Energy-saving halogen lamp convenient to mount and dismount

A halogen bulb and halogen lamp technology, applied in the field of halogen lamps, can solve the problems of halogen bulb failure, waste of resources, and inability to arbitrarily choose different styles of outer bulbs, etc., to achieve the effects of protecting the environment, improving products, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

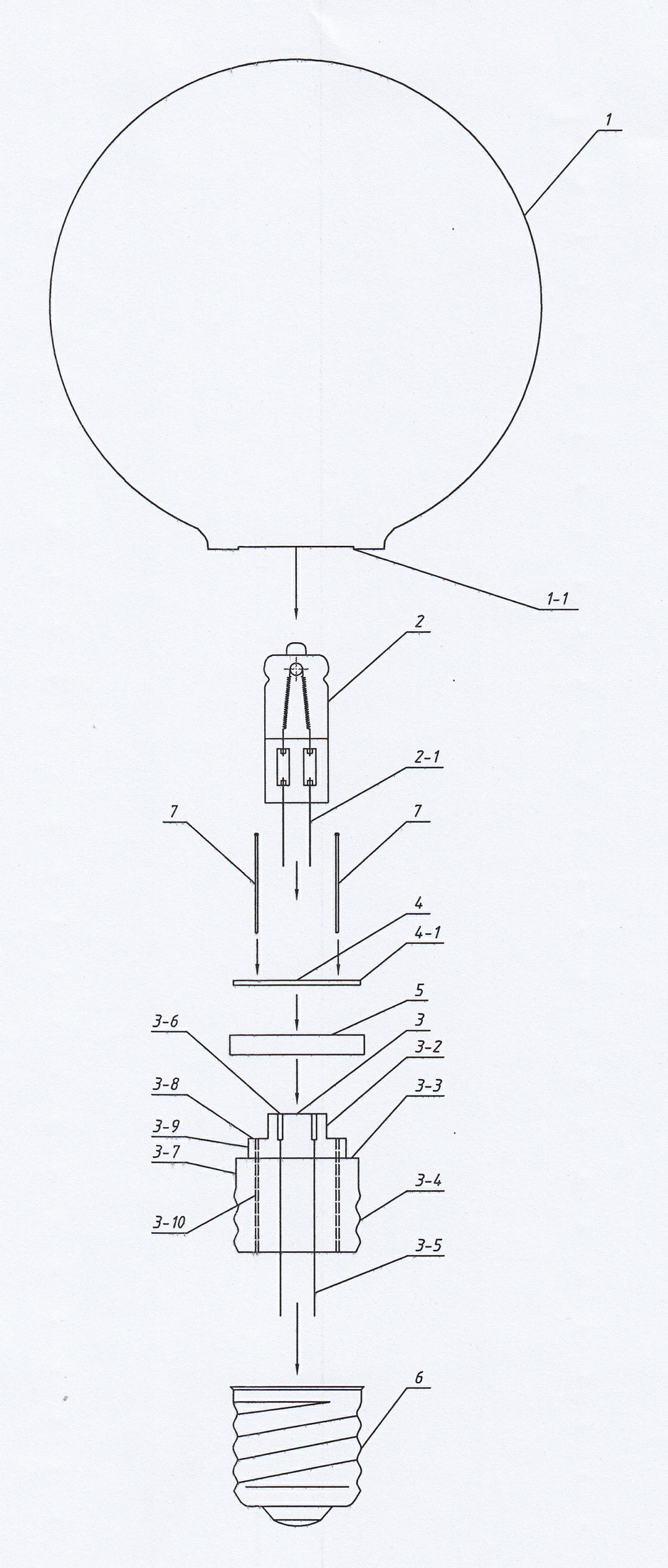

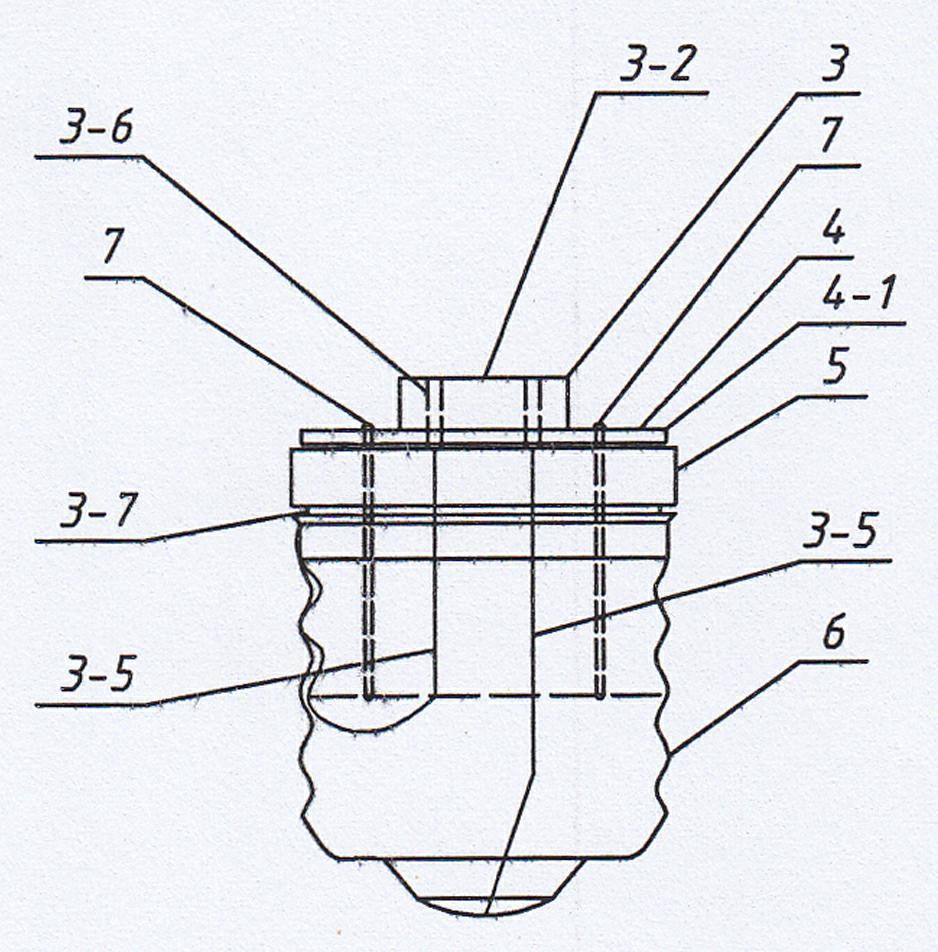

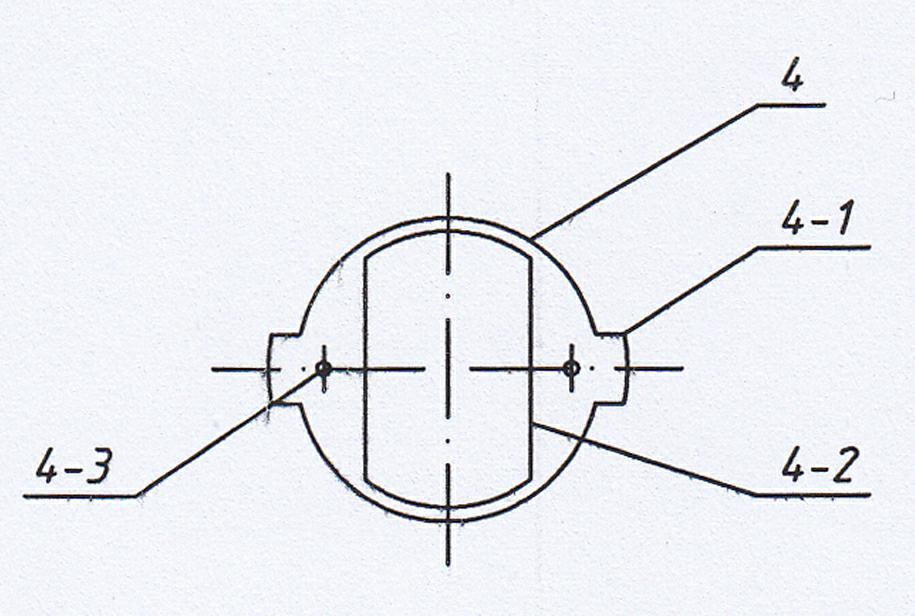

[0020] see Figure 1-Figure 5 As shown, an energy-saving halogen bulb that is easy to disassemble and assemble is composed of a thin ceramic outer bulb 1, a halogen lamp 2, a ceramic insulating lamp holder 3, a connecting snap ring 4, a soft elastic gasket 5, and a threaded lamp cap 6. A ceramic insulating lamp holder 3 is arranged in the E27 threaded lamp holder 6. The ceramic insulating lamp holder 3 is a three-stage cylinder with a small upper part and a larger lower part. The intersection of the small cylinder 3-2 and the middle cylinder 3-9 is the first limit Position platform 3-8, the intersection of middle cylinder 3-9 and large cylinder 3-7 is the second limit platform 3-3, and the outer cylinder of large cylinder 3-7 is provided with external thread 3-4, and positioning On the first limiting platform 3-8, the outer side of the metal connecting snap ring 4 is provided with two symmetrically arranged outer flanges 4-1, and the elastic soft gasket 5 is inserted into the ...

Embodiment 2

[0023] see Figure 6 As shown, the universal lamp cap 8 of the present embodiment adopts a B22d socket lamp cap, and the large cylinder of the ceramic insulated lamp holder 3 does not have an external thread, and the large cylinder matches the inner wall of the socket lamp cap 8, and the two are fixedly connected by an adhesive. The first electrode lead wires 3-5 respectively extend to the two mutually insulated and isolated electrodes at the center of the bottom end of the lamp cap 8, and are soldered firmly with tin wires, and the rest of the components and connection structure are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com