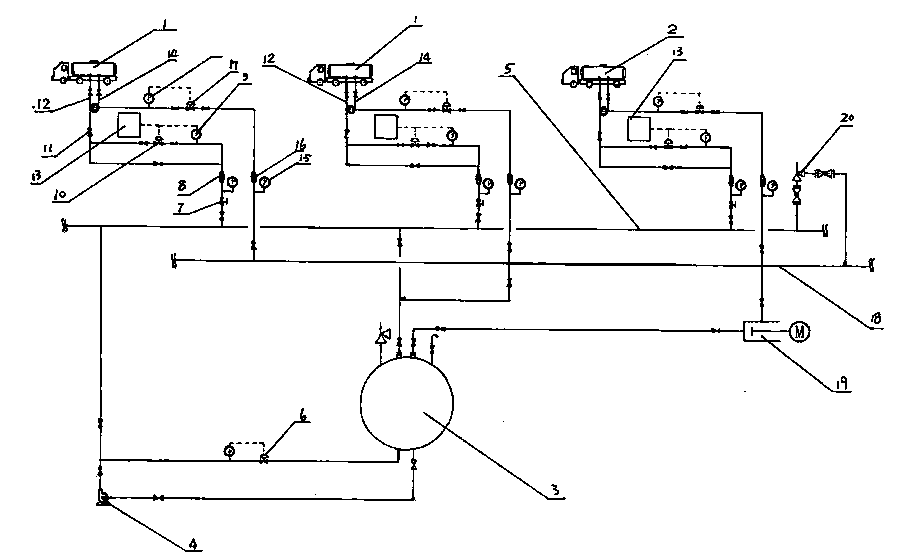

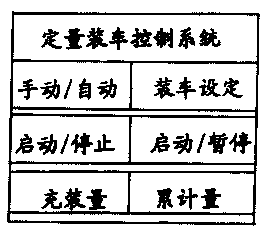

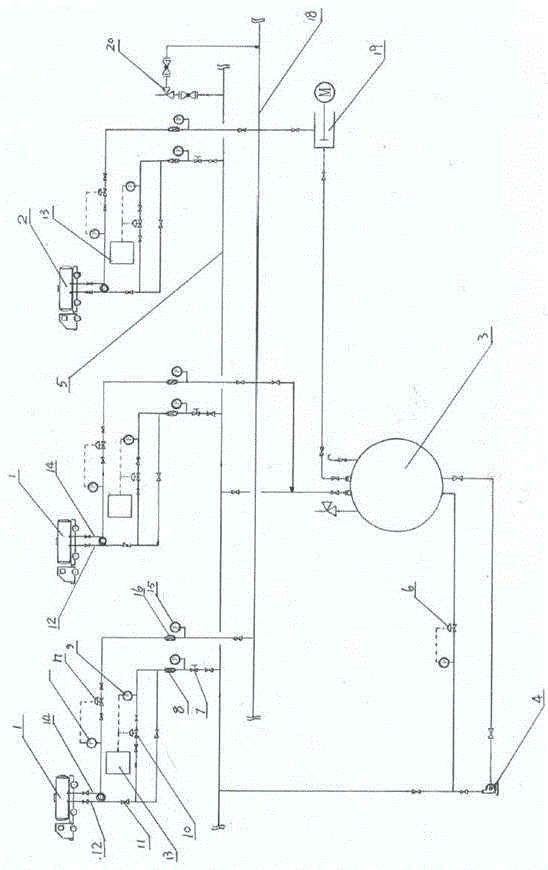

Device and method for filling and unloading liquid ammonia

ActiveCN104197187AVersatileDiversified operating modesContainer discharging methodsContainer filling under pressureBall valveLiquid ammonia

The invention relates to a device and a method for filling and unloading liquid ammonia. The device comprises a liquid ammonia buffer storage tank, a liquid ammonia filling and unloading arm and a delivery pump, and is characterized in that the liquid ammonia buffer storage tank is connected with the delivery pump; the delivery pump is connected with a liquid phase main pipeline; an outlet of the delivery pump is further provided with a backflow pipeline; a backflow regulating valve is arranged on the backflow pipeline; the liquid phase main pipeline passes through a rapid cut-off valve, a flame arrester, a mass flowmeter, a regulating valve of the mass flowmeter, a manual ball valve and the liquid ammonia filling and unloading arm on a liquid ammonia pipeline in sequence; the mass flowmeter and the regulating valve of the mass flowmeter are connected with a filling and unloading quantitative control system; a tank car is further connected with a gas phase filling and unloading arm; the gas phase filling and unloading arm is connected with a gas phase main pipeline or a compressor via a pipeline provided with a pressure meter, a flame arrester and a pneumatic regulating valve in sequence; the gas phase filling and unloading arm is then connected with an ammonia buffer storage tank; and the liquid phase main pipeline is further connected with the gas phase main pipeline via a safety valve. The device and the method can be applied to the field of filling and unloading various easily liquified liquid such as liquid ammonia, dimethyl ether and natural gas.

Owner:WENGFU (GRP) CO LTD

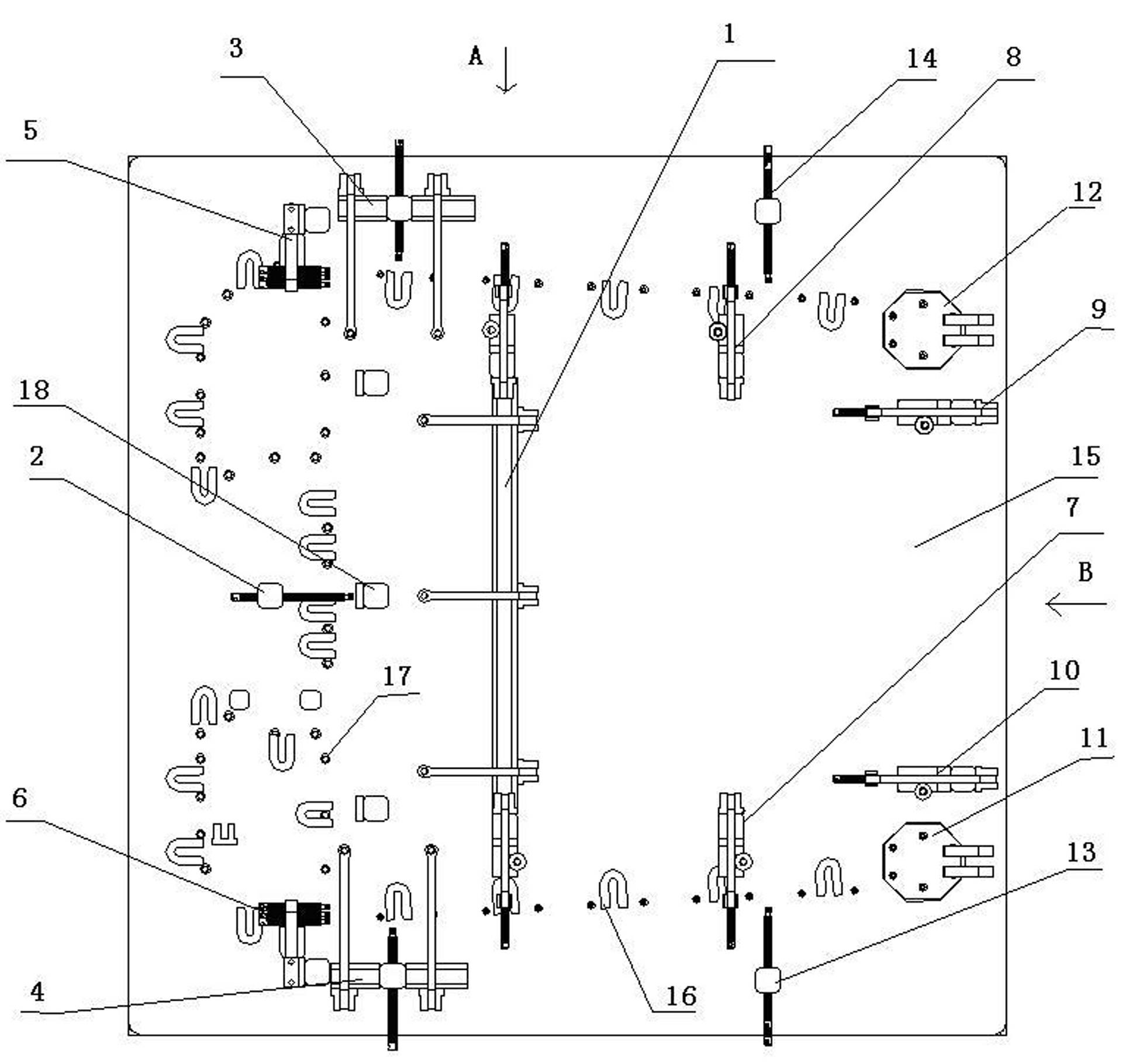

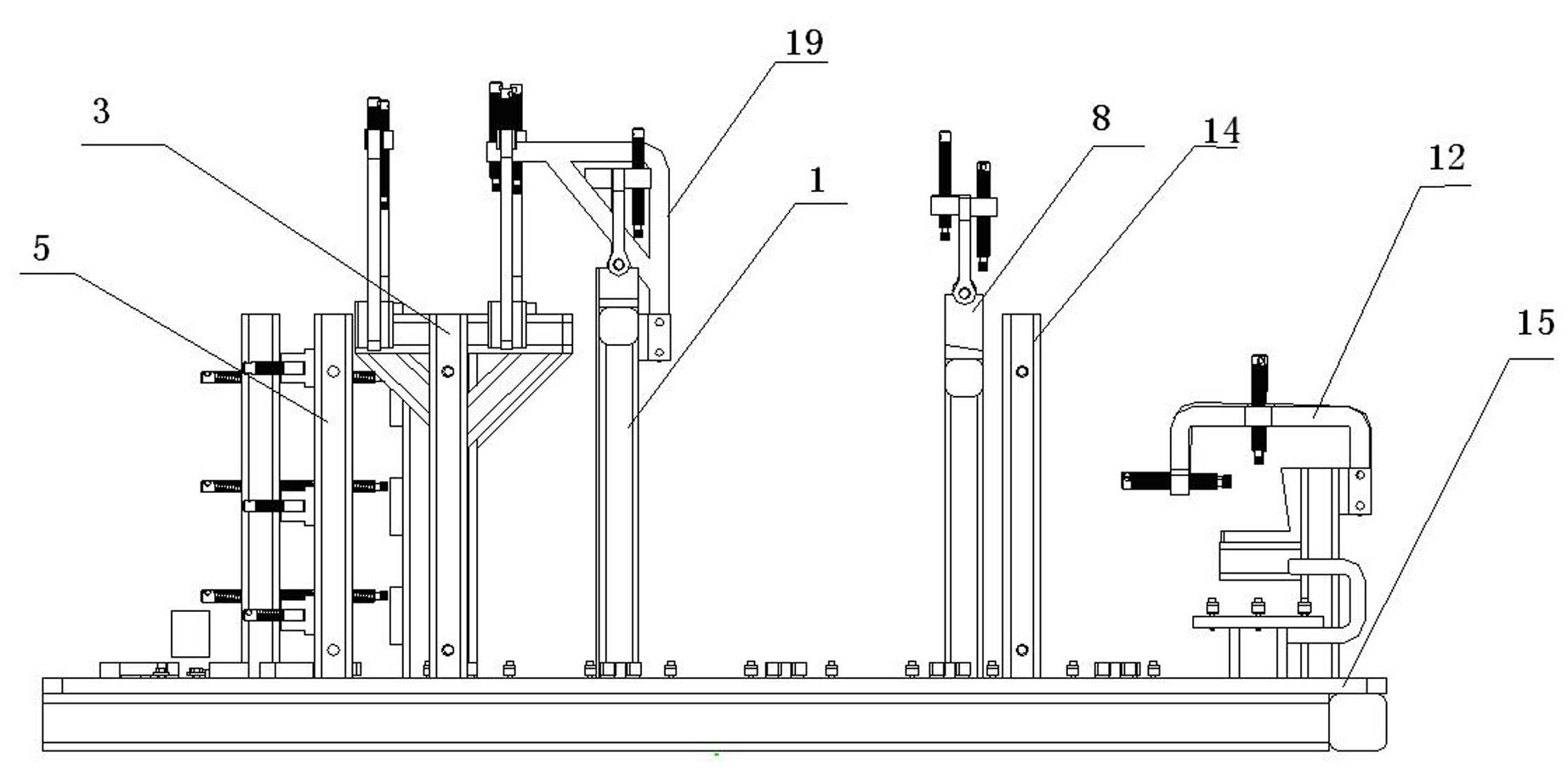

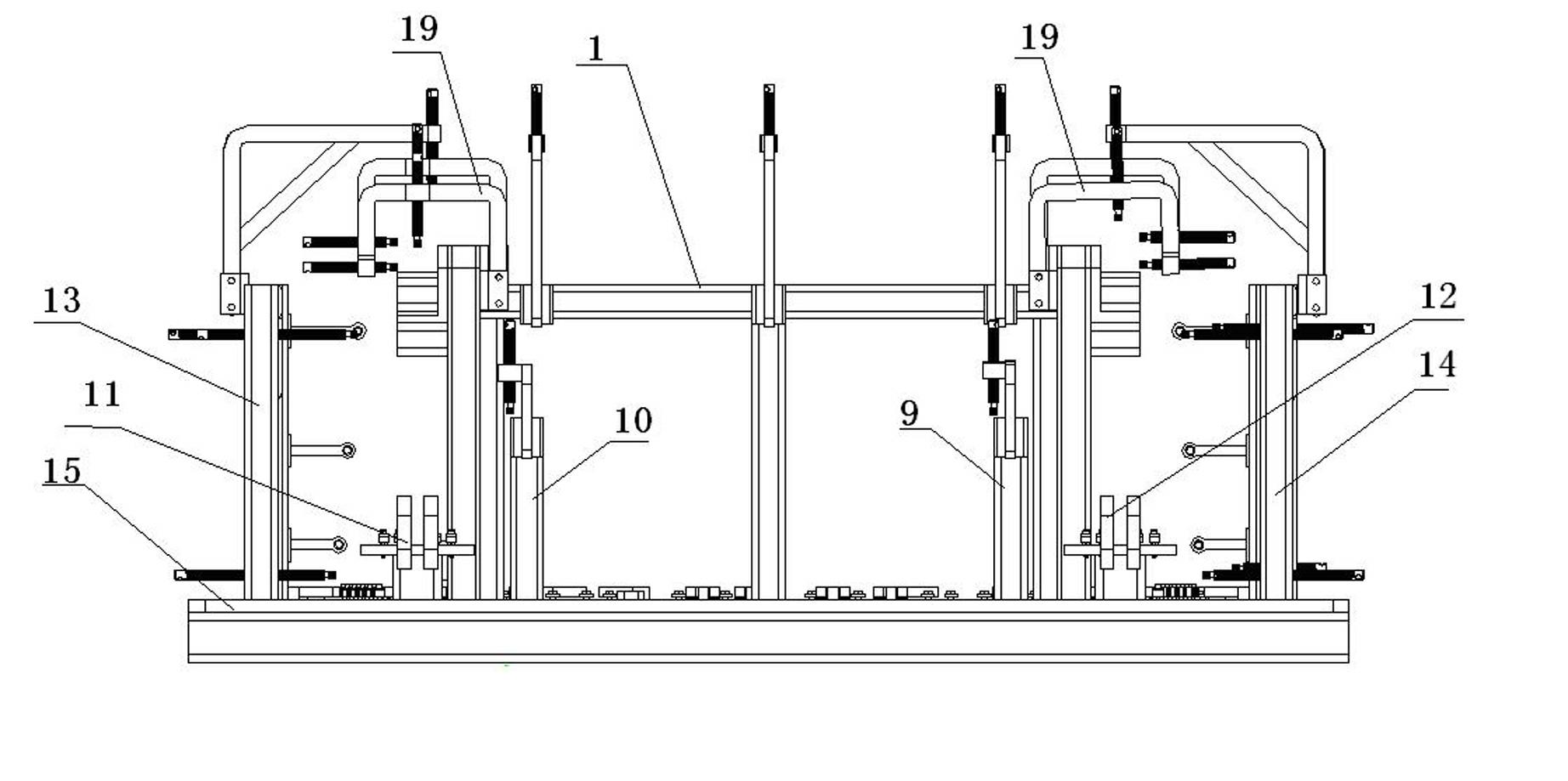

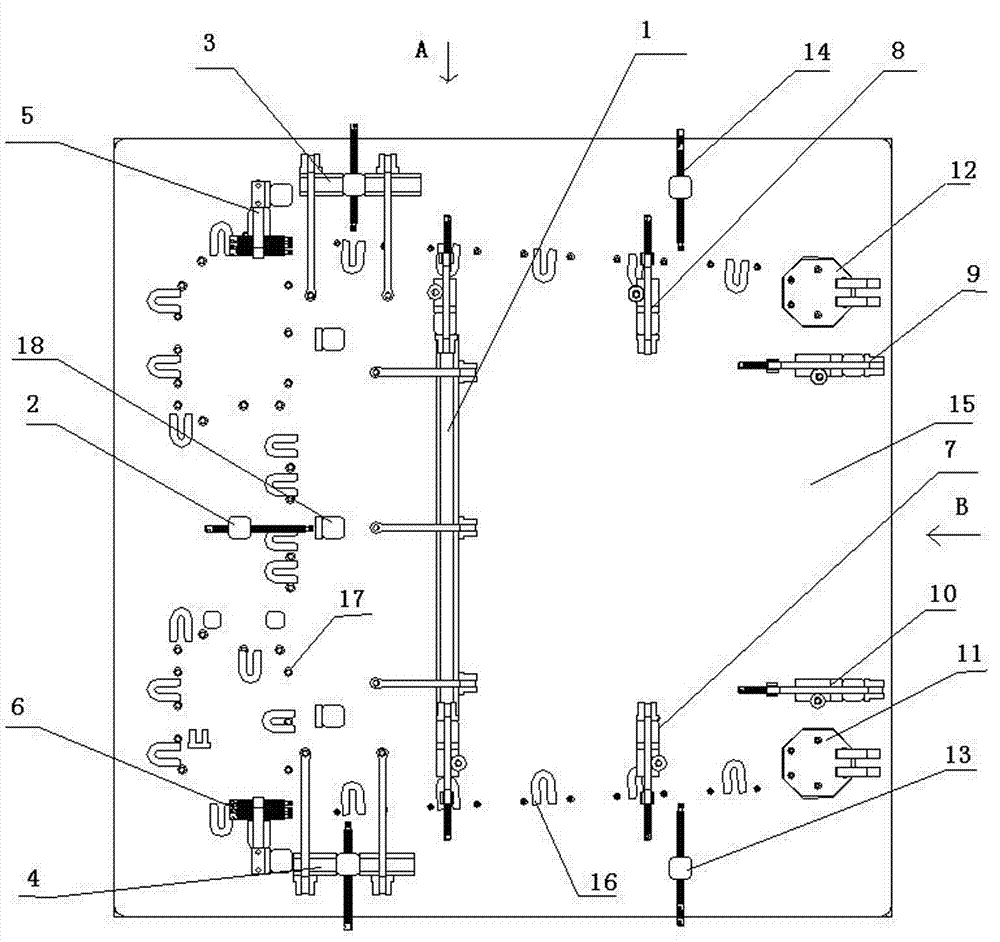

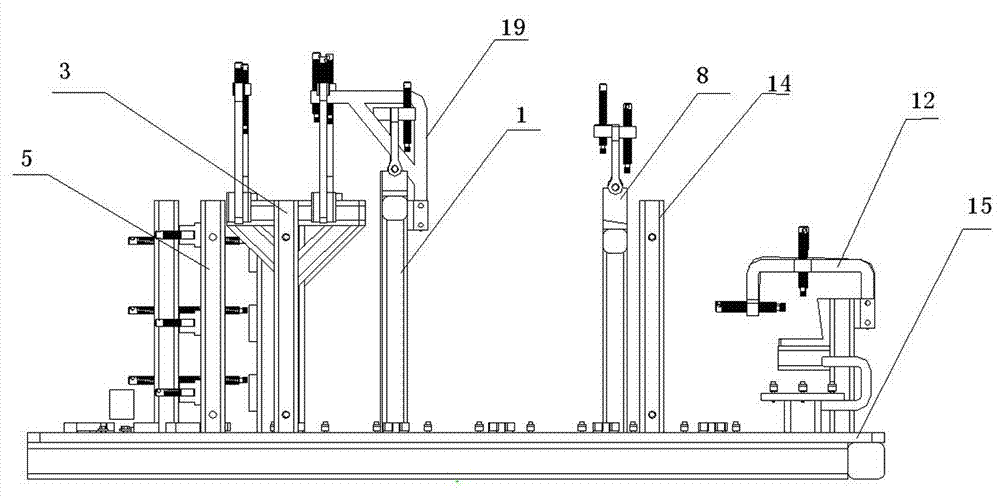

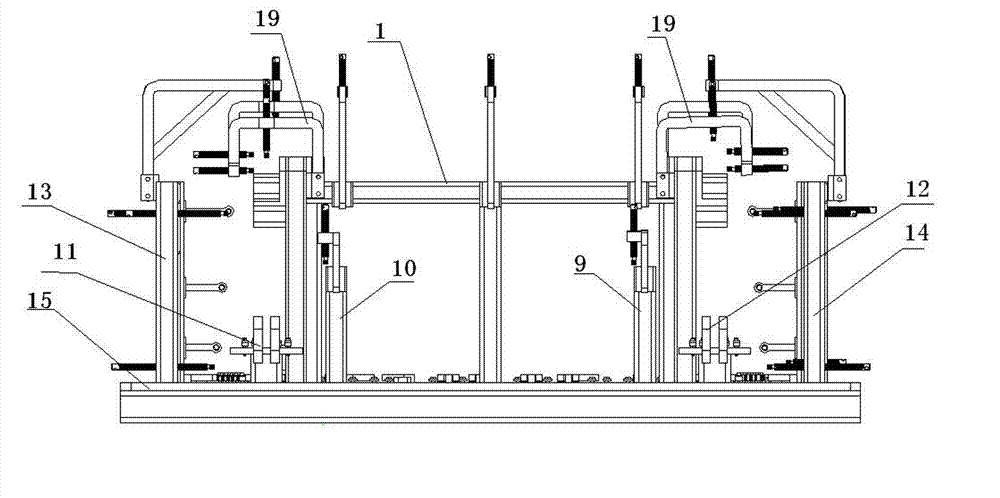

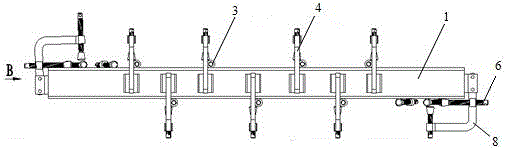

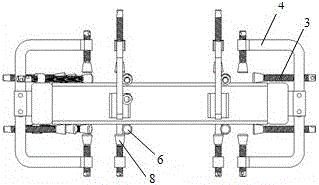

Installing and welding tool for cab

ActiveCN102152050AGuaranteed dimensional accuracy requirementsNo lateral bendingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringVertical Dimensions

The invention relates to an installing and welding tool for a cab, which comprises a baseplate, a three-direction pressing and positioning device arranged on the baseplate, a large-floor middle pressing device, a crash barrier positioning and pressing device, a left pressing device, a right pressing device, a camber beam positioning and pressing device, a doorframe pressing device, a cross beam positioning and pressing device and an end chuck positioning block, wherein the large-floor middle pressing device, the crash barrier positioning and pressing device, the left pressing device and the right pressing device are arranged on one side of the three-direction pressing and positioning device, the camber beam positioning and pressing device, the doorframe pressing device, the cross beam positioning and pressing device and the end chuck positioning block are arranged on the other side of the three-direction pressing and positioning device, the left pressing device and the right pressing device are respectively arranged on two ends of the three-direction pressing and positioning device, the large-floor middle pressing device is arranged between the left pressing device and the right pressing device, one end of the large-floor middle pressing device is further provided with a large-floor rear positioning device, and the two ends of the three-direction pressing and positioning device are provided with pressing and positioning mechanisms. By means of the invention, the vertical dimensions of end parts of a cross beam and a camber beam are ensured, the cross beam is prevented fromlateral bending, and the installing and welding tool has the advantages of convenience for operation and bodilessness, good generality and capability of clamping manually and is convenient, flexible and reliable to mount and dismount.

Owner:南京雷尔伟新技术股份有限公司

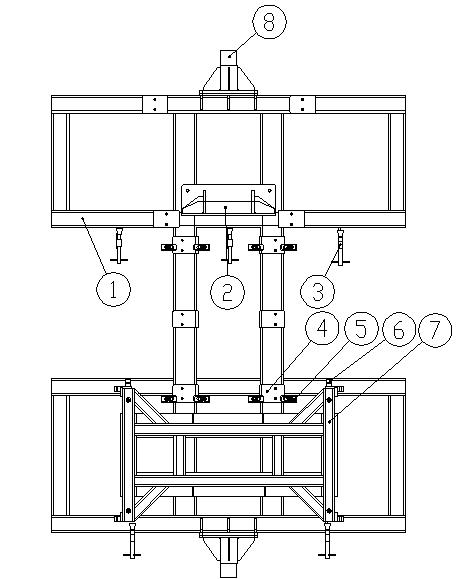

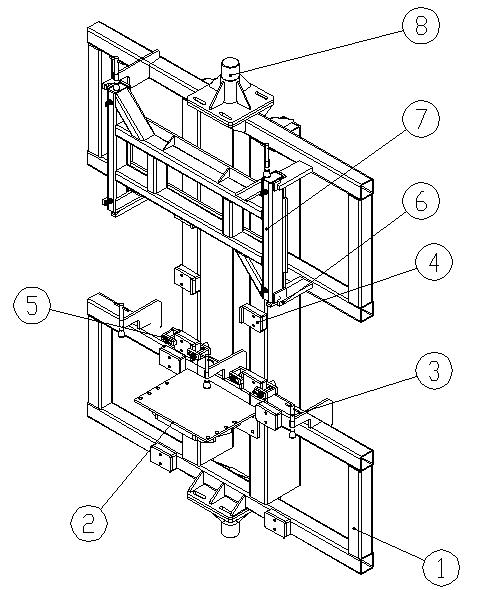

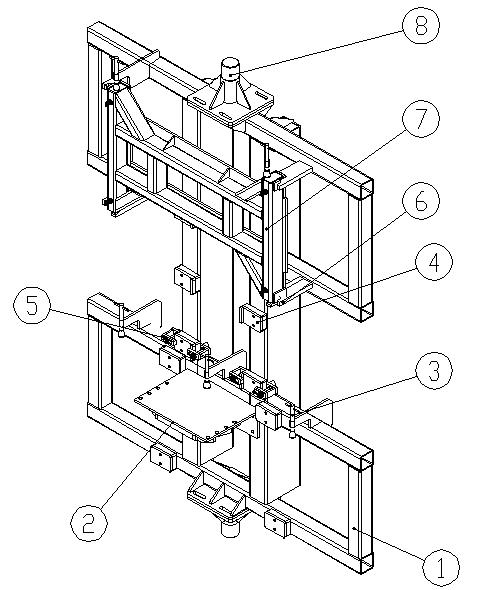

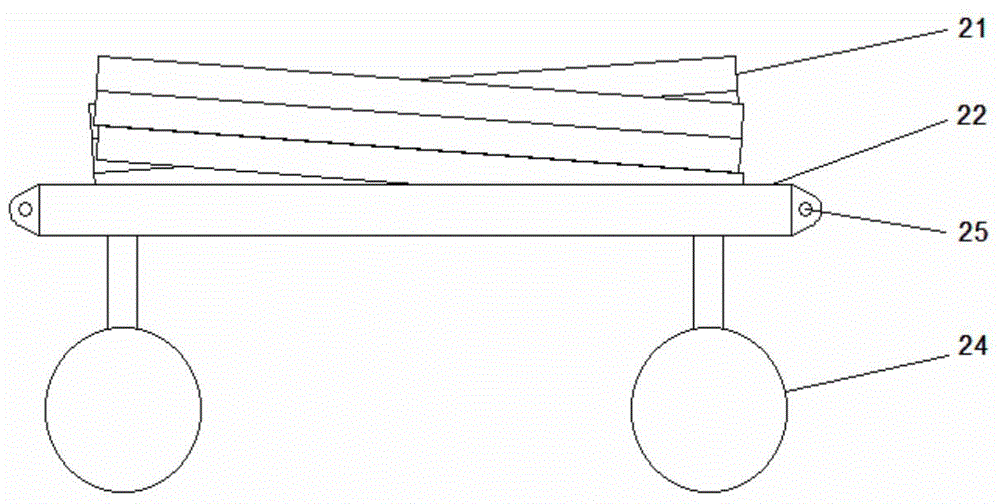

80-ton adjustable large-piece hoister

The 80-ton adjustable large sling includes one rectangular support frame comprising transverse beams and longitudinal beams, two long hangers mounted onto the longitudinal beams, suspending sets in the ends of hangers, pinch wheels and guide wheels in the joints between long hanger and longitudinal beam, one towing shifter on the joining beam for towing long hangers, support legs below the ends of the longitudinal beams, and one hanging plate with holes for hoisting steel cables to pass through. The sling has high adaptability, convenient operation, capacity of raising hoisting efficiency and high large goods hoisting safety and reliability.

Owner:天津港第二港埠有限公司

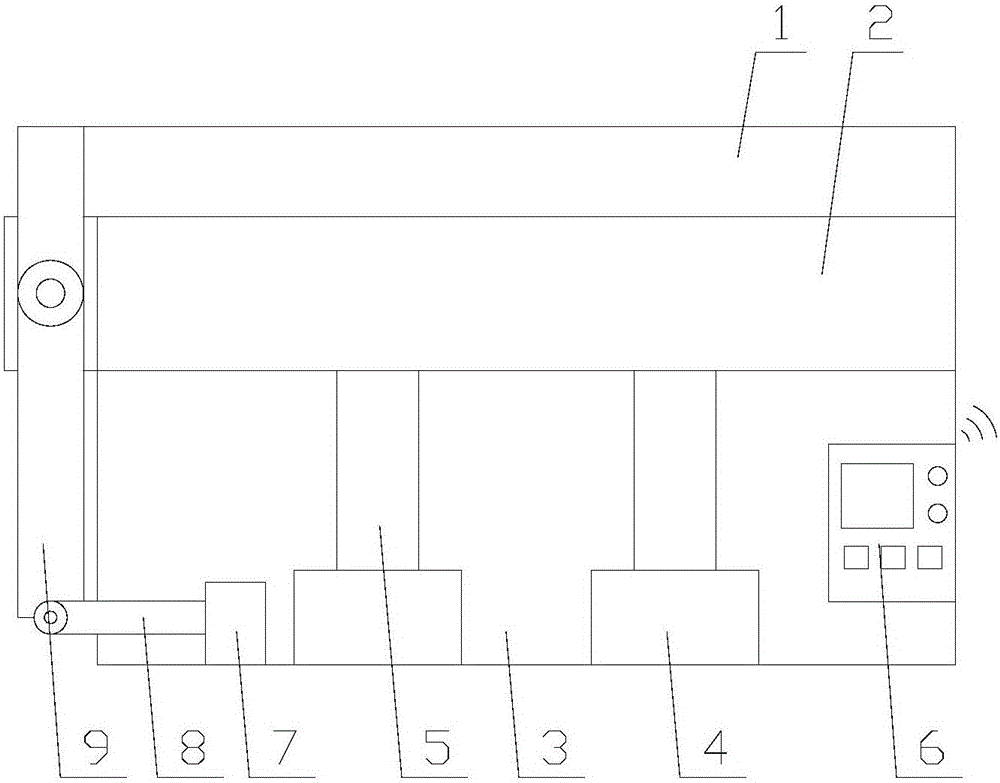

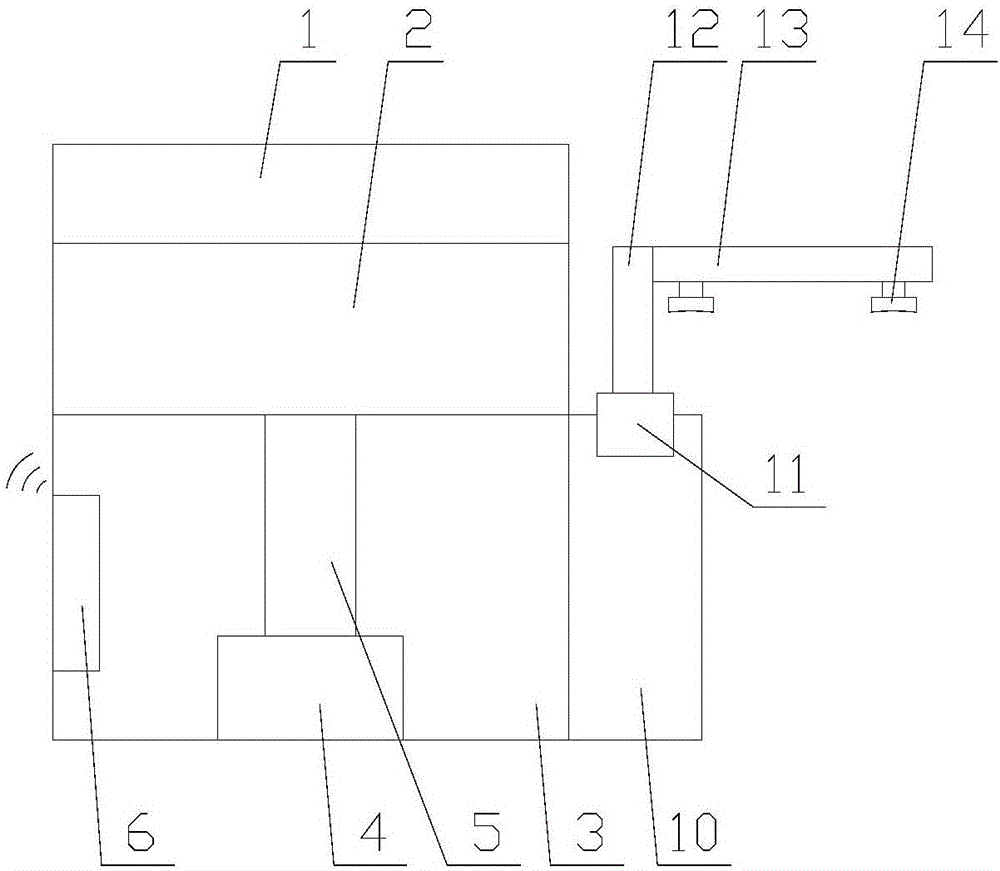

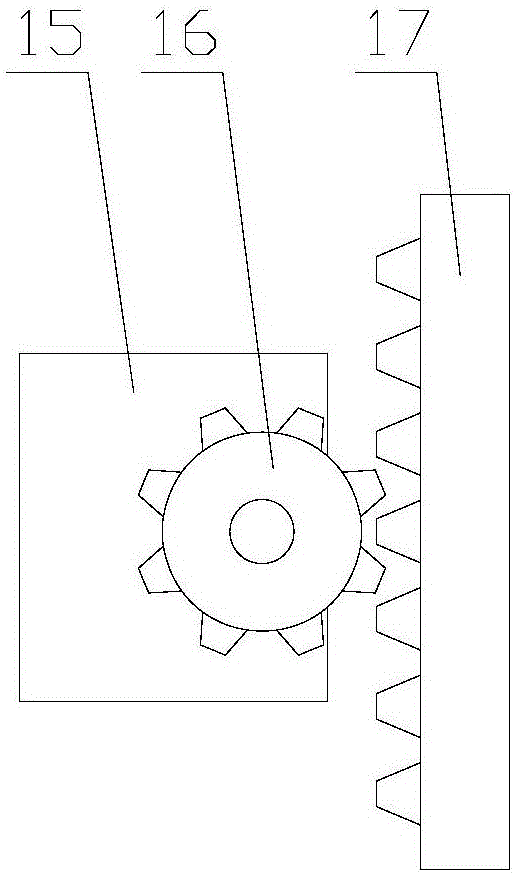

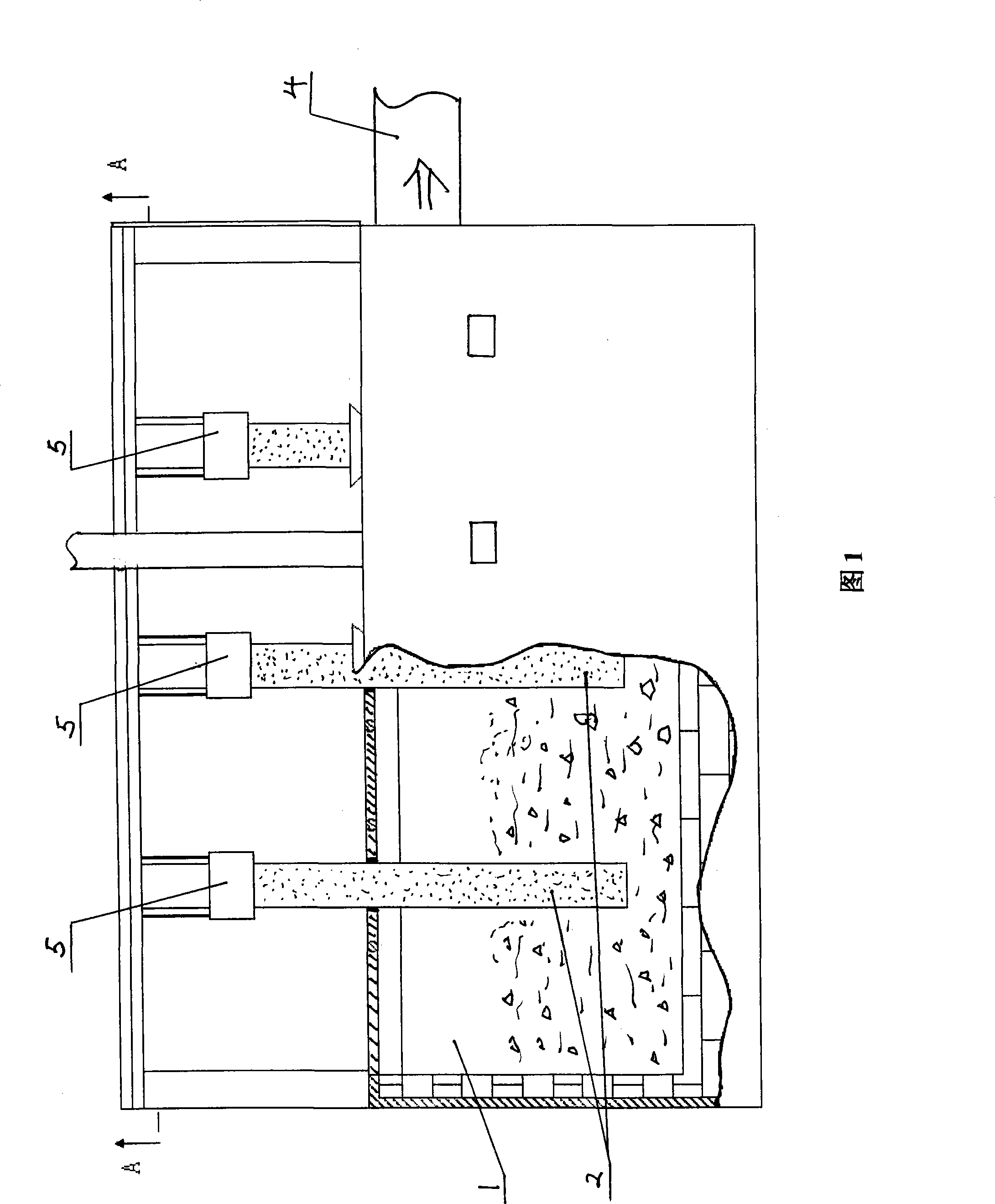

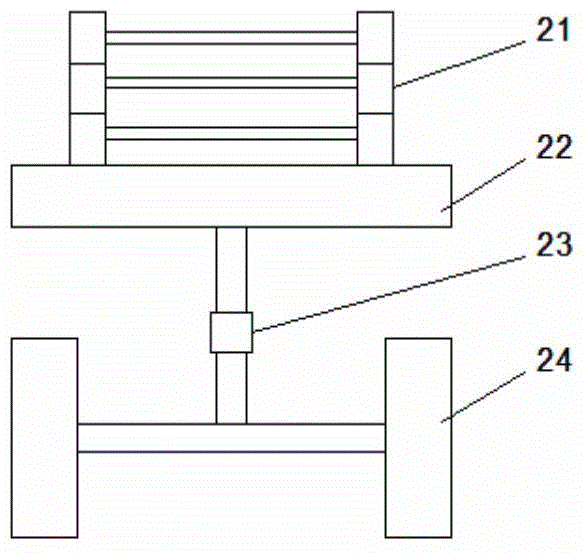

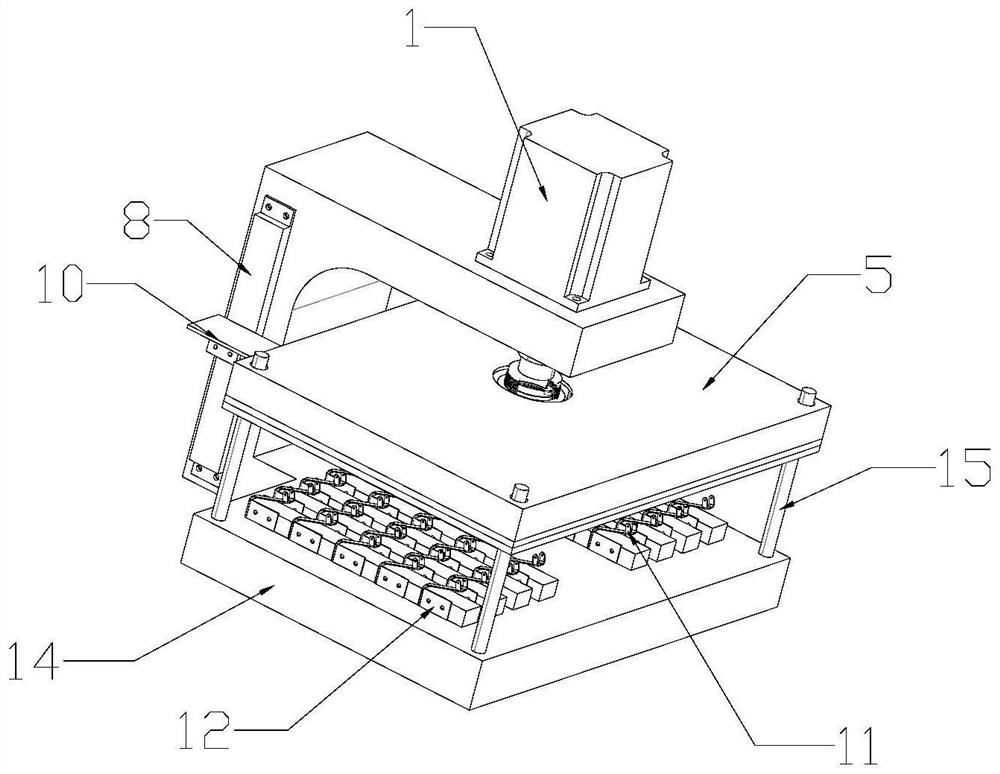

Solar photovoltaic production equipment

InactiveCN106608532ARealize intelligent controlAchieve adsorptionLaminationLamination apparatusEngineeringMotor control

The invention relates to solar photovoltaic production equipment which comprises a top cover, a machine body, a support frame, a central control mechanism, a laminating mechanism, and a loading and unloading mechanism, wherein the loading and unloading mechanism comprises a base, a steering component, a lifting component and a loading and unloading component; the laminating mechanism comprises an upper vacuum chamber, a heating plate, a lower vacuum chamber and a pressure plate; the central control mechanism comprises a central control module, as well as a motor control module, a wireless communication module, a pressure detection module, a display control module, a key control module, a state indication module and a working power supply module which are connected with the central control module. According to the solar photovoltaic production equipment, the steering component is used for controlling moving of the loading and unloading mechanism; displacement of a product can be controlled by the lifting component; due to the loading and unloading component, adsorption to the product is realized, so that reliable loading and unloading is realized, and the reliability of the equipment is improved; and moreover, due to the central control mechanism, intelligent control of the production equipment can be realized, and the intelligence of the equipment is improved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

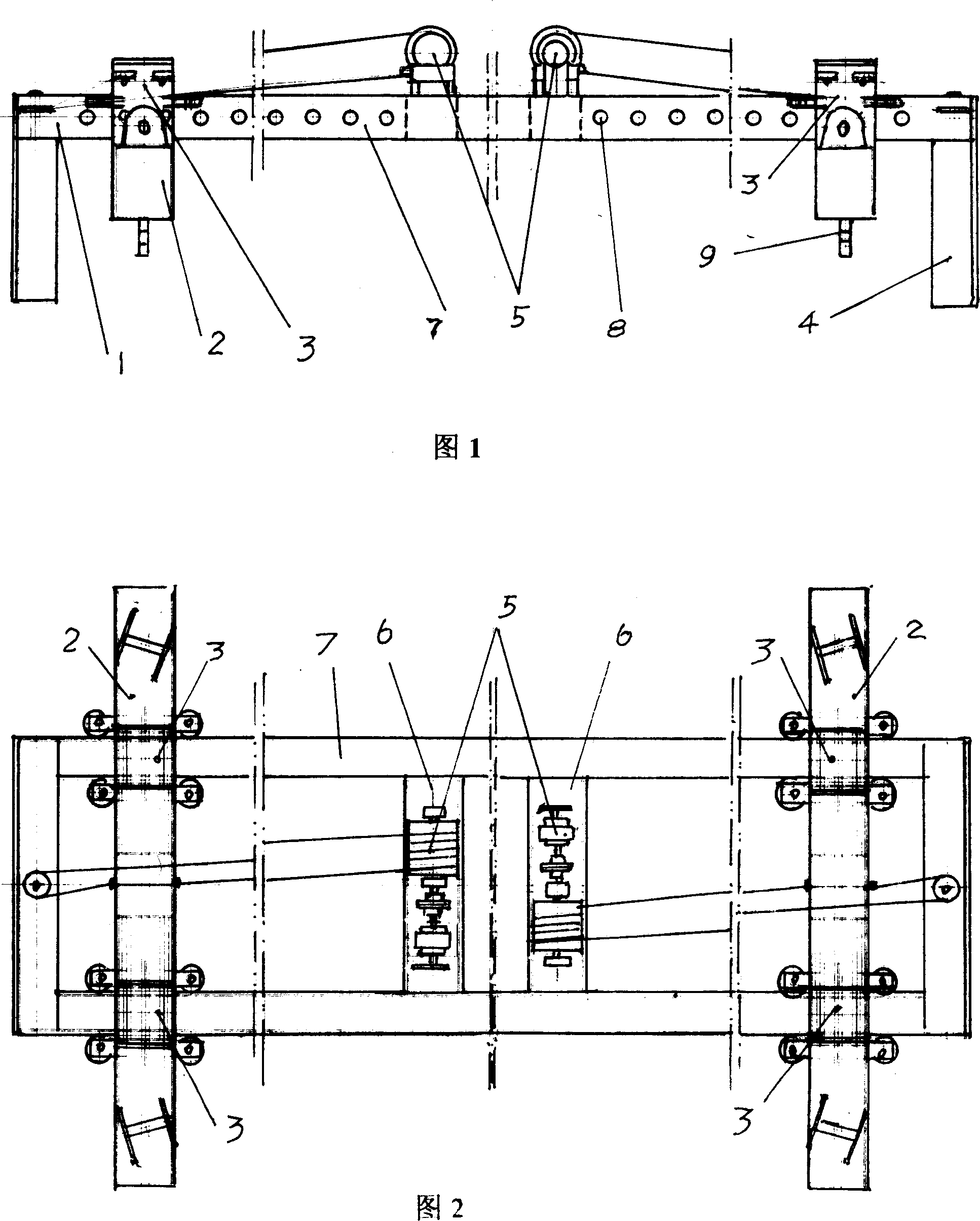

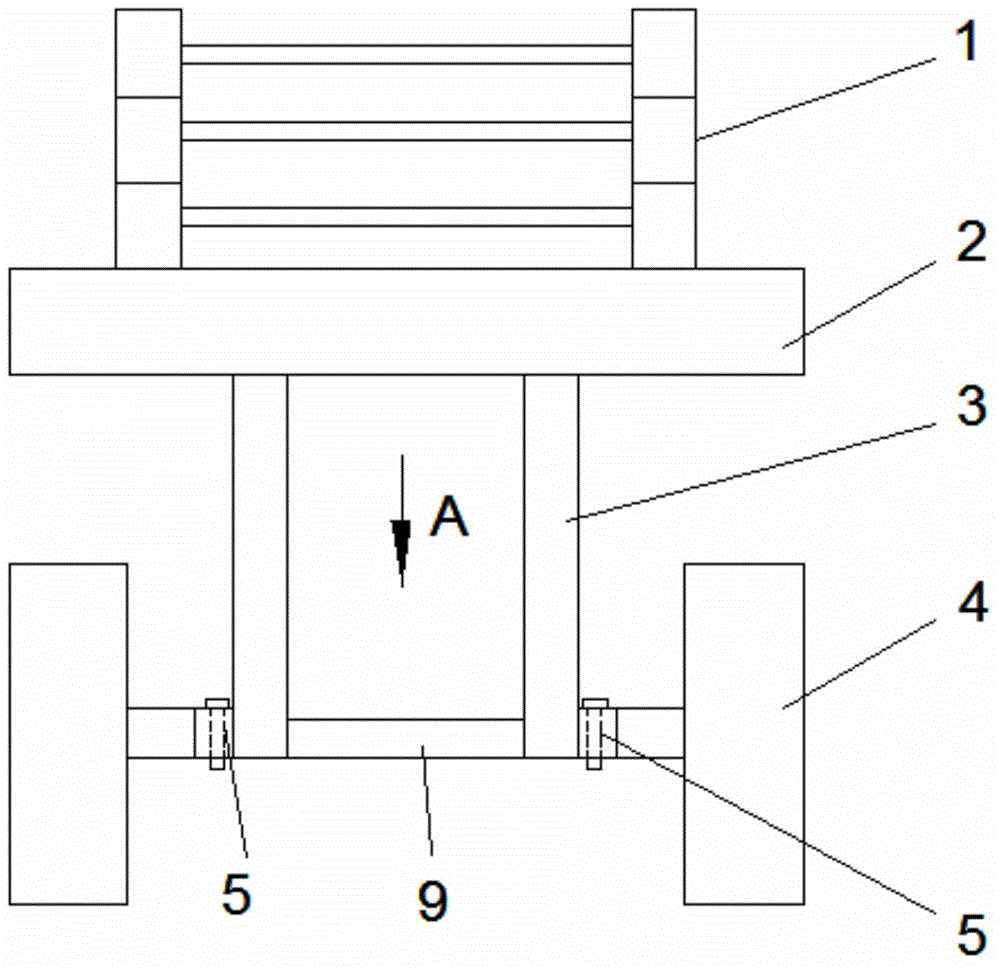

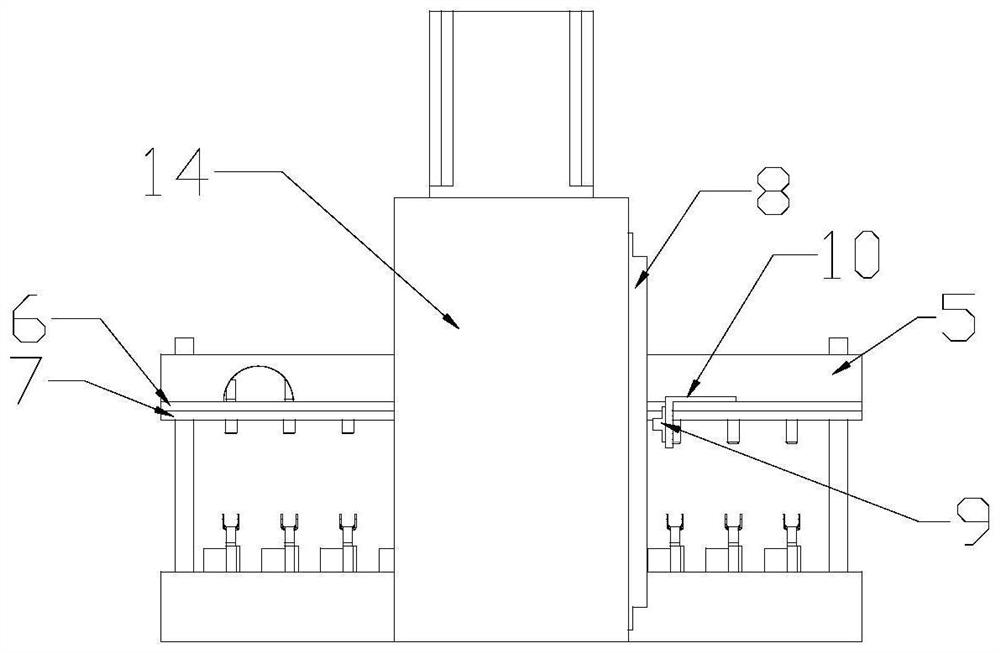

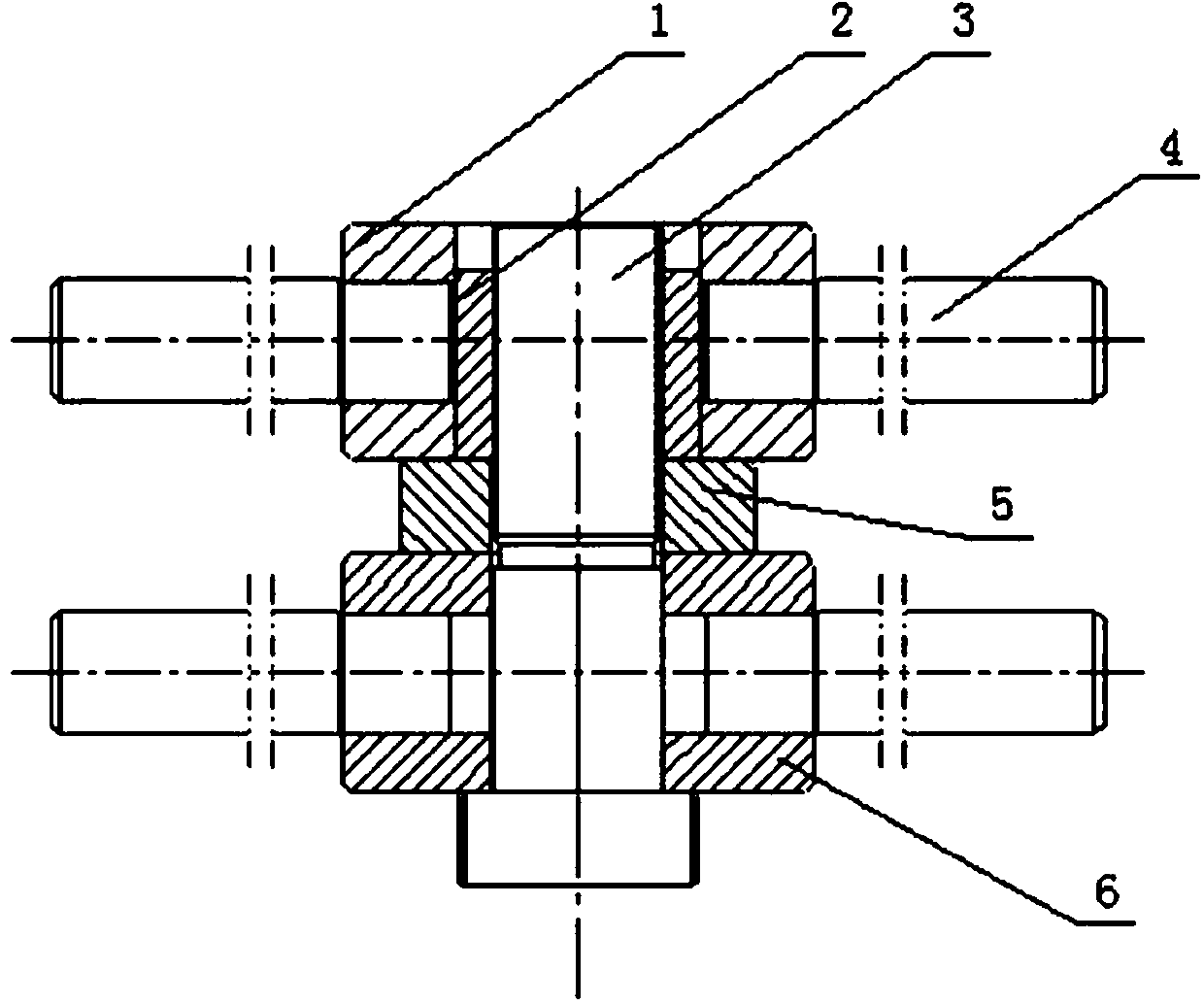

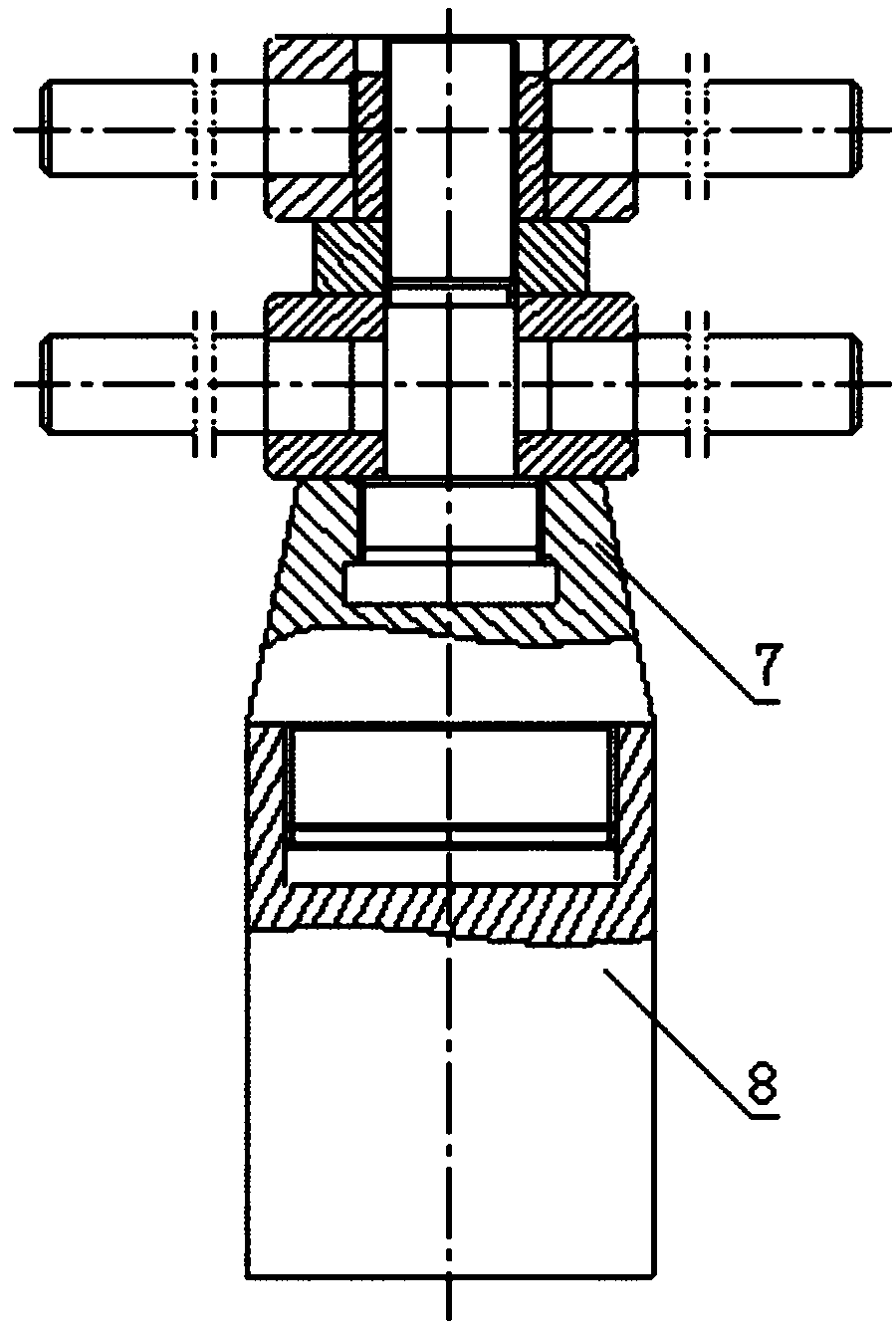

Bolster and buffer welding tool

ActiveCN102152049AReduce welding difficultyImprove weld seam qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention relates to a bolster and buffer welding tool which is characterized by comprising a tool steel structure (1), a corbel clamping tool (7), a corbel positioning block (6), a pressing plate device (5), a position changing unit, a coupler plate mounting base (2), a steel aluminum cushion block (4) and a compacting device (3), wherein two ends of the tool steel structure (1) are providedwith connecting bases (8) mounted on the position changing unit; one end of the tool steel structure (1) is fixedly welded with the coupler plate mounting base (2), and the corbel positioning block (6) and the steel aluminum cushion block (4) are positioned based on the coupler plate mounting base (2), the corbel clamping tool (7) is positioned by the other end of the tool steel structure (1) viathe corbel positioning block (6); and the pressing plate device (5) and the compacting device (3) are fixedly welded on the tool steel structure (1). The bolster and buffer welding tool adopts the position changing unit to adjust the tool angle to realize 360-degree rotation of the tool, and turns vertical welding and overhead welding into flat welding, thereby reducing overlap stack and lack of penetration, and meanwhile, a pair of F-shaped pliers is adopted for being matched with the compacting device to fix welding members, thus welding deformation is prevented and good welding quality, accurate positioning and convenience in loading and unloading are guaranteed.

Owner:南京雷尔伟新技术股份有限公司

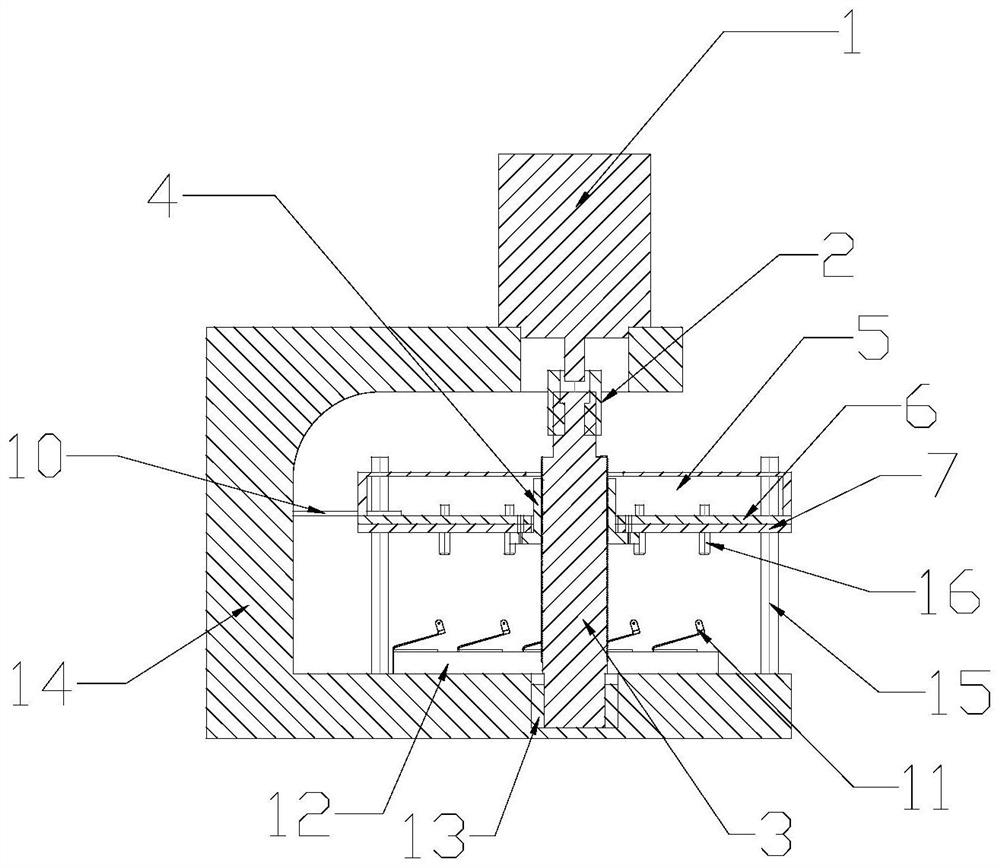

Large diameter cylinder type graphite electrode giant electric furnace

ActiveCN101251334AEasy to useHandling and unloading safetyElectric heating for furnacesElectric arc furnaceGraphite electrode

The invention relates to a giant electric furnace for zinc pyrometallurgy, in particular to an electric furnace using columned straight graphite electrodes with diameter range 200mm to 800mm, belonging to the electric furnace equipment field. The giant electric furnace for zinc pyrometallurgy is characterized in that: the hearth of the furnace body of the electric furnace is a quadrate sealed chamber, the upper side of which is side by side provided with at least two graphite electrode access sockets, each graphite electrode access socket is provided with a graphite electrode, and a feeding tube is connected with the upper side of the hearth of the furnace body of the electric furnace. The graphite electrodes are clipped by two arc connecting clamps connected with a connecting lead, and each graphite electrode can move from top to bottom along with the arc connecting clamps. The periphery of each arc connecting clamp is provided with a cooling jacket. The graphite electrodes have straight columned shapes, the diameters of which are 200mm to 800mm. The giant electric furnace for zinc pyrometallurgy using columned graphite electrodes with large diameters has the advantages of simple structure, safe and convenient use, operation and maintenance. The giant electric furnace for zinc pyrometallurgy effectively improves the output of the zinc pyrometallurgy for a single electric furnace, allowing the annual production capacity of the single electric furnace above ten thousand tons, thus the giant electric furnace for zinc pyrometallurgy establishes the foundation for the development of the large scale electric furnace industrialization, and also has excellent socioeconomic performance and application prospects in the market.

Owner:YUNNAN HAOLONG IND GROUP XINGYU SMELTING

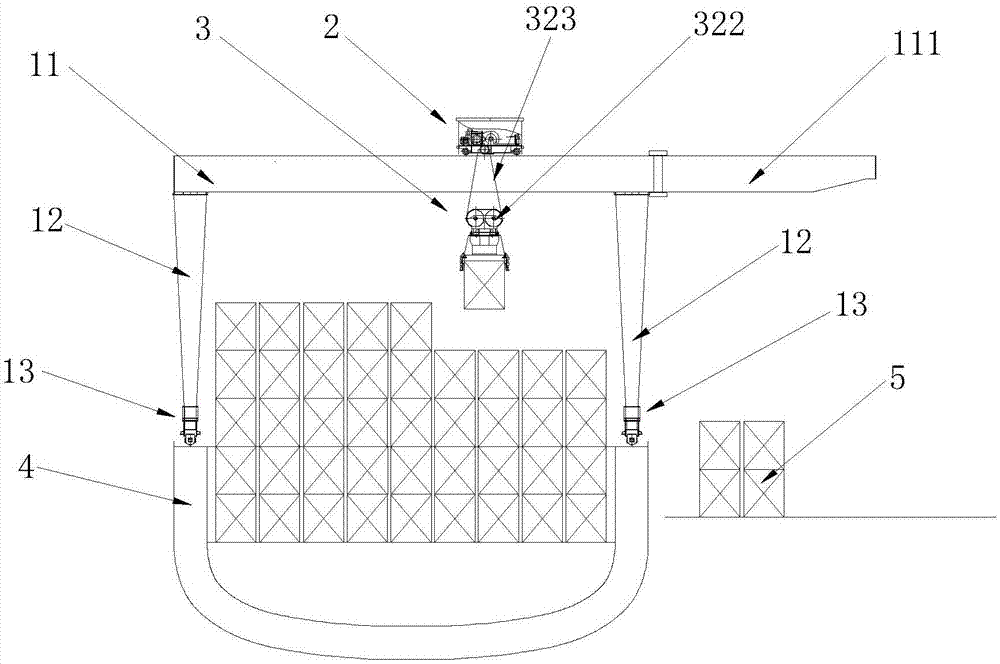

Container crane and working method thereof

The invention provides a container crane comprising a first travelling mechanism, a lifting mechanism and a mounting bracket arranged on a ship across, and the mounting bracket comprises a cross beam and at least two columns for supporting the cross beam; and the lifting mechanism is connected to the first travelling mechanism arranged on the cross beam. The container crane can be directly installed on a bulwark of the ship, and is convenient for loading and unloading containers, and the container crane has the advantages of simple structure and reliable operation. The invention relates to a working method of the container crane, and the working method is simple in process and reliable in principles.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD +1

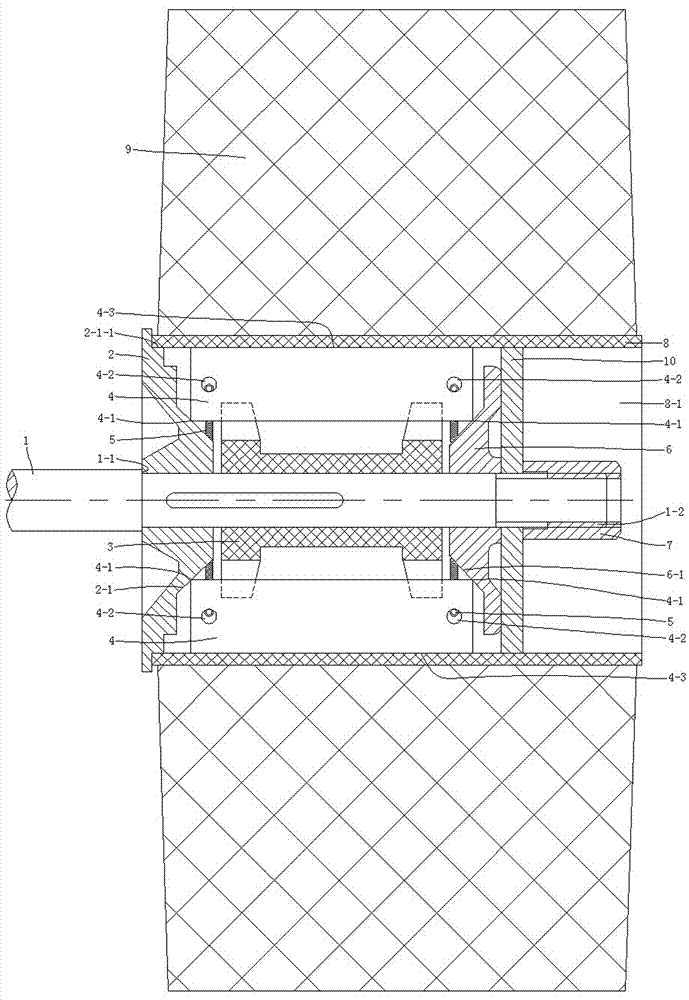

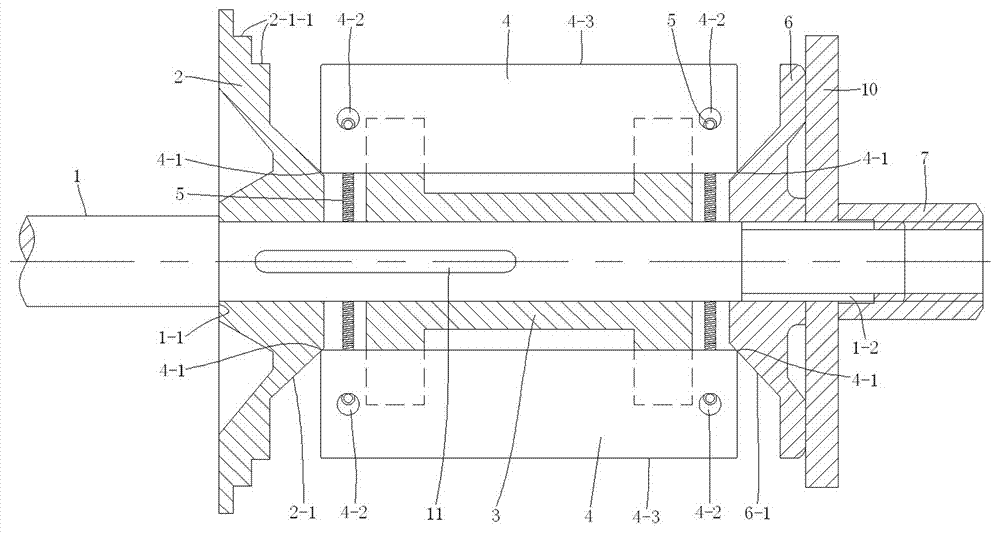

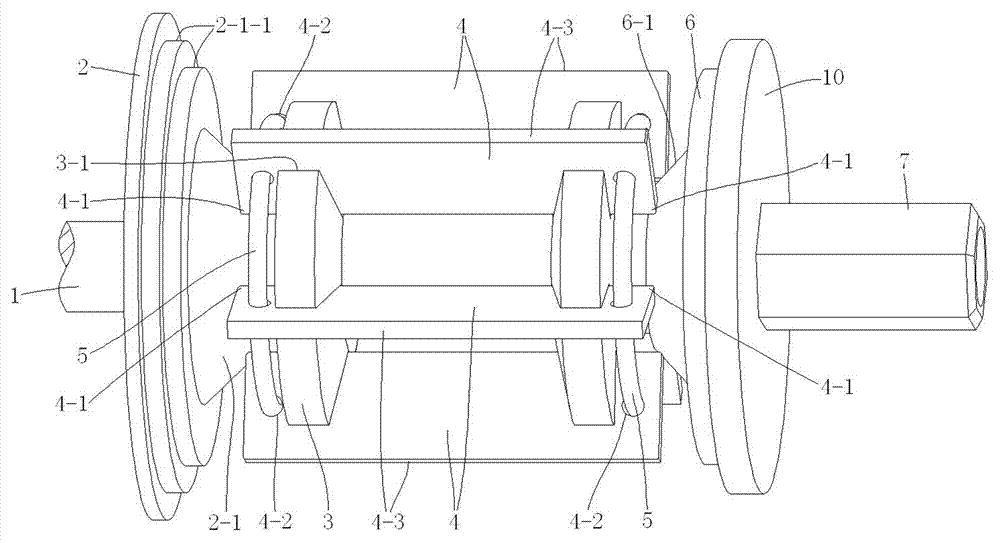

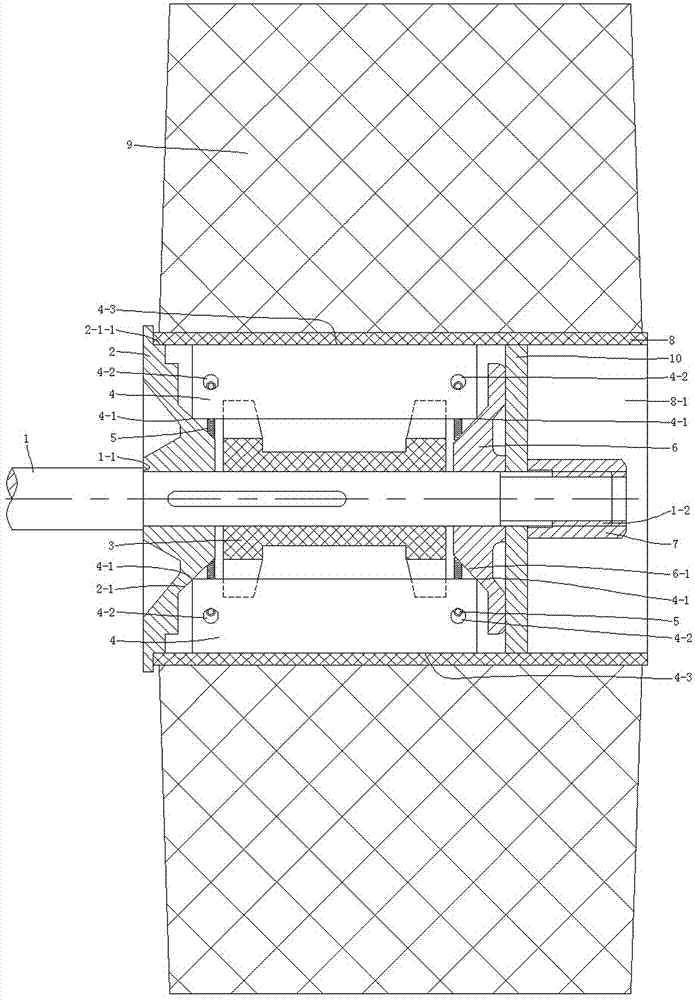

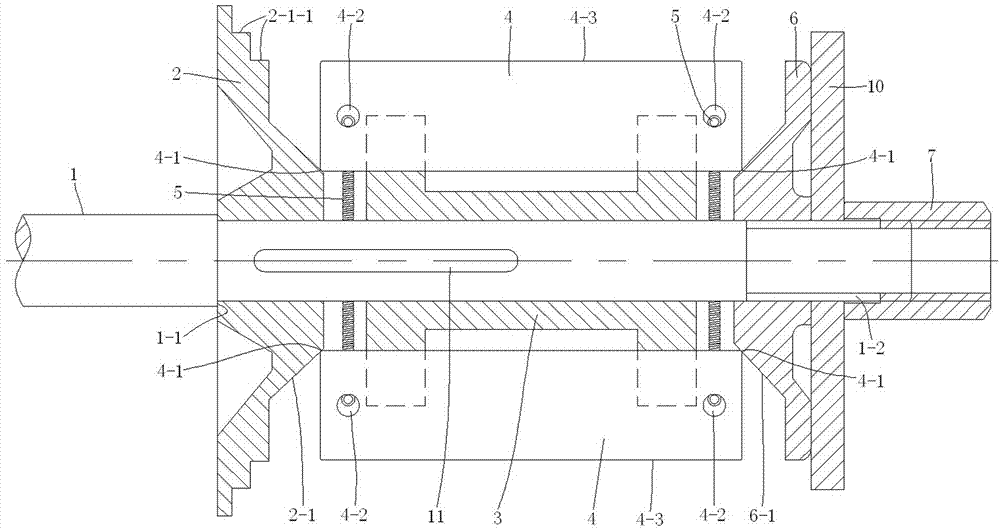

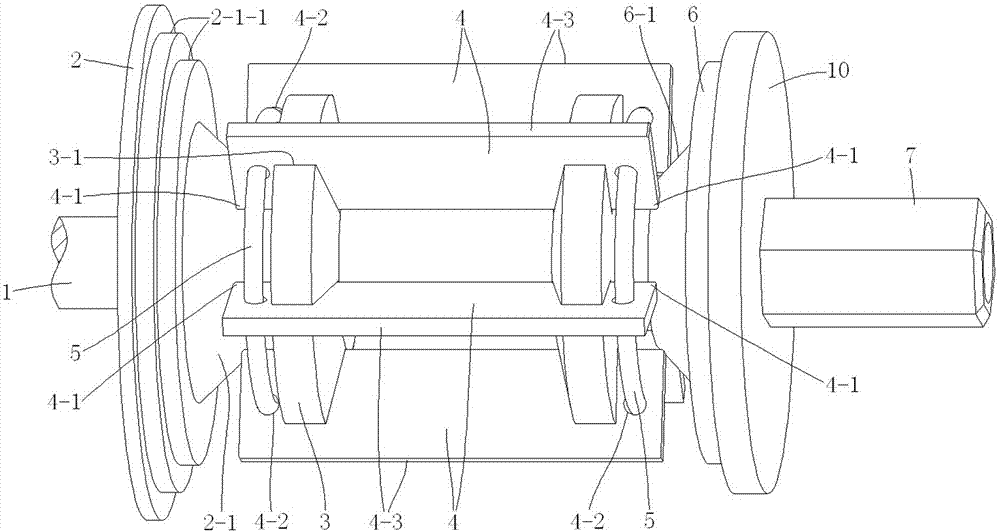

Bobbin fixing device

The invention discloses a bobbin fixing device. The bobbin fixing device comprises a rotating shaft, a first expansion block, a guide block, expansion pieces, ring springs, a second expansion block and a tightening nut. One end of the rotating shaft is provided with a step surface, and the other end of the rotating shaft is provided with a threaded section. The tightening nut is screwed on the threaded section. Both the first expansion block and the second expansion block are of a hollow cone frustum with a conical surface. The first expansion block is sleeved on the rotating shaft, and one end of the first expansion block is abutted against the step surface of the rotating shaft. The second expansion block is sleeved on the rotating shaft, and one end of the second expansion block is abutted against the tightening nut. The guide block is arranged between the first expansion block and the second expansion block, and at least three grooves are formed in the guide block, wherein the grooves extend along the rotating shaft axially and are evenly distributed along the rotating shaft circumferentially. The expansion pieces are plate-like rectangular solids, at least three in number and respectively embedded in the grooves of the guide block in a sliding and matched mode, the bottom ends of two sides of each expansion piece are respectively abutted against the conical surfaces of the first expansion block and the second expansion block, through holes are formed in the expansion pieces, and the ring springs penetrate through the through holes to connect the expansion pieces together. By means of the bobbin fixing device, a bobbin does not slip in the process of backing-off, and the bobbin fixing device can be adapted to large bobbins with high speeds and inclination angles.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

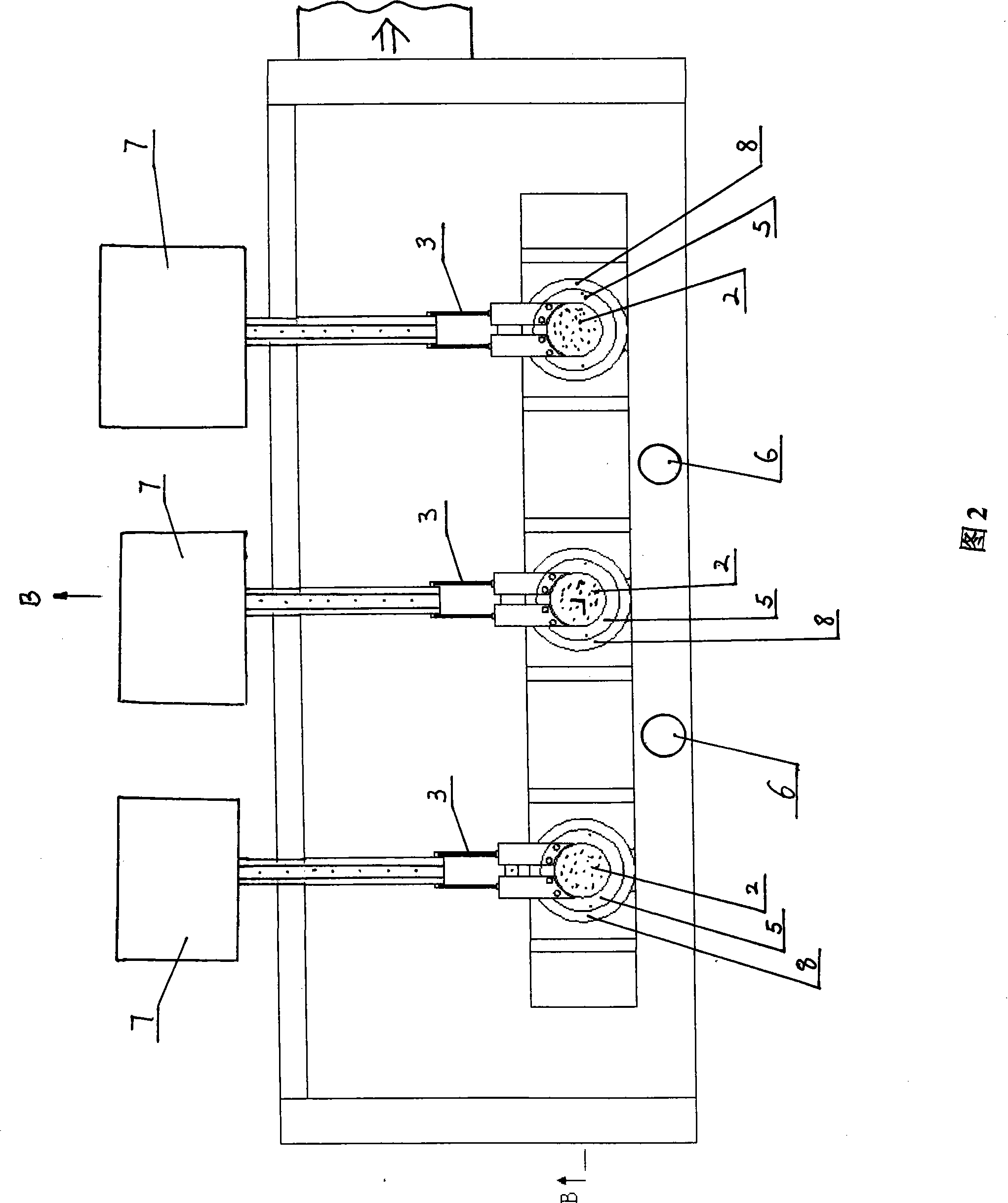

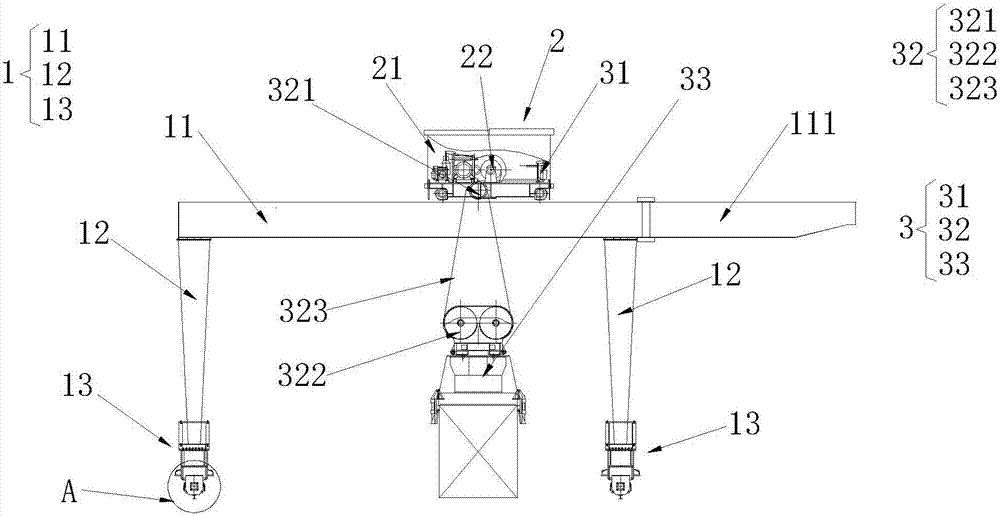

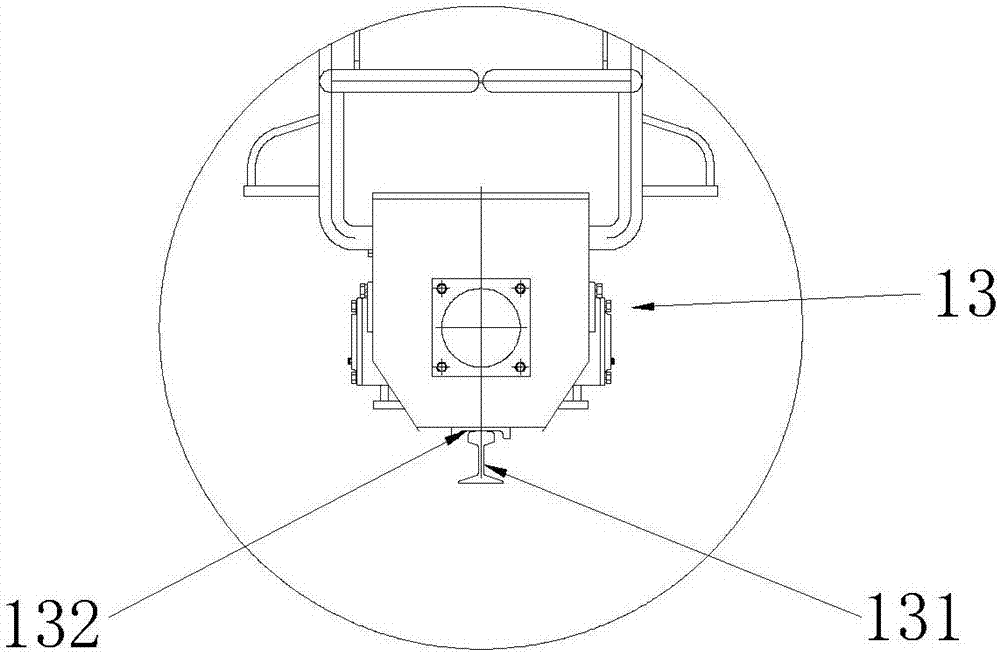

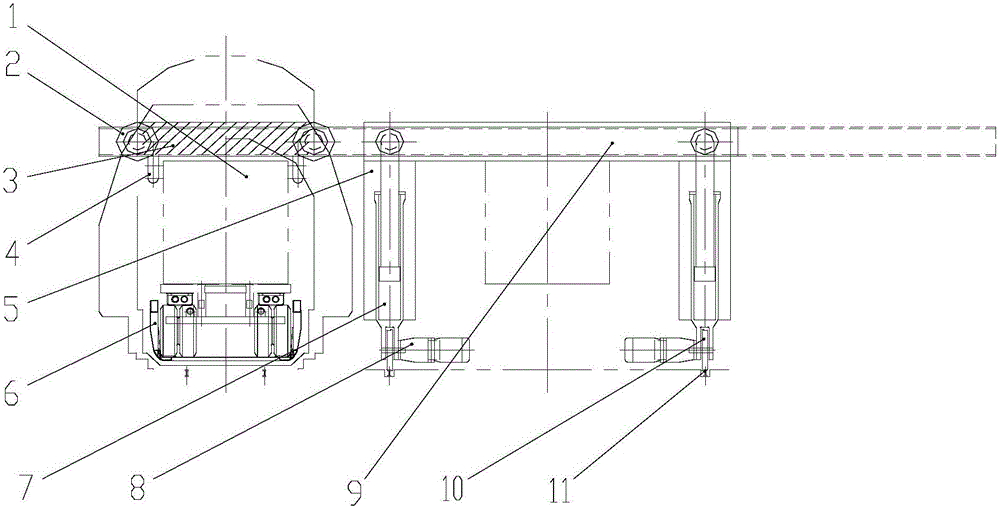

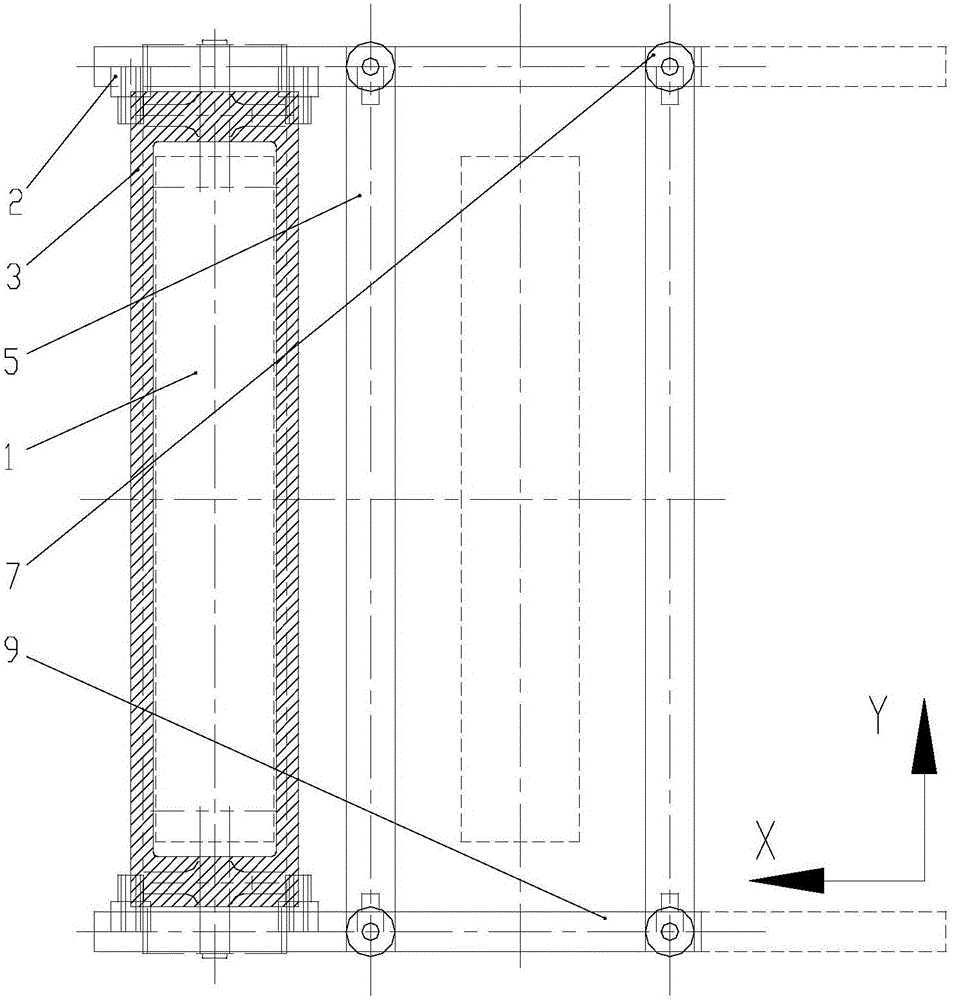

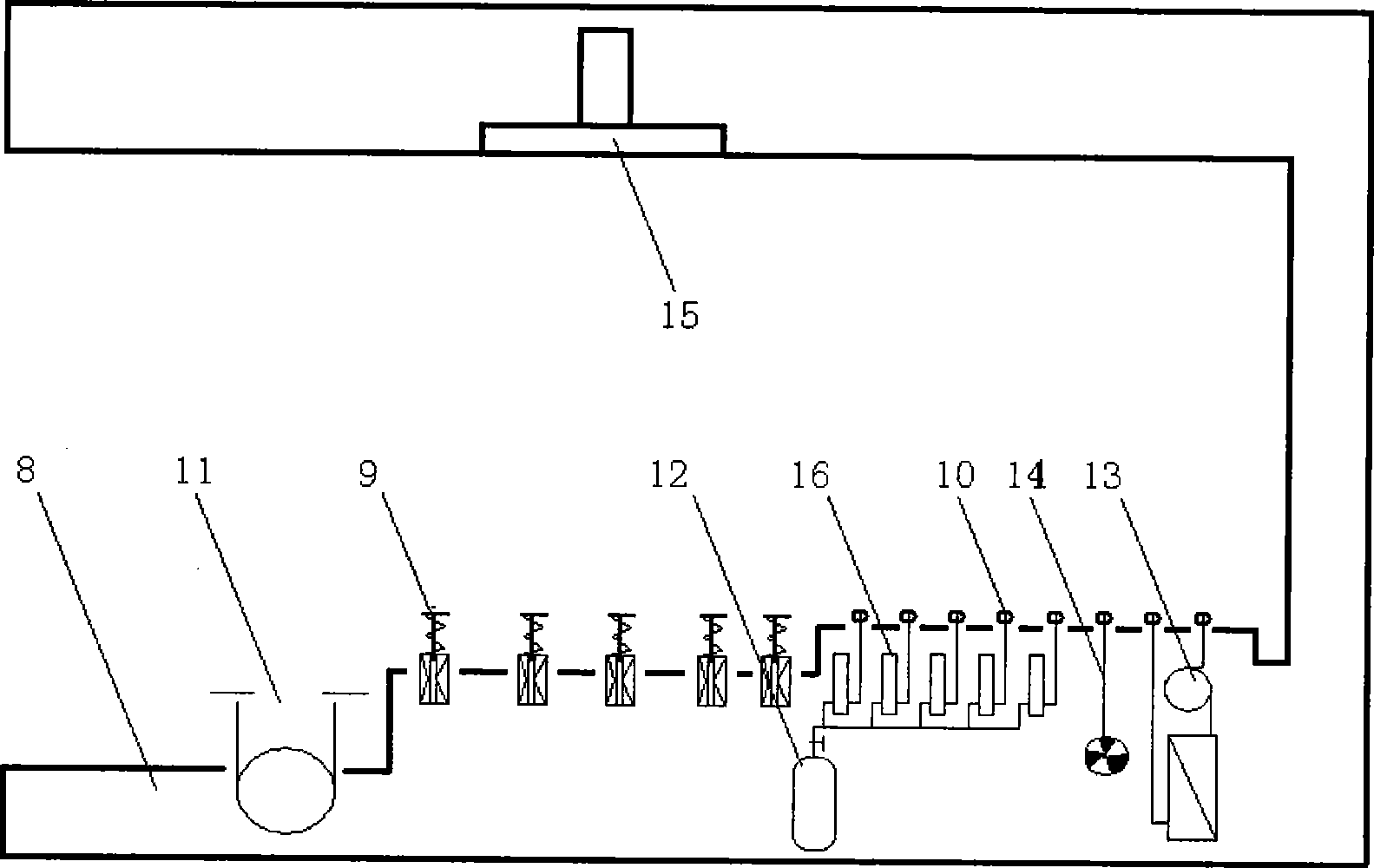

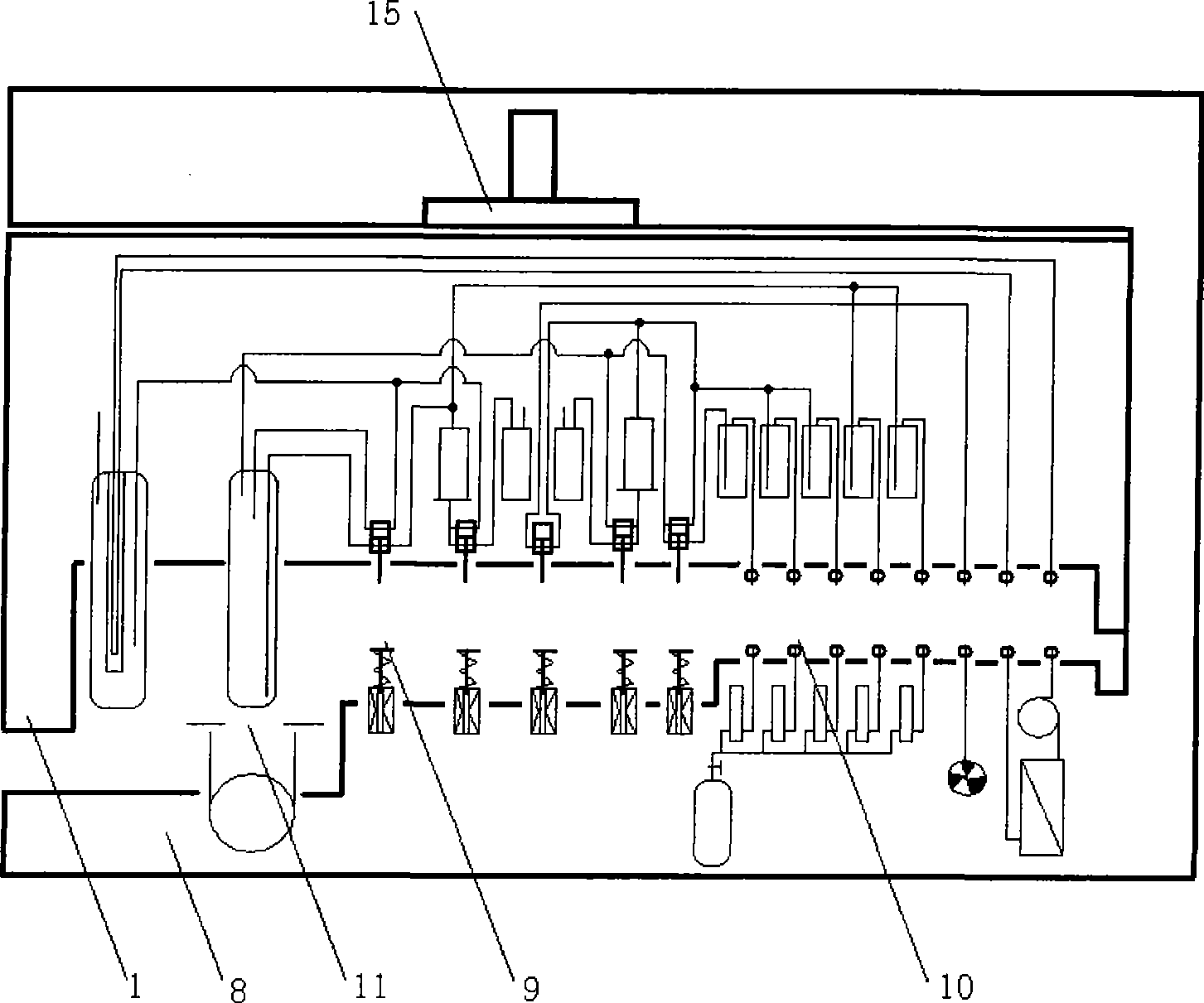

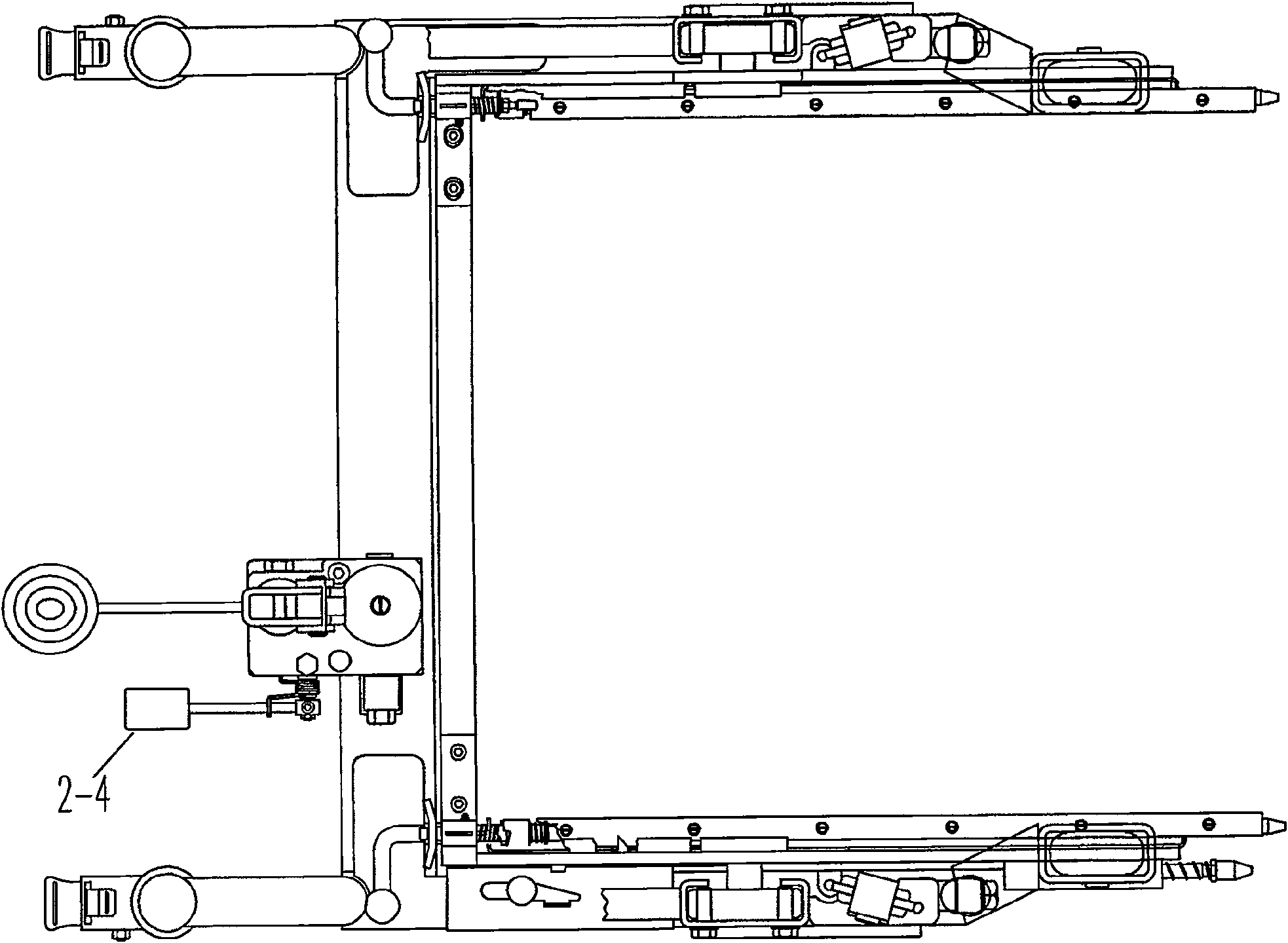

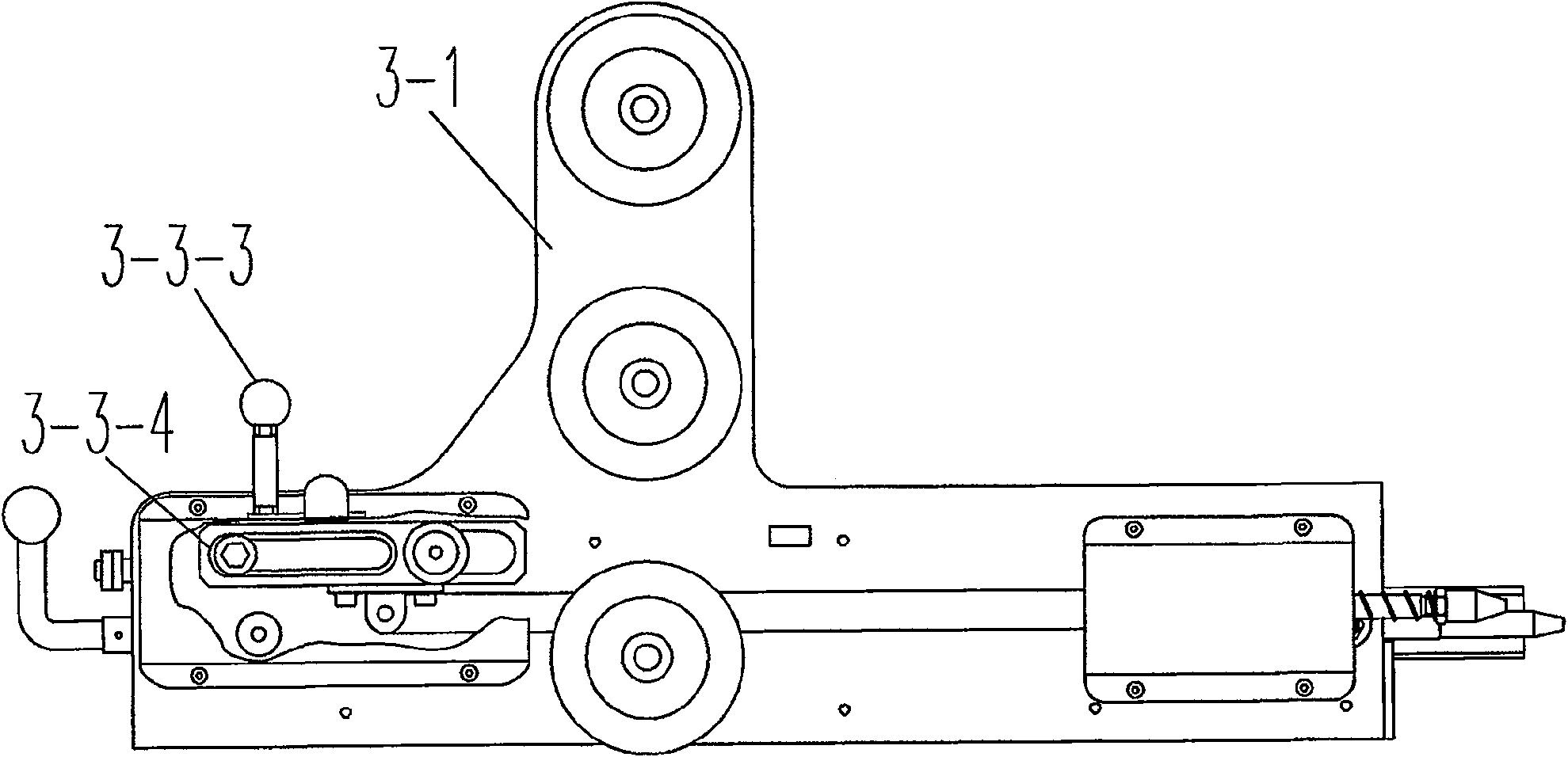

Loading and unloading gantry cantilever crane for freight train depot for united transportation of railways and highways and loading and unloading method

InactiveCN106629414AQuick loading and unloadingReliable loading and unloadingTrolley cranesTravelling gearFreight trainsEngineering

The invention relates to a loading and unloading gantry cantilever crane for a freight train depot for united transportation of railways and highways and a loading and unloading method. The gantry cantilever crane mainly comprises a gantry cart, a gantry trolley and a cart track, wherein the gantry cart at least comprises a cart cross beam, a cart lifting mechanism, a cart traveling driving mechanism and cart wheels; the gantry trolley at least comprises a trolley traveling driving mechanism, a hanger and trolley wheels; the gantry cantilever crane is positioned beyond the limit of the train depot; the cart track is parallel to the direction of rails so as to facilitate loading and loading of various train wagons; and the gantry trolley can move along the cart cross beam in the direction perpendicular to the rails so as to facilitate unloading and unloading of cargoes on X5 wagons. By the gantry cantilever crane and the loading and unloading method, loading and unloading of containers of the train wagons and semi-trailer wagons can be quick and reliable; and therefore, united transportation of railways and highways can be efficient and digitized.

Owner:山西聚鑫顺科技有限公司

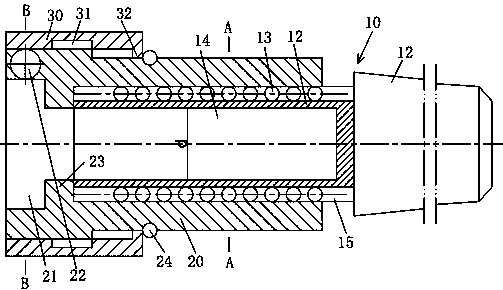

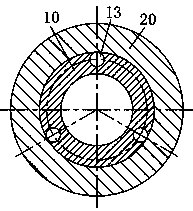

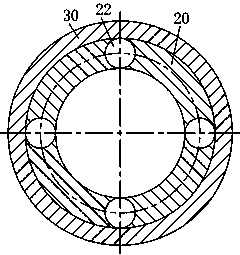

Steel ball positioning and fastening type die handle for machining internal and external threads and using method thereof

InactiveCN106735627ASimple structureEasy loading and unloadingThread cutting machinesEngineeringSteel ball

The invention relates to a steel ball positioning and fastening type die handle for machining internal and external threads and a using method thereof. The steel ball positioning and fastening type die handle for machining internal and external threads comprises a cone mandrel. A shaft lever at one end of the cone mandrel is sleeved with a rolling and sliding sleeve. A cone which is connected with a cone hole of a tail center sleeve of a lathe is arranged at the other end of the cone mandrel. A mounting hole is formed in one end face of the rolling and sliding sleeve and can be used for mounting a circular die and a screw tap fixing piece used for fixing a screw tap. A plurality of positioning steel balls which can move up and down are arranged on the side wall of the mounting hole at intervals. One end of the rolling and sliding sleeve is further sleeved with a locking sleeve, and the locking sleeve presses the positioning steel balls after sliding towards the cone, so that the circular die or the screw tap fixing piece is locked through the positioning steel balls. The steel ball positioning and fastening type die handle is simple in structure, convenient to mount and dismount, and wide in application range.

Owner:FUZHOU UNIV

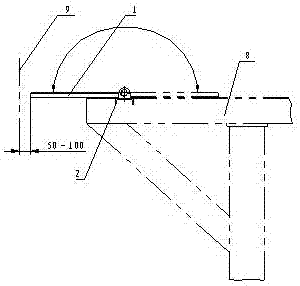

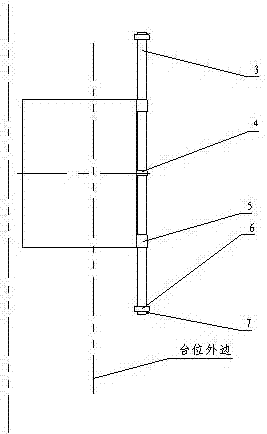

Overturn pedal for locomotive maintenance platform

InactiveCN108005427AReduce gapReliable loading and unloadingIndustrial buildingsFall riskPulp and paper industry

The invention discloses an overturn pedal for a locomotive maintenance platform, relates to the overturn pedal for the locomotive maintenance platform between a double-layer locomotive maintenance platform and a locomotive body, and mainly aims at solving the problem that a certain gap exists between the locomotive combined factory double-layer maintenance platform and the locomotive body due to hoisting, and operators tend to miss their steps through the gap and a falling risk at a high position occurs when operating in the locomotive body. One edge of a rectangular pedal is connected to a pedal shaft through sleeves at the two ends of the edge, and the pedal shaft is fixed to a panel of an assembly position through end support bases at the two ends and a middle support base of the pedalshaft. When the locomotive body is hoisted, a certain gap exists between the assembly position and the locomotive body, and hoisting appliances can be assembled and disassembled through the gap; whenthe locomotive body is overhauled, the pedal is overturned at 180 degrees to the locomotive body direction, the gap between the assembly position and the locomotive body is narrowed, thus the operators can enter the locomotive body to conduct overhaul through the pedal, and the risk that the operators miss their steps to fall at the high position is avoided.

Owner:CRRC LUOYANG CO LTD

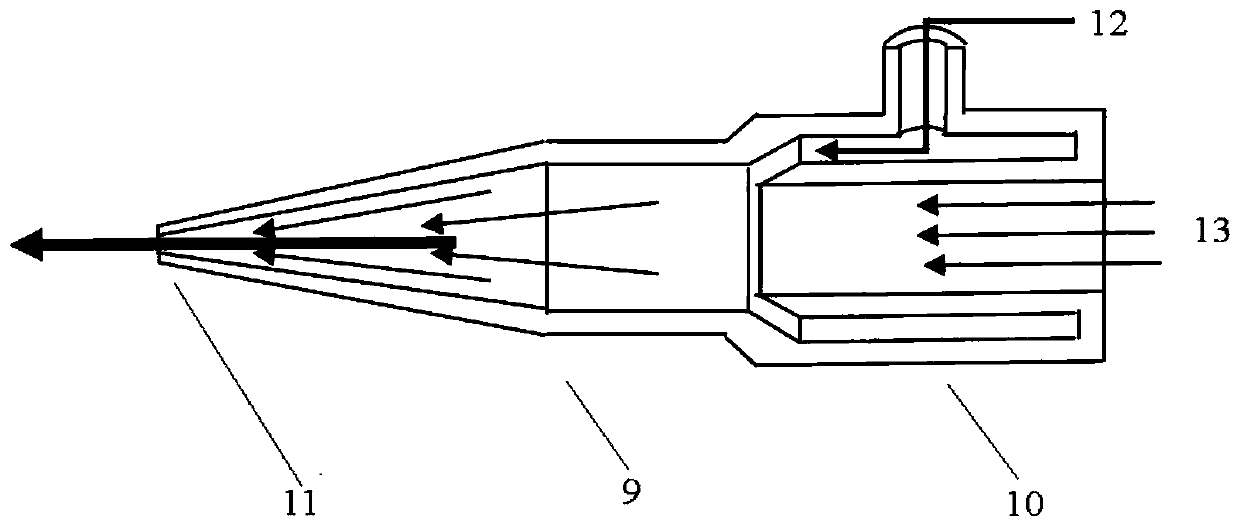

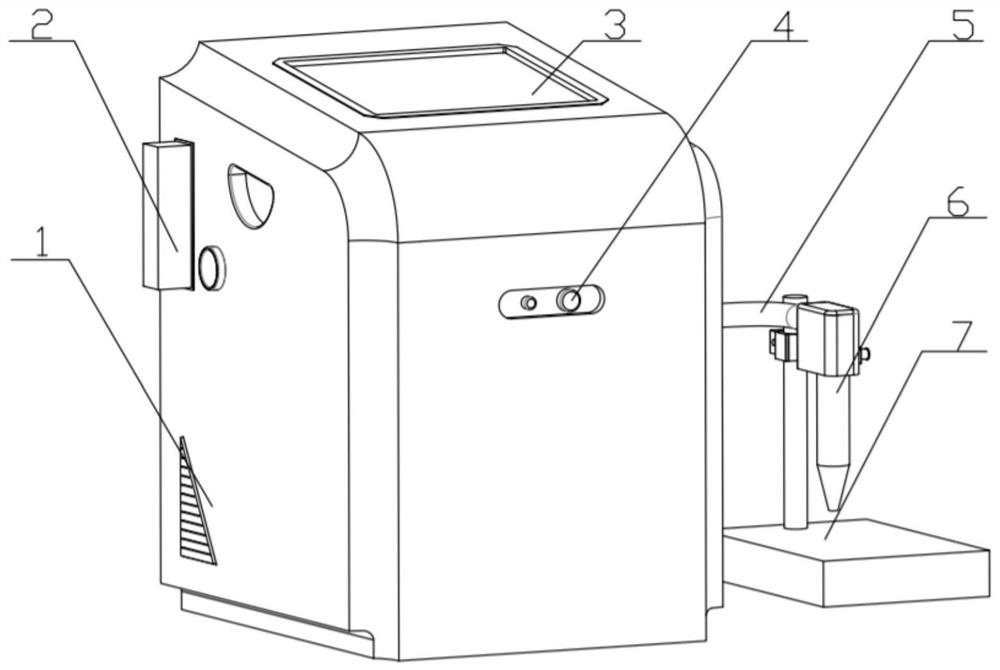

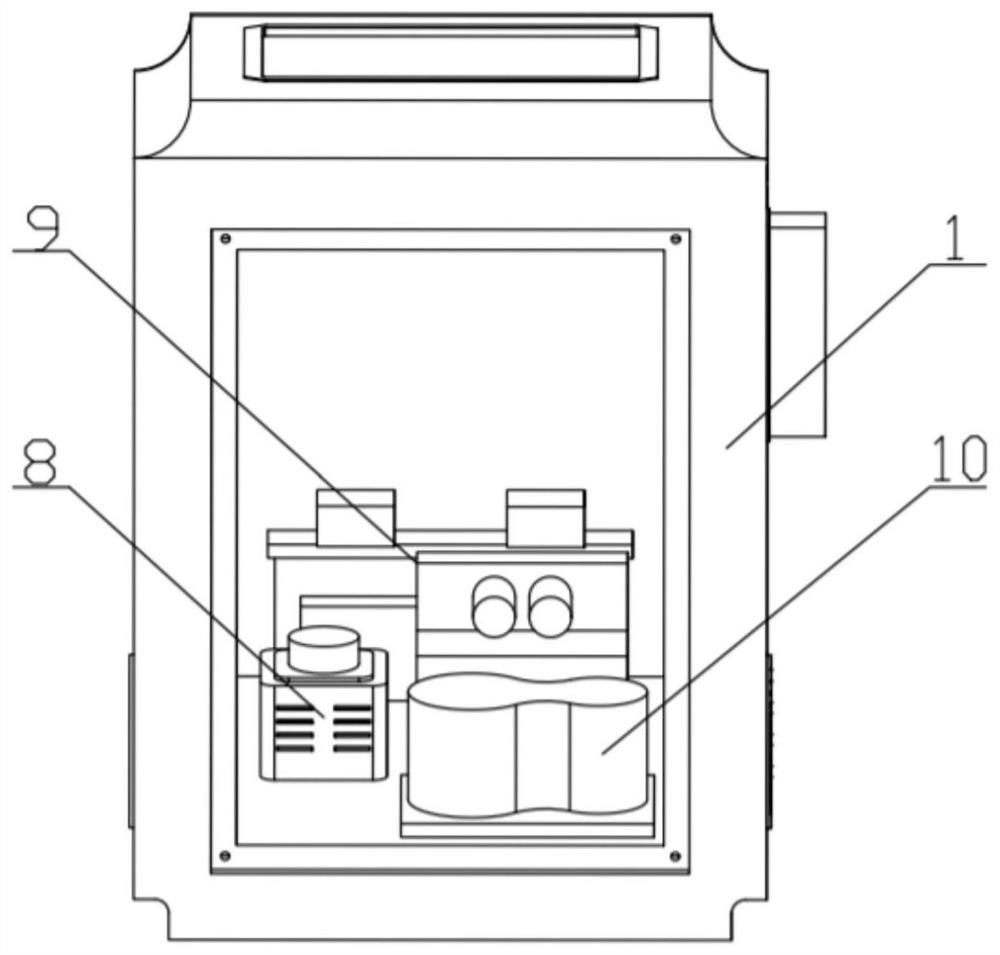

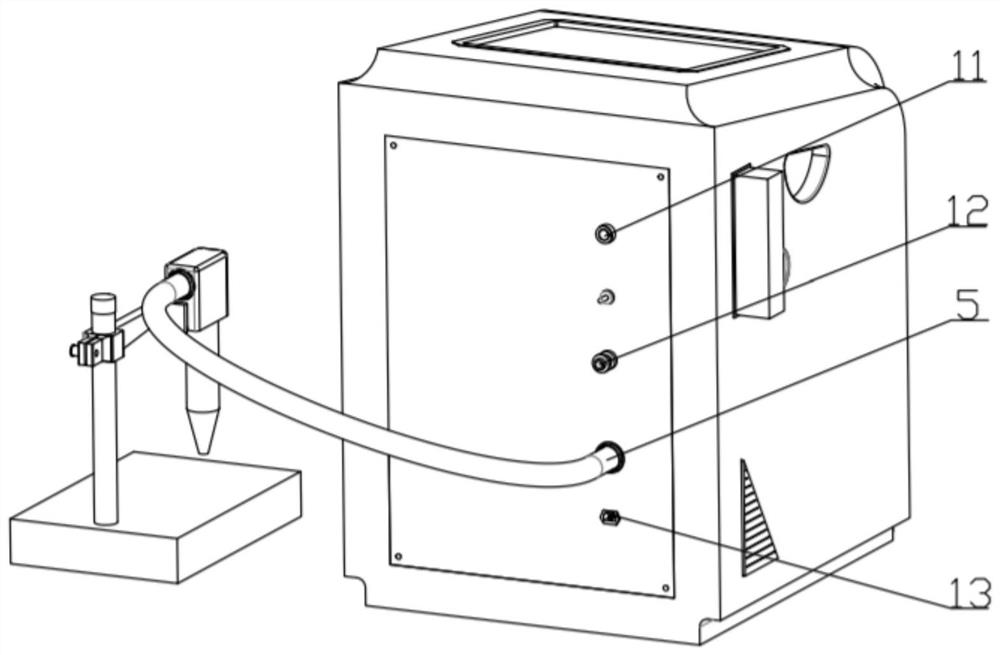

Disposal reagent kit and automatic chemosynthesis main machine

InactiveCN101461950AEasy to closeReduce Radiation HazardsRadioactive preparation carriersRadioactive preparation formsDiseaseChemical synthesis

The invention provides a disposable kit and an automatic chemical synthesis main machine. The disposable kit and the automatic chemical synthesis main machine are used for synthesizing a short-life radio-labeling medicine for disease diagnosis. The invention comprises two parts of the main machine and the kit. The kit is characterized in that a pipe communicated with a reagent or container is provided with a valve piece set which can be conveniently connected and disconnected with a valve piece of the chemical automatic synthesis main machine; the kit comprises a gas channel sealing interface which can be conveniently connected and disconnected with a gas channel sealing interface of the main machine; a container for holding the reagent and the container or pipe needing to be sealed in storage and transportation are provided with sealing devices which can be quickly opened; and the spatial position and the communication relation of the structure correspond to the particular synthetic reaction and the corresponding main machine structure. The main machine has corresponding characteristics. Under conditions of larger cost-performance ratio, the invention reduces the complex manual operation procedures before and after the synthesis and facilitates the in-site synthesis of the short-life chemicals.

Owner:王建刚

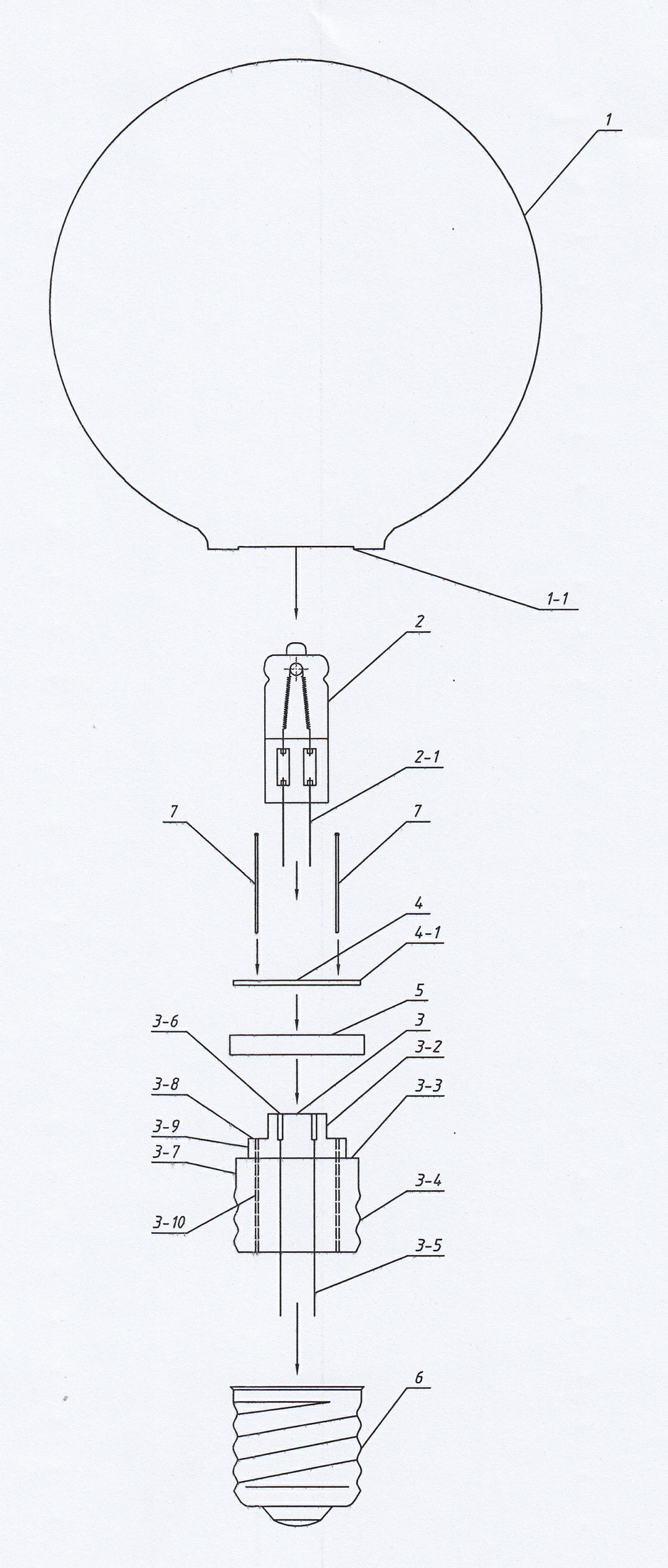

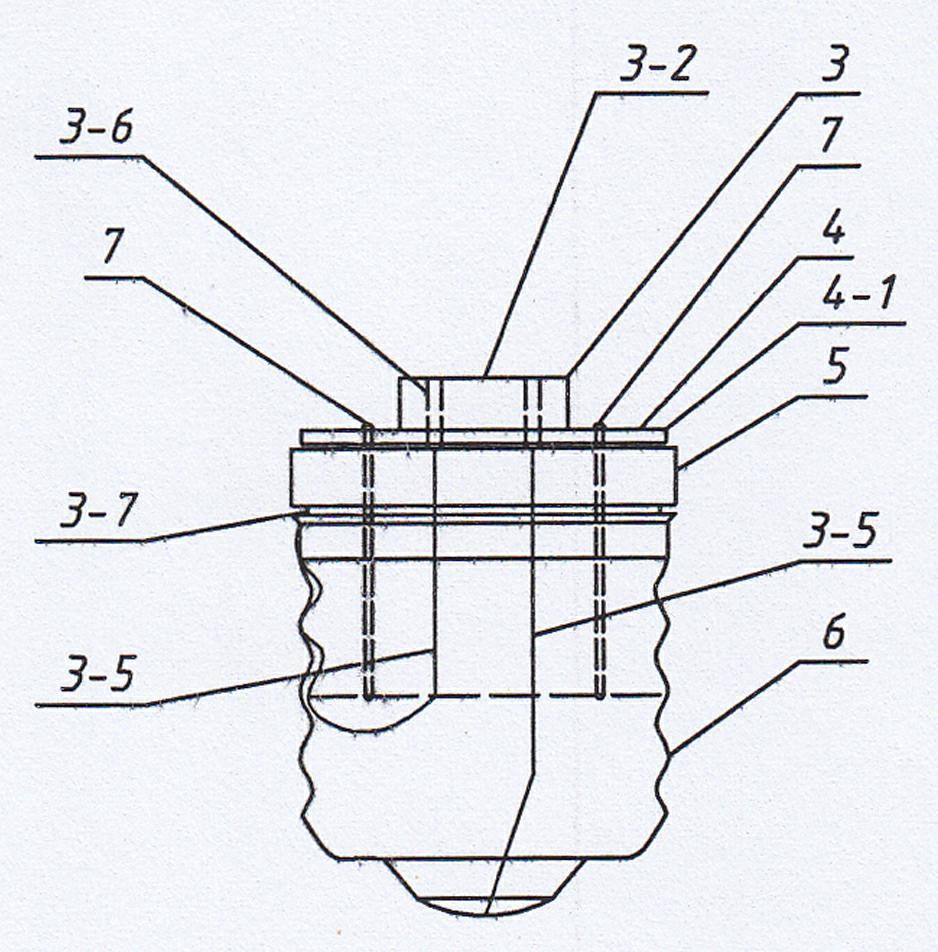

Energy-saving halogen lamp convenient to mount and dismount

InactiveCN102592959AQuick loading and unloadingLoading and unloading safetyIncandescent lamp energy savingIncadescent envelopes/vesselsThree levelEngineering

The invention discloses an energy-saving halogen lamp convenient to mount and dismount, wherein an insulating lamp holder is a three-level column body with a small upper part and a large lower part; the intersection part of a small column body and a middle cylindrical body is provided with a first spacing platform; the intersection part of the middle cylindrical body and the large column body is provided with a second spacing platform; a connecting clamping ring and an elastic flexible gasket are also arranged; the outer side of the connecting clamping ring is provided with at least two outer protruding edges which are distributed symmetrically; the elastic flexible gasket is sleeved on the middle cylindrical body and is placed on the second spacing platform; the connecting clamping ring is sleeved on the small column body and is fixedly connected to the first spacing platform through a rivet; the bottom of an outer lamp shell is provided with at least two openings which are matched with the outer protruding edges of the connecting clamping ring; and the openings of the lamp shell are clamped and fixed on the connecting clamping ring. The halogen lamp has the advantages that the invalid halogen lamp can be dismounted rapidly and is replaced with a new halogen lamp, and other components of the lamp are used continuously, thus not only is the environment protected, but also the resource waste is reduced, and the using cost is lowered greatly.

Owner:文德彪

Preparation method of fretting wear resistant alloy coating

The invention relates to the technical field of thermal spraying materials and coatings, in particular to a preparation method of a fretting wear resistant alloy coating. The preparation method comprises the following steps of: (1) pretreating a workpiece to be sprayed; and (2) spraying the fretting wear resistant alloy coating on the pretreated workpiece by adopting a plasma arc powder spraying process. The spraying angle is 90 degrees, the arc voltage is 60-62V, the power is 30-31 kW, the spraying distance is 62-64 mm, the powder feeding amount is controlled to be 35-45 g / min, and the spraying moving speed of a spray gun is controlled to be 600mm / s. According to the process method and parameters, the anti-oxidation and cooling fog discharging method, the rapid and reliable protective shielding tool and the accurate spray gun motion control of the robot, the obtained coating has an ideal coating structure, extremely low oxide inclusion, coating bonding strength greatly higher than theindex requirement, porosity and coating hardness meeting the requirements, and coating thickness and precision meeting the requirements and controllable.

Owner:机械科学研究院浙江分院有限公司

Movable shears-fork type lift

InactiveCN105060191AReduce wearSafe and efficient loading and unloadingLifting devicesUniversal jointEngineering

The invention discloses a movable shears-fork type lift which comprises a chassis, front wheels and rear wheels. The upper portion of the chassis is provided with two shears-fork arms. A support is arranged between the two shears-fork arms. The bottom of the chassis is connected with a front shaft through vertical supporting rods. The movable shears-fork type lift is characterized in that the number of the supporting rods is two, the portions, on the outer sides of the supporting rods, of the front shaft are provided with rotating shafts, the front shaft is connected with the rotating shafts through universal joints, the outer ends of the rotating shafts are connected with the front wheels, the front wheels are connected with a front wheel steering mechanism which comprises a trapezoid arm, a transverse pull rod and a shifting fork, the front end of the shifting fork is connected with the inner end of the transverse pull rod, the outer end of the transverse pull rod is hinged to the front end of the trapezoid arm, the rear end of the trapezoid arm is connected with the front wheels, the rear end of the shifting fork is connected with the steering transverse pull rod through a pin shaft, the middle of the shifting fork is in bearing connection with the front shaft, the shifting fork is shifted to rotate so as to drive the steering transverse pull rod to rotate, and the transverse pull rod drives the wheels to rotate. According to the movable shears-fork type lift, the rotating angles of the left front wheel and the right front wheel meet the Ackman theorem, tire abrasion is small, the assembling and disassembling efficiency is high, and safety and reliability are high.

Owner:SHANDONG KINGELEVATOR GRP CO LTD

Automatic detection device for mass elastic elements

PendingCN114413760AEnsure consistencyGuaranteed accuracyUsing optical meansElectric machineryStructural engineering

The invention provides a large-batch elastic element automatic detection device which comprises a lead screw, the upper portion of the lead screw is fixedly connected to a motor, the bottom of the lead screw is movably connected to a bottom plate of a base, the middle of the lead screw is sleeved with a lead screw nut, the lead screw nut is fixedly connected to an insulating plate, and a circuit board and a plurality of elastic piece contacts are fixedly installed above the insulating plate. The lead screw rotates to drive the circuit board, the insulating plate and the elastic piece contacts to move up and down, the end of each elastic piece contact is electrically communicated with the circuit board, a grating ruler assembly is installed on one side of the insulating plate and used for collecting displacement data of the insulating plate, and an elastic piece installation plate is arranged above the bottom plate and used for fixing elastic pieces. And the motor and the circuit board are connected to an external computer through lines. According to the automatic detection device for the large-batch elastic elements, the consistency and the accuracy of detection references before and after 72-hour pressing are ensured, the detection cost is saved, and the detection efficiency is greatly improved.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

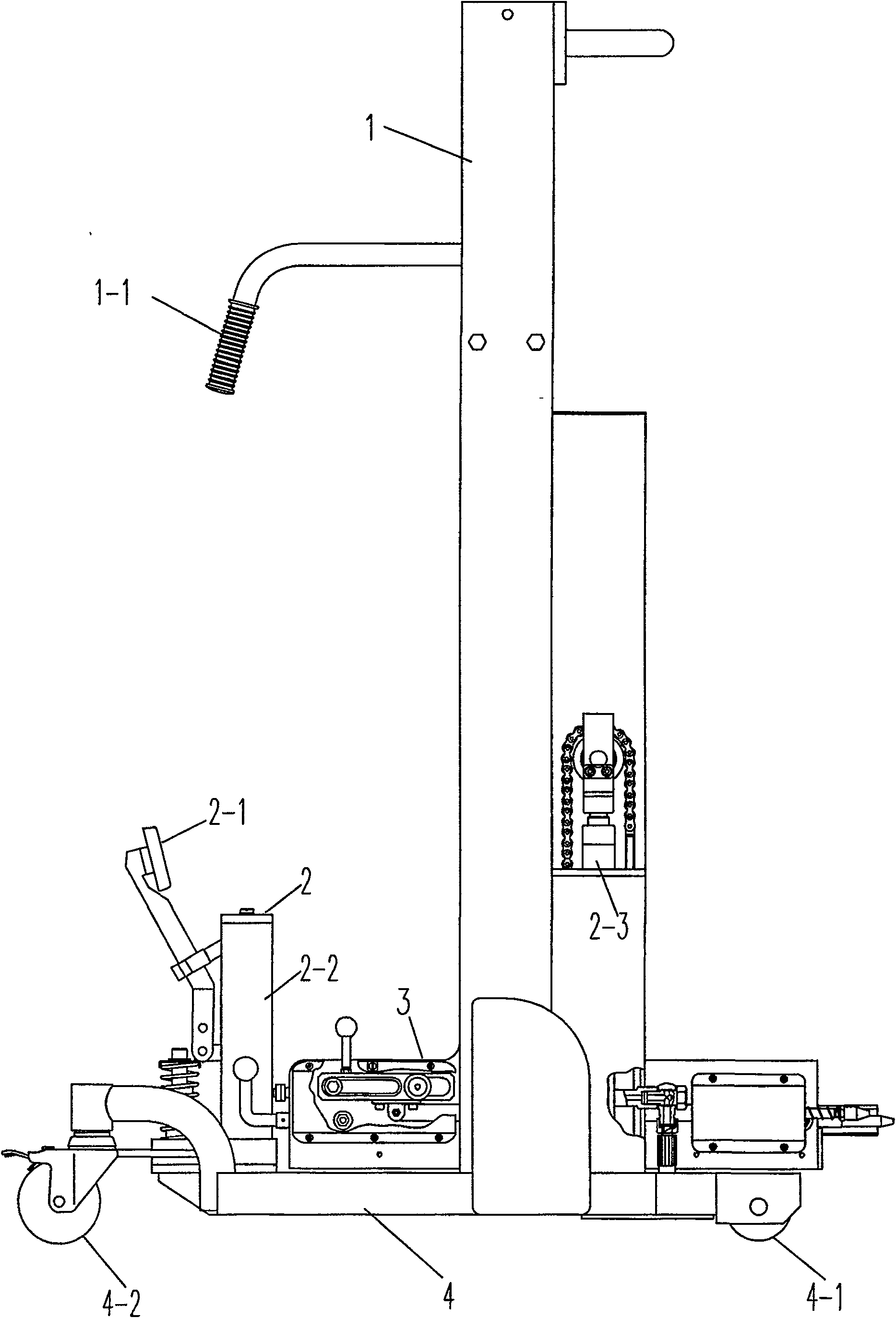

Hydraulic service vehicle

InactiveCN100554133CGuaranteed to move normallyGuaranteed connection lockLifting devicesVehicle frameFuel tank

The invention relates to a small transport vehicle, especially a hydraulic service vehicle specially used for loading, unloading and transporting power distribution circuit breakers, including a door frame, a hydraulic system, a boom, and a vehicle frame, and the door frame matches and moves with the boom Connection, the door frame is fixedly connected with the frame, the frame is equipped with two directional wheels and two universal wheels, the hydraulic system is equipped with a rising pedal, a fuel tank, a lifting cylinder, a descending pedal, the fuel tank is connected with the frame, and the lifting cylinder It is connected with the boom, and the boom is provided with a boom frame, a connecting unlocking device and a positioning locking device. The connecting unlocking device is installed on the two inner sides of the boom frame, and the positioning locking device is installed on the outside of the boom frame. The present invention has a reasonable structural design, and has the characteristics of being movable and lifting. The connection unlocking device ensures the connection locking between the present invention and the switch cabinet, and the positioning locking device ensures the locking between the present invention and the short circuit, and the connection unlocking device and the positioning locking device exist The interlocking relationship makes the short circuit breaker safe and reliable during loading and unloading and transportation, and the lifting is stable, the rotation is flexible, and the operation is convenient, which is conducive to reducing labor intensity, improving production efficiency, and realizing safe loading and unloading.

Owner:梁木荣

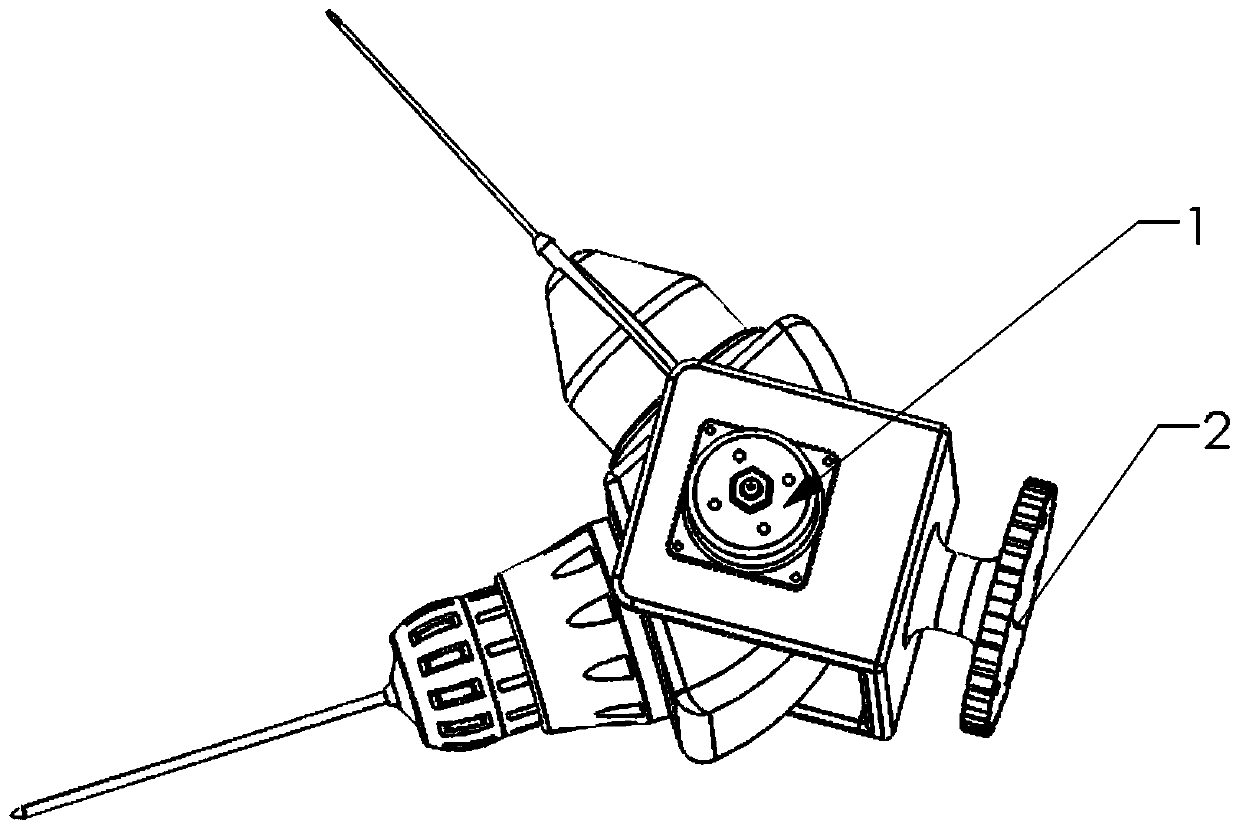

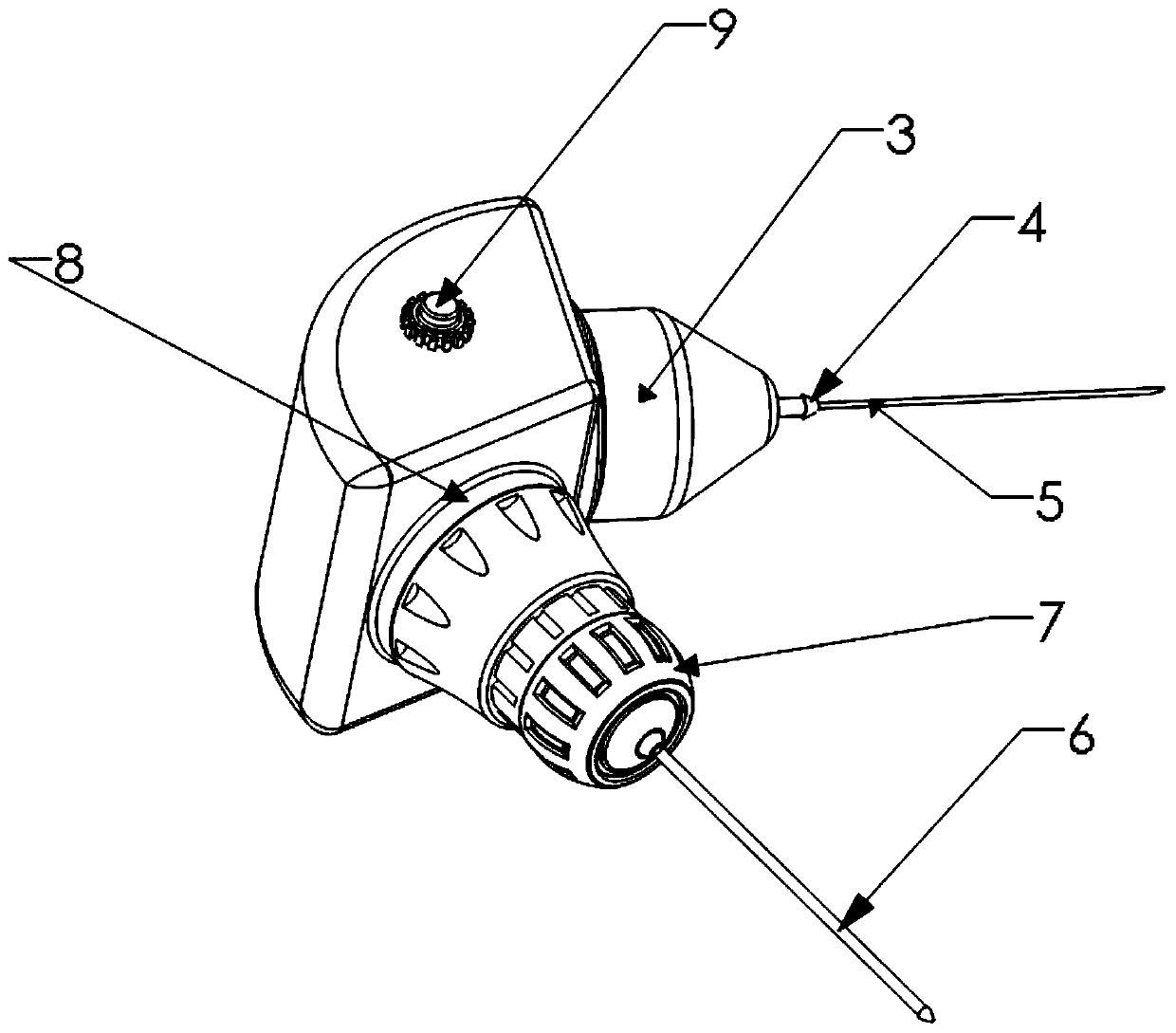

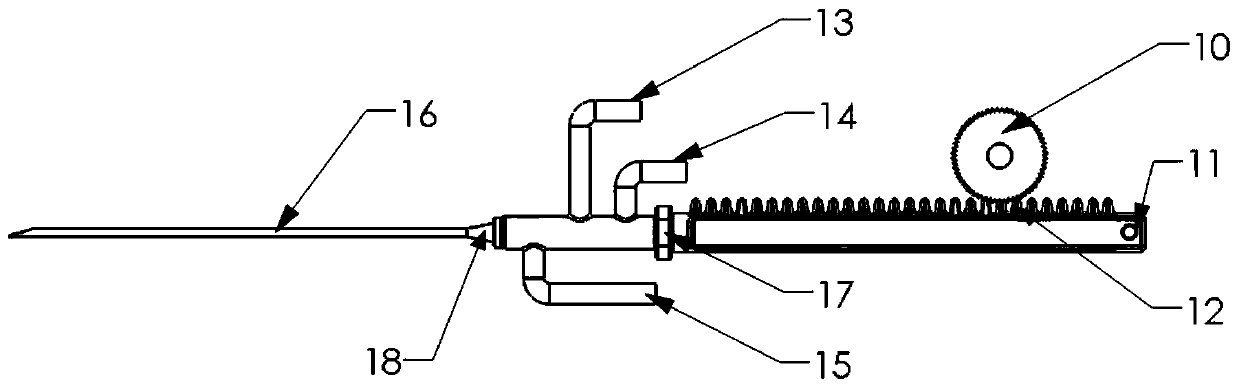

Novel medical plasma end effector mechanism

InactiveCN110507383AImplement auto-scalingSmooth motionSurgeryMedical devicesNovel treatment methodActuator

The invention relates to the field of medical rehabilitation equipment, in particular to a novel medical plasma end effector mechanism, which mainly comprises a loading end, a rotating motor, a needletube base, a needle tube loading and unloading position, a drill bit base, a tightening and clamping mechanism, a CAP (plasma) needle tube and a drill bit. CAP is a low-temperature normal-pressure plasma, and is a novel treatment method for treating certain cancers. The CAP needle tube connecting the base serves as a supporting structure, the supporting structure is hollow inside and comprises parts used for injection and needle tube stretching and retracting. The needle tube loading and unloading position is connected with the needle tube base and is mainly used for reliably clamping, assembling and disassembling the CAP needle tube; the drill bit base serves as a base support of the drill bit part and internally comprises drill bit transmission parts. The tightening and clamping mechanism serves as a mechanism for clamping the drill bit, the effect of opening and closing the connector can be achieved through rotation, and the drill bit is clamped, assembled and disassembled. A wholeend effector is connected with a mechanical arm and other devices through a loading end. According to the invention, the selection specificity advantage of a CAP technology in the aspect of cancer treatment is utilized, the CAP needle tube and the drill bit are clamped to realize cancer treatment of hard tissue parts such as brain and skull of a human body, the structure is reasonable, the operation is simple, and safety and effectiveness are realized.

Owner:江苏黛希芬生物科技有限公司

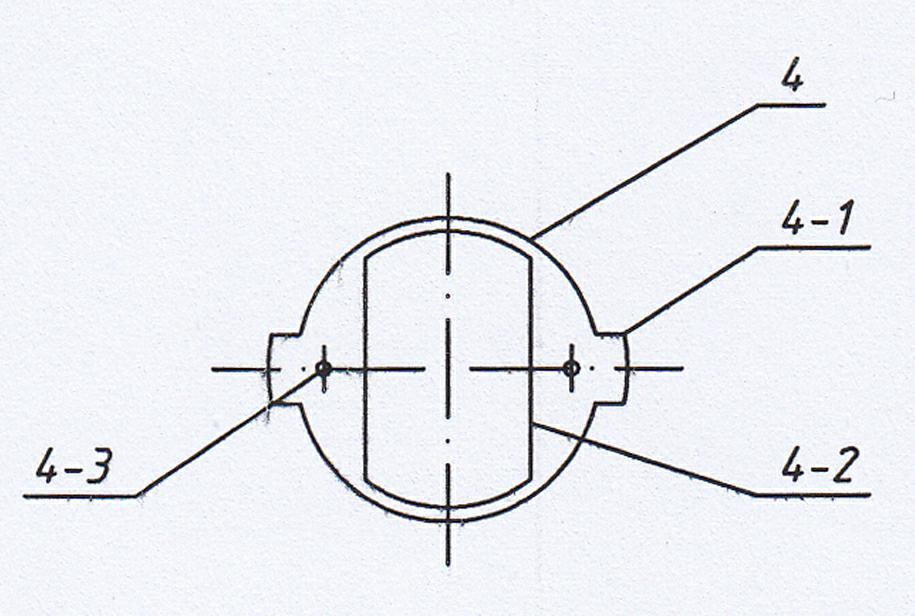

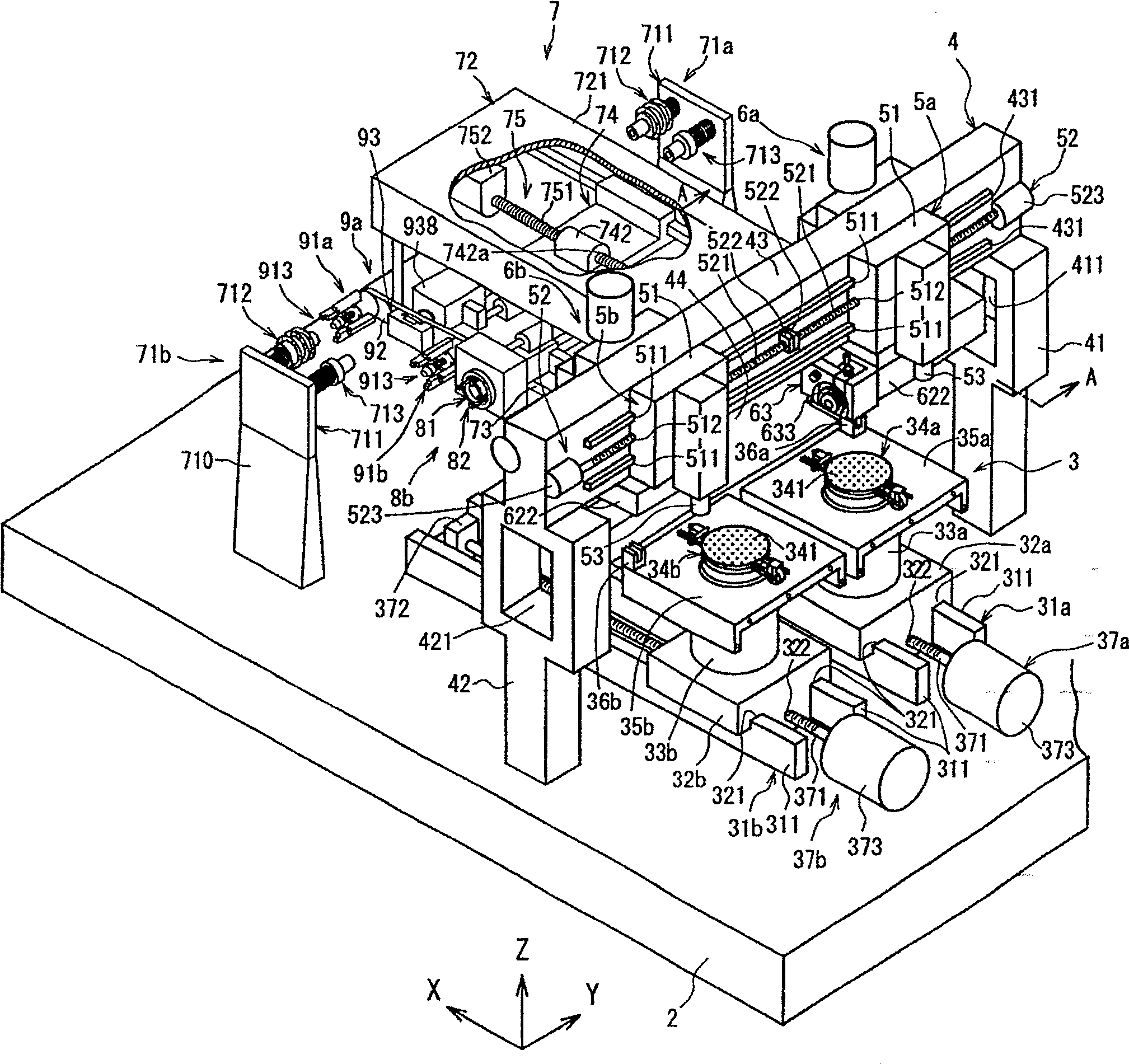

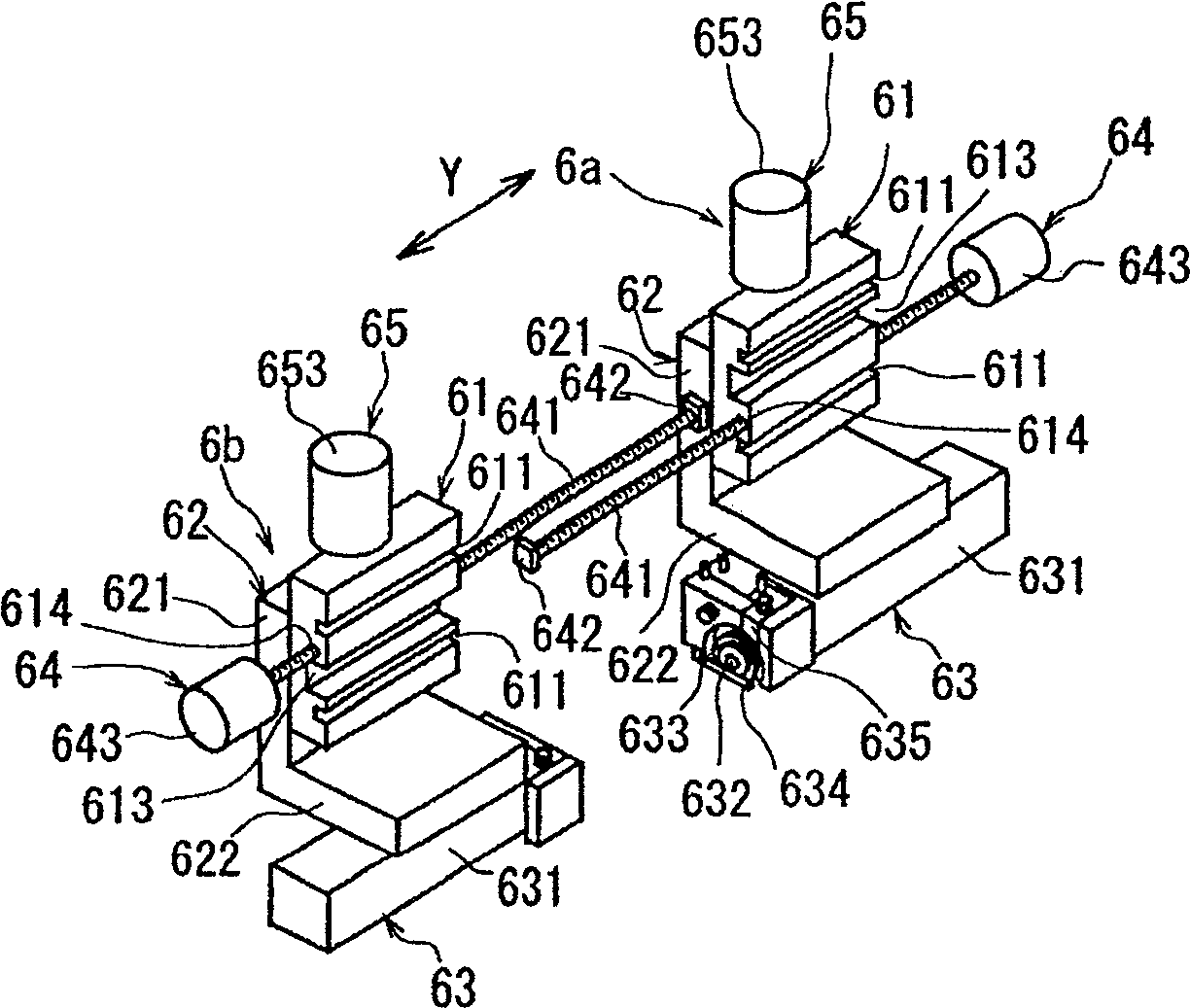

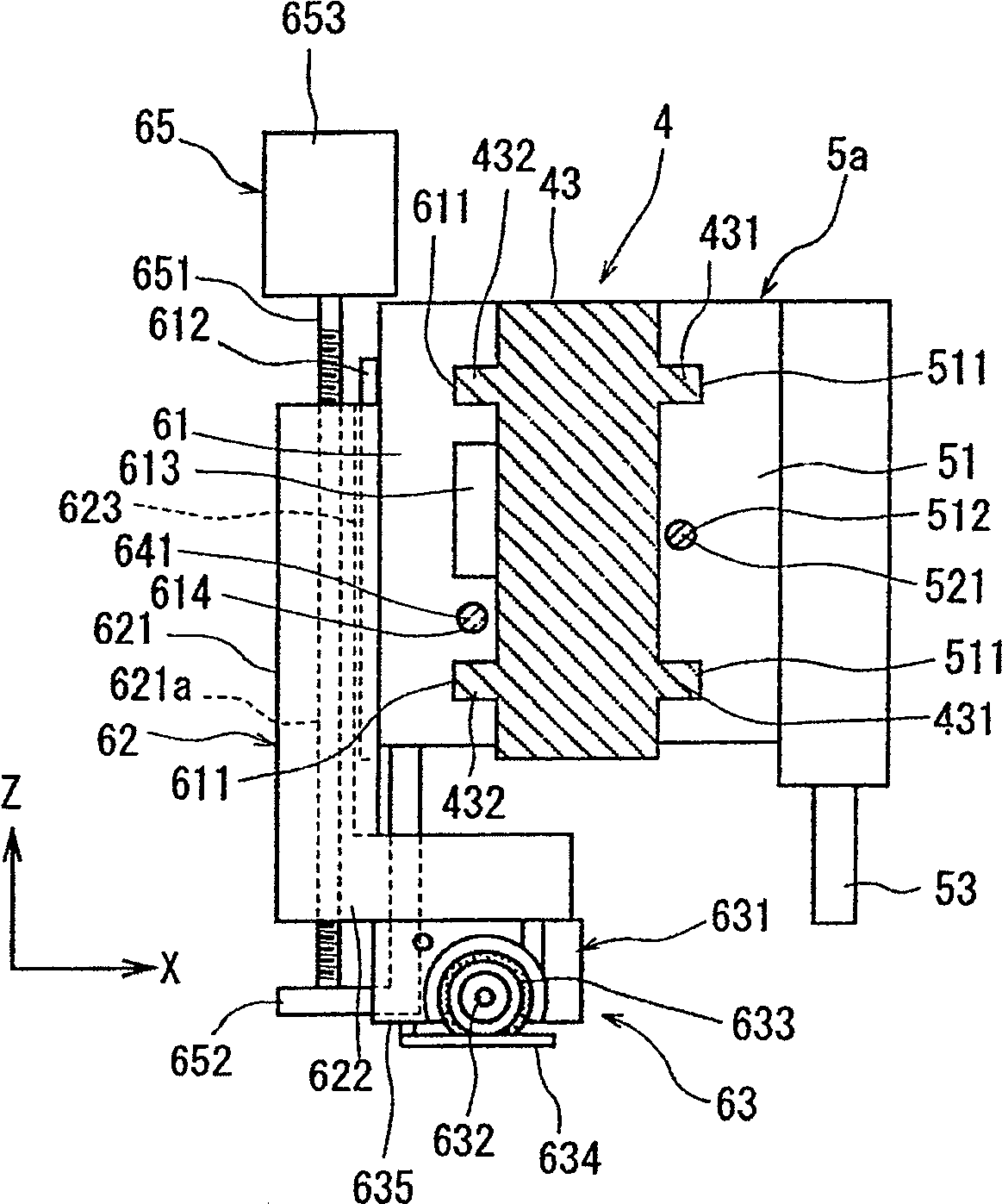

Apparatus for exchanging a cutting blade

ActiveCN100537129CReliable loading and unloadingSemiconductor/solid-state device manufacturingFine working devicesEngineeringMechanical engineering

PROBLEM TO BE SOLVED: To provide a cutting blade exchanging device which can positively align the axis of a cutting blade gripped by a blade gripping means of a blade attachment / detachment means with an axis of a rotating spindle. SOLUTION: The cutting blade exchanging device functions to exchange cutting blades. Each of the cutting blade attachment / detachment mechanisms 9a, 9b is formed of: the cutting blade gripping means 91a, 91b for gripping the periphery of a hub 636 of the cutting blade 635; a support plate 92 on which the cutting blade gripping means is mounted; a support means 93 supporting the support plate 92; and a moving means 83 for reciprocatively moving the support means. Each cutting blade gripping means is formed of: a plurality of gripping members 911 arranged at circumferential intervals, for gripping the periphery of the hub 636 of the cutting blade 635; a gripping member moving means for operating the plurality of gripping members in a radial direction; and a positioning means arranged at the center of the plurality of gripping members, for engaging with an engaging recess 632a formed at the axial center in a front end surface of the rotary spindle 632.

Owner:DISCO CORP

A device and method for filling and unloading liquid ammonia

ActiveCN104197187BVersatileDiversified operating modesContainer discharging methodsContainer filling under pressureFlame arresterGas phase

Owner:WENGFU (GRP) CO LTD

Installing and welding tool for cab

ActiveCN102152050BGuaranteed dimensional accuracy requirementsNo lateral bendingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to an installing and welding tool for a cab, which comprises a baseplate, a three-direction pressing and positioning device arranged on the baseplate, a large-floor middle pressing device, a crash barrier positioning and pressing device, a left pressing device, a right pressing device, a camber beam positioning and pressing device, a doorframe pressing device, a cross beam positioning and pressing device and an end chuck positioning block, wherein the large-floor middle pressing device, the crash barrier positioning and pressing device, the left pressing device and the right pressing device are arranged on one side of the three-direction pressing and positioning device, the camber beam positioning and pressing device, the doorframe pressing device, the cross beam positioning and pressing device and the end chuck positioning block are arranged on the other side of the three-direction pressing and positioning device, the left pressing device and the right pressing device are respectively arranged on two ends of the three-direction pressing and positioning device, the large-floor middle pressing device is arranged between the left pressing device and the right pressing device, one end of the large-floor middle pressing device is further provided with a large-floor rear positioning device, and the two ends of the three-direction pressing and positioning device are provided with pressing and positioning mechanisms. By means of the invention, the vertical dimensions of end parts of a cross beam and a camber beam are ensured, the cross beam is prevented fromlateral bending, and the installing and welding tool has the advantages of convenience for operation and bodilessness, good generality and capability of clamping manually and is convenient, flexible and reliable to mount and dismount.

Owner:南京雷尔伟新技术股份有限公司

Thread wrench with smooth disassembling and assembling effect

The invention relates to a thread wrench with a smooth disassembling and assembling effect, and belongs to the field of thread assembly. The thread wrench comprises a central column, a hexagonal nut and wrench sockets, thread sections with opposite thread directions are machined on the side walls of the upper end and the lower end of the central column correspondingly, the lower-end thread of thecentral column is screwed into a thread hole of an upper assembly part, the lower wrench socket sleeving the central column and the upper end surface of the upper assembly part are tightly pressed through the hexagonal nut connected with the upper end of the central column, the threads on the two assembly parts are tightened through the lower wrench socket under the action of the friction force between the lower end surface of the lower wrench socket and the upper end surface of the upper assembly part, after the assembly is completed, the hexagonal nut is loosened, the pressing force betweenthe lower wrench socket and the upper end surface of the upper assembly part is removed so that the central column can be easily disassembled. The thread wrench has the advantages that the structure is simple, the assembly is convenient, reliable assembly and disassembly of the two thread butt joint parts are realized, and the wrench tool can be smoothly disassembled.

Owner:山东乐乐机械有限公司

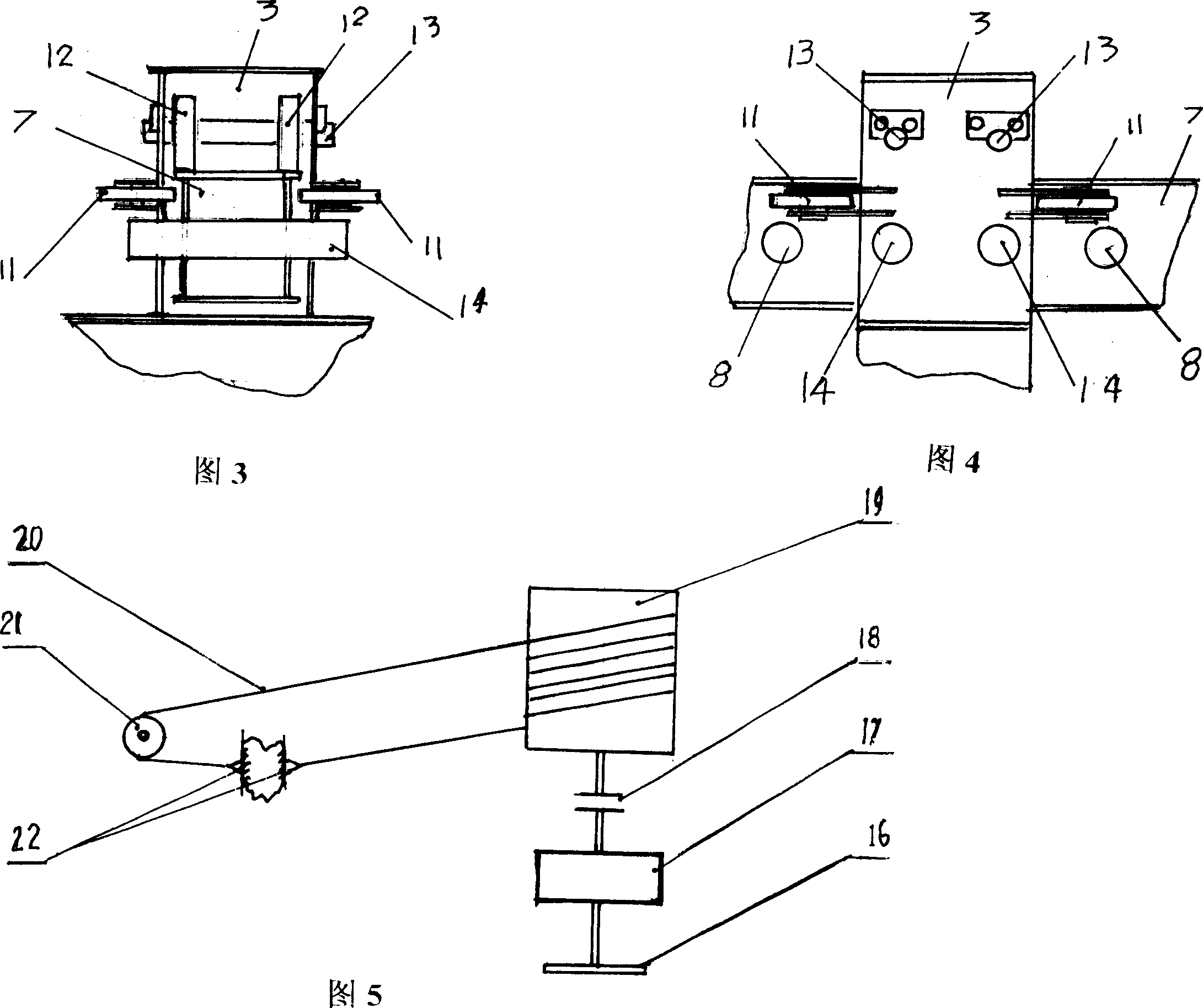

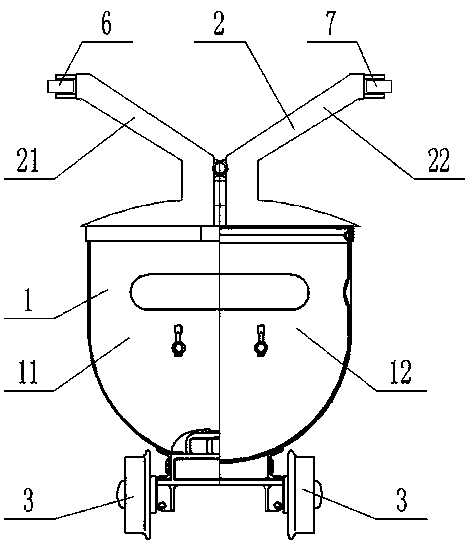

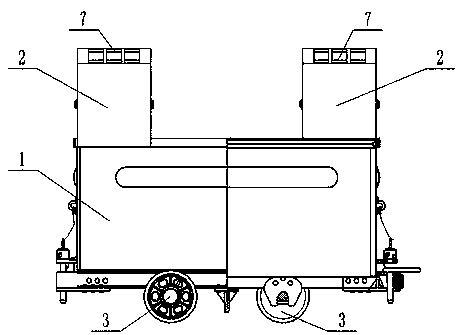

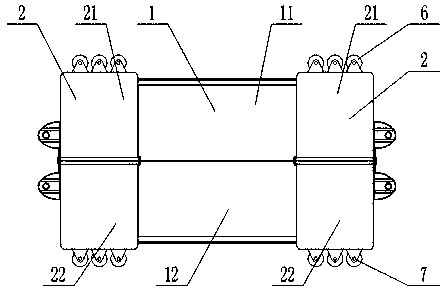

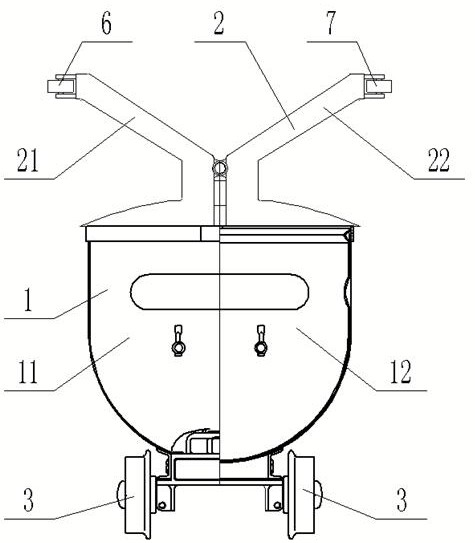

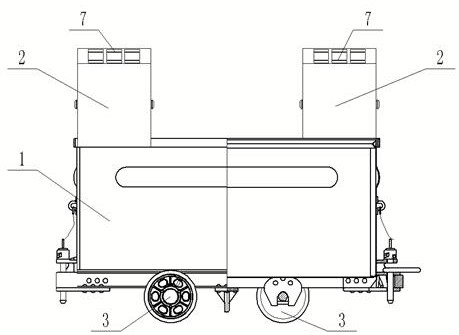

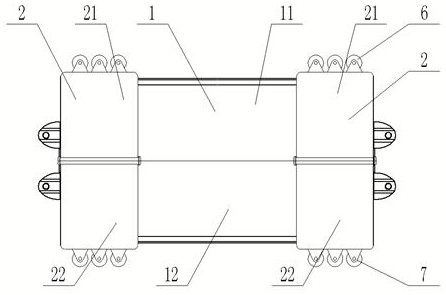

Top curved rail side pressing type bottom dumping car and use method

ActiveCN109398383AReliable loading and unloadingStrong ability to resist instabilityTipping wagonsAutomotive engineeringCoal

The invention discloses a top curved rail side pressing type bottom dumping car and a use method and belongs to the field of underground coal mine car transporting devices. Technical problems to be solved are that an existing bottom dumping car is not simply structured, is inconvenient to load and unload and cannot be used for various mineral conditions. A technical scheme adopted to solve the technical problems is that the top curved rail side pressing type bottom dumping car comprises a compartment; a clamping mechanism is arranged above the compartment; the compartment is divided into a left box body and a right box body; running wheels are arranged on the two sides of the bottom of the left box body and the two sides of the bottom of the right box body; and curved rails are arranged above the clamping mechanism. When the car passes through the curved rails, the clamping device opens the compartment to perform coal loading and unloading operations; and after the car passes through the curved rails, the left box body and the right box body are automatically closed; and therefore, the use is convenient. The top curved rail side pressing type bottom dumping car can be widely applied to the field of underground transportation.

Owner:TAIYUAN UNIV OF TECH

Bobbin fixing device

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

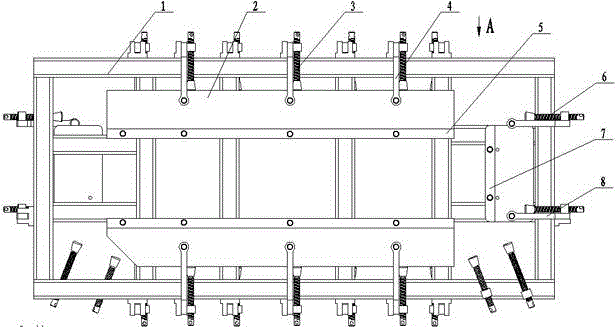

Assembly welding tooling for door frame of driver's cab

ActiveCN102642108BGuaranteed dimensional accuracy requirementsGuaranteed flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringJamb

The invention discloses an assembly welding tooling for a door frame of a driver's cab. The assembly welding tooling comprises a support framework and a base board fixedly connected onto the support frame, wherein the support framework is in a frame structure, and comprises a cross beam and a longitudinal beam connected with the cross beam, a plurality of longitudinal pressing devices are arranged on the longitudinal beam, and a plurality of lateral compressing devices are arranged on the cross beam. According to the assembly welding tooling for the door frame of the driver's cab, the cross beam and the longitudinal beam of the door frame of the driver's cab are fixed on the base board by the aid of the lateral pressing devices and the longitudinal compressing devices, flatness and perpendicularity of the cross beam and the longitudinal beam are guaranteed, welding contraction deformation is prevented, welding difficulty is reduced, welding quality is improved simultaneously, enough rigidity and strength are provided, positioning is accurate, the cross beam and the longitudinal beam are clamped manually, assembly and disassembly are convenient, flexible and reliable, removing is convenient, and positioning can be adjusted according to welding deformation degree of products due to adoption of an adjustable structural design so as to meet requirements of dimensional accuracy of the door frame of the driver's cab after welding.

Owner:南京雷尔伟新技术股份有限公司

Plasma radiation cancer treatment equipment

PendingCN112843498AEasy to useImprove practicalityX-ray/gamma-ray/particle-irradiation therapyElectrolysisMedicine

The invention provides plasma radiation cancer treatment equipment, and relates to the field of medical rehabilitation equipment. The plasma radiation cancer treatment equipment comprises a control end and an execution end, the control end comprises a control end shell, a barometer is installed on the side wall of the control end shell, a control panel is arranged at the upper end of the control end shell, and a voltage adjusting knob is installed on the front side wall of the control end shell; a circuit board, a voltage adjusting device and a high-voltage electrode are installed in the control end shell, a flexible pipeline is arranged behind the control end shell, and the tail end of the flexible pipeline is connected with the execution end. By arranging a CAP radiation tube which is hollow inside and connected with a ventilation tube and the high-low voltage electrode, electrolysis can be completed in the radiation tube, the CAP radiation tube realizes cancer treatment on part of hard tissues in a human body by radiating CAP plasmas by utilizing the selective specificity advantage of the CAP technology in the aspect of cancer treatment, and the plasma radiation cancer treatment equipment is reasonable in structure, simple to operate, safe, effective and high in practicability.

Owner:宁萌

Upper curved rail side pressure bottom unloading mine car and using method

ActiveCN109398383BReliable loading and unloadingRealize coal unloadingTipping wagonsStructural engineeringMechanical engineering

The invention discloses a top curved rail side pressing type bottom dumping car and a use method and belongs to the field of underground coal mine car transporting devices. Technical problems to be solved are that an existing bottom dumping car is not simply structured, is inconvenient to load and unload and cannot be used for various mineral conditions. A technical scheme adopted to solve the technical problems is that the top curved rail side pressing type bottom dumping car comprises a compartment; a clamping mechanism is arranged above the compartment; the compartment is divided into a left box body and a right box body; running wheels are arranged on the two sides of the bottom of the left box body and the two sides of the bottom of the right box body; and curved rails are arranged above the clamping mechanism. When the car passes through the curved rails, the clamping device opens the compartment to perform coal loading and unloading operations; and after the car passes through the curved rails, the left box body and the right box body are automatically closed; and therefore, the use is convenient. The top curved rail side pressing type bottom dumping car can be widely applied to the field of underground transportation.

Owner:TAIYUAN UNIV OF TECH

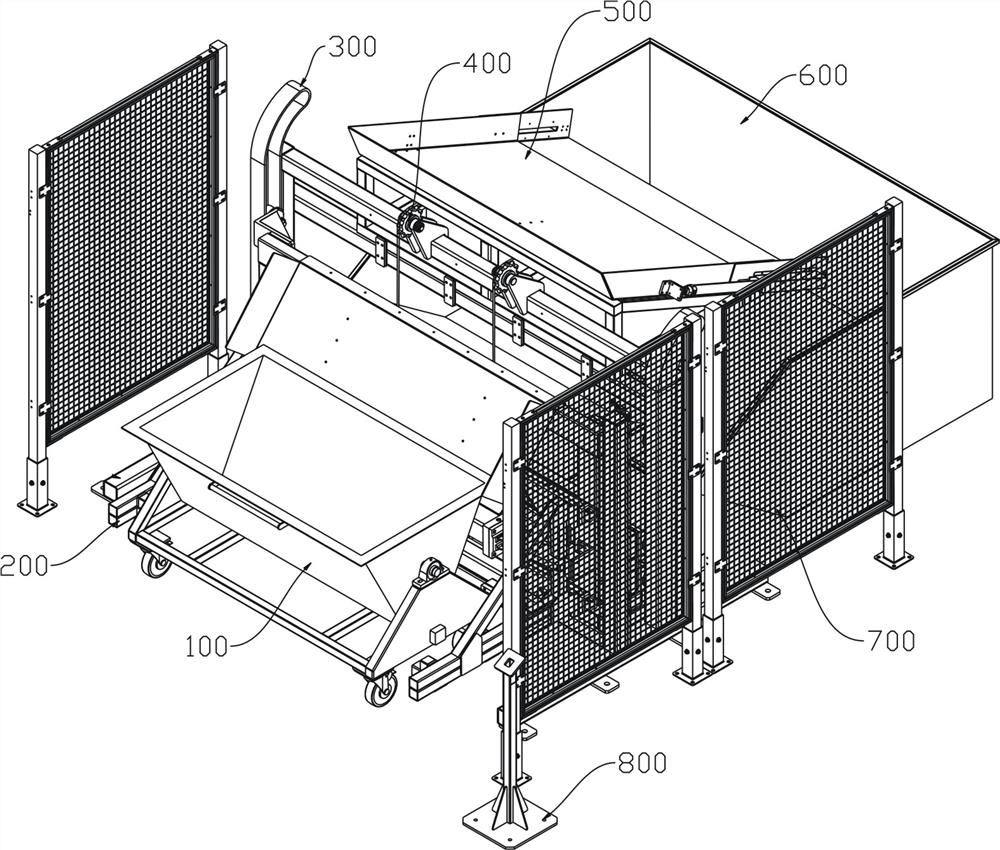

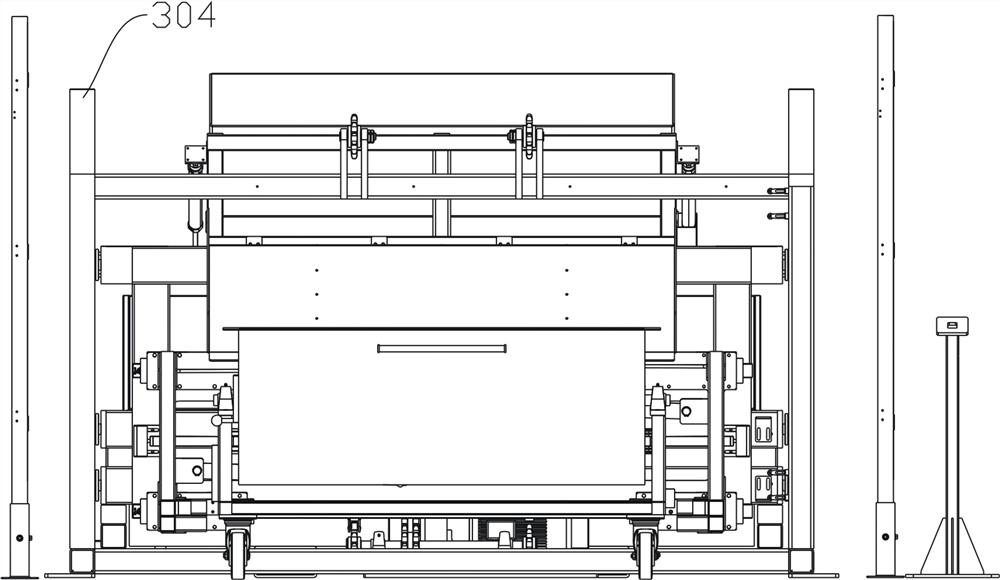

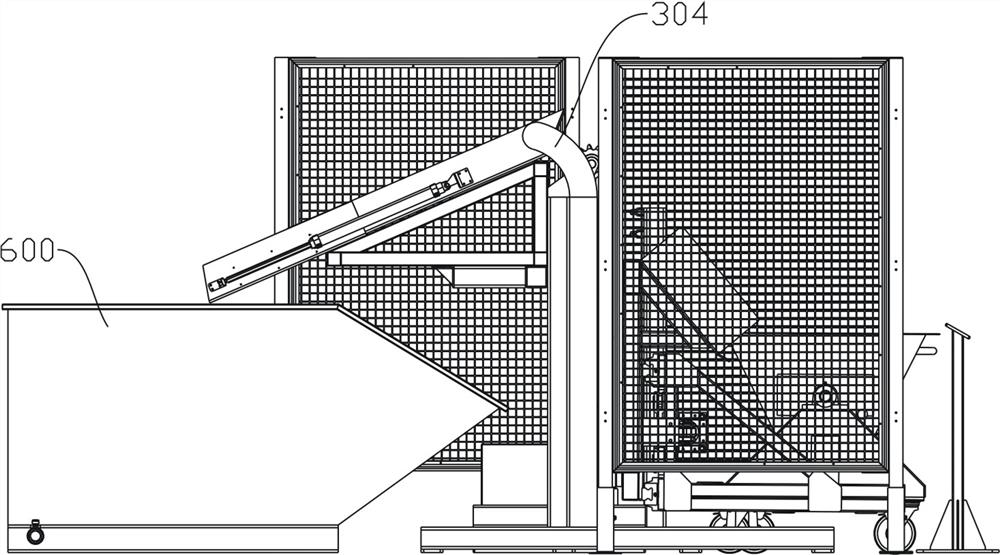

Material slag collecting device

PendingCN113895977AEasy to unloadReliable loading and unloadingBottle emptyingLoading/unloadingSlagStructural engineering

The invention discloses a material slag collecting device which comprises a base frame, an enclasping mechanism, a lifting frame, a power device and a material slag box, wherein the base frame is fixedly mounted on a working base face; the enclasping mechanism is mounted at the feeding end of the base frame and is used for enclasping a trolley filled with material slags; one side of the lifting frame is fixedly mounted on the enclasping mechanism, and the other side of the lifting frame is connected to the base frame; the power device is fixedly mounted on the base frame, is connected with the lifting frame, and drives the lifting frame on which the enclasping mechanism is mounted to move up and down and take the direction-changing motion on the base frame; and the material slag box is placed at the discharging end of the base frame. The material slag collecting device is reasonable in design, ingenious in structure and convenient to use and is used for collecting machining material slags, and is convenient for centralized treatment of the material slags; reasonable design of the enclasping mechanism can make loading and unloading of the trolley stable and reliable; reasonable design of the lifting frame and the power device can enable the enclasping mechanism to stably and reliably move up and down and take the direction-changing motion, so that the trolley can better unload materials; and the material slags discharged from the trolley are collected through the material slag box.

Owner:中科九微科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com