Upper curved rail side pressure bottom unloading mine car and using method

A technology for unloading mine trucks and curved rails, which is used in dump trucks, transport passenger cars, railway car body parts, etc., can solve the problems of low unloading efficiency, large size, and unsuitable use, and achieves prevention of coal accumulation and strong anti-instability ability. , Stable and reliable loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

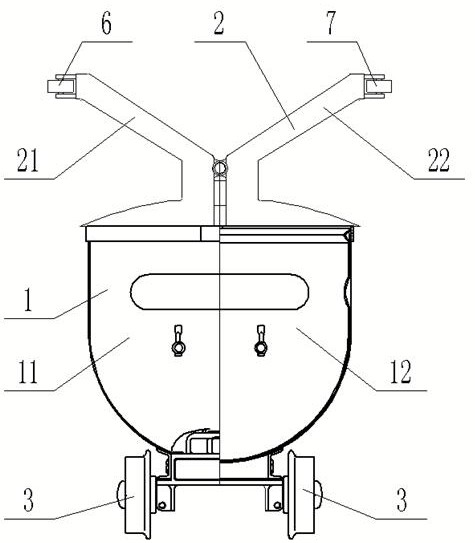

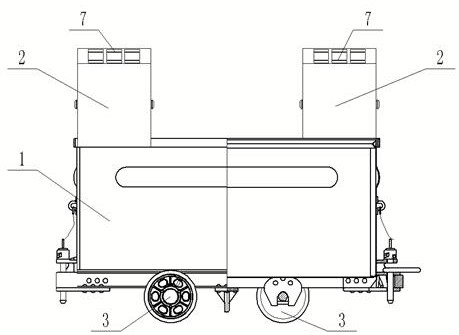

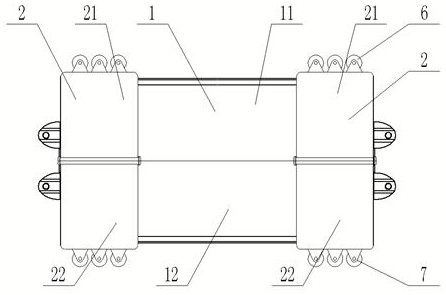

[0027] Such as Figure 1~Figure 5 As shown in the present invention, the upper curved track side pressure bottom unloading mine car comprises a compartment 1, a clamping mechanism 2 is arranged above the compartment 1, and the compartment 1 is divided into a left box body 11 and a right box body 12, and the left box body 11 and the right box body Both sides of the bottom of the box body 12 are provided with traveling wheels 3, and the clamping mechanism 2 includes a left clip 21 and a right clip 22, which are connected by hinges, and the bottom of the left clip 21 is connected to the left box. The upper part of the body 11 is connected, the bottom of the right clip 22 is connected with the upper part of the right box body 12, the upper part of the left clip 21 is provided with a left curved rail 4, the upper part of the right clip 22 is provided with a right curved rail 5, and the left clip 21 and the left curved rail 4 is provided with a left guide wheel 6, between the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com