Preparation method of fretting wear resistant alloy coating

An anti-fretting wear and alloy coating technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve the problem of difficult to obtain satisfactory anti-fretting wear alloy coating quality and deteriorate the interlayer of the coating. The bonding strength with the matrix, the fusion and adhesion of the molten droplets are not ideal, and the effect of convenient and fast loading and unloading of workpieces, ensuring the quality of sandblasting and spraying, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing an anti-fretting wear alloy coating, comprising the following steps:

[0042] (1) Ultrasonic degreasing and sandblasting roughening of the workpiece to be sprayed;

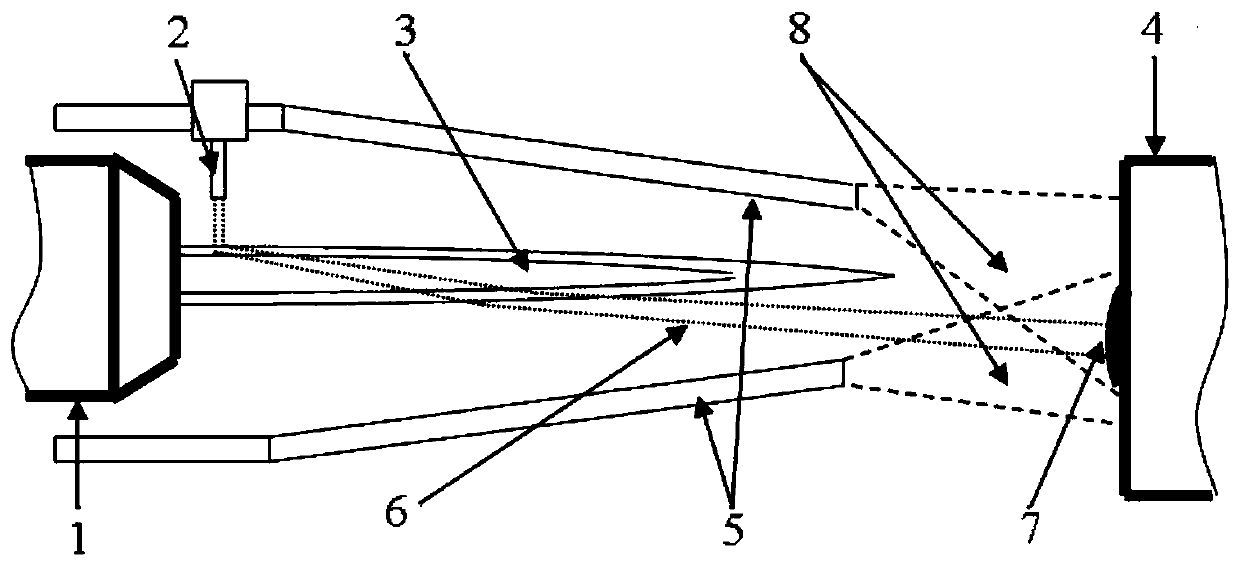

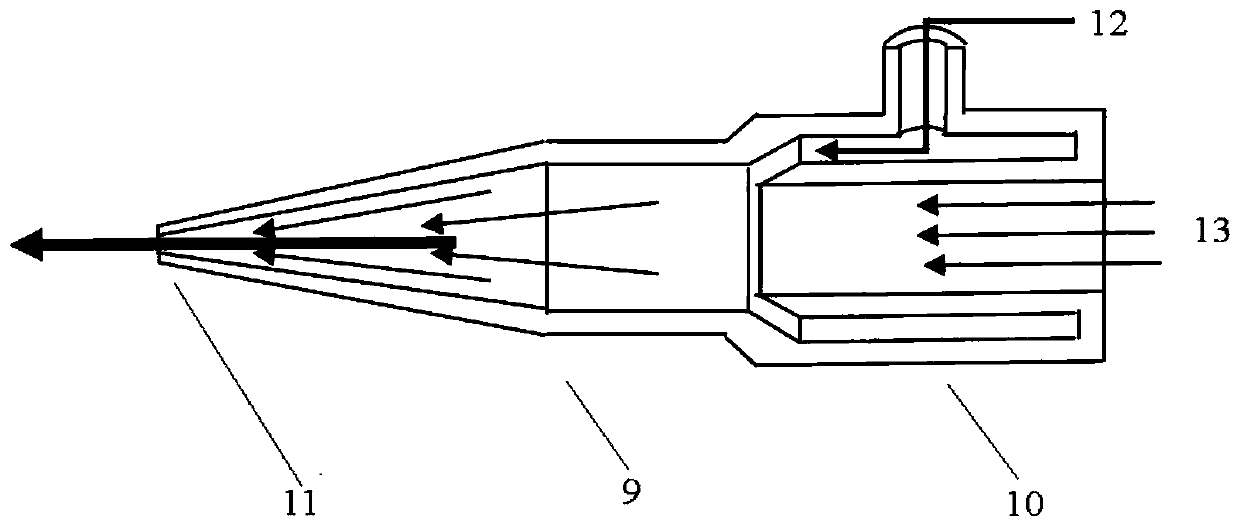

[0043] (2) Place the workpiece to be sprayed after step (1) in the protective gear, which includes the box body and the protective cover ( figure 2 ), with a convenient and stable workpiece clamping mechanism inside, and then in an inert gas protection atmosphere (Ar 3000L / min, H 2 300L / min), the anti-fretting wear alloy coating is sprayed by plasma arc powder spraying process, and the anti-fretting wear alloy coating is composed of the following components in mass percentage: Ni 36%, In 5%, Cu balance: The spraying angle is 90°; the arc voltage is 62V; the power is 31kW; the spraying distance is 64mm; ; Both sides of the spray gun nozzle 1 are provided with two extended cooling protective gas spray pipes 5 and one near the surface of the workpiece such as image 3 The air knife ...

Embodiment 2

[0050] A method for preparing an anti-fretting wear alloy coating, comprising the following steps:

[0051] (1) Ultrasonic degreasing and sandblasting roughening of the workpiece to be sprayed;

[0052] (2) Place the workpiece to be sprayed after step (1) in the protective gear, which includes the box body and the protective cover ( figure 2 ), the box body is equipped with a convenient and stable workpiece clamping mechanism. Manually turn the screw to compress the blade, and then close the cover to protect the top and side of the blade from being sprayed, and then spraying can be carried out. Then in an inert gas protection atmosphere (Ar 3000L / min, H 2 320L / min) for reference figure 1 , the anti-fretting wear alloy coating is sprayed by plasma arc powder spraying process, and the anti-fretting wear alloy coating is composed of the following components in mass percentage: Ni 32%, In 3%, Cu balance: spraying angle 90° ;Arc voltage 60V; Power 30kW; Spraying distance 62mm...

Embodiment 3

[0055] A method for preparing an anti-fretting wear alloy coating, comprising the following steps:

[0056] (1) Ultrasonic degreasing and sandblasting roughening of the workpiece to be sprayed;

[0057] (2) Place the workpiece to be sprayed after step (1) in the protective gear, which includes the box body and the protective cover ( figure 2 ), the box body is equipped with a convenient and stable workpiece clamping mechanism, and then in an inert gas protection atmosphere (Ar 3000L / min, H 2 310L / min) for reference figure 1 , the anti-fretting wear alloy coating is sprayed by plasma arc powder spraying process, and the anti-fretting wear alloy coating is composed of the following components in mass percentage: Ni 35%, In 4%, Cu balance: spraying angle 90° ; Arc voltage 60~62V; Power 30kW; Spraying distance 63mm; Air knife type degassing device on the side of the workpiece surface ( image 3 ). The specific structure is a device with the function of ejection and suction....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com