Installing and welding tool for cab

A technology for assembling welding equipment and driver's cab, which is applied in the field of welding equipment and driver's cab assembly welding equipment, can solve the problems of cab deformation, inconvenient operation, low production efficiency, etc., meet the requirements of guaranteed dimensional accuracy, good versatility, and easy to get rid of the womb Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0016] This example:

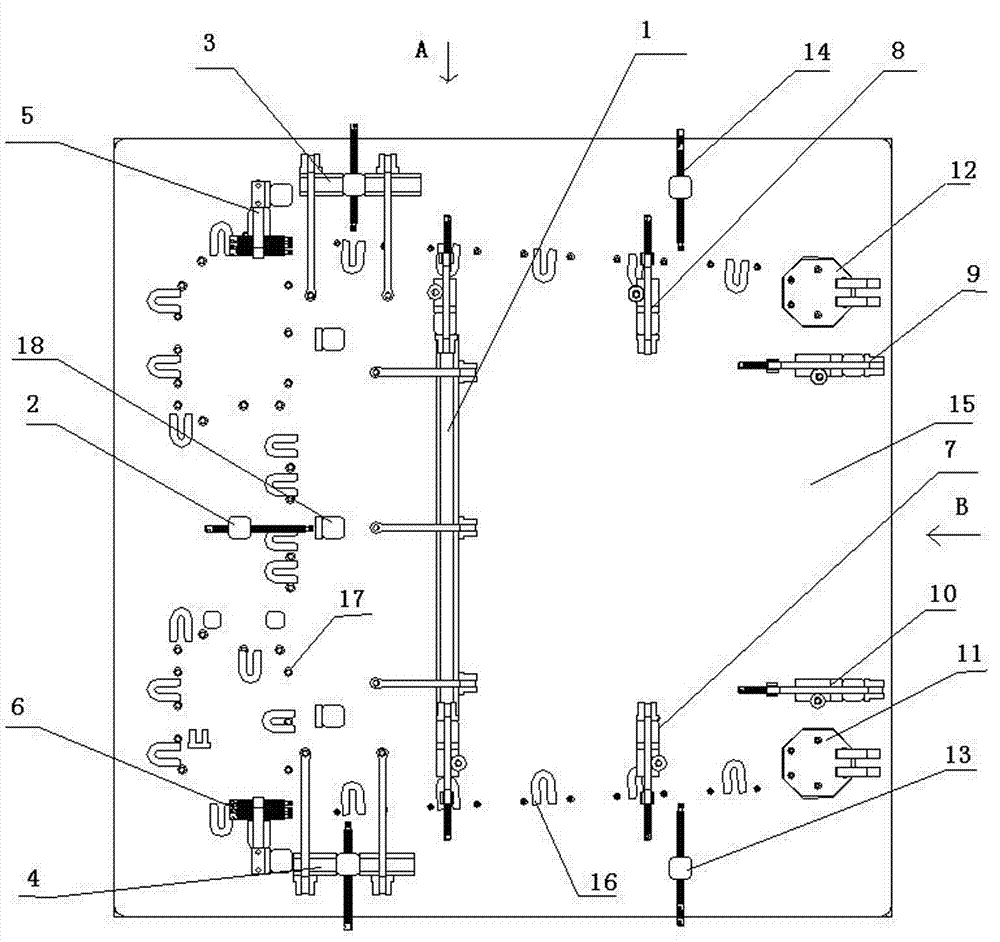

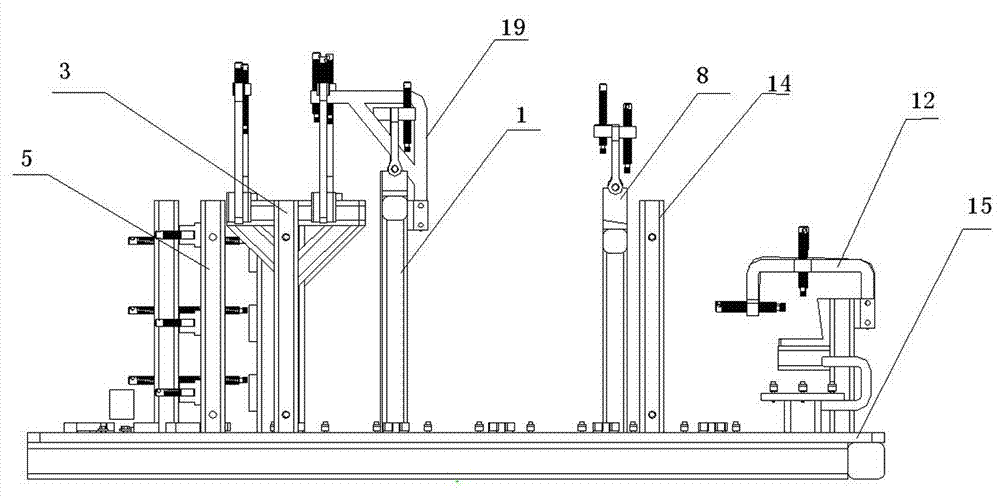

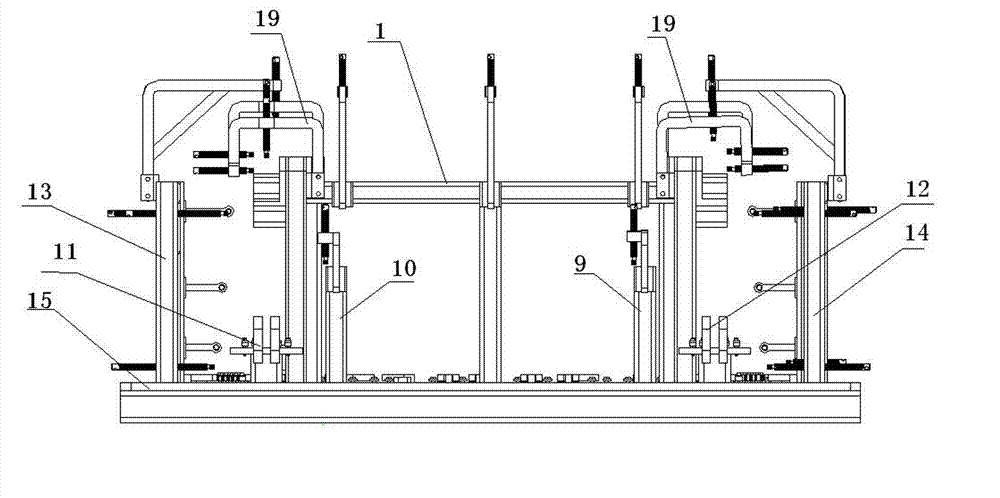

[0017] see figure 1 In order to control the welding deformation as much as possible and ensure the size of the product, it is decided to redesign and manufacture the production and assembly welding tooling suitable for the full-welded driver's cab. The welding-resistant tooling for the driver's cab in this embodiment includes a bottom plate and a three-way pressing and positioning device installed on the bottom plate 1. The middle pressing device of the large floor 2. The anti-collision barrier positioning and pressing device, the left pressing device 5, the right pressing device 6, the curved beam positioning and pressing device, the beam positioning and pressing device, and the end chuck positioning block, door frame pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com