Apparatus for exchanging a cutting blade

A cutting insert and cutting device technology, which is applied in the field of cutting insert replacement devices to achieve the effect of reliable loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the cutting insert replacement device according to the present invention will be described in detail with reference to the drawings.

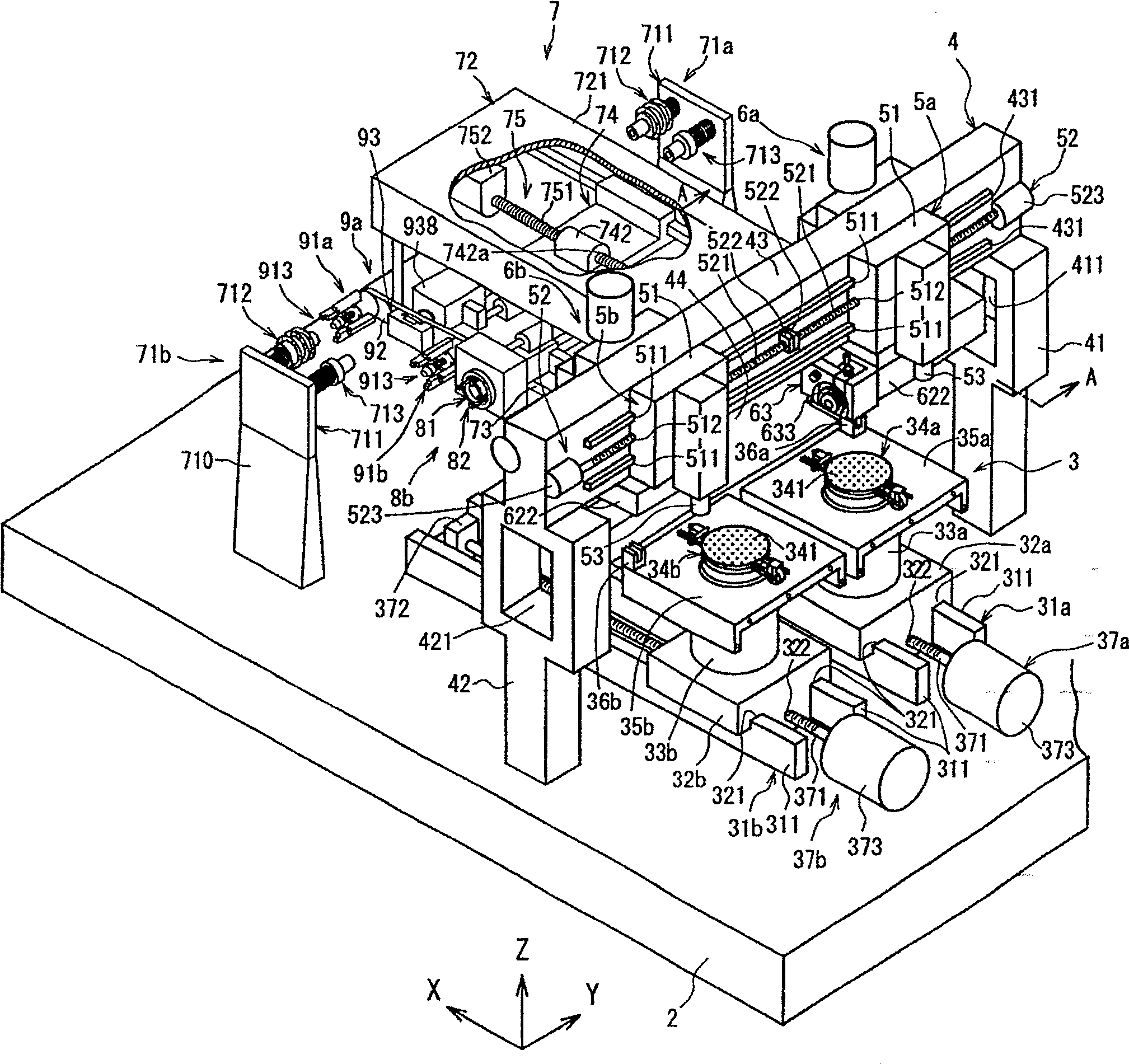

[0033] exist figure 1 , shows a perspective view of main parts of a cutting device equipped with a cutting tip replacement device according to the present invention.

[0034] figure 1 The cutting device shown has a stationary abutment 2 . On this stationary base 2, a clamping table mechanism 3 for holding a workpiece and moving it in the cutting feeding direction indicated by an arrow X is arranged.

[0035] The clamping table mechanism 3 in the illustrated embodiment has a first guide rail 31 a and a second guide rail 31 b arranged on the upper surface of the stationary base 2 . The first guide rail 31a and the second guide rail 31b are constituted by a pair of rail members 311, 311, respectively, and extend in parallel to each other along the cutting feed direction indicated by the arrow X in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com